Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (11): 139-146.doi: 10.19964/j.issn.1006-4990.2023-0101

• Environment·Health·Safety • Previous Articles Next Articles

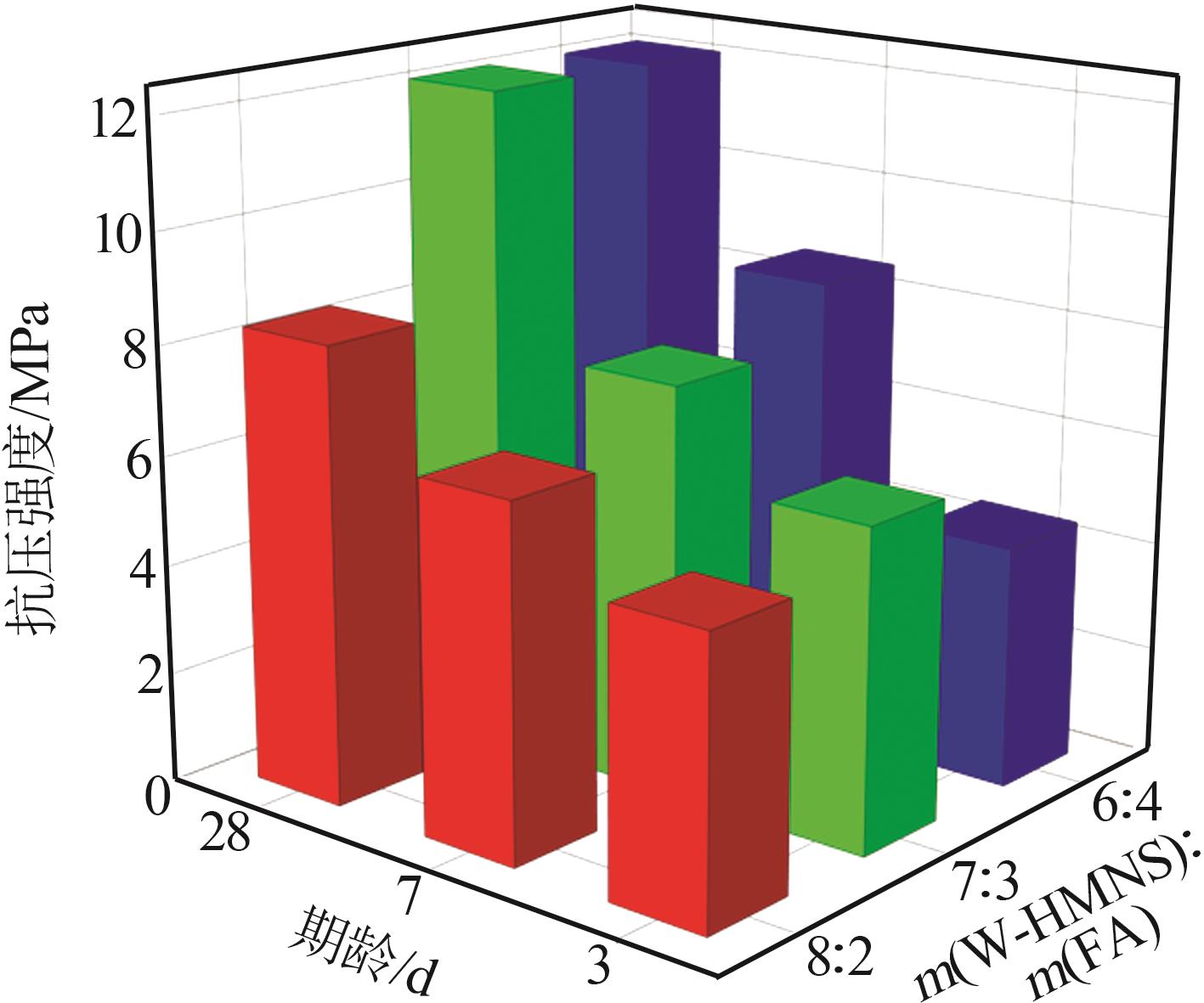

