Inorganic Chemicals Industry ›› 2021, Vol. 53 ›› Issue (8): 36-43.doi: 10.19964/j.issn.1006-4990.2020-0545

• Research & Development • Previous Articles Next Articles

Preliminary study on scrubbing and stripping operation of the extracted organic phase in wet phosphoric acid process by hydrochloric acid route

Zhang Shaojie( ),Tang Shengwei,Wang Yang,Zheng Dongyue,Zhong Benhe,Chen Yanxiao(

),Tang Shengwei,Wang Yang,Zheng Dongyue,Zhong Benhe,Chen Yanxiao( )

)

- School of Chemical Engineering,Sichuan University,Chengdu 610065,China

-

Received:2020-10-12Online:2021-08-10Published:2021-08-11 -

Contact:Chen Yanxiao E-mail:sjzhang@stu.scu.edu.cn;yxchen888@163.com

CLC Number:

Cite this article

Zhang Shaojie,Tang Shengwei,Wang Yang,Zheng Dongyue,Zhong Benhe,Chen Yanxiao. Preliminary study on scrubbing and stripping operation of the extracted organic phase in wet phosphoric acid process by hydrochloric acid route[J]. Inorganic Chemicals Industry, 2021, 53(8): 36-43.

share this article

Table 5

Experimental results of H3PO4 stripping when H2SO4 solution was used as stripping agent under different conditions"

| 序 号 | 温 度/ ℃ | V(A)/ V(O) | 时间/ min | c(H2SO4) 浓度/ (mol·L-1) | 反萃酸组成 | n(H3PO4)/ n(Ca2+) | 反萃取率 SE/% | |

|---|---|---|---|---|---|---|---|---|

| w (H3PO4)/% | w (CaCl2)/% | |||||||

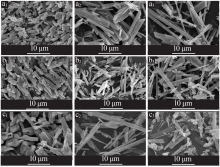

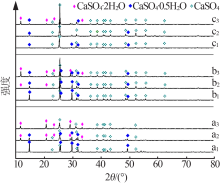

| a1 | 20 | 1∶3 | 70 | 0.404 5 | 8.35 | 0.21 | 45.19 | 56.33 |

| a2 | 20 | 2∶3 | 70 | 0.212 3 | 5.45 | 0.23 | 26.51 | 85.92 |

| a3 | 20 | 1∶1 | 70 | 0.134 9 | 3.87 | 0.20 | 21.76 | 92.28 |

| b1 | 40 | 1∶3 | 70 | 0.404 5 | 9.47 | 0.26 | 41.03 | 67.12 |

| b2 | 40 | 2∶3 | 70 | 0.212 3 | 5.46 | 0.25 | 24.71 | 89.84 |

| b3 | 40 | 1∶1 | 70 | 0.134 9 | 3.58 | 0.20 | 20.11 | 93.23 |

| c1 | 60 | 1∶3 | 70 | 0.404 5 | 9.56 | 0.24 | 45.21 | 75.71 |

| c2 | 60 | 2∶3 | 70 | 0.212 3 | 5.94 | 0.24 | 28.51 | 92.62 |

| c3 | 60 | 1∶1 | 70 | 0.134 9 | 3.92 | 0.20 | 22.17 | 96.05 |

| [1] | 马航, 冯霄. 基于湿、热法磷加工体系共生耦合的磷资源产业可持续性发展研究[J]. 无机盐工业, 2018, 50(11):1-6. |

| [2] |

Assuncao M C, Cote G, Andre M, et al. Phosphoric acid recovery from concentrated aqueous feeds by a mixture of di-isopropyl ether(DiPE) and tri-n-butylphosphate(TBP):Extraction data and mo-delling[J]. RSC Advances, 2017, 7(12):6922-6930.

