Inorganic Chemicals Industry ›› 2022, Vol. 54 ›› Issue (5): 109-115.doi: 10.19964/j.issn.1006-4990.2021-0434

• Environment·Health·Safety • Previous Articles Next Articles

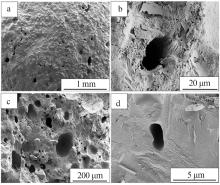

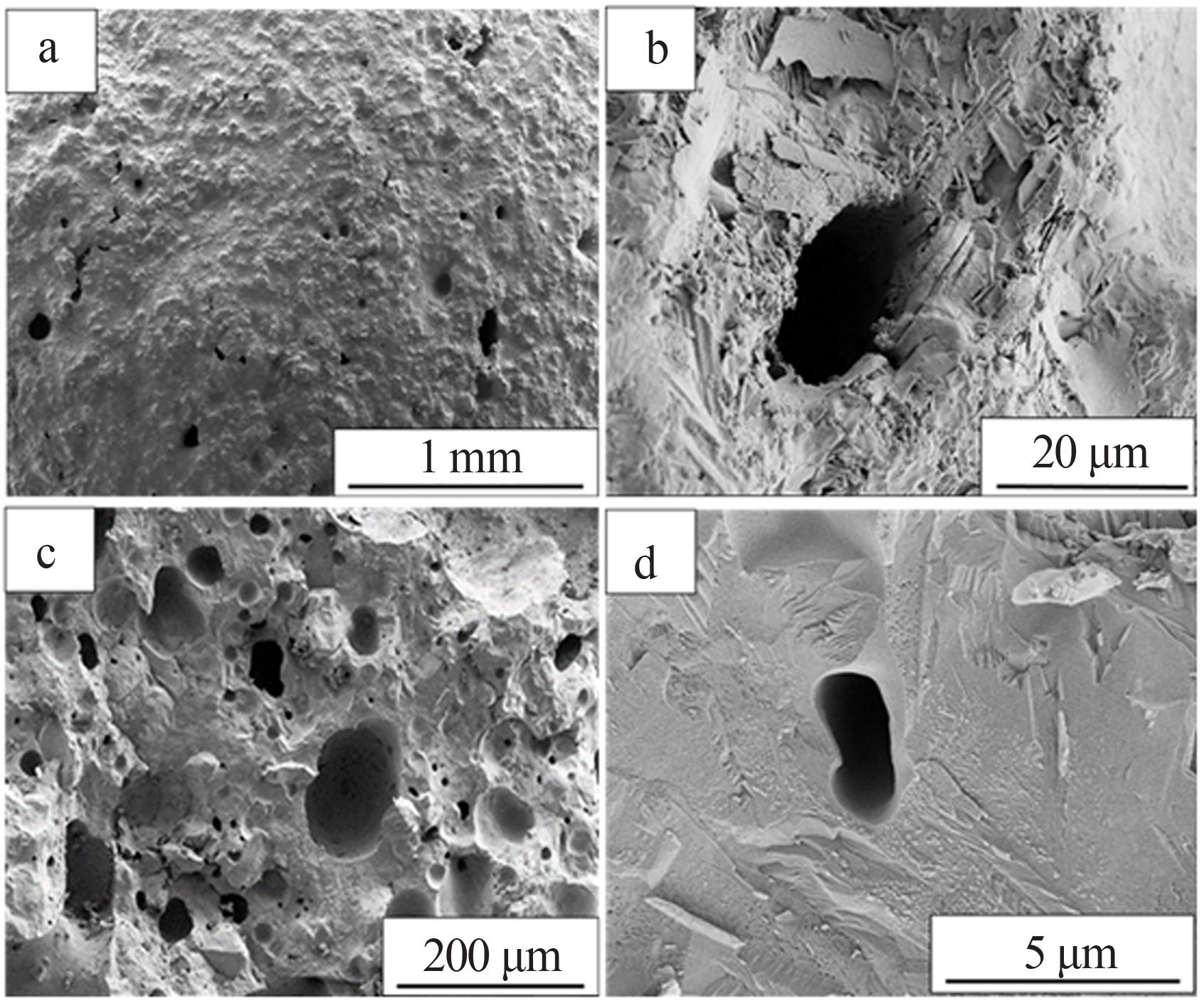

Study on preparation and performance of ceramsite from sediment in Yellow River desilting basin

YANG Liyan1( ),MA Xin2,MEI Ruifeng2,YANG Dashan1,LIANG Jialin1,LI Chunquan1,SUN Zhiming1(

),MA Xin2,MEI Ruifeng2,YANG Dashan1,LIANG Jialin1,LI Chunquan1,SUN Zhiming1( )

