Inorganic Chemicals Industry ›› 2022, Vol. 54 ›› Issue (9): 119-125.doi: 10.19964/j.issn.1006-4990.2021-0750

• Environment·Health·Safety • Previous Articles Next Articles

Optimization of preparation of sludge/fly ash composite ceramsite filler materials by response surface methodology

FANG Weicheng( ),CHENG Xingxing,SUN Changrong

),CHENG Xingxing,SUN Changrong

- Dongguan City College,College of Urban Construction and Environment,Dongguan 523419,China

-

Received:2021-12-14Online:2022-09-10Published:2022-09-22

CLC Number:

Cite this article

FANG Weicheng,CHENG Xingxing,SUN Changrong. Optimization of preparation of sludge/fly ash composite ceramsite filler materials by response surface methodology[J]. Inorganic Chemicals Industry, 2022, 54(9): 119-125.

share this article

Table 2

Chemical composition of raw material of composite ceramsite filter materials with various proportion"

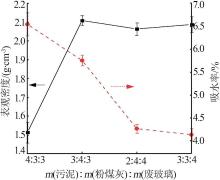

m(污泥)∶m(粉煤灰)∶ m(废玻璃) | 质量分数/% | |||||||

|---|---|---|---|---|---|---|---|---|

| Na2O | MgO | Al2O3 | SiO2 | K2O | CaO | Fe2O3 | 其他 | |

| 4∶3∶3 | 3.701 | 3.308 | 22.573 | 44.888 | 2.511 | 9.194 | 4.416 | 8.595 |

| 3∶4∶3 | 3.669 | 3.068 | 22.220 | 47.908 | 2.506 | 8.907 | 4.356 | 1.274 |

| 2∶4∶4 | 4.573 | 2.828 | 19.136 | 53.853 | 2.196 | 8.381 | 3.809 | 5.224 |

| 3∶3∶4 | 4.605 | 3.067 | 19.489 | 50.833 | 2.200 | 8.668 | 3.869 | 7.269 |

Table 3

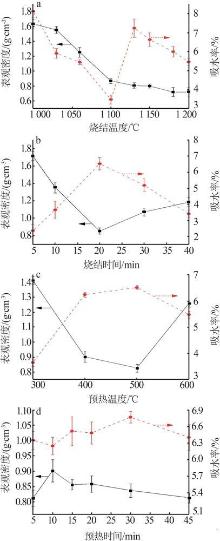

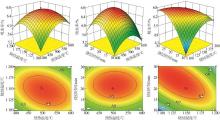

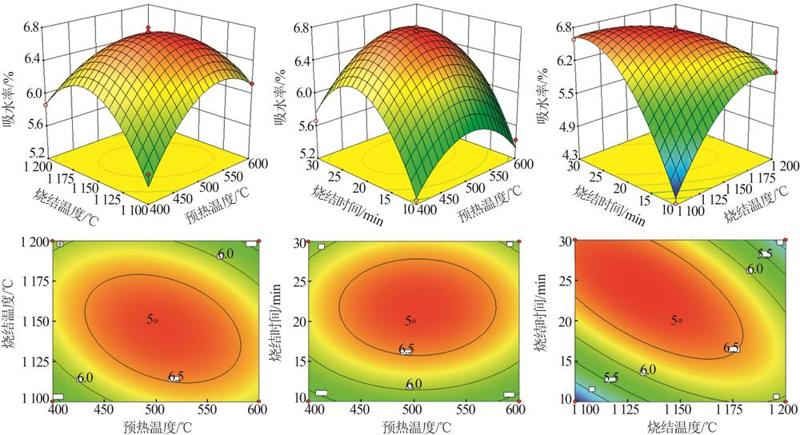

Experiment result of response surface"

| 序号 | 自变量水平 | 因变量 Y(吸水率/%) | ||

|---|---|---|---|---|

| A(预热温度/℃) | B(烧结温度/℃) | C(烧结时间/min) | ||

| 1 | 1(600) | -1(1 100) | 0(20) | 6.14 |

| 2 | 1(600) | 0(1 150) | -1(10) | 5.44 |

| 3 | 0(500) | 0(1 150) | 0(20) | 6.69 |

| 4 | 0(500) | 1(1 200) | 1(30) | 4.88 |

| 5 | 0(500) | -1(1 100) | -1(10) | 4.32 |

| 6 | 1(600) | 0(1 150) | 1(30) | 5.88 |

| 7 | -1(400) | 0(1 150) | -1(10) | 5.25 |

| 8 | 0(500) | 0(1 150) | 0(20) | 6.62 |

| 9 | -1(400) | 1(1 200) | 0(20) | 5.88 |

| 10 | 0(500) | -1(1 100) | 1(30) | 6.58 |

| 11 | 0(500) | 0(1 150) | 0(20) | 6.88 |

| 12 | -1(400) | 0(1 150) | 1(30) | 5.68 |

| 13 | 0(500) | 0(1 150) | 0(20) | 6.76 |

| 14 | -1(400) | -1(1 100) | 0(20) | 5.54 |

| 15 | 1(600) | 1(1 200) | 0(20) | 5.16 |

| 16 | 0(500) | 0(1 150) | 0(20) | 6.74 |

| 17 | 0(500) | 1(1 200) | -1(10) | 5.98 |

Table 5

Performance of composite ceramsite filter material and compared with other ceramsite filter materials"