doi: 10.1039/C6RA25440C |

| [3] | 钟本和, 陈亮, 李军, 等. 溶剂萃取法净化湿法磷酸的新进展[J]. 化工进展, 2005, 24(6):596-602. |

| [4] | 雷武. 探讨湿法磷酸生产中节约硫酸的途径[J]. 磷肥与复肥, 2001, 16(4):29-31. |

| [5] | Zhang P. Comprehensive recovery and sustainable development of phosphate resources[J]. Procedia Engineering, 2014(83):37-51. |

| [6] | 徐进, 孙志岩. 磷石膏综合利用制约因素分析及对策探讨[J]. 化工矿物与加工, 2009, 38(6):25-27. |

| [7] | 叶学东. 磷石膏利用现状及“十三五”发展思路[C]// 中国建筑材料联合会石膏建材分会第六届年会第十届全国石膏技术交流大会暨展览会. 西宁:中国建筑材料联合会石膏建材分会, 2015:25-30. |

| [8] | 贡长生. 现代磷化工技术和应用.上册[M]. 北京: 化学工业出版社, 2013. |

| [9] | 孙国超, 李燕凤, 袁圣娟. 窑法磷酸工业生产评述[J]. 化肥工业, 2019, 46(3):10-15,51. |

| [10] | 殷宪国. 中国窑法磷酸工业化技术进展[J]. 磷肥与复肥, 2014, 29(5):37-40. |

| [11] | 娄伦武, 陈铭, 赵宗尧, 等. 盐酸法分解磷矿制磷酸研究现状[J]. 化肥工业, 2017, 44(4):5-8,11. |

| [12] |

Jin Y, Li J, Luo J H, et al. Liquid-liquid equilibrium in the system phosphoric acid/water/tri-n-butyl phosphate/calcium chloride[J]. Journal of Chemical & Engineering Data, 2010, 55(9):3196-3199.

doi: 10.1021/je100054k |

| [13] |

Jin Y, Zou D, Wu S Q, et al. Extraction kinetics of phosphoric acid from the phosphoric acid-calcium chloride solution by tri-n-butyl phosphate[J]. Industrial & Engineering Chemistry Research, 2015, 54(1):108-116.

doi: 10.1021/ie503273j |

| [14] | 李军, 金央, 罗建洪, 等. 盐酸分解中低品位磷矿制备工业级和食品级磷酸的方法:中国,101774556A[P]. 2010-07-14. |

