Inorganic Chemicals Industry ›› 2022, Vol. 54 ›› Issue (1): 91-95.doi: 10.19964/j.issn.1006-4990.2021-0140

• Chemical Equipment and Design • Previous Articles Next Articles

Study on hydraulics of pulsed extraction separation device for nitric acid/hydrochloric acid in chloride salt system

PAN Baicheng1( ),SUN Ze1(

),SUN Ze1( ),MA Zhen2,ZHANG Haijun3,DONG Changji2,SONG Xingfu1

),MA Zhen2,ZHANG Haijun3,DONG Changji2,SONG Xingfu1

- 1. Engineering Research Center of Resources(Salt Lake) Process Engineering,Ministry of Education,East China University of Science and Technology,Shanghai 200237,China

2. Qinghai Salt Lake Industry Corporation Limited

3. Qinghai Salt Lake Nitrate Industry Corporation Limited

-

Received:2021-03-10Online:2022-01-10Published:2022-03-14 -

Contact:SUN Ze E-mail:baicpan@163.com;zsun@ecust.edu.cn

CLC Number:

Cite this article

PAN Baicheng,SUN Ze,MA Zhen,ZHANG Haijun,DONG Changji,SONG Xingfu. Study on hydraulics of pulsed extraction separation device for nitric acid/hydrochloric acid in chloride salt system[J]. Inorganic Chemicals Industry, 2022, 54(1): 91-95.

share this article

| [1] | 国家市场监督管理总局, 中国国家标准化管理委员会. GB/T36376—2018 太阳能熔盐(硝基型)[S]. 北京: 中国标准出版社, 2018. |

| [2] | 杜芳林, 李江年, 罗华平, 等. 硝酸和氯化钾直接法制取硝酸钾新工艺的开发[J]. