| [1] |

REN Teng, LI Shengdong, WANG Dexi, CHU Fuzhou, SHAO Lixin.

Numerical simulation analysis of influence of jet position on mixing effect of carbonization reactor

[J]. Inorganic Chemicals Industry, 2023, 55(7): 109-114.

|

| [2] |

LU Dachuan, GU Weihua, ZHAO Jing, ZHUANG Xuning, DONG Bin, BAI Jianfeng.

Research progress of influencing factors of pyrolysis of municipal sludge and residue recycling

[J]. Inorganic Chemicals Industry, 2023, 55(5): 8-15.

|

| [3] |

ZHANG Sen,WAN Jun,CHEN Tianhu,DONG Shiwei,XU Liang,LI Yaqian,ZHAO Yueling.

Research on heat treatment of NaCl-KCl waste salt in pesticide industry

[J]. Inorganic Chemicals Industry, 2023, 55(2): 106-112.

|

| [4] |

ZHANG Xing,XU Jie,WANG Zibing,HOU Peng,HE Long,LIU Huan.

Effect of feedstock particle size on kinetics of limestone thermal decomposition reaction

[J]. Inorganic Chemicals Industry, 2023, 55(2): 79-84.

|

| [5] |

YANG Wenbo,WU Pan,HE Jian,LIU Changjun,JIANG Wei.

Study on effect of heating rate on structure-activity of g-C3N4 photocatalyst by pyrolysis of urea

[J]. Inorganic Chemicals Industry, 2022, 54(4): 169-174.

|

| [6] |

SHEN Jiaqi,YAN Shenghu,ZHANG Yue,LIU Jianwu,SHEN Jiefa.

Study on intensification of gas-liquid reaction process for sodium chloride waste salt to ammonium alkali

[J]. Inorganic Chemicals Industry, 2022, 54(12): 99-105.

|

| [7] |

TIAN Yijuan,YAN Chaoqun,CHENG Zhiliang,QUAN Xuejun,LI Gang.

Detoxification of Cr(Ⅵ) from chromite ore processing residue by pyrolysis with citrus peel

[J]. Inorganic Chemicals Industry, 2021, 53(12): 129-134.

|

| [8] |

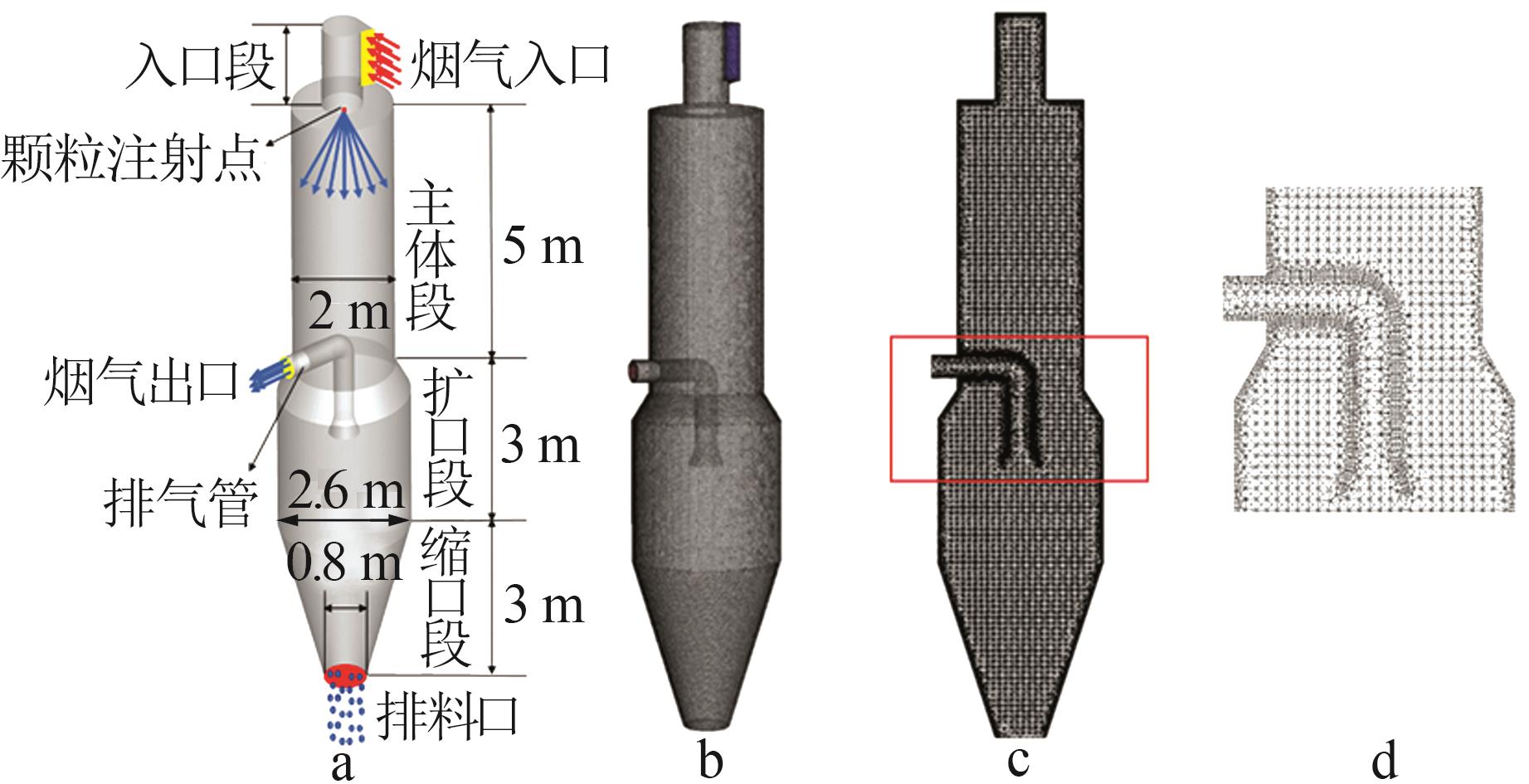

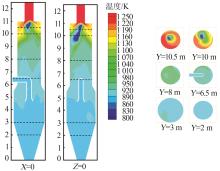

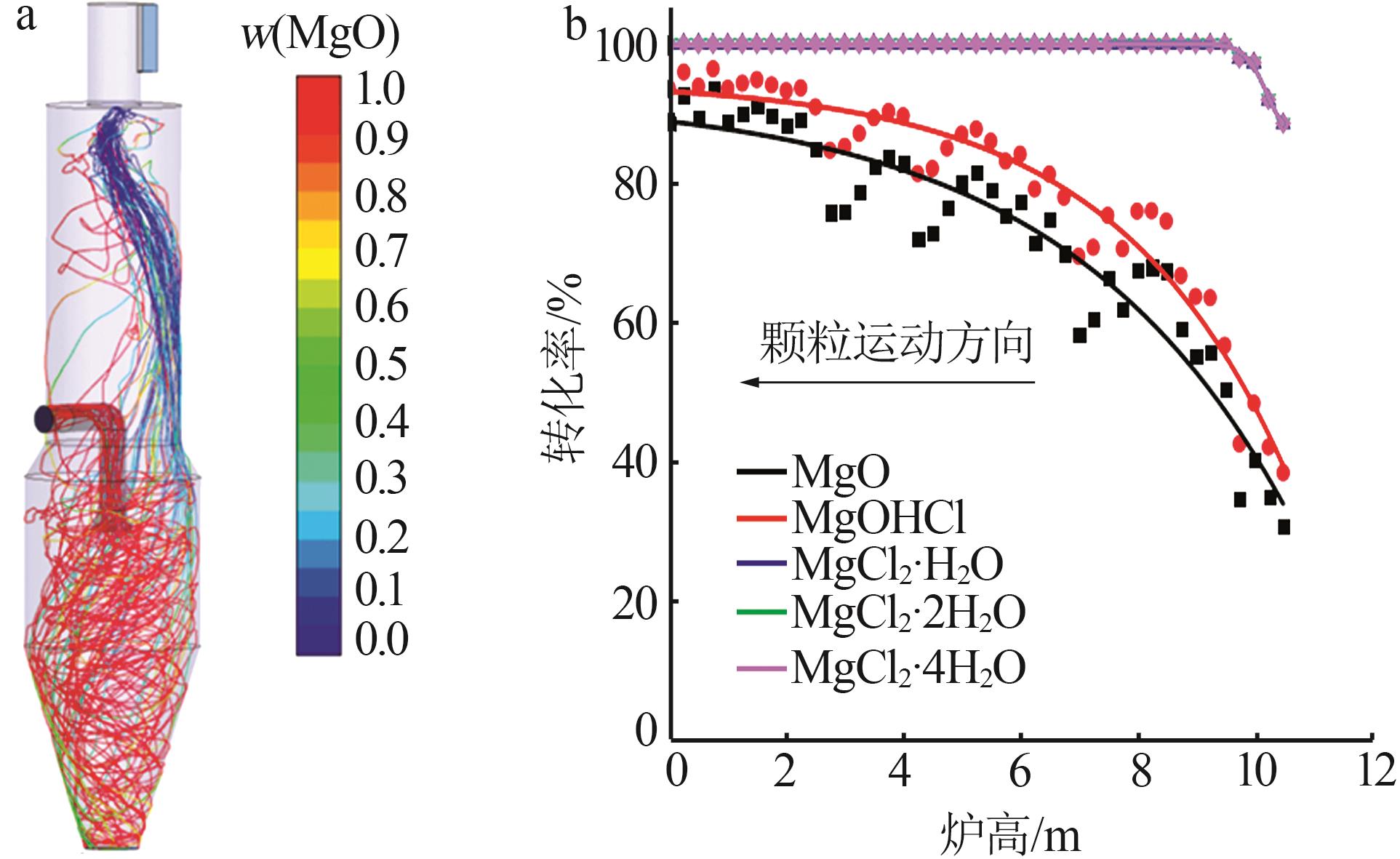

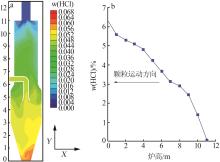

CHEN Xue,ZHANG Menghui,ZHAO Liang,DONG Hui,WANG Dexi.

Study on pyrolysis process of Mg(NO3)2·nH2O

[J]. Inorganic Chemicals Industry, 2021, 53(12): 91-94.

|

| [9] |

Zhang Yan,Zhao Zhenzhong,Ma Zhaohui,Zhao Yancai,Chen Zhiyu,Ma Zhengqiang.

Optimization of process for preparation of battery grade lithium carbonate by carbonization

[J]. Inorganic Chemicals Industry, 2020, 52(3): 68-71.

|

| [10] |

Zhu Guihua,He Weize,Tang Haoting,Yi Shanzhen,Chen Yong.

Simulation and improvement of flow field in side-entry wind salt mud drying room

[J]. Inorganic Chemicals Industry, 2020, 52(12): 80-85.

|

| [11] |

Feng Junli,Yang Junfan,Wu Jingwu,Li Xu,Zhang Qingjian.

Determination of mercury in crude zinc oxide by DMA-80 mercury analyzer

[J]. Inorganic Chemicals Industry, 2019, 51(8): 73-75.

|

| [12] |

DU Yong-Sheng, SUN Qing-Guo, HUO Yan, HAN Ji-Long, LI Ming-Zhen.

Study on preparation of magnesium oxide by

spray pyrolysis of magnesium chloride

[J]. INORGANICCHEMICALSINDUSTRY, 2013, 45(4): 13-.

|

| [13] |

YU He-Hua.

Research on influencing factors of preparation of silicon tetrafluoride

gas by pyrolysis from sodium fluosilicate

[J]. INORGANICCHEMICALSINDUSTRY, 2013, 45(4): 46-.

|

| [14] |

ZHANG Xiao-Gang, ZHANG Jin, TANG Ying, LIU Dai-Jun, LI Bin, RONG Chou.

Experiment research on pyrolysis of witherite in production of barium hydroxide

[J]. INORGANICCHEMICALSINDUSTRY, 2012, 44(7): 19-.

|

| [15] |

LI Jing-Guan, ZHANG Lin-Jin, CHEN Chuan-Hui, YE Xu-Chu.

Numerical simulation of oxygen volume fraction in chromite roasting process

[J]. INORGANICCHEMICALSINDUSTRY, 2012, 44(2): 33-.

|

), ZHAO Liang1, ZHANG Menghui1, XU Hanlu1, DONG Hui1,2(

), ZHAO Liang1, ZHANG Menghui1, XU Hanlu1, DONG Hui1,2( )

)