| 陶粒 | 表观密度/ (g·cm-3) | 吸水率 (1 h)/% | 比表 面积/ (m2·g-1) | 破碎率 与磨损率之和/% | 盐酸可 溶率/% |

|---|---|---|---|---|---|

| 行业标准 | 越小越好 | ≤10 | ≥0.5 | ≤6 | ≤2 |

| 复合陶粒滤料 | 0.650 | 6.91 | 4.87 | 0.82 | 0.08 |

| 给水污泥陶粒[ | 1.390 | 23.65 | 5.24 | — | 0.25 |

| 高强陶粒滤料[ | 0.947 | 3.60 | — | — | — |

| 污泥陶粒[ | 0.996 | 0.12 | — | — | — |

| 河道底泥陶粒[ | 1.155 | 36.68 | — | 0.78 | — |

| [1] | 万琼,韩庆吉,张新艳,等.以给水厂污泥制备新型陶粒及其性能优化[J].硅酸盐通报,2019,38(4):1228-1236. |

| WAN Qiong, HAN Qingji, ZHANG Xinyan, et al.Preparation and performance optimization of ceramsites using waste sludge[J].Bulletin of the Chinese Ceramic Society,2019,38(4):1228-1236. | |

| [2] | 杨丽艳,马鑫,梅锐锋,等.黄河流域沉沙池泥沙制备陶粒及其性能研究[J].无机盐工业,2022,54(5):109-115. |

| YANG Liyan, MA Xin, MEI Ruifeng, et al.Study on preparation and performance of ceramsite from sediment in Yellow River desilt⁃ilting basin[J].Inorganic Chemicals Industry,2022,54(5):109-115 | |

| [3] | 郑凯,蒋善庆,武福平.给水厂污泥陶粒制备及其对氮磷吸附研究[J].环境污染与防治,2020,42(1):35-38,43. |

| ZHENG Kai, JIANG Shanqing, WU Fuping.Study on preparation of ceramsite made from waterworks sludge and its performance for adsorption of nitrogen and phosphorus[J].Environmental Pollution & Control,2020,42(1):35-38,43. | |

| [4] | WANG Di, CHEN Nan, YU Yang, et al.Investigation on the adsorption of phosphorus by Fe-loaded ceramic adsorbent[J].Journal of Colloid and Interface Science,2016,464:277-284. |

| [5] | 喻学敏,周军,陈浩.以橡胶颗粒与陶粒为生物滤池填料的运行效果研究[J].工业水处理,2021,41(9):69-73. |

| YU Xuemin, ZHOU Jun, CHEN Hao.Operation effect of biological filter with rubber and ceramsite as filler[J].Industrial Water Treatment,2021,41(9):69-73. | |

| [6] | 周高燕,章静,战晓慧,等.新型污泥陶粒-曝气生物滤池对喷水织造废水的处理研究[J].浙江大学学报:理学版,2021,48(2):231-240. |

| ZHOU Gaoyan, ZHANG Jing, ZHAN Xiaohui, et al.Study on treatment of water⁃jet weaving wastewater by new type sewage sludge ceramsite for biological aerated filter[J].Journal of Zhejiang University:Science Edition,2021,48(2):231-240. | |

| [7] |

张晓亚,李佳丽,冯丽娟,等.城市污泥陶粒制备技术与应用研究进展[J].无机盐工业,2021.Doi:10.19964/j.issn.1006-4990.2021-0568.

doi: 10.19964/j.issn.1006-4990.2021-0568. |

|

ZHANG Xiaoya, LI Jiali, FENG Lijuan, et al.Research progress on preparation technology and application of municipal sludge ceramsite[J].Inorganic Chemicals Industry,2021.Doi:10.19964/j.issn.1006-4990.2021-0568.

