| 1 |

罗东燕,邱树恒,陈霏,等.用蒸压法将磷石膏制备α半水石膏的研究[J].新型建筑材料,2015,42(9):23-26,46.

|

|

LUO Dongyan, QIU Shuheng, CHEN Fei,et al.The research of using phosphogypsum manufacture of α-semi⁃hydrated gypsum by autoclaved method[J].New Building Materials,2015,42(9):23-26,46.

|

| 2 |

蒋建亚,张苏花,付旭东,等.磷化工废渣磷石膏的特性及其资源化利用[J].山西建筑,2021,47(9):1-4.

|

|

JIANG Jianya, ZHANG Suhua, FU Xudong,et al.Characteristics and resource utilization of phosphogypsum from phosphorus chemi⁃

|

|

mical waste[J].Shanxi Architecture,2021,47(9):1-4.

|

| 3 |

李纯,薛鹏丽,张文静,等.我国磷石膏处置现状及绿色发展对策[J].化工环保,2021,41(1):102-106.

|

|

LI Chun, XUE Pengli, ZHANG Wenjing,et al.Disposal status of phosphogypsum in China and countermeasures for green development[J].Environmental Protection of Chemical Industry,2021,41(1):102-106.

|

| 4 |

耿庆钰,李建锡,韩伟明,等.磷石膏蒸压制备半水硫酸钙晶须[J].人工晶体学报,2016,45(7):1892-1897,1905.

|

|

GENG Qingyu, LI Jianxi, HAN Weiming,et al.Preparation of calcium sulfate hemihydrate whisker by phosphogypsum autoclave method[J].Journal of Synthetic Crystals,2016,45(7):1892-1897,1905.

|

| 5 |

党春阁,郭亚静.磷石膏综合利用现状、问题及政策建议[C]∥中国环境科学学会.2020中国环境科学学会科学技术年会论文集(第二卷).2020:1067-1071.

|

|

DANG Chunge, GUO Yajing.Current Situation,problems and policy

|

|

suggestions of comprehensive utilization of phosphogypsum[C]∥Chinese Society For Environmental Sciences.Proceedings of the 2020 Chinese Society for Environmental Sciences Science and Technology Annual Conference(Volume Ⅱ),2020:1067-1071.

|

| 6 |

段正洋,李建锡,郑书瑞,等.转晶剂对磷石膏制备α半水石膏影响的研究[J].硅酸盐通报,2015,34(5):1397-1401,1406.

|

|

DUAN Zhengyang, LI Jianxi, ZHENG Shurui,et al.Study on medium crystal agent in preparation of α-hemihydrate gypsum with phosphogypsum[J].Bulletin of the Chinese Ceramic Society,2015,

|

|

34(5):1397-1401,1406.

|

| 7 |

丁萌,李建锡,李兵兵.磷石膏制备α半水石膏的试验研究[J].硅酸盐通报,2013,32(11):2379-2384.

|

|

DING Meng, LI Jianxi, LI Bingbing.Preparation of α-hemihydrate gypsum with posphogypsum[J].Bulletin of the Chinese Ceramic Society,2013,32(11):2379-2384.

