Inorganic Chemicals Industry ›› 2025, Vol. 57 ›› Issue (5): 18-25.doi: 10.19964/j.issn.1006-4990.2024-0264

• High-value utilization of magnesium resources • Previous Articles Next Articles

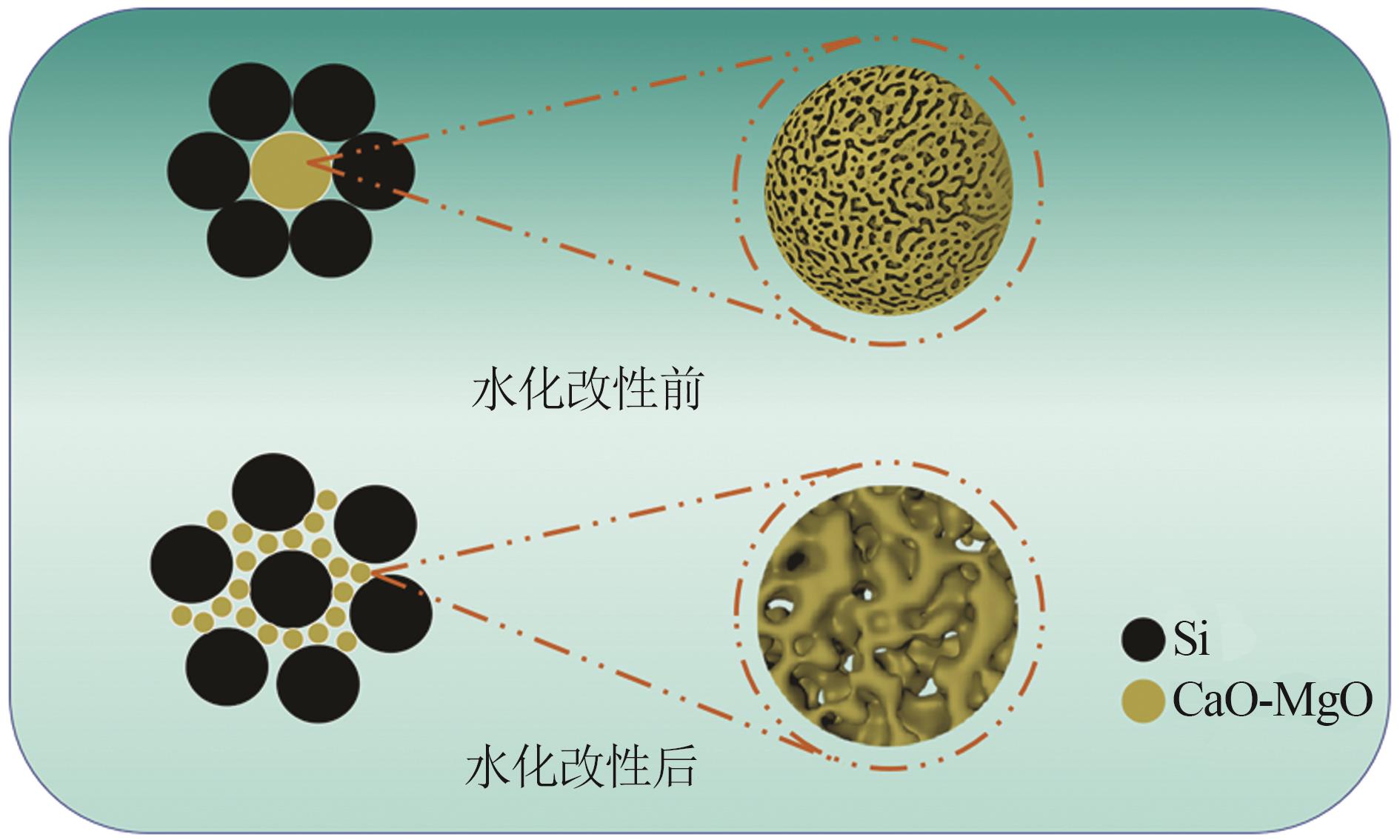

Study on effect and mechanism of hydration of dolime on its magnesium extraction experiment

LI Zhi1( ), HUANG Xiaorui1,2(

), HUANG Xiaorui1,2( ), JIANG Zhenyu1, LI Xue1, ZHAO Kun1, XU Guangwen1,2(

), JIANG Zhenyu1, LI Xue1, ZHAO Kun1, XU Guangwen1,2( )

)

- 1. Key Laboratory of Resources Chemicals and Materials of Ministry of Education,Shenyang University of Chemical Technology,Shenyang 110142,China

2. School of Chemical Engineering,University of Science and Technology Liaoning,Anshan 114051,China

-

Received:2024-05-10Online:2025-05-10Published:2025-06-05 -

Contact:HUANG Xiaorui, XU Guangwen E-mail:3488675843@qq.com;huangxiaorui@syuct.edu.cn;gwxu@ipe.ac.cn

CLC Number:

Cite this article

LI Zhi, HUANG Xiaorui, JIANG Zhenyu, LI Xue, ZHAO Kun, XU Guangwen. Study on effect and mechanism of hydration of dolime on its magnesium extraction experiment[J]. Inorganic Chemicals Industry, 2025, 57(5): 18-25.

share this article

| 1 | 单智伟,王悦存,王鹏飞,等.集成化白云石悬浮煅烧引领镁产业变革[J].中国材料进展,2024,43(1):46-53. |

| SHAN Zhiwei, WANG Yuecun, WANG Pengfei,et al.Integrated suspension calcination of dolomite leads great change in magnesium industry[J].Materials China,2024,43(1):46-53. | |

| 2 | JAYASATHYAKAWIN S, RAVICHANDRAN M, BASKAR N,et al.Mechanical properties and applications of magnesium alloy⁃review[J].Materials Today:Proceedings,2020,27:909-913. |

| 3 | MURTHY Y I.State⁃of⁃art studies on applications of magnesium alloys in construction industry[J].International Journal of Structural Engineering,2024,14(2):186-202. |

| 4 | 朵云霞,王丽娟,李仪,等.海绵钛中杂质元素Al来源及控制技术研究[J].钢铁钒钛,2022,43(1):36-39. |

| Yunxia DUO, WANG Lijuan, LI Yi,et al.Source analysis and control technology of impurity Al in titanium sponge[J].Iron Steel Vanadium Titanium,2022,43(1):36-39. | |

| 5 | 李吉帆,盛卓,李开华,等.镁热法生产海绵钛过程反应器温度场模拟研究[J].钢铁钒钛,2023,44(2):20-27. |

| LI Jifan, SHENG Zhuo, LI Kaihua,et al.Numerical simulation of the temperature field in titanium sponge reactor during magnesium thermal production process[J].Iron Steel Vanadium Titanium,2023,44(2):20-27. | |

| 6 | 毕秋艳,党力,曹海莲,等.青海盐湖镁资源开发与利用研究进展[J].盐湖研究,2022,30(1):101-109. |

| BI Qiuyan, DANG Li, CAO Hailian,et al.Development and utilization of magnesium resources in Qinghai salt lakes[J].Journal of Salt Lake Research,2022,30(1):101-109. | |

| 7 | 郭丽莉,李振,王晓民,等.水氯镁石和高钙菱镁石制备氢氧化镁[J].有色金属(冶炼部分),2022(1):103-107. |

| GUO Lili, LI Zhen, WANG Xiaomin,et al.Preparation of magnesium hydroxide from bischofite and high⁃calcium magnesite[J].Nonferrous Metals(Extractive Metallurgy),2022(1):103-107. | |

| 8 | 乔小斌,李直,徐梓馥,等.盐湖提锂副产镁渣的炼镁工艺研究[J].现代化工,2023,43(S2):136-140. |

| QIAO Xiaobin, LI Zhi, XU Zifu,et al.Research on magnesium refining process of by⁃product magnesium slag from lithium extraction in salt lake[J].Modern Chemical Industry,2023,43(S2):136-140. | |

| 9 | 田驰,侯欣彤,韩振南,等.真空下活性煅白制备的反应动力学研究[J].辽宁化工,2021,50(7):929-934. |

| TIAN Chi, HOU Xintong, HAN Zhennan,et al.Reaction kinetics study of calcined dolomite under vacuum calcination[J].Liaoning Chemical Industry,2021,50(7):929-934. | |

| 10 | 吴晓阳.中国镁资源开发利用现状及发展对策[J].现代矿业,2023,39(9):33-38,48. |

| WU Xiaoyang.Present situation and development countermeasures of exploitation and utilization of magnesium resources in China[J].Modern Mining,2023,39(9):33-38,48. | |

