Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (12): 104-112.doi: 10.19964/j.issn.1006-4990.2024-0110

• Research & Development • Previous Articles Next Articles

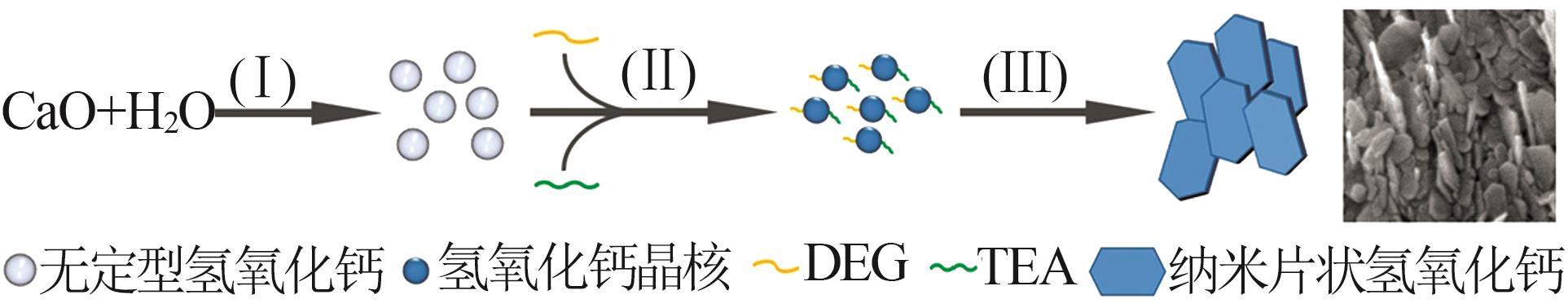

Preparation and structural characterization of high specific surface area calcium hydroxide by wet digestion of quicklime

WANG Jie1,2( ), ZHAO Xubo3, TANG Yong1,2, QIN Lingyi2, CHEN Xiaopeng1, LIAO Dankui1(

), ZHAO Xubo3, TANG Yong1,2, QIN Lingyi2, CHEN Xiaopeng1, LIAO Dankui1( ), TONG Zhangfa1(

), TONG Zhangfa1( ), WANG Linlin1

), WANG Linlin1

- 1.School of Chemistry and Chemical Engineering,Guangxi University,Nanning 530004,China

2.Guangxi Engineering Academy of Calcium Carbonate Industrialization Co.,Ltd.,Nanning 530004,China

3.Shangsi Desheng New Material Technology Co.,Ltd.,Fanagchenggang 535500,China

-

Received:2024-02-28Online:2024-12-10Published:2024-04-23 -

Contact:LIAO Dankui, TONG Zhangfa E-mail:1094301190@qq.com;liaodankuigx@163.com;zhftong@sina.com

CLC Number:

Cite this article

WANG Jie, ZHAO Xubo, TANG Yong, QIN Lingyi, CHEN Xiaopeng, LIAO Dankui, TONG Zhangfa, WANG Linlin. Preparation and structural characterization of high specific surface area calcium hydroxide by wet digestion of quicklime[J]. Inorganic Chemicals Industry, 2024, 56(12): 104-112.

share this article

| [1] | DÖLLE K, RÖHLEN P.Determination of the feasibility of a renewed approach to the mechanical cleaning stage in wastewater treatment plant:A laboratory study[J].Asian Journal of Advanced Research and Reports,2023,17(9):126-134. |

| [2] | HONG J, ZOU X, QIN Z,et al.Effect of CO2 on the desulfurization of sintering flue gas with hydrated lime[J].Materials(Basel,Switzerland),2022,16(1):303. |

| [3] | OTSUKA Y, KONO H, KIKUCHI M.Mechanochemical synthesis of cerium chlorapatite from a mixture of cerium chloride heptahydrate,dicalcium phosphate dihydrate,and calcium hydroxide for biomedical application[J].Bio-Medical Materials and Engineering,2024,35(1):77-85. |

| [4] | HE Kejia, TANG Zuozhou, SONG Qiang,et al.Process analysis of SO3 removal by Ca(OH)2 particles from flue gas[J].Chemical Engineering Science,2022,247:117054. |

| [5] | HE Kejia, SONG Qiang, YAN Zhennan,et al.Study on competitive absorption of SO3 and SO2 by calcium hydroxide[J].Fuel,2019,242:355-361. |