|

| 8 |

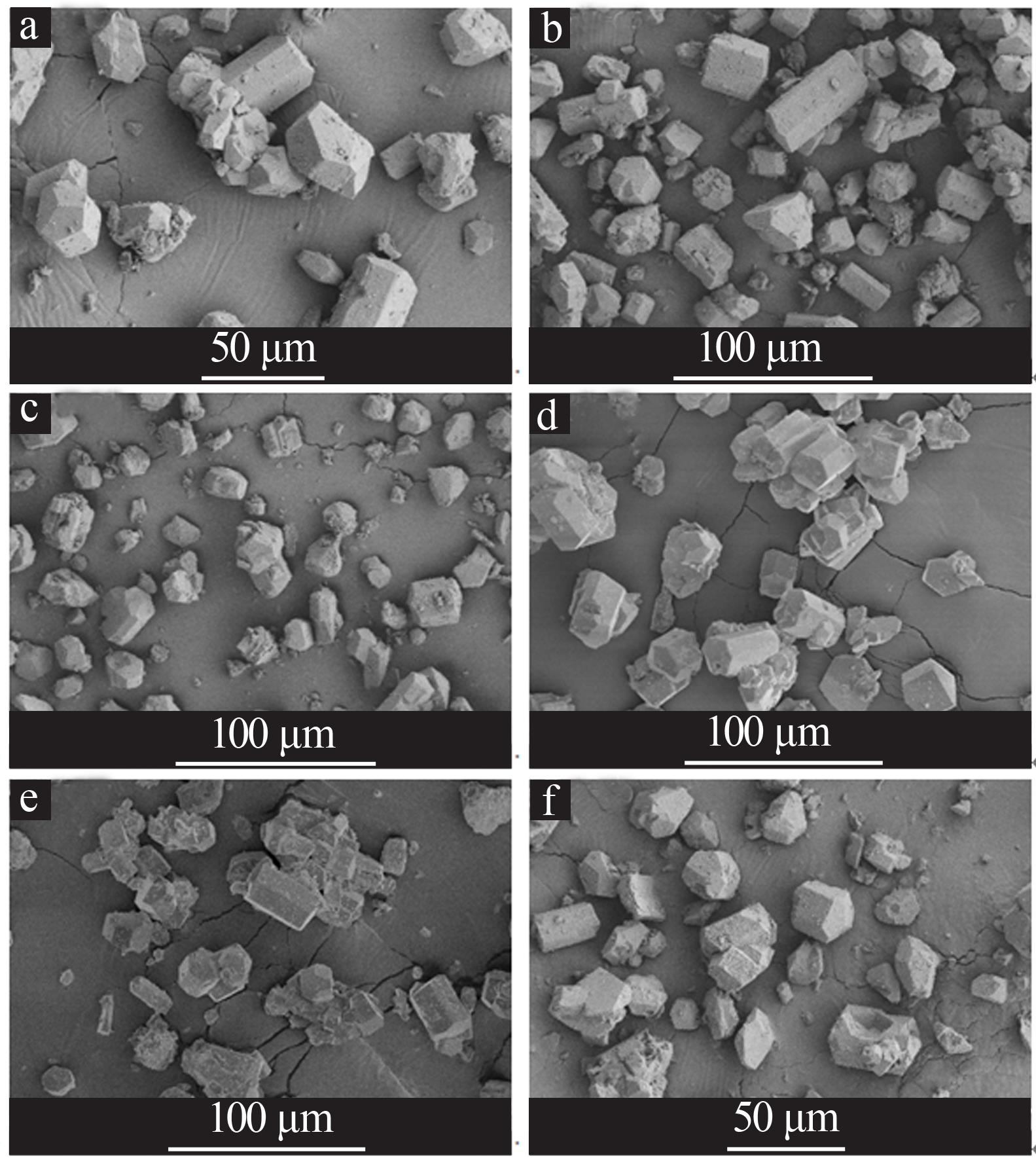

何玉龙,陈德玉,蔡攀,等.晶形控制剂对α半水石膏结晶形态的调控研究[J].人工晶体学报,2016,45(1):192-199.

|

|

HE Yulong, CHEN Deyu, CAI Pan,et al.Regulation of crystal morphology of α-hemihydrate gypsum in the presence of medium crystal agent[J].Journal of Synthetic Crystals,2016,45(1):192-199.

|

| 9 |

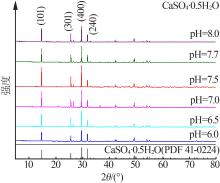

陈金文,易芸,张慧,等.蒸压参数与杂质对磷石膏制备α-半水石膏的影响[J].无机盐工业,2022,54(3):91-96.

|

|

CHEN Jinwen, YI Yun, ZHANG Hui,et al.Effect of autoclave parameters and impurities on preparation of α-hemihydrate gypsum from phosphogypsum[J].Inorganic Chemicals Industry,2022,54(3):91-96.