)

- 1.School of Chemical and Environment Engineering,China University of Mining and Technology(Beijing),Beijing 100083,China

2.Water Conservancy Science Research Institute of Inner Mongolia

-

Received:2020-07-16Online:2022-05-10Published:2022-05-31 -

Contact:SUN Zhiming E-mail:747938928@qq.com;zhimingsun@cumtb.edu.cn

CLC Number:

Cite this article

YANG Liyan,MA Xin,MEI Ruifeng,YANG Dashan,LIANG Jialin,LI Chunquan,SUN Zhiming. Study on preparation and performance of ceramsite from sediment in Yellow River desilting basin[J]. Inorganic Chemicals Industry, 2022, 54(5): 109-115.

share this article

| 1 | 冯家豪,赵广举,穆兴民,等.黄河中游泥沙输移特性及机理研究[J].泥沙研究,2020,45(5):34-41. |

| FENG Jiahao, ZHAO Guangju, MU Xingmin,et al.Characteristics and mechanism of sediment transport in the Middle Yellow River[J].Journal of Sediment Research,2020,45(5):34-41. | |

| 2 | 田勇,屈博,李勇,等.黄河下游滩区治理研究与展望[J].人民黄河,2019,41(2):14-19. |

| TIAN Yong, QU Bo, LI Yong,et al.Research and perspective on floodplain treatment in the lower Yellow River[J].Yellow River,2019,41(2):14-19. | |

| 3 | CHIANG K Y, CHIEN Kuangli, HWANG S J.Study on the characteristics of building bricks produced from reservoir sediment[J].Journal of Hazardous Materials,2008,159(2/3):499-504. |

| 4 | SOMLAI J, JOBBÁGY V, KOVÁCS J,et al.Radiological aspects of the usability of red mud as building material additive[J].Journal of Hazardous Materials,2008,150(3):541-545. |

| 5 | 卢书慧,张旭东,张治昊.黄河泥沙基本特性分析及治理措施建议[J].水利建设与管理,2018,38(3):29-32. |

| LU Shuhui, ZHANG Xudong, ZHANG Zhihao.Analysis on basic characteristics of sediment in the Yellow River and suggestions for control measures[J].Water Conservancy Construction and Management,2018,38(3):29-32. | |

| 6 | 杨瑞兵,裴自勇.黄河下游泥沙治理与开发运用探索[J].治黄科技信息,2017,(3):3-4. |

| YANG Ruibing, PEI Ziyong.Exploration on treatment and development and application of sediment in the lower reaches of the Yellow River[J].Science and Technology Information on Yellow Control,2017,(3):3-4. | |

| 7 | NYSSEN J, VAN DEN BRANDEN J, SPALEVIĆ V,et al.Twentieth century land resilience in Montenegro and consequent hydrolo⁃ |

| gical response[J].Land Degradation & Development,2014,25(4):336-349. | |

| 8 | 徐晓虹,吴建锋,郑树清.一种利用黄河泥沙和赤泥制备发泡陶瓷隔热保温板的方法:中国,105198481B[P].2017-06-13. |

| XU Xiaohong, WU Jianfeng, ZHENG Shuqing.A method for preparing foamed ceramic thermal insulation board by using Yellow River sediment and red mud:CN,105198481B[P].2017-06-13. | |

| 9 | 王萍,郑光和,邵菁,等.利用黄河泥沙制作防汛备防石的试验研究[J].人民黄河,2012,34(5):12-13,31. |

| WANG Ping, ZHENG Guanghe, SHAO Jing,et al.Study on the reserved blocks made with sediment in the Yellow River via roller compacted technique[J].Yellow River,2012,34(5):12-13,31. | |

| 10 | MEZENCEVOVA A, YEBOAH N N, BURNS S E,et al.Utilization of Savannah Harbor River sediment as the primary raw material in production of fired brick[J].Journal of Environmental Management,2012,113:128-136. |

| 11 | 汪欣林,马鑫,梅锐锋,等.泥沙资源化利用技术研究进展[J].化工矿物与加工,2021,50(4):36-44. |

| WANG Xinlin, MA Xin, MEI Ruifeng,et al.Research progress on the technologies for sediment utilization[J].Industrial Minerals & Processing,2021,50(4):36-44. | |

| 12 | 朱玲,吴辉琴,岑钒浬,等.粉煤灰陶粒轻骨料混凝土弹性模量试验研究[J].广西科技大学学报,2021,32(2):26-32. |

| ZHU Ling, WU Huiqin, CEN Fanli,et al.Experimental research on elastic modulus of fly ash ceramsite lightweight aggregate concrete[J].Journal of Guangxi University of Science and Technology,2021,32(2):26-32. | |

| 13 | 郑凯,蒋善庆,武福平.给水厂污泥陶粒制备及其对氮磷吸附研究[J].环境污染与防治,2020,42(1):35-38,43. |

| ZHENG Kai, JIANG Shanqing, WU Fuping.Study on preparation of ceramsite made from waterworks sludge and its performance for adsorption of nitrogen and phosphorus[J].Environmental Pollution & Control,2020,42(1):35-38,43. | |

| 14 | 郝晓平,韩进文,高志强,等.锌冶炼废渣的综合利用[J].无机盐工业,2017,49(7):55-58. |

| HAO Xiaoping, HAN Jinwen, GAO Zhiqiang,et al.Comprehensive utilization of zinc smelting slag[J].Inorganic Chemicals Industry,2017,49(7):55-58. | |

| 15 | 石志平,姜澜,杨洪亮,等.铝灰的回收处理及资源化利用研究现状[J].无机盐工业,2020,52(9):21-25. |

| SHI Zhiping, JIANG Lan, YANG Hongliang,et al.Research status of recycling and resource utilization of aluminum dross[J].Inorganic Chemicals Industry,2020,52(9):21-25. | |

| 16 | 刘代俊.中国无机固体废弃物处理技术进展[J].无机盐工业,2020,52(3):1-10. |

| LIU Daijun.Advance in inorganic solid waste treatment technology in China[J].Inorganic Chemicals Industry,2020,52(3):1-10. | |

| 17 | 吴俊权,马晶,汪应玲,等.高硅铁尾矿制备陶粒工艺试验研究[J].矿产保护与利用,2020,40(6):126-132. |

| WU Junquan, MA Jing, WANG Yingling,et al.Experimental study on preparation of ceramsite with high silicon iron tailings[J]. | |

| Conservation and Utilization of Mineral Resources,2020,40(6):126-132. | |

| 18 | 王梓,陈鸿骏,薛泽洋,等.铁尾矿粉煤灰陶粒的制备与表征[J].材料研究与应用,2020,14(3):217-225. |

| WANG Zi, CHEN Hongjun, XUE Zeyang,et al.Preparation and characterization of the iron tailing/fly ash ceramsites[J].Materials Research and Application,2020,14(3):217-225. | |

| 19 | 张振文,胡彭青,周海华,等.基于固体废弃物的高性能陶粒的研究[J].低温建筑技术,2010,32(1):11-13. |

| ZHANG Zhenwen, HU Pengqing, ZHOU Haihua,et al.Study on high performance ceramic from solid waste[J].Low Temperature Architecture Technology,2010,32(1):11-13. | |

| 20 | 汪学彬,杨重卿,张祥伟,等.工业固体废弃物制备陶粒及其应用研究进展[J].中国粉体技术,2021,27(2):1-8. |

| WANG Xuebin, YANG Chongqing, ZHANG Xiangwei,et al.Preparation and application of ceramsite prepared from industrial solid waste:A review[J].China Powder Science and Technology,2021,27(2):1-8. | |

| 21 | 段美学,闫传霖,赵蔚琳.利用金矿尾矿烧制陶粒的正交实验研究[J].中国粉体技术,2014,20(4):64-67. |

| DUAN Meixue, YAN Chuanlin, ZHAO Weilin.Orthogonal test of preparing ceramsites using gold tailings[J].China Powder Science and Technology,2014,20(4):64-67. | |

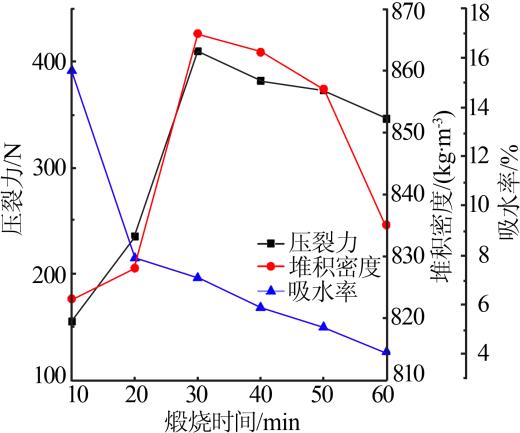

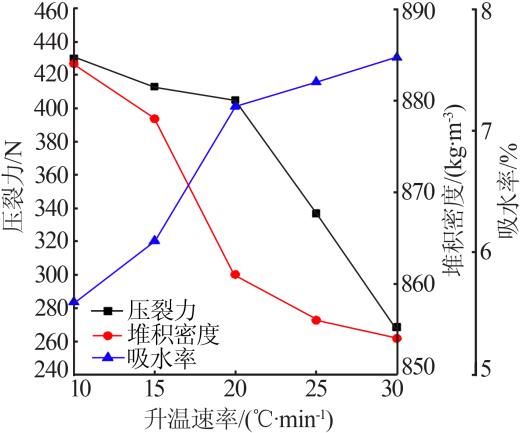

| 22 | 王继娜,徐开东,李志新,等.焙烧工艺对赤泥陶粒烧成特性及性能的影响[J].非金属矿,2021,44(1):20-22. |

| WANG Jina, XU Kaidong, LI Zhixin,et al.The influence of roasting technology on the sintering characteristics and properties of red mud ceramsite[J].Non-Metallic Mines,2021,44(1):20-22. |