doi: 10.19964/j.issn.1006-4990.2021-0568. |

|

| [8] | WU Haiming, FAN Jinlin, ZHANG Jian, et al.Intensified organics and nitrogen removal in the intermittent⁃aerated constructed wetland using a novel sludge⁃ceramsite as substrate[J].Bioresource Technology,2016,210:101-107. |

| [9] | 程海翔,周海,李建辉,等.城市污泥及其焚烧灰混合料烧结陶粒的实验研究[J].环境工程学报,2016,10(2):845-850. |

| CHENG Haixiang, ZHOU Hai, LI Jianhui, et al.Experimental study on manufacturing haydite by sintering municipal sludge and its incineration ash[J].Chinese Journal of Environmental Engineer⁃ing,2016,10(2):845-850. | |

| [10] | 荣辉,张鸿飞,张磊,等.污泥陶粒焙烧制度优化及其对陶粒性能的影响[J].新型建筑材料,2019,46(4):68-72,87. |

| RONG Hui, ZHANG Hongfei, ZHANG Lei, et al.Optimization of sludge ceramsite baking system and its effect on ceramsite performance[J].New Building Materials,2019,46(4):68-72,87. | |

| [11] | 肖继波,黄志达,陈玉莹,等.高效除磷型底泥陶粒的制备及性能分析[J].浙江农林大学学报,2019,36(2):415-421. |

| XIAO Jibo, HUANG Zhida, CHEN Yuying, et al.Preparation and properties analysis of sediment ceramsite with high efficiency phosphorus removal[J].Journal of Zhejiang A & F University,2019,36(2):415-421. | |

| [12] | 欧阳嘉,林衍,于东盛,等.Plackett-Burman设计和响应曲面法优化除磷陶粒的制备[J].环境工程学报,2017,11(4):2291-2298. |

| OUYANG Jia, LIN Yan, YU Dongsheng, et al.Plackett-Burman design and response surface method to optimize the preparation of phosphorus removal ceramsite[J].Chinese Journal of Environmental Engineering,2017,11(4):2291-2298. | |

| [13] | 王矿宾,许胜霞,王永勤.响应曲面法优化双氟磺酰亚胺锂提纯工艺研究[J].无机盐工业,2020,52(9):62-65. |

| WANG Kuangbin, XU Shengxia, WANG Yongqin.Research on purification process of lithium difluorosulfimide optimized by response surface method[J].Inorganic Chemicals Industry,2020,52(9):62-65. | |

| [14] |

DIWANI N, FAKHFAKH J, ATHMOUNI K, et al.Optimization,extraction,structure analysis and antioxidant properties of flavan-3-ol polymers:Proanthocyanidins isolated from Periploca angustifolia using surface response methodology[J].Industrial Crops and Products,2020,144.Doi:10.1016/j.indcrop.2019.112040.

doi: 10.1016/j.indcrop.2019.112040. |

| [15] | 宋文惠,杨莹,张洁,等.Box-Behnken分析优化花果茶泡腾片的制作工艺研究[J].食品研究与开发,2020,41(7):137-142. |

| SONG Wenhui, YANG Ying, ZHANG Jie, et al.Study on the formulation and process of box⁃behnken analysis for optimizin flower tea effervescent tablets[J].Food Research and Development,2020,41(7):137-142. | |

| [16] | 韩露.新型污泥陶粒的制备及其在污水处理中的应用[D].郑州:郑州大学,2018. |

| HAN Lu.Study on the preparation of new sludge ceramsite and application in sewage treatment[D].Zhengzhou:Zhengzhou University,2018. | |

| [17] | 卢雪霏.不同烧结方式和烧结制度对城市污泥陶粒性能的影响研究[D].沈阳:沈阳建筑大学,2020. |

| LU Xuefei.Effects of different sintering methods and sintering systems on the properties of municipal sludge ceramsite[D].Shenyang:Shenyang Jianzhu University,2020. | |

| [18] | 林春绵,王建超,甄万顺.利用污泥烧制陶粒滤料的实验研究[J].浙江工业大学学报,2018,46(5):585-590. |

| LIN Chunmian, WANG Jianchao, ZHEN Wanshun.Experimental study on sintering ceramsite filter material with sludge[J].Journal of Zhejiang University of Technology,2018,46(5):585-590. | |

| [19] | 罗立群,周鹏飞,涂序.焙烧陶粒膨胀剂的研究应用进展[J].硅酸盐通报,2019,38(10):3170-3177. |

| LUO Liqun, ZHOU Pengfei, TU Xu.Progress on research and application of roasted ceramsite expanding agents[J].Bulletin of the Chinese Ceramic Society,2019,38(10):3170-3177. | |

| [20] | 秦晋一,封硕,方姣,等.二氧化硅对污泥烧结陶粒结构强度和孔隙率的影响[J].新型建筑材料,2019,46(9):117-122. |

| QIN Jinyi, FENG Shuo, FANG Jiao, et al.Effect of SiO2 on structural strength and porosity of sludge sintered ceramsite[J].New Building Materials,2019,46(9):117-122. | |