| 11 | 车玉思,杜胜敏,宋建勋,等.金属镁生产新工艺研究现状与进展[J].中国有色金属学报,2022,32(6):1719-1733. |

| CHE Yusi, DU Shengmin, SONG Jianxun,et al.Research status and progress of novel technology for magnesium production[J].The Chinese Journal of Nonferrous Metals,2022,32(6):1719-1733. | |

| 12 | 梁文玉,孙晓林,李凤善,等.金属镁冶炼工艺研究进展[J].中国有色冶金,2020,49(4):36-44,53. |

| LIANG Wenyu, SUN Xiaolin, LI Fengshan,et al.Research progress on magnesium smelting methods[J].China Nonferrous Metallurgy,2020,49(4):36-44,53. | |

| 13 | 朱福兴,李亮,李开华,等.电解法制镁的产品质量分析及控制[J].轻金属,2019(11):45-50. |

| ZHU Fuxing, LI Liang, LI Kaihua,et al.Product quality analysis and control of magnesium by electrolysis[J].Light Metals,2019(11):45-50. | |

| 14 | FU Daxue, WANG Yaowu, ZHANG Ting′an,et al.Review on the silicothermic process for primary magnesium production[J].Metallurgical and Materials Transactions B,2023,54(1):1-21. |

| 15 | XU Jilei, LIU Jinhui, ZHAO Yuming,et al.Mechanism of solid⁃liquid reaction in magnesium smelting by silicothermic process[J].Ceramics International,2024,50(9):14830-14841. |

| 16 | 韩继标,傅大学,郭军华,等.镁蒸气在真空条件下的冷凝行为[J].稀有金属材料与工程,2021,50(9):3361-3365. |

| HAN Jibiao, FU Daxue, GUO Junhua,et al.Condensation behavior of magnesium vapor in vacuum[J].Rare Metal Materials and Engineering,2021,50(9):3361-3365. | |

| 17 | 徐祥斌,曹慧君,徐佳.煅白热容的理论计算及试验测定[J].轻金属,2018(3):46-48. |

| XU Xiangbin, CAO Huijun, XU Jia.Theoretical calculation and experimental determination of calcined dolomite heat capacity[J].Light Metals,2018(3):46-48. | |

| 18 | 刘红湘,田阳,杨斌,等.皮江法炼镁与真空碳热还原法炼镁生命周期评价比较研究[J].有色金属(冶炼部分),2021(11):37-45. |

| LIU Hongxiang, TIAN Yang, YANG Bin,et al.Comparison on life cycle assessment of magnesium smelting by pidgeon process and vacuum carbothermal reduction method[J].Nonferrous Metals(Extractive Metallurgy),2021(11):37-45. | |

| 19 | 郑芮,杨博,王安,等.硅热法炼镁增产提质的原理探索与应用[J].中国有色金属学报,2023,33(7):2347-2355. |

| ZHENG Rui, YANG Bo, WANG An,et al.Principle exploration and application of simultaneous achieving production and quality of magnesium in silicothermic reduction process[J].The Chinese Journal of Nonferrous Metals,2023,33(7):2347-2355. | |

| 20 | 郭军华,丁天然,李培艳,等.加强炼镁传热效率的研究进展[J].有色金属科学与工程,2023,14(6):756-763,772. |

| GUO Junhua, DING Tianran, LI Peiyan,et al.Research progress in strengthening the heat transfer efficiency of magnesium smelting[J].Nonferrous Metals Science and Engineering,2023,14(6):756-763,772. | |

| 21 | HIDAYAT T, SIREGAR M Y, SANTOSO I,et al.The effects of reductant and additive on the magnesium extraction from calcined dolomite via metallothermic reduction under vacuum condition[J].Vacuum,2022,202:111196. |

| 22 | YOOSUK B, UDOMSAP P, PUTTASAWAT B.Hydration⁃dehydration technique for property and activity improvement of calcined natural dolomite in heterogeneous biodiesel production:Structural transformation aspect[J].Applied Catalysis A:General,2011,395(1/2):87-94. |

| 23 | 阿旦春,肖学英,文静,等.氢氧化镁制备活性MgO及MOC的工艺研究[J].矿产综合利用,2022(3):17-26. |

| Danchun A, XIAO Xueying, WEN Jing,et al.Study on the preparation of active MgO and MOC from magnesium hydroxide[J].Comprehensive Utilization of Mineral Resources,2022(3):17-26. | |