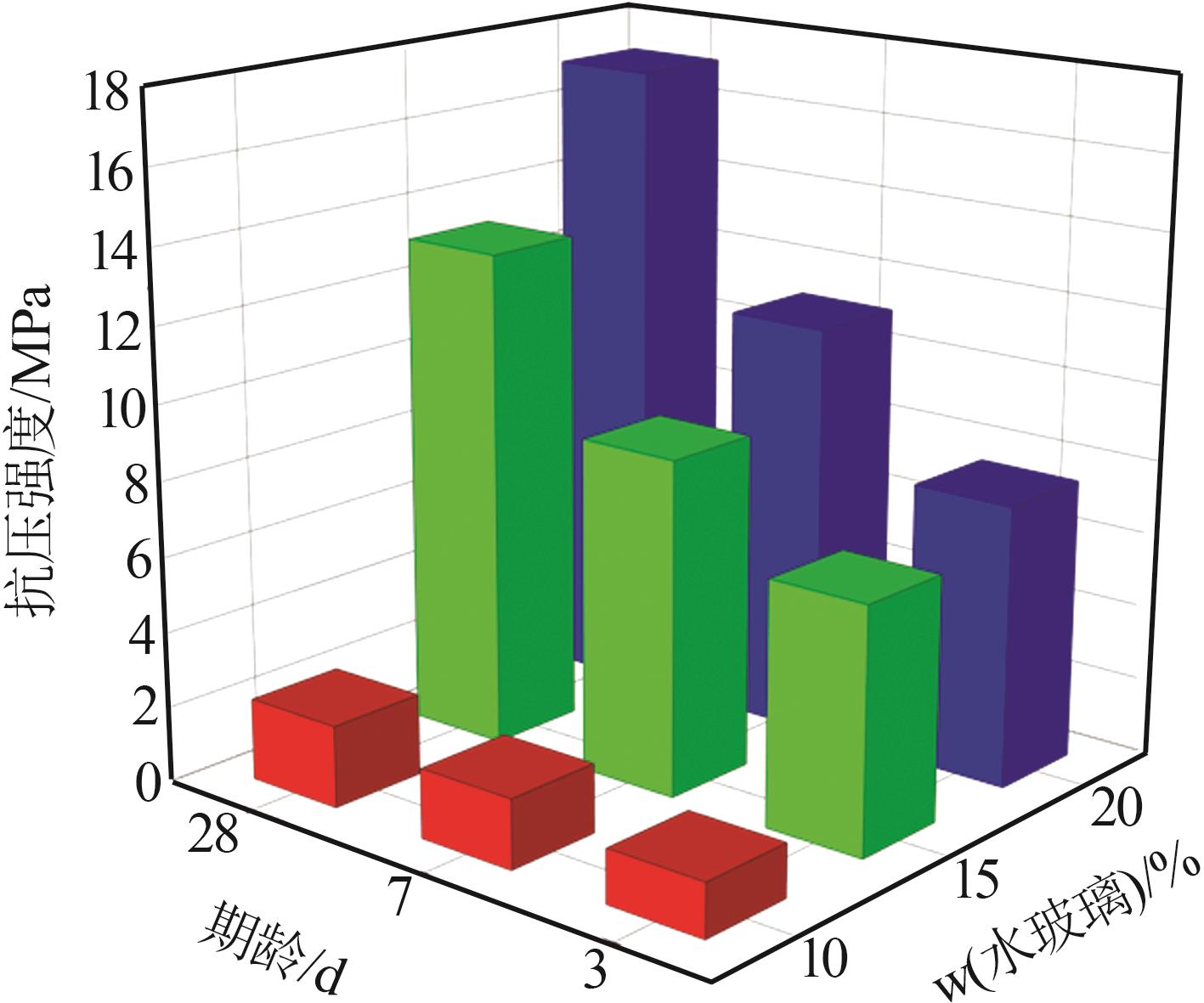

Preparation and properties of high-magnesium nickel slag-fly ash based geopolymer

SUN Zhigao( ), WU Yuan, YANG Xingchun, ZHANG Dongliang, WANG Mitang(

), WU Yuan, YANG Xingchun, ZHANG Dongliang, WANG Mitang( )

