| [1] |

LI Shuai, LI Tianxiang, ZHU Jing, LIU Songlin.

Study on purification process of sodium fluoride

[J]. Inorganic Chemicals Industry, 2024, 56(9): 90-97.

|

| [2] |

YANG Hanshuo, WANG Dexi, YU Honglei, YANG Yali, JIANG Jiuchuang.

Experimental study on hydrodynamic cavitation⁃enhanced carbothermic reduction process for production of magnesium carbonate hydromagnesite

[J]. Inorganic Chemicals Industry, 2024, 56(7): 74-79.

|

| [3] |

LI Yongxiang, YANG Xiaolong, LU Zhonghai, MA Hang, WAN Banglong, LI Yundong.

Research progress of flame retardant application of ammonium poly-phosphate

[J]. Inorganic Chemicals Industry, 2024, 56(5): 20-30.

|

| [4] |

YANG Yousheng, YAO Zhihao, ZHAO Zhixing, FENG Xia, ZENG Ying, YU Xudong.

Research progress of lithium-rich sulfate type salt lake brine evaporation experiment

[J]. Inorganic Chemicals Industry, 2024, 56(4): 1-7.

|

| [5] |

LI Zhiwei, FU Zhenhai, ZHANG Zhihong, LI Shengting.

Prediction model of brine evaporation rate based on back-propagation neural network

[J]. Inorganic Chemicals Industry, 2024, 56(1): 53-58.

|

| [6] |

WANG Jiming, NIE Zhen, FAN Fu, GUO Tingfeng, HAN Jiahuan.

Study on potassium and lithium resource loss in brine of West Taijinar Salt Lake and simulated evaporation process

[J]. Inorganic Chemicals Industry, 2023, 55(5): 31-38.

|

| [7] |

WANG Lijuan, YAN Kezhou, GUO Zhiqiang, ZHAO Zhonghe, GUO Yanxia, CHENG Fangqin.

Preparation of poly-aluminum chloride from acid leaching liquor of red mud-coal gangue activated by sodium salt

[J]. Inorganic Chemicals Industry, 2023, 55(4): 76-83.

|

| [8] |

LI Yunfei, LIU Shuqing, TANG Shengwei, ZHANG Tao.

Preparation of α-hemihydrate gypsum in Mg-Na mixed salt solution system under atmospheric pressure

[J]. Inorganic Chemicals Industry, 2023, 55(11): 100-106.

|

| [9] |

LI Sen, WANG Jin, WANG Yingying, CAI Mingfang.

Synthesis and modification of NaA zeolite and its application in polyurethane system

[J]. Inorganic Chemicals Industry, 2023, 55(10): 78-85.

|

| [10] |

LIANG Hai,YUAN Tianlong,WANG Wanting,YANG Yunhong,LIANG Wenjie,WANG Xiaomin,DENG Xinzhong.

Synthesis of micron?tubular?magnesium oxide clusters and its adsorption performance for phosphate

[J]. Inorganic Chemicals Industry, 2022, 54(9): 77-84.

|

| [11] |

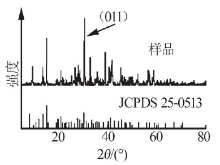

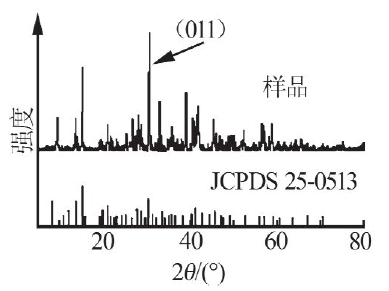

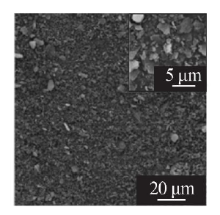

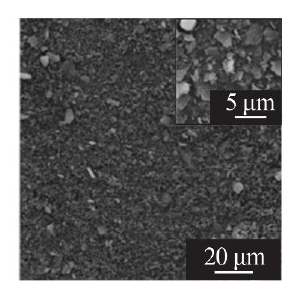

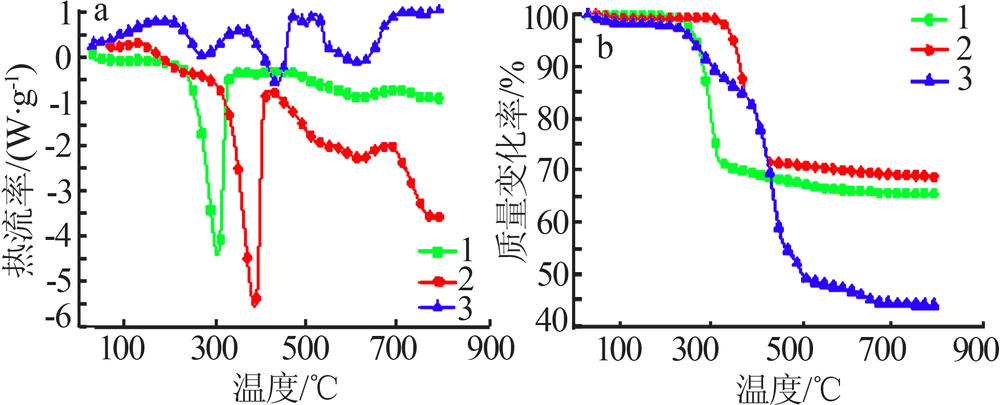

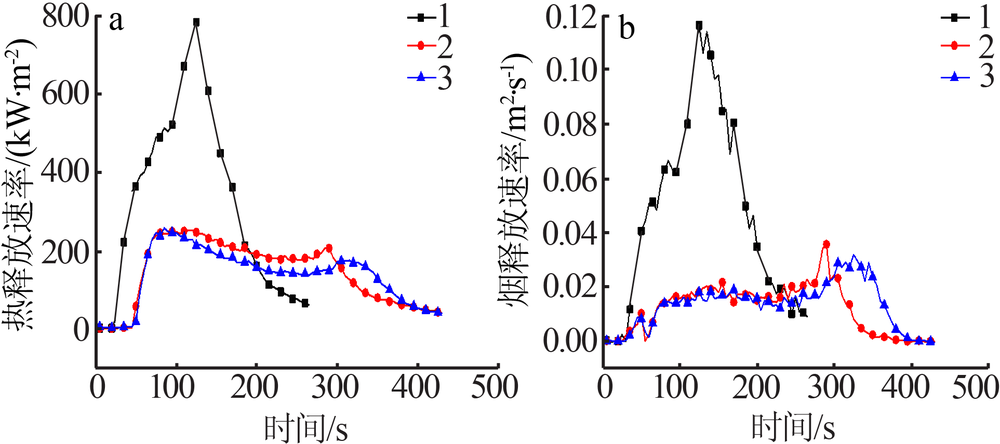

PANG Hongchang,WANG Zhiyu,TIAN Peng,NING Guiling.

Study on synthesis and properties of two component magnesium based flame retardant by“one?pot method”

[J]. Inorganic Chemicals Industry, 2022, 54(8): 54-58.

|

| [12] |

ZHANG Yu,QI Xiaoyu,FENG Mengyao,SUN Nannan,ZHAO Cuilian.

Study on permeability of mesoporous silica antireflective film regulated by conductivity

[J]. Inorganic Chemicals Industry, 2022, 54(8): 80-84.

|

| [13] |

WANG Zhiyuan,DOU Zewei,XIONG Lijia,FAN Tianbo,LIU Yunyi,GUO Hongfan.

Principle and application of ammonium(ammonia) circulation process

[J]. Inorganic Chemicals Industry, 2022, 54(8): 47-53.

|

| [14] |

XU Qingying,YANG Dingyi,LÜ Wei,LI Xiang,QIAN Yunfeng,DU Baocong.

Effect of grinding time on properties of phosphogypsum based cementitious materials

[J]. Inorganic Chemicals Industry, 2022, 54(5): 101-108.

|

| [15] |

SU Jianjun,ZENG Ying,LI Longgang,QIN Jiazheng,YU Mingxiang,LIU He.

Study on isothermal evaporation of potassium?extracted old brine and frozen brine in West Taijinar Salt Lake at 25 ℃

[J]. Inorganic Chemicals Industry, 2022, 54(5): 84-89.

|

),Ning Guiling

),Ning Guiling