| [15] | 王和平, 王海良, 赵志全. 《磷矿石和磷精矿化学分析方法》国家标准修订说明[J]. 化工标准化与质量监督, 1996(8):8-9. |

| [16] | 吴佩芝. CaSO4-H3PO4-H2SO4-H2O四元系统及其应用(上)[J]. 磷肥与复肥, 1997(5):31-36. |

| [17] | 吴佩芝. 第三讲湿法磷酸生产中硫酸钙的结晶过程[J]. 磷肥与复肥, 1993, 8(4):16-21. |

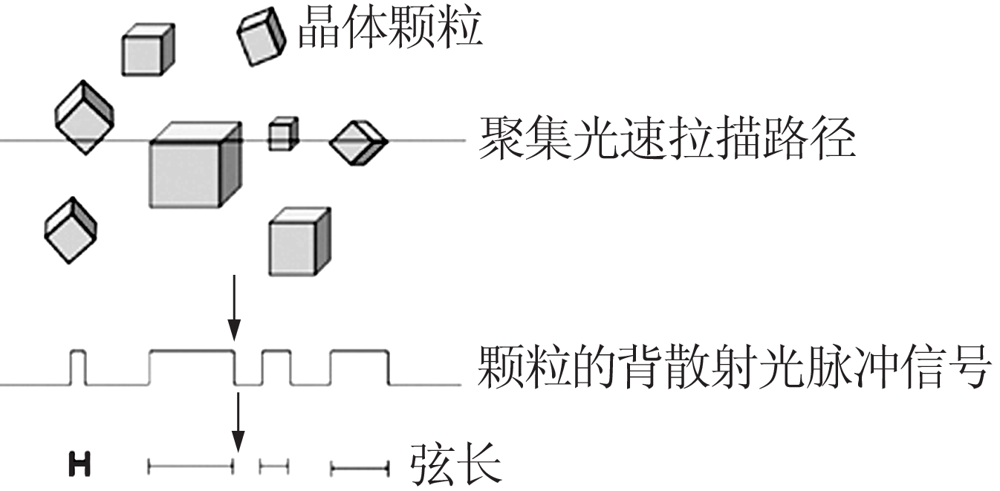

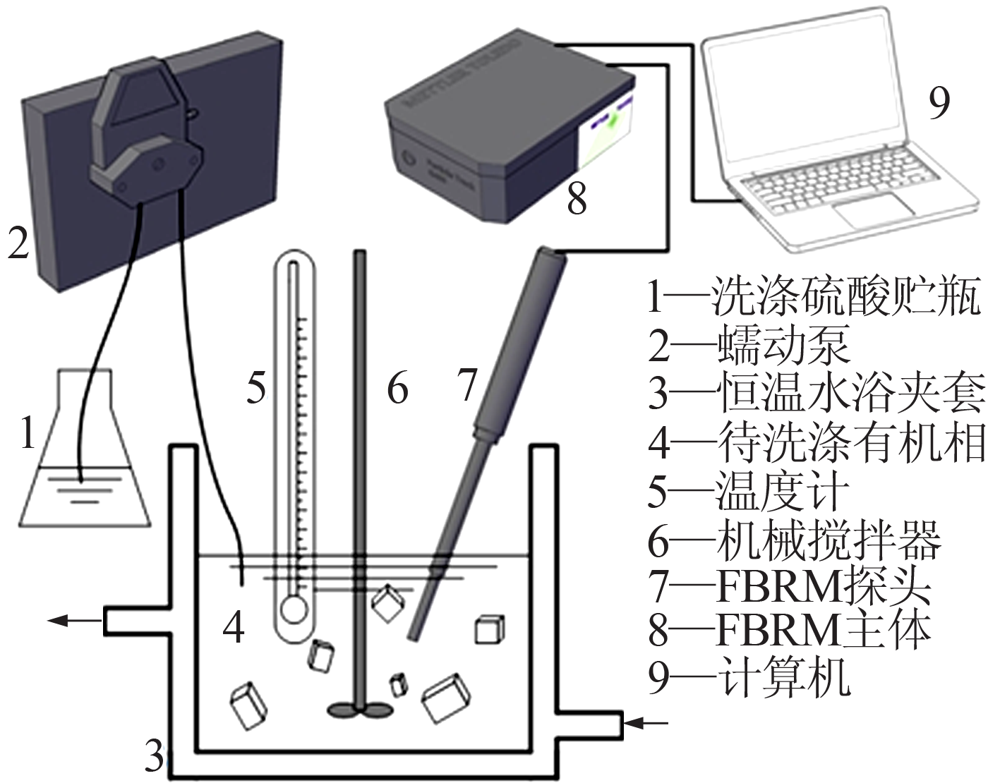

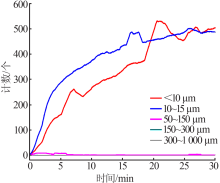

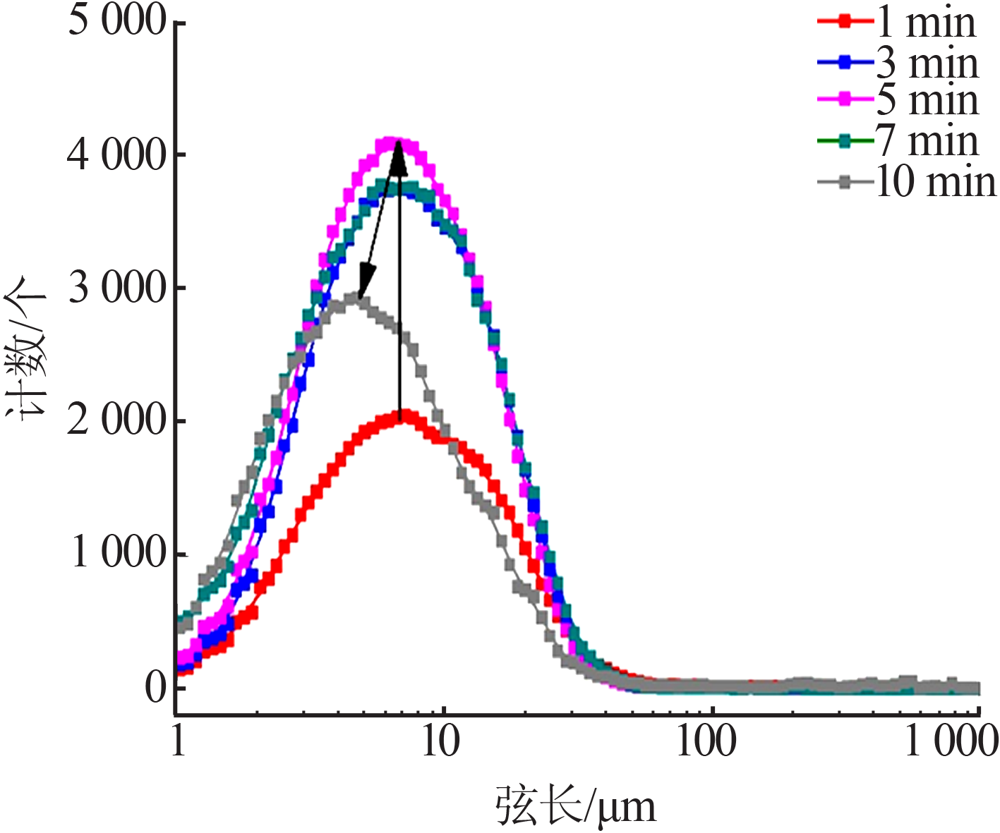

| [18] | Unno J, Hirasawa I. Transformation of CSD when crystal shape ch-anges with crystal size into CLD from FBRM by using Monte Carlo Analysis[J]. Advances in Chemical Engineering and Science, 2017(7):91-107. |

| [19] | 朱鹏程, 王国栋, 曾波. 磷石膏浮选脱硅试验研究[J]. 矿产综合利用, 2014(6):39-42. |