| [1] | ZHAO Feiyan, ZHANG Xiaodong, DU Yanxia, WANG Qiang, LI Xiaoyan. Preparation technology and research progress of fly ash ceramsite [J]. Inorganic Chemicals Industry, 2024, 56(4): 16-23. |

| [2] | DENG Hua, HOU Shuomin, LI Zhongjun, XU Gang, CHI Ru′an, XI Benjun. Current situation and prospect of comprehensive utilization of phosphogypsum [J]. Inorganic Chemicals Industry, 2024, 56(1): 1-8. |

| [3] | LIU Guanfa, ZENG Chaocong, WANG Zekai, ZENG Xiangrong, HUANG Wanfu. Study on preparation of high strength sintered ceramsite from tungsten smelting slag and its property [J]. Inorganic Chemicals Industry, 2023, 55(8): 132-139. |

| [4] | LI Yu, ZHAO Wei, ZHANG Xinghua, WANG Rui, YAN Bingji, GUO Hongwei. Syudy on preparation of high-strength ceramsite from fluorite tailings and its properties [J]. Inorganic Chemicals Industry, 2023, 55(5): 100-108. |

| [5] | JIANG Ziwen,QUAN Xuejun,LI Gang,LU Cunfang,GUO Yijun,CHEN Hao,ZHOU Yankuo,CHENG Zhiliang. Research progress of resource utilization of chromium slag [J]. Inorganic Chemicals Industry, 2023, 55(2): 26-35. |

| [6] | FANG Weicheng,CHENG Xingxing,SUN Changrong. Optimization of preparation of sludge/fly ash composite ceramsite filler materials by response surface methodology [J]. Inorganic Chemicals Industry, 2022, 54(9): 119-125. |

| [7] | ZHANG Xiaoya,LI Jiali,FENG Lijuan,WANG Ji. Research progress on preparation technology and application of municipal sludge ceramsite [J]. Inorganic Chemicals Industry, 2022, 54(9): 28-38. |

| [8] | CUI Rongzheng,BAI Haidan,Gao Yongfeng,XIU Xuefeng. Current situation of comprehensive utilization of phosphogypsum and its development trend of 14th Five-Year Plan [J]. Inorganic Chemicals Industry, 2022, 54(4): 1-4. |

| [9] | SUN Zhicheng,DU Wei,WANG Runpu,CHENG Penggao,ZHANG Rong,GAO Weixing,WANG Zhanhe,HU Kaibao,TANG Na. Study on pilot scale process of producing liquid salt from Jilantai salt lake tailings [J]. Inorganic Chemicals Industry, 2022, 54(10): 46-52. |

| [10] | Liu Lincheng,Zuo Haibin,Xu Zhiqiang. Resource utilization approach of industrial gypsum and its prospect [J]. Inorganic Chemicals Industry, 2021, 53(10): 1-9. |

| [11] | Zhang Xiangcheng,Meng Yongbiao. Brief analysis on present situation of comprehensive utilization of fly ash in China [J]. Inorganic Chemicals Industry, 2020, 52(2): 1-5. |

| [12] | Liu Yuelong,Wang Linlin,Liu Gousheng. Extraction of rubidium and cerium salts from lithium tail liquid of medium and low grade lithium clay by ammonium sulfate process [J]. Inorganic Chemicals Industry, 2020, 52(11): 60-63. |

| [13] | Fu Yuhang1,2,3,Yan Rongbei1,2,3,Peng Chuanfeng1,2,3. Study on comprehensive utilization of residues in salt making area [J]. Inorganic Chemicals Industry, 2019, 51(7): 55-57. |

| [14] | GU Han-Nian, CUI Shan-Shan, WANG Ning, ZHAO Cheng-Dong. Distribution features and leaching effect of alkali in red mud [J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(2): 45-. |

| [15] | WAN Ya-Meng, WANG Bao-Qing, WANG Dan, REN Bao-Zeng. Research progress of alumina recovery technology from coal fly ash [J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(11): 7-. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||