)

- School of Materials and Chemistry,University of Shanghai for Science and Technology,Shanghai 200093,China

-

Received:2023-02-28Online:2023-11-10Published:2023-11-16 -

Contact:WANG Mitang E-mail:sunzhigao0@163.com;btwmt@126.com

CLC Number:

Cite this article

SUN Zhigao, WU Yuan, YANG Xingchun, ZHANG Dongliang, WANG Mitang. Preparation and properties of high-magnesium nickel slag-fly ash based geopolymer[J]. Inorganic Chemicals Industry, 2023, 55(11): 139-146.

share this article

| 1 | MARAGKOS I, GIANNOPOULOU I P, PANIAS D.Synthesis of ferronickel slag-based geopolymers[J].Minerals Engineering,2009,22(2):196-203. |

| 2 | WU Qisheng, WANG Shunxiang, YANG Tao,et al.Effect of high-ment[J].Journal of Materials in Civil Engineering,2019,31(5):04019051. |

| 3 | WANG Dengquan, WANG Qiang, ZHUANG Shiyu,et al.Evaluation of alkali-activated blast furnace ferronickel slag as a cementitious material:Reaction mechanism,engineering properties and leaching behaviors[J].Construction and Building Materials,2018,188:860-873. |

| 4 | SUJIONO E H, SETIAWAN A, HUSAIN H,et al.The influence of nickel slag aggregate concentration to compressive and flexural strength on fly ash-based geopolymer composite[C]//International Conference on Advanced Materials Science & Technology. AIP Publishing LLC,2016. |

| 5 | RAHMAN M A, SARKER P K, SHAIKH F U A,et al.Soundness and compressive strength of Portland cement blended with ground granulated ferronickel slag[J].Construction and Building Materials,2017,140:194-202. |

| 6 | HUA Sudong, ZHANG Lili, ZHANG Jian,et al.Study on physical and chemical properties of high magnesium nickel slag-phosphogysum composite cementitious materials in different particle sizes[J].Journal of Advanced Concrete Technology,2020,18(3):129-138. |

| 7 | YANG Tao, ZHANG Zuhua, ZHU Huajun,et al.Re-examining the suitability of high magnesium nickel slag as precursors for alkali-activated materials[J].Construction and Building Materials,2019,213:109-120. |

| 8 | HUANG Yiduo, WANG Qiang, SHI Mengxiao.Characteristics and reactivity of ferronickel slag powder[J].Construction and Building Materials,2017,156:773-789. |

| 9 | CHOI Y C, CHOI S.Alkali-silica reactivity of cementitious materials using ferro-nickel slag fine aggregates produced in different cooling conditions[J].Construction and Building Materials,2015,99:279-287. |

| 10 | SCHÖLER A, WINNEFELD F, HAHA M BEN,et al.The effect of glass composition on the reactivity of synthetic glasses[J].Journal of the American Ceramic Society,2017,100(6):2553-2567. |

| 11 | WANG Mitang, FENG Chunfu, LIU Yun,et al.Enhancement of pozzolanic activity of high-magnesium nickel slag via phase separation by adding CaO[J].Materials Today Communications,2023,34:105427. |

| 12 | MYSEN B O, VIRGO D, SEIFERT F A.The structure of silicate melts:Implications for chemical and physical properties of natural magma[J].Reviews of Geophysics,1982,20(3):353-383. |

| 13 | 盛广宏,翟建平.镍工业冶金渣的资源化[J].金属矿山,2005(10):68-71. |

| SHENG Guanghong, ZHAI Jianping.Making metallurgical slag from nickel industry a resource[J].Metal Mine,2005(10):68-71. | |

| 14 | LUO Zhongqiu, MA Yue, MU Weihong,et al.Magnesium phosphate cement prepared with electric furnace ferronickel slag:Properties and its hydration mechanism[J].Construction and Building Materials,2021,300:123991. |

| 15 | LI Jincheng, SUN Zhigao, WANG Lei,et al.Properties and mechanism of high-magnesium nickel slag-fly ash based geopolymer activated by phosphoric acid[J].Construction and Building Materials,2022,345:128256. |