| [20] | 朱鹏程, 彭操, 苟苹, 等. 脱硅磷石膏制备硫酸铵和碳酸钙的研究[J]. 化工矿物与加工, 2017, 46(6):14-17,24. |

| [36] | 杨海鹏. Cu-Ce改性USY分子筛的低温NH3-SCR性能的研究[D]. 杭州: 浙江大学, 2014. |

| [37] | 周昊. Mn-Ce/ETS-10催化剂的低温脱硝性能研究[D]. 南京: 南京大学, 2017. |

| [38] | 乔辉. Ce改性对原位合成Cu-SSZ-13脱除柴油车尾气NOx的影响[D]. 太原: 太原理工大学, 2014. |

| [39] | 樊银明. Ce原位引入和负载于Mn/SAPO-34的低温NH3-SCR抗硫抗水性能与分子模拟研究[D]. 广州: 华南理工大学, 2017. |

| [40] | 黄增斌, 李翠清, 王振, 等. 不同分子筛负载锰铈催化剂的低温NH3-SCR脱硝性能[J]. 燃料化学学报, 2016, 44(11):1388-1393. |

| [41] |

Van Kooten W E J, Kaptein J, Van den Bleek C M, et al. Hydroth-ermal deactivation of Ce-ZSM-5,Ce-beta,Ce-mordenite and Ce-Y zeolite de NOx catalysts[J]. Catalysis Letters, 1999, 63(3/4):227-231.

