| [1] |

QIAN Zhihui, ZHU Qin, MA Jiao, GUO Yujiao, XIANG Mingwu, GUO Junming.

Study on preparation and electrochemical properties of nano-sized LiNi0.05Mn1.95O4 cathode materials

[J]. Inorganic Chemicals Industry, 2024, 56(4): 50-56.

|

| [2] |

ZHANG Yu, ZHAO Zhichao, ZHAO Cuilian, SUN Nannan.

Study on effect of MTMS modification on weatherability of SiO2 anti-reflective coating

[J]. Inorganic Chemicals Industry, 2024, 56(3): 64-69.

|

| [3] |

CHEN Tiandong, ZHAO Guangzhao, HAI Chunxi, DONG Shengde, HE Xin, XU Qi, FENG Hang, YUAN Shaoxiong, MA Luxiang, ZHOU Yuan.

Research and industrialization progress on coating and doping modification of lithium-rich manganese-based materials

[J]. Inorganic Chemicals Industry, 2023, 55(9): 1-8.

|

| [4] |

PAN Xiaoxiao, ZHUANG Shuxin, SUN Yuqing, SUN Gaoxing, REN Yan, JIANG Shengyu.

Research progress of modified-LiFePO4 as cathode materials for lithium ion batteries

[J]. Inorganic Chemicals Industry, 2023, 55(6): 18-26.

|

| [5] |

ZHANG Lijie,SUN Yanmin,LI He,ZENG Xianjun,LIN Xiaodong,HUANG Guihong.

Research progress of catalyst coating process

[J]. Inorganic Chemicals Industry, 2023, 55(2): 19-25.

|

| [6] |

TIAN Yu, ZHANG Zheng, ZHANG Xingran, CHEN Jie, WANG Yan, PENG Hao.

Research progress of trivalent chromium electrodeposition process

[J]. Inorganic Chemicals Industry, 2023, 55(12): 26-35.

|

| [7] |

ZHOU Min.

Preparation of PANI/TIO composites and their application in polyurethane coatings

[J]. Inorganic Chemicals Industry, 2023, 55(1): 112-117.

|

| [8] |

XU Qianjin,XU Jingang,TIAN Peng,LIU Kunji,GAO Tingting,NING Guiling.

Research progress of alumina coated cathode materials for lithium-ion batteries

[J]. Inorganic Chemicals Industry, 2023, 55(1): 46-55.

|

| [9] |

TANG Jianping,WANG Guosheng.

Study on preparation technology and waterproof property of fused magnesia coating

[J]. Inorganic Chemicals Industry, 2022, 54(5): 90-95.

|

| [10] |

LI Fangkun,WANG Xinyi,XU Xijun,WU Yiwen,YANG Yan,LIU Jun.

Nanoconfined encapsulation of iron-germanium alloy anode and its lithium ion storage performance

[J]. Inorganic Chemicals Industry, 2022, 54(4): 88-93.

|

| [11] |

ZHOU Kai,PAN Guoxiang,LI Jinhua,XIA Shengjie,XU Minhong,SHEN Hui,KOSO Aoki.

Study on preparation and heat resistance of iron oxide yellow coated with double layer Al(OH)3@Zn(OH)2

[J]. Inorganic Chemicals Industry, 2022, 54(2): 50-53.

|

| [12] |

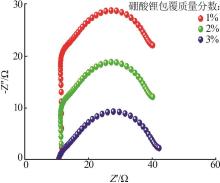

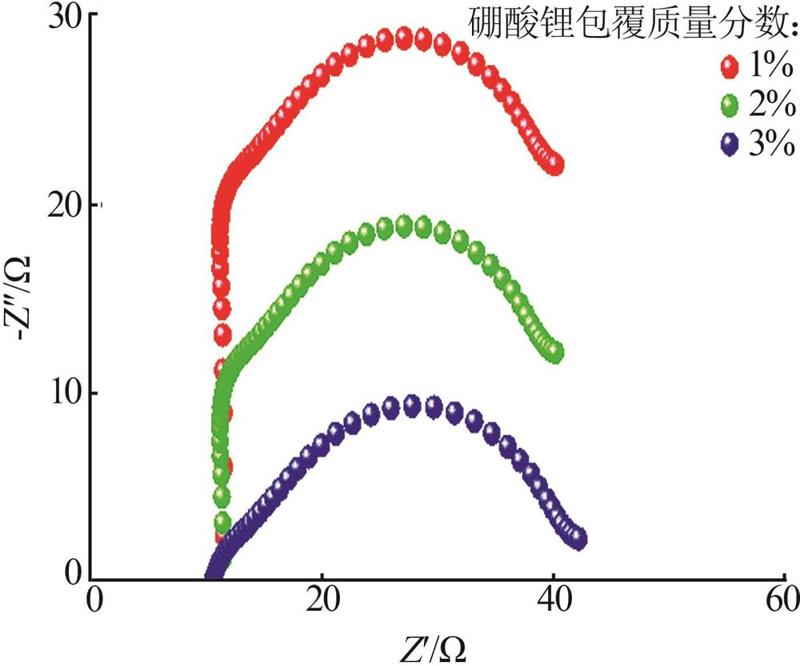

ZOU Changwu,SUN Jiu,FAN Weifeng,ZHANG Bin,WANG Zhengqiang,ZHANG Zheng.

Study on preparation and electrochemical properties of lithium nickel cobalt aluminate modified by boric acid spray coating

[J]. Inorganic Chemicals Industry, 2022, 54(1): 66-70.

|

| [13] |

Zhao Duan,Zhou Geng,Hou Shunli,Lan Ziwei,Zhang Jianru,Li Jian,Wang Jiatai.

Research progress of coating modification of high nickel ternary materials for lithium-ion batteries

[J]. Inorganic Chemicals Industry, 2021, 53(8): 1-7.

|

| [14] |

SUN Yaoyao,SONG Jiale,ZHENG Bin,LI Weiguang.

Research progress of graphene anticorrosive coating

[J]. Inorganic Chemicals Industry, 2021, 53(11): 30-35.

|

| [15] |

Liu Yang,Cai Zongying,Cao Weigang,Liu Yuzhao.

Research progress on lithium sodium titanate for lithium ion batteries

[J]. Inorganic Chemicals Industry, 2021, 53(10): 36-40.

|

),ZHOU Xiaochong2,MO Liangjun1

),ZHOU Xiaochong2,MO Liangjun1