| [6] | HAN Y, HWANG G, KIM D,et al.Porous Ca-based bead sorbents for simultaneous removal of SO2,fine particulate matters,and heavy metals from pilot plant sewage sludge incineration[J].Journal of Hazardous Materials,2015,283:44-52. |

| [7] | 王鑫,韦明,刘琨.特种氢氧化钙的制备技术与应用进展[J].现代化工,2023,43(12):26-30. |

| WANG Xin, WEI Ming, LIU Kun.Progress in preparation technology and application of special kinds of calcium hydroxide[J].Modern Chemical Industry,2023,43(12):26-30. | |

| [8] | SHIN H G, KIM H, KIM Y N,et al.Preparation and characterization of high surface area calcium hydroxide sorbent for SO2 removal[J].Current Applied Physics,2009,9(3):S276-S279. |

| [9] | 郝志飞,张印民,张永锋,等.湿法改性制备高比表面积氢氧化钙及表征[J].无机盐工业,2015,47(12):19-21. |

| HAO Zhifei, ZHANG Yinmin, ZHANG Yongfeng,et al.Wet modified preparation and characterization of calcium hydroxide with high specific surface area[J].Inorganic Chemicals Industry,2015,47(12):19-21. | |

| [10] | 刘越,郑强,邢佳斌,等.石灰石干法制备高性能氢氧化钙的工艺及应用研究[J].无机盐工业,2023,55(10):42-49,85. |

| LIU Yue, ZHENG Qiang, XING Jiabin,et al.Study on process and application of high-performance calcium hydroxide prepared by dry digestion from limestone[J].Inorganic Chemicals Industry,2023,55(10):42-49,85. | |

| [11] | 熊爽,严金生,周洲,等.生石灰消化反应条件对氢氧化钙特性影响[J].无机盐工业,2023,55(12):50-58. |

| XIONG Shuang, YAN Jinsheng, ZHOU Zhou,et al.Effect of reaction conditions of quicklime digestion on properties of calcium hydroxide[J].Inorganic Chemicals Industry,2023,55(12):50- 58. | |

| [12] | DONG Yanhui, ZHANG Dan, LI Daguang,et al.Control of ostwald ripening[J].Science China Materials,2023,66(3):1249-1255. |

| [13] | 陈奇,廖丹葵,张庆年,等.电导率法快捷高效测定生石灰活性度[J].无机盐工业,2023,55(9):114-120. |

| CHEN Qi, LIAO Dankui, ZHANG Qingnian,et al.Fast and efficient determination of quicklime activity by conductivity meth-od[J].Inorganic Chemicals Industry,2023,55(9):114-120. | |

| [14] | 夏铁玉,张辉,周明顺,等.生石灰高温性能检测方法及其应用[J].烧结球团,2018,43(3):24-27,42. |

| XIA Tieyu, ZHANG Hui, ZHOU Mingshun,et al.Testing method of high temperature performance of quick lime and its application[J].Sintering and Pelletizing,2018,43(3):24-27,42. | |

| [15] | 徐荣声,孟泽,冯倩,等.氯化锌-水蒸气协同活化玉米芯制活性炭的研究[J].无机盐工业,2023,55(12):119-127. |

| XU Rongsheng, MENG Ze, FENG Qian,et al.Study on preparation of activated carbon from corn cob by zinc chloride and water vapor[J].Inorganic Chemicals Industry,2023,55(12):119-127. | |

| [16] | YASEEN M, ULLAH S, AHMAD W,et al.Fabrication of Zn and Mn loaded activated carbon derived from corn cobs for the adsorptive desulfurization of model and real fuel oils[J].Fuel,2021,284:119102. |

| [17] | THOMMES M, KANEKO K, NEIMARK A V,et al.Physisorption of gases,with special reference to the evaluation of surface area and pore size distribution(IUPAC Technical Report)[J].Pure and Applied Chemistry,2015,87(9/10):1051-1069. |

| [18] | RODRIGUEZ-NAVARRO C, BURGOS-CARA A, DI LORENZO F,et al.Nonclassical crystallization of calcium hydroxide via amorphous precursors and the role of additives[J].Crystal Growth & Design,2020,20(7):4418-4432. |

| [19] | MISHRA R K, FLATT R J, HEINZ H.Force field for tricalcium silicate and insight into nanoscale properties:Cleavage,initial hydration,and adsorption of organic molecules[J].The Journal of Physical Chemistry C,2013,117(20):10417-10432. |