doi: 10.1023/A:1019037609388 |

| [42] | 王俊强. Ce改性Cu-SSZ-13分子筛上NH3选择性催化还原NO的性能与机理研究[D]. 太原: 太原理工大学, 2018. |

| [43] | 周愉千, 刘超, 宋鹏, 等. CeOx/AC催化剂NH3选择性催化还原NO[J]. 环境工程学报, 2012, 6(8):2720-2724. |

| [44] | 沈伯雄, 史展亮, 郭宾彬, 等. CeO2/ACFN和MnOx/ACFN低温选择性催化还原NO研究[J]. 洁净煤技术, 2007, 13(1):32-35,27. |

| [45] | 韦正乐, 黄碧纯, 黄华存, 等. CeO2/ACFN低温选择性催化还原烟气中的NO[J]. 化工进展, 2008, 27(3):412-416. |

| [46] |

Guo R T, Zhou Y, Pan W G, et al. Effect of preparation methods on the performance of CeO2/Al2O3 catalysts for selective catalytic re-duction of NO with NH3[J]. Journal of Industrial and Engineering Chemistry, 2013, 19(6):2022-2025.

doi: 10.1016/j.jiec.2013.03.010 |

| [47] | 陈凯歌, 陈若愚, 唐喆, 等. 低温等离子改性对Ce/TiO2-Al2O3 脱硝性能的影响[J]. 硅酸盐通报, 2017, 36(10):3466-3474. |

| [48] |

Liu C X, Chen L, Li J H, et al. Enhancement of activity and sulfur resistance of CeO2 supported on TiO2-SiO2 for the selective cataly-tic reduction of NO by NH3[J]. Environmental science & technology, 2012, 46:6182-6189.

doi: 10.1021/es3001773 |

| [49] | Zhang L, Li L L, Cao Y, et al. Promotional effect of doping SnO2 into TiO2 over a CeO2/TiO2 catalyst for selective catalytic reduction of NO by NH3[J]. Catalysis Science & Technology, 2015, 5:2188-2196. |

| [1] | ZHOU Qinglie, WANG Baoqi, ZHANG Zhiye, ZHANG Yinghu, WANG Jian, YANG Lin. Development of new process of removing metal cations from wet-process phosphoric acid by extraction [J]. Inorganic Chemicals Industry, 2023, 55(3): 84-91. |

| [2] | LI Huifang, WANG Xiao, BAI Youpeng, ZHANG Shixiang. Study on extraction of lithium from low grade high clay leaching solution by solvent extraction [J]. Inorganic Chemicals Industry, 2023, 55(10): 63-69. |

| [3] | JIN Fenli,ZHA Zhengjiong,WANG Yongcheng,ZHOU Huan. Separation characteristics of nitric acid type tin stripping waste solution and distillation enhanced recovery of meta stannic acid [J]. Inorganic Chemicals Industry, 2022, 54(8): 101-106. |