|

| 10 |

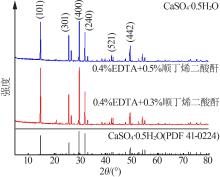

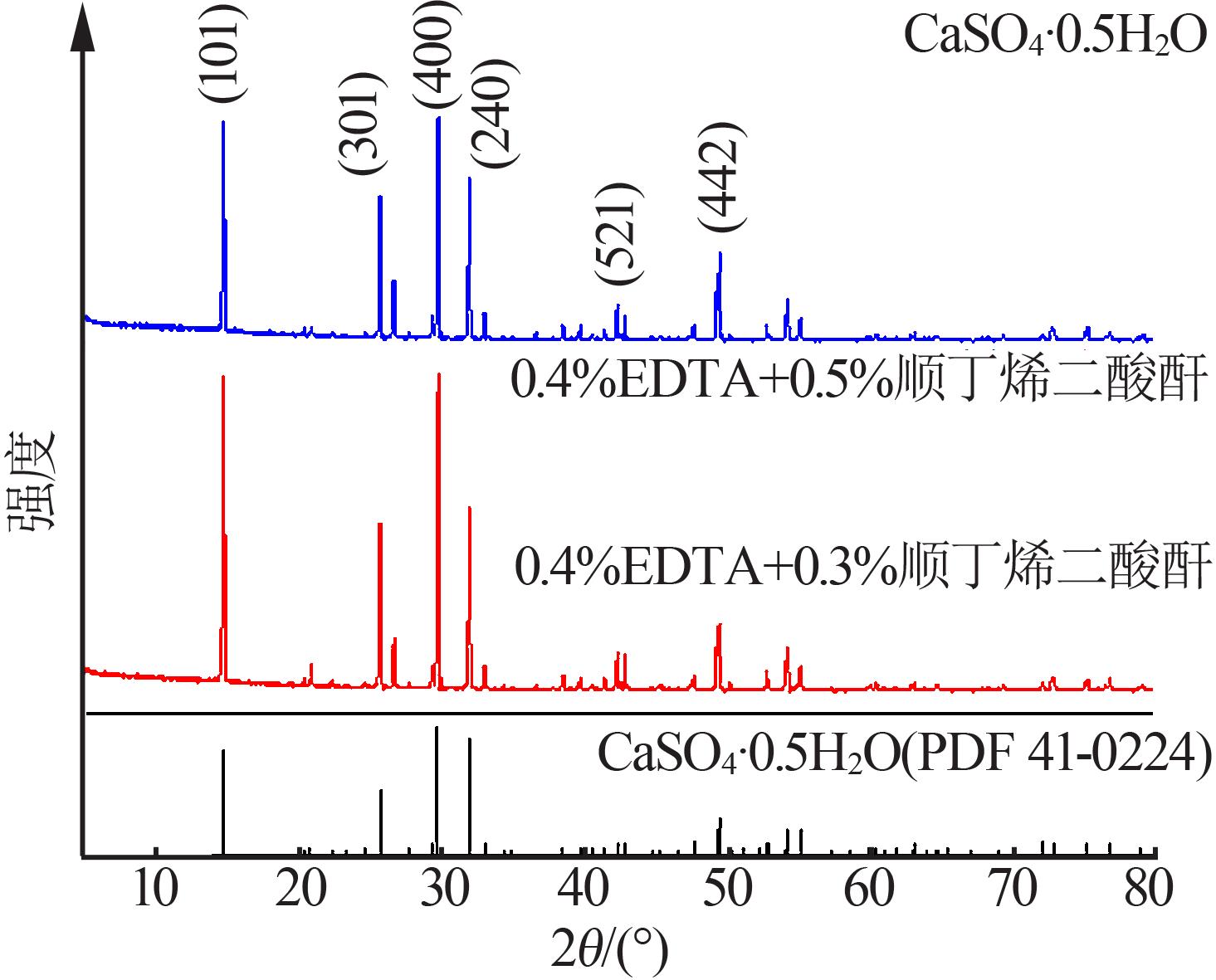

沈金水,卢都友,许仲梓.EDTA对加压水热法制备α-半水磷石膏的影响[J].硅酸盐通报,2015,34(10):2816-2821.