| 24 | 张超,宋建勋,车玉思,等.工艺参数对硅热法炼镁过程的影响机理[J].中国有色金属学报,2021,31(5):1347-1357. |

| ZHANG Chao, SONG Jianxun, CHE Yusi,et al.Influence mechanism of technology parameters on silicothermic reduction proc⁃ess[J].The Chinese Journal of Nonferrous Metals,2021,31(5):1347-1357. | |

| 25 | FU Daxue, JI Zonghui, GUO Junhua,et al.Diffusion and phase transformations during the reaction between ferrosilicon and CaO·MgO under vacuum[J].Journal of Materials Research and Technology,2020,9(3):4379-4385. |

| [1] | WANG Feng, SONG Yu, HE Zhaoyi, XIA Yuhua, BI Yanli, FENG Hao, CAO Dongwei. Study on mechanical properties and microscopic characterization of phosphogypsum composite cementitious materials [J]. Inorganic Chemicals Industry, 2025, 57(5): 93-99. |

| [2] | CHENG Xiaoqiang, MA Jun, FENG Bin, BAI Liguang, ZHAO Xiaodong. Discussion on application of post-treatment process in fixed bed hydrogen peroxide production process [J]. Inorganic Chemicals Industry, 2025, 57(2): 98-104. |

| [3] | LIU Guangming. Study on photocatalytic and mechanical properties of C3N5/NH2-MIL-125(Ti) modified concrete mortar [J]. Inorganic Chemicals Industry, 2025, 57(1): 120-128. |

| [4] | CHENG Ziyang, CHEN Guofu. Early hydration kinetics research of nano-SiO2 and cement composite cementitious materials [J]. Inorganic Chemicals Industry, 2024, 56(7): 80-87. |

| [5] | YU Zhou, HE Zhaoyi, TANG Liang, HE Sheng, XIAO Haixin, XIAO Yixun. Study on preparation and microscopic properties of typical sulfate solid waste composite cementitious materials [J]. Inorganic Chemicals Industry, 2024, 56(4): 90-97. |

| [6] | ZHANG Guidong, YANG Xuejiao, GUO Xudong, YANG Lin. Study on hydration properties of type Ⅱ anhydrite prepared by calcination and atmospheric acidification [J]. Inorganic Chemicals Industry, 2024, 56(2): 104-110. |

| [7] | NI Dong, TANG Liang, HE Zhaoyi, WANG Jian, PEI Shanshan, XIA Lei. Study on sulfate activation performance of electrolytic manganese residue in hydrated lime-slag system [J]. Inorganic Chemicals Industry, 2024, 56(11): 151-157. |

| [8] | JIANG Lilong, LI Jianqiu, YANG Lin, ZHANG Qinggang. Study on performance of concrete with high-Mg phosphate tailing as mineral admixture [J]. Inorganic Chemicals Industry, 2024, 56(1): 90-95. |

| [9] | XU Li, ZHANG Qiang. Experimental study on properties of iron tailings powder cement-based materials [J]. Inorganic Chemicals Industry, 2023, 55(6): 116-123. |

| [10] | DU Guanggang, HE Tong, XU Zehui, LIU Lei. Study on properties of calcium oxide in SCA under different calcination conditions [J]. Inorganic Chemicals Industry, 2023, 55(10): 35-41. |

| [11] | ZHANG Taiyue,XIE Fan,GUO Junyuan. Study on performance optimization and mechanism of phosphogypsum based composite cementitious materials [J]. Inorganic Chemicals Industry, 2022, 54(9): 136-142. |

| [12] | LIU Yingqiang,GUO Runhua,LIU Xijie. Influence of silica fume and metakaolin on properties of slag?fly ash microbead cementitious materials [J]. Inorganic Chemicals Industry, 2022, 54(6): 102-108. |

| [13] | WANG Youyou,YUAN Hao,HAN Qingqing,CHEN Shiying. Activation of activator on fly ash?titanium gypsum?calcium carbide slag system and its hydration mechanism [J]. Inorganic Chemicals Industry, 2022, 54(6): 115-119. |

| [14] | SHI Han,YUAN Biao,SHEN Peng. Research progress on new inorganic solid adsorbents in field of natural gas dehydration [J]. Inorganic Chemicals Industry, 2022, 54(5): 11-18. |

| [15] | WANG Lei,LI Jincheng,ZHANG Xiaowei,ZHANG Dongliang,WANG Mitang. Geopolymer activator and its excitation principle [J]. Inorganic Chemicals Industry, 2022, 54(2): 16-20. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||