| [21] | 李亮.粉煤灰陶粒制备试验研究[J].硅酸盐通报,2017,36(5):1577-1581,1589. |

| LI Liang.Experimental study on preparation of fly ash ceramsi⁃te[J].Bulletin of the Chinese Ceramic Society,2017,36(5):1577-1581,1589. | |

| [22] | 洪雷.粉煤灰和废玻璃制备高强复合陶粒的试验研究[J].新型建筑材料,2013,40(8):32-34,47. |

| HONG Lei.Experimental study on preparation of high strength composite ceramsite using fly ash and waste glass[J].New Building Materials,2013,40(8):32-34,47. |

| [1] | TANG Kaijing, LIU Chuanbei, LI Yingding, JIANG Yong, WU Junnan, ZHANG Tao. Research on preparation and mechanism of superhydrophobic phosphogypsum products [J]. Inorganic Chemicals Industry, 2025, 57(1): 97-102. |

| [2] | LIU Xiaowen, LI Jun, ZHOU Zhaoan, MAO Anzhang, ZHOU Aiqing. Study on response surface methodology optimization of PAC for deep purification of fluorine ion in high concentration sodium sulfate solution [J]. Inorganic Chemicals Industry, 2024, 56(6): 67-72. |

| [3] | LI Chunli, ZHANG Huanhuan, CHENG Zhuo, TANG Xiuhua, ZHANG Fengzhen, YE Yuling. Anti-solvent crystallization process of NH4VO3 in NaVO3-NH4Cl-H2O solution system [J]. Inorganic Chemicals Industry, 2024, 56(5): 39-44. |

| [4] | ZHANG Conghua, YAN Wenbin, XIAO Jiajun, ZHAO Ke, PENG Shangquan, WEI Yuhong. Reductive leaching technology of manganese anode slag using tartaric acid as reducing agent optimized by RSM [J]. Inorganic Chemicals Industry, 2023, 55(9): 106-113. |

| [5] | WANG Yingnan, SHENG Linlin, HUANG Juan, HUANG Zhanbin. Study on adsorption performance of lead from water by coal-fired slag [J]. Inorganic Chemicals Industry, 2023, 55(8): 109-115. |

| [6] | TENG Jiayang, FENG Qingge, ZHANG Xuan, QIN Fanghong, FENG Jinghang, HU Jiawen, CHEN Chaohong. Study on preparation of pseudo-boehmite from aluminum dross resource treatment [J]. Inorganic Chemicals Industry, 2023, 55(11): 130-138. |

| [7] | ZHANG Zhiqiang, CUI Kangping, CHEN Xing, LI Haiyang. Optimization of preparation of ultrafine chromium oxide by carbothermal reduction of sodium dichromate by response surface methodology [J]. Inorganic Chemicals Industry, 2023, 55(10): 136-144. |

| [8] | FU Ziqi, ZHANG Cheng, SHENG Yong, JI Lijun. Study on preparation of phosphoric acid by leaching fluoride residue from wet-process phosphoric acid with organic solvents [J]. Inorganic Chemicals Industry, 2022, 54(7): 129-134. |

| [9] | TANG Jianping,WANG Guosheng. Study on preparation technology and waterproof property of fused magnesia coating [J]. Inorganic Chemicals Industry, 2022, 54(5): 90-95. |

| [10] | LI Yajiao,ZHAO Yiwei,JU Kai,TANG Renlong,LI Longqing,SHAO Xiaoping,ZHANG Gaofeng,REN Wuang. Study on optimization of extraction conditions in process of determination of ammonia content in fly ash based on response surface method [J]. Inorganic Chemicals Industry, 2022, 54(4): 145-151. |

| [11] | Huang Jiming,Liu Runqing,Wu Sizhan,Song Juan. Optimization of extraction process of chlorination roasting-water leaching process for low-grade rhodochrosite by response surface methodology [J]. Inorganic Chemicals Industry, 2019, 51(3): 34-37. |

| [12] | CHEN Bo, SONG Xing-Fu, XU Yan-Xia, SUN Yu-Zhu, YU Jian-Guo. Optimization of preparation of calcium carbonate from continuous crystallization process of ammonium carbonate and conversion of calcium sulfate by response surface methodology [J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(9): 18-. |

| [13] | Liu Jia;Xie Tian;Qiu Shuyi;Hu Hong;Zeng Guang. Optimization of technology for preparation of ammonium sulphate from phosphogysum by response surface methodology [J]. INORGANICCHEMICALSINDUSTRY, 2009, 0(5): 0-0. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||