| [20] | NALET C, NONAT A.Ionic complexation and adsorption of small organic molecules on calcium silicate hydrate:Relation with their retarding effect on the hydration of C3S[J].Cement and Concrete Research,2016,89:97-108. |

| [21] | ZHANG Yanrong, KONG Xiangming, LU Zichen,et al.Influence of triethanolamine on the hydration product of portlandite in cement paste and the mechanism[J].Cement and Concrete Research,2016,87:64-76. |

| [22] | 郭思瑶,赵通林,郑思侬,等.胺-醇复配捕收剂对铁矿反浮选脱硅的影响 [J/OL].矿产综合利用,1-10[2024-04-23].https://link.cnki.net/urlid/51.1251.TD.20231117.1631.023. |

| GUO Siyao, ZHAO Tonglin, ZHENG Sinong,et al.Effect of amine-alcohol complex trapping agent on desilication of iron ore by reverse flotation[J/OL].Multipurpose Utilization of Mineral Resources,1-10[2024-04-23].https://link.cnki.net/urlid/51.1251.TD.20231117.1631.023. | |

| [23] | CHAUDHARI O, BIERNACKI J J, NORTHRUP S.Effect of carboxylic and hydroxycarboxylic acids on cement hydration:Experimental and molecular modeling study[J].Journal of Materials Science,2017,52(24):13719-13735. |

| [24] | NAVRÁTILOVÁ E, TIHLAŘÍKOVÁ E, NEDĚLA V,et al.Effect of the preparation of lime putties on their properties[J].Scientific Reports,2017,7(1):17260. |

| [25] | MOHD DAUD F D, VIGNESH K, SREEKANTAN S,et al.Ca(OH)2 nano-pods:Investigation on the effect of solvent ratio on morphology and CO2 adsorption capacity[J].RSC Advances,2016,6(42):36031-36038. |

| [26] | 周婧琦,黄琴,秦令祥,等.山药淀粉与燕麦β-葡聚糖共混体系理化及消化性能研究[J].食品工业科技,2022,43(18):114-121. |

| ZHOU Jingqi, HUANG Qin, QIN Lingxiang,et al.Physicochemical and digestive properties of yam starch/oat β-glucan blends[J].Science and Technology of Food Industry,2022,43(18):114- 121. | |

| [27] | 汤勇,唐名德,焦妍惠,等.加压碳酸化法制备片状纳米碳酸钙及其表征[J].材料导报,2023,37(17):130-136. |

| TANG Yong, TANG Mingde, JIAO Yanhui,et al.Preparation and characterization of flake-like nano calcium carbonate by pressurized carbonation[J].Materials Reports,2023,37(17):130-136. | |

| [28] | RODRIGUEZ-NAVARRO C, VETTORI I, RUIZ-AGUDO E.Kinetics and mechanism of calcium hydroxide conversion into calcium alkoxides:Implications in heritage conservation using nanolimes[J].Langmuir,2016,32(20):5183-5194. |

| [29] | WANG Jian, KONG Xiangming, YIN Jianhao,et al.Impacts of two alkanolamines on crystallization and morphology of calcium hydroxide[J].Cement and Concrete Research,2020,138:106250. |

| [30] | 周刚,杨思奥,王凯丽,等.TEPA改性Cu-BTC@SiO2复合气凝胶制备及其捕集CO2特性研究[J/OL].煤炭科学技术,1-12[2024-04-23].https://link.cnki.net/urlid/11.2402.TD.20230928.1544.002. |

| ZHOU Gang, YANG Siao, WANG Kaili,et al.TEPA modification Cu-BTC@SiO2 Preparation of composite aerogel and its CO2 capture characteristics [J/OL].Coal Science and Technology,1-12[2024-04-23].https://link.cnki.net/urlid/11.2402.TD.20230928.1544.002. | |

| [31] | ZHU Jinmeng, ZHANG Peiyao, DING Jinghan,et al.Nano Ca(OH)2:A review on synthesis,properties and applications[J].Journal of Cultural Heritage,2021,50:25-42. |

| [32] | HARUTYUNYAN V S.Adsorption energy of stoichiometric molecules and surface energy at morphologically important facets of a Ca(OH)2 crystal[J].Materials Chemistry and Physics,2012,134(1):200-213. |