| 16 | 刘洋,吴锦绣,封春甫,等.富镁镍渣-粉煤灰基地质聚合物的制备与性能表征[J].硅酸盐通报,2021,40(3):921-928. |

| LIU Yang, WU Jinxiu, FENG Chunfu,et al.Preparation and performance characterization of magnesium-rich nickel slag-fly ash-based geopolymer[J].Bulletin of the Chinese Ceramic Society,2021,40(3):921-928. | |

| 17 | WINNEFELD F, HAHA M BEN, LE SAOUT G,et al.Influence of slag composition on the hydration of alkali-activated slags[J].Journal of Sustainable Cement-Based Materials,2015,4(2):85-100. |

| 18 | DUXSON P, FERNÁNDEZ-JIMÉNEZ A, PROVIS J L,et al.Geopolymer technology:The current state of the art[J].Journal of Materials Science,2007,42(9):2917-2933. |

| 19 | PROVIS J L, LUKEY G C, VAN DEVENTER J S J.Do geopolymers actually contain nanocrystalline zeolites?A reexamination of existing results[J].Chemistry of Materials,2005,17(12):3075-3085. |

| 20 | XU Lingling, DENG Min.Dolomite used as raw material to produce MgO-based expansive agent[J].Cement and Concrete Research,2005,35(8):1480-1485. |

| 21 | AGUIAR H, SERRA J, GONZÁLEZ P,et al.Structural study of sol-gel silicate glasses by IR and Raman spectroscopies[J].Journal of Non-Crystalline Solids,2009,355(8):475-480. |

| 22 | LEE W K W, VAN DEVENTER J S J.Use of infrared spectroscopy to study geopolymerization of heterogeneous amorphous aluminosilicates[J].Langmuir,2003,19(21):8726-8734. |

| 23 | ZHANG Zuhua, WANG Hao, PROVIS J L.Quantitative study of the reactivity of fly ash in geopolymerization by FTIR[J].Journal of Sustainable Cement-Based Materials,2012,1(4):154-166. |

| 24 | ZHANG Z, ZHU Yingcan, YANG Tao,et al.Conversion of local industrial wastes into greener cement through geopolymer technology:A case study of high-magnesium nickel slag[J].Journal of Cleaner Production,2017,141:463-471. |

| 25 | ISHIDA K, JENKINS D M, HAWTHORNE F C.Mid-IR bands of synthetic calcic amphiboles of tremolite-pargasite series and of natural calcic amphiboles[J].American Mineralogist,2008,93(7):1112-1118. |

| 26 | WANG Mitang, LIU Yun, FENG Chunfu,et al.Pozzolanic activity enhancement of magnesium-rich nickel slag and geopolymer preparation[J].Journal of Material Cycles and Waste Management,2022,24(6):2598-2607. |

| 27 | MIHAILOVA I, RADEV L, ALEKSANDROVA V,et al.Carbonate-apatite forming ability of polyphase glass-ceramics in the CaO-MgO-SiO2 system[J].Journal of Chemical Technology & Metallurgy,2015,50(4):502-511. |

| 28 | BOUAISSI A, LI Longyuan, BAKRI ABDULLAH M M AL,et al.Mechanical properties and microstructure analysis of FA-GGBS-HMNS based geopolymer concrete[J].Construction and Building Materials,2019,210:198-209. |

| 29 | MO Liwu, LV Liming, DENG Min,et al.Influence of fly ash and metakaolin on the microstructure and compressive strength of magnesium potassium phosphate cement paste[J].Cement and Concrete Research,2018,111:116-129. |

| 30 | KIM M S, Yubin JUN, LEE Changha,et al.Use of CaO as an activator for producing a price-competitive non-cement structural binder using ground granulated blast furnace slag[J].Cement and Concrete Research,2013,54:208-214. |

| [1] | ZHAO Feiyan, ZHANG Xiaodong, DU Yanxia, WANG Qiang, LI Xiaoyan. Preparation technology and research progress of fly ash ceramsite [J]. Inorganic Chemicals Industry, 2024, 56(4): 16-23. |