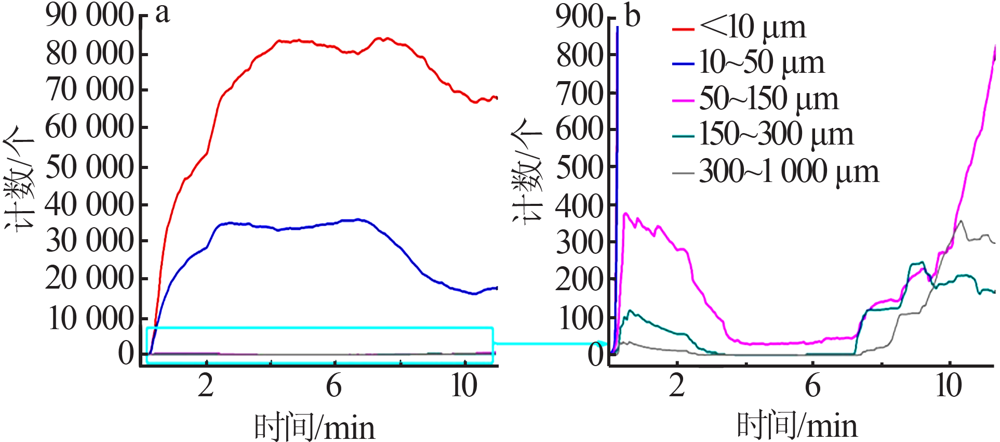

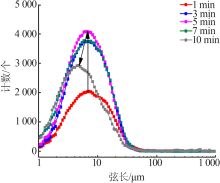

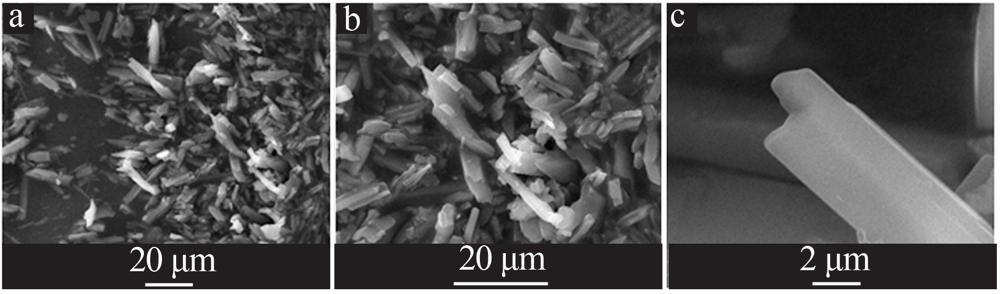

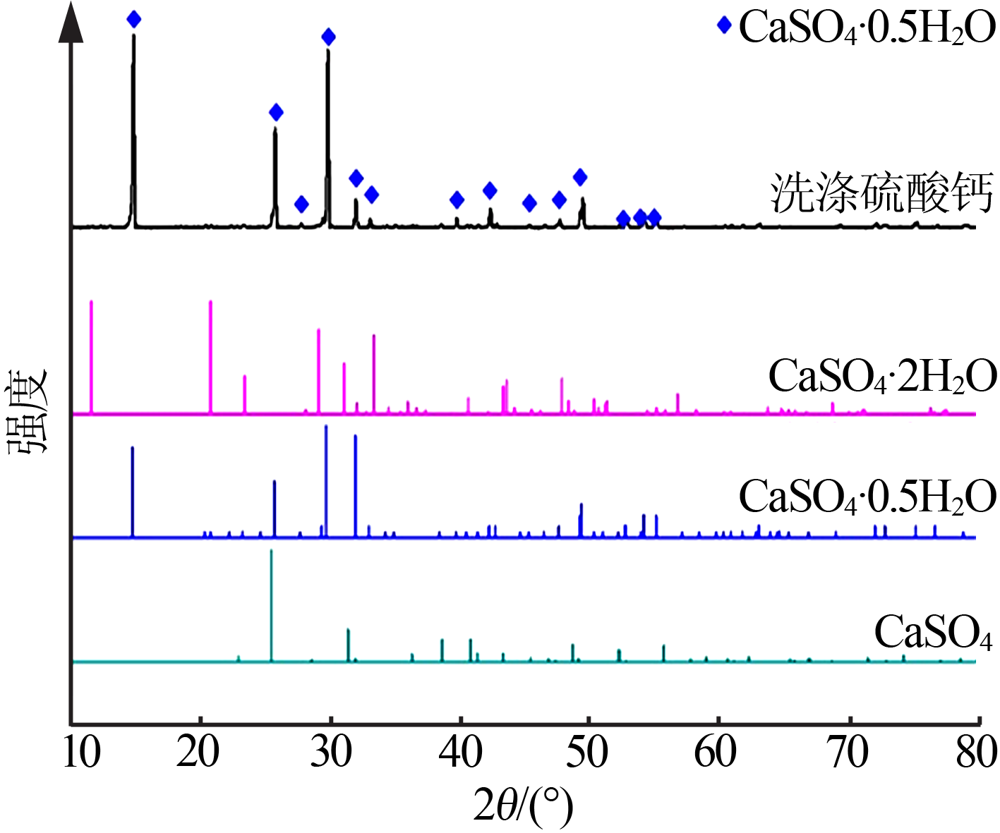

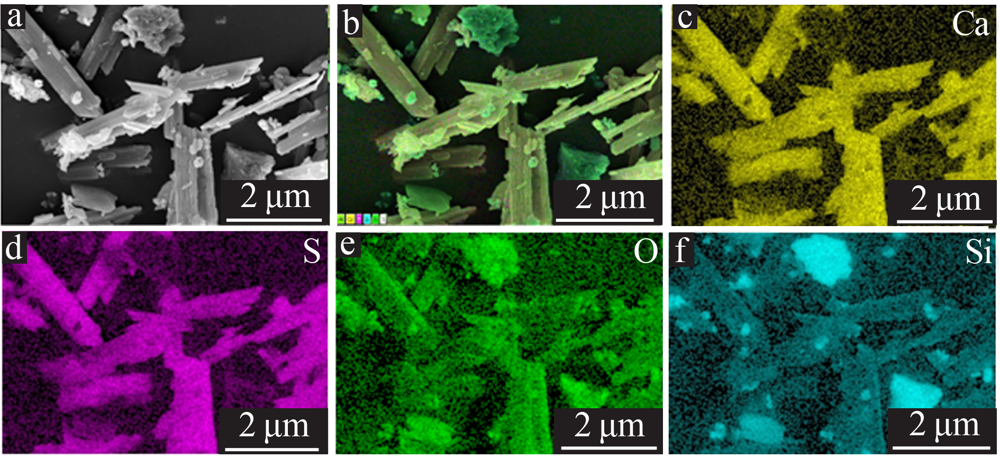

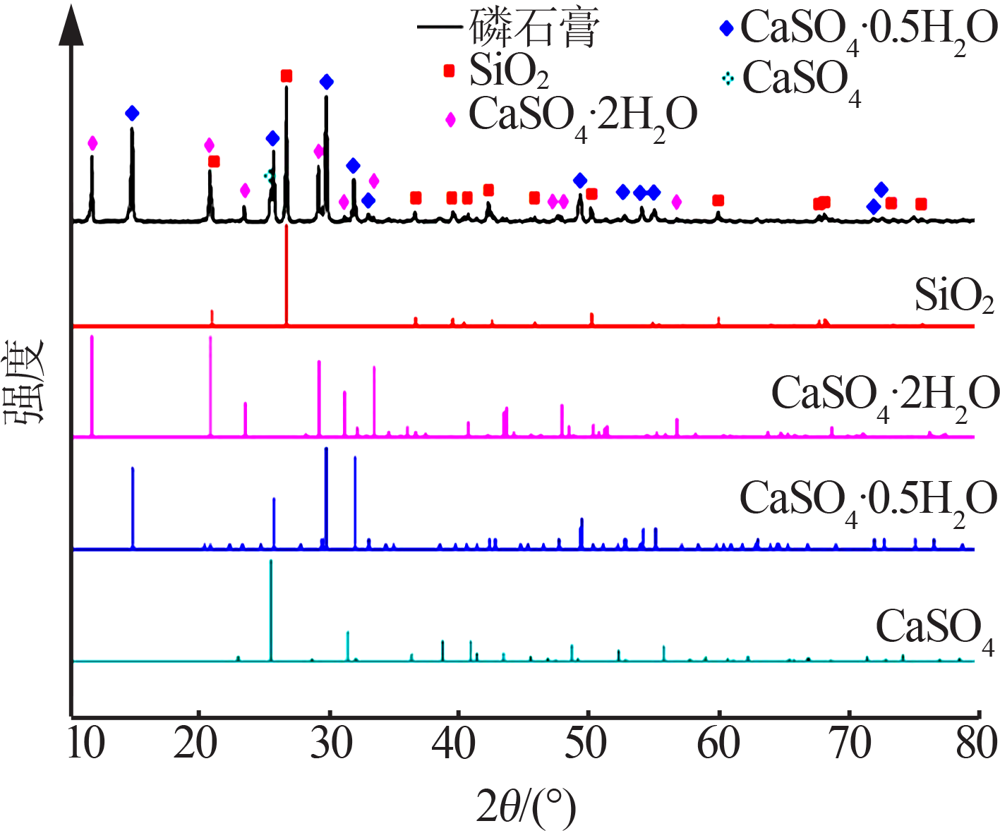

| [4] | HE Lei,ZHU Ganyu,ZHENG Guangming,WU Wenfen,ZhANG Jianbo,LI Fang,LI Huiquan,CHEN Wen. Study on crystallization process and mechanism of phosphogypsum in wet process phosphoric acid system [J]. Inorganic Chemicals Industry, 2022, 54(7): 110-116. |

| [5] | KANG Jin,WEI Lina,CHENG Huaigang. Research progress on application of ionic liquids in extracting lithium from salt lakes [J]. Inorganic Chemicals Industry, 2022, 54(1): 1-6. |

| [6] | PAN Baicheng,SUN Ze,MA Zhen,ZHANG Haijun,DONG Changji,SONG Xingfu. Study on hydraulics of pulsed extraction separation device for nitric acid/hydrochloric acid in chloride salt system [J]. Inorganic Chemicals Industry, 2022, 54(1): 91-95. |