|

|

SHEN Jinshui, LU Duyou, XU Zhongzi.Effect of ethylenediaminetetraacetic acid on the preparation of α-hemihydrate gypsum from phosphogypsum with hydrothermal autoclave method[J].Bulletin of the Chinese Ceramic Society,2015,34(10):2816-2821.

|

| 11 |

刘金凤.工业磷石膏基α-半水石膏的制备及其浆体性能调控研究[D].绵阳:西南科技大学,2019.

|

|

LIU Jinfeng.Preparation of industrial phosphogypsum⁃based α-hemihydrate gypsum and regulation of its paste properties[D].Mianyang:Southwest University of Science and Technology,2019.

|

| 12 |

马保国,茹晓红,邹开波,等.常压水热Ca-Na-Cl溶液中用磷石膏制备α-半水石膏[J].化工学报,2013,64(7):2701-2707.

|

|

MA Baoguo, RU Xiaohong, ZOU Kaibo,et al.Preparation of α-calcium sulfate hemihydrate from phosphogypsum in Ca-Na-Cl solutions under atmospheric pressure[J].CIESC Journal,2013,64(7):2701-2707.

|

| 13 |

张稼祥,徐玲玲.EDTA对脱硫石膏制备α-半水石膏晶体生长的影响[J].南京工业大学学报:自然科学版,2018,40(2):90-94,131.

|

|

ZHANG Jiaxiang, XU Lingling.Effects of EDTA on crystal growth of α-hemihydrate gypsum prepared by flue gas desulphurization gypsum[J].Journal of Nanjing Tech University:Natural Science Edition,2018,40(2):90-94,131.

|

|

上接第 118 页)

|

|

ence of P 2O5 and F on the clinker formation and cement performances[J].Construction and Building Materials,2019,203:432- 442.

|

| 15 |

乔秀臣,马大伟,薛玉兵.煅烧硬石膏溶解特性对钙矾石形成的影响[J].硅酸盐通报,2021,40(1):201-206.

|

|

QIAO Xiuchen, MA Dawei, XUE Yubing.Influence of calcined anhydrite solubility on the formation of ettringite[J].Bulletin of the Chinese Ceramic Society,2021,40(1):201-206.

|

| 16 |

龚晓强,刘杰胜,徐晶云,等.石灰改性磷石膏对水泥砂浆性能影响的研究[J].武汉轻工大学学报,2019,38(1):51-55,72.

|

|

GONG Xiaoqiang, LIU Jiesheng, XU Jingyun,et al.Effect of lime⁃modified phosphogypsum on properties of cement mortar[J].Journal of Wuhan Polytechnic University,2019,38(1):51-55,72.

|

| 17 |

蔡开朗,廖其龙.钙矾石类膨胀剂膨胀效能的作用及机理研究[J].非金属矿,2019,42(3):48-51.

|

|

CAI Kailang, LIAO Qilong.The expansion efficiency of ettringite type expansion agent and its mechanism[J].Non-Metallic Mines, 2019,42(3):48-51.

|

| 18 |

刘新,冯攀,沈叙言,等.水泥水化产物:水化硅酸钙(C-S-H)的研究进展[J].材料导报,2021,35(9):9157-9167.

|

|

LIU Xin, FENG Pan, SHEN Xuyan,et al.Advances in the underst⁃

|

|

anding of cement hydrate—Calcium silicate hydrate(C-S-H)[J].Materials Reports,2021,35(9):9157-9167.

|

),WEI Jiazhan1,2,3(

),WEI Jiazhan1,2,3( ),CHEN Ping2,4,DUAN Pengxuan2,3

),CHEN Ping2,4,DUAN Pengxuan2,3