| [1] | HUANG Tianyin, SUN Ling, ZHAO Qinzheng, CHEN Xin, SONG Xiaojie, WU Bingdang. Study on performance and mechanism of titanium salt coagulant for treatment of oily wastewater [J]. Inorganic Chemicals Industry, 2025, 57(2): 68-75. |

| [2] | TU Yanping, BAI Dengxian, CHENG Shukai, XIE Junjie, HUANG Zhiliang, CHEN Guofu. Effect of high temperature modification of mineral powder and quicklime on properties of phosphogypsum cement based materials [J]. Inorganic Chemicals Industry, 2024, 56(6): 94-101. |

| [3] | YAO Yong, LI Shizhu, ZHENG Dongchen, ZENG Tinghua, WU Zhichao, YU Chi, LIU Faqian. Study on preparation,evaluation and application of new low-carbon emission nano calcium hydroxide desulfurizer [J]. Inorganic Chemicals Industry, 2023, 55(4): 38-44. |

| [4] | ZHANG Xing,XU Jie,WANG Zibing,HOU Peng,HE Long,LIU Huan. Effect of feedstock particle size on kinetics of limestone thermal decomposition reaction [J]. Inorganic Chemicals Industry, 2023, 55(2): 79-84. |

| [5] | YANG Fengling,ZHAI Min,REN Lei,ZHANG Yuanyuan,CHENG Fangqin,DONG Hongyu. Influencing factors of crystallization products in wet desulfurization of carbide slag [J]. Inorganic Chemicals Industry, 2023, 55(2): 92-98. |

| [6] | XIONG Shuang, YAN Jinsheng, ZHOU Zhou, ZHOU Baodi, CHEN Xiaopeng, TONG Zhangfa. Effect of reaction conditions of quicklime digestion on properties of calcium hydroxide [J]. Inorganic Chemicals Industry, 2023, 55(12): 50-58. |

| [7] | LIU Yue, ZHENG Qiang, XING Jiabin, XING Run, MA Yali, JIA Songyan, LI Xue. Study on process and application of high-performance calcium hydroxide prepared by dry digestion from limestone [J]. Inorganic Chemicals Industry, 2023, 55(10): 42-49. |

| [8] | YANG Yongyu,TIAN Peng,ZHOU Ruohui,XU Qianjin,LIU Kunji,NING Guiling. Effect of gibbsite activation on preparation of boehmite by hydrothermal method [J]. Inorganic Chemicals Industry, 2022, 54(9): 55-62. |

| [9] | XU Qingying,YANG Dingyi,LÜ Wei,LI Xiang,QIAN Yunfeng,DU Baocong. Effect of grinding time on properties of phosphogypsum based cementitious materials [J]. Inorganic Chemicals Industry, 2022, 54(5): 101-108. |

| [10] | HU Zhongyang,SITU Yue,HUANG Hong,ZOU Jiantao. Spherical silica synthesized from cheap silicon and its particle size control [J]. Inorganic Chemicals Industry, 2022, 54(5): 79-83. |

| [11] | LU Zheng,CHEN Kunfeng,XUE Dongfeng. Study on large-scale preparation and electrochemical properties of high thermal stabilized α-Fe2O3 [J]. Inorganic Chemicals Industry, 2022, 54(3): 45-50. |

| [12] | SU Shaolong,QU Xiaolong,SUN Yanmin,ZHONG Dule,NAN Jun,HAO Ziquan. Study on preparation and performance of high efficient and environmental friendly desulfurizer [J]. Inorganic Chemicals Industry, 2022, 54(3): 77-81. |

| [13] | Wang Bin,Deng Xiaochuan,Shi Yifei,Dong Chaochao,Fan Faying,Zhu Chaoliang,Fan Jie,Ma Wanxia,Zuo Fangtao. Optimizing preparation process of lithium carbonate reaction crystallization by Taguchi experimental design method [J]. Inorganic Chemicals Industry, 2021, 53(8): 60-65. |

| [14] | Qiu Zhanjiang,Qin Xuezheng,Qin Xuehong,Yuan Shaoqiang,Yang Yuehui. Study on fractal characteristics of particle size distribution of zircon sand in ball milling [J]. Inorganic Chemicals Industry, 2020, 52(5): 56-58. |

| [15] | Su Shaolong,Qu Xiaolong,Zhong Dule,Sun Yanmin,Ma Yueqian. Study on determination of CaO,Ca(OH)2 and CaCO3 in industrial calcium hydroxide [J]. Inorganic Chemicals Industry, 2020, 52(5): 75-77. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||