| [7] | Su Shu,Xu Dehua,Li Chaorong,Yang Xiushan,Wang Xinlong,Zhang Zhiye. Study on defluorination of phosphoric acid by nitric acid process [J]. Inorganic Chemicals Industry, 2021, 53(9): 24-29. |

| [8] | Wei Lina,Kang Jin,Li Hu,Li Enze,Cheng Huaigang,Cheng Fangqin. Research progress of lithium extractants and extraction systems from salt lakes [J]. Inorganic Chemicals Industry, 2021, 53(5): 21-25. |

| [9] | ZHAO Yuanfang,GAO Youfei,DU Zhaoxin. Experimental research on purification of wet process phosphoric acid by methyl isobutyl ketone in rotating disc column [J]. Inorganic Chemicals Industry, 2021, 53(12): 105-108. |

| [10] | Su Lei,Zhang Haijun,Wang Jin,Yu Xuefeng,Dong Changji,Sun Ze,Song Xingfu,Yu Jianguo. Study on preparation of molten salt grade potassium nitrate by reactive extraction method [J]. Inorganic Chemicals Industry, 2020, 52(5): 35-39. |

| [11] | Liao Xiaoting,Li Jun,Chen Ming. Process study on preparation of industrial grade ammonium dihydrogen phosphate from urea phosphate mother liquor [J]. Inorganic Chemicals Industry, 2020, 52(4): 79-83. |

| [12] | Qin Yaru,Shi Chenglong,Wang Xingquan,Song Guixiu,Li Hongxia,Zhang Jingjing. Study on scrubbing process of lithium extraction from brine in ionic liquid system [J]. Inorganic Chemicals Industry, 2020, 52(3): 55-58. |

| [13] | Zhang Yongxing,Ma Yameng,Zhang Lizhen,Zhang Xiufeng,Tan Xiumin. Experimental research on extracting lithium from concentrated salt lake brine [J]. Inorganic Chemicals Industry, 2019, 51(3): 38-40. |

| [14] | Yang Nan,Li Jun. Extraction of sulfate ion from wet process phosphoric acid by amine extractants [J]. Inorganic Chemicals Industry, 2019, 51(3): 41-44. |

| [15] | Zhou Xiumei,Sun Guixing. Optimization technology for stable operation of ammonium chloride crystal system in potassium dihydrogen phosphate production plant [J]. Inorganic Chemicals Industry, 2019, 51(12): 58-60. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||