| [2] | LI Kuai, LI Zhaoshuai, DONG Tingxuan, LI Dan, GUO Shengwei, HAN Fenglan. Study on effect of wet magnetic separation on distribution of Fe and heavy metal in fly ash [J]. Inorganic Chemicals Industry, 2024, 56(4): 98-104. |

| [3] | LI Qiaoyun, HUANG Xiuxing, WEI Wenye, CHEN Zhen. Study on adsorption of methylene blue by activated carbon with acid/alkali synergistically modified fly ash [J]. Inorganic Chemicals Industry, 2024, 56(3): 131-136. |

| [4] | LI Wen, WANG Wenxiang, FANG Hongsheng, WU Pingxiao. Study on effect mechanism of silicon-aluminum additives on stabilization of heavy metals in fly ash by mechanochemical stabilization method [J]. Inorganic Chemicals Industry, 2023, 55(4): 84-91. |

| [5] | YANG Hongjun, WANG Min, GE Haiwen, QIAO Youmin, QIAO Ziyang. Study on recycling process of potassium from calcium aluminate fly ash [J]. Inorganic Chemicals Industry, 2023, 55(10): 121-127. |

| [6] | HE Wenchao,XUE Jing,WANG Wei. Research on strength and creep characteristics of concrete containing fly ash microbead [J]. Inorganic Chemicals Industry, 2023, 55(1): 124-128. |

| [7] | LIU Darui,XU Lijun,LI Shichun,CAO Kun,TU Ya,LI Wenqing,LIU Qingliang. Research progress of recovery of strategic metal lithium from fly ash [J]. Inorganic Chemicals Industry, 2023, 55(1): 56-63. |

| [8] | LEI Ming,ZHU Hanyu,LIU Zilong,CHEN Guopeng,YUAN Junsheng. Distribution and speciation of heavy metals in hardened solid of net slurry co?disposed by cement kiln [J]. Inorganic Chemicals Industry, 2022, 54(8): 107-113. |

| [9] | CAI Zhuoyu,LIU Qing,BI Jiaqi,LIU Yushan,ZHENG Shaowei,ZHAO Guodong. Study on Pb2+ solidification and radiation protection performance of blast furnace slag?fly ash based geopolymer [J]. Inorganic Chemicals Industry, 2022, 54(8): 125-131. |

| [10] | CUI Jiaxin,WANG Lianyong,LU Simeng,SUN Yanwen,WANG Rui,HE Yan,HAN Jianli. Research on performance of hydrothermally synthesized zeolite with fly ash from different producing areas [J]. Inorganic Chemicals Industry, 2022, 54(5): 96-100. |

| [11] | CUI Jiaxin,WANG Lianyong,LI Yao,HE Yan,WANG Rui,HAN Jianli. Preparation and properties characterization of water quenching slag-fly ash based 4A zeolite [J]. Inorganic Chemicals Industry, 2022, 54(4): 135-140. |

| [12] | LI Yajiao,ZHAO Yiwei,JU Kai,TANG Renlong,LI Longqing,SHAO Xiaoping,ZHANG Gaofeng,REN Wuang. Study on optimization of extraction conditions in process of determination of ammonia content in fly ash based on response surface method [J]. Inorganic Chemicals Industry, 2022, 54(4): 145-151. |

| [13] | MA Yue,CHENG Yan. Effect of thermal treatment on structure and hydrophobicity of SiO2 aerogels derived from fly ash acid sludge [J]. Inorganic Chemicals Industry, 2022, 54(3): 109-112. |

| [14] | CHANG Wei,LIU Honghui,JIANG Xuguang. Study on dechlorination and heavy metal leaching characteristics of MSWI fly ash during water-washing [J]. Inorganic Chemicals Industry, 2022, 54(3): 113-118. |

| [15] | XUE Haiyue,WANG Lianyong,LIU Xiangyu,HAN Jianli,YANG Yifan. Analysis and prospect of using fly ash based zeolite for infrared suppression of tail flame of aircraft [J]. Inorganic Chemicals Industry, 2022, 54(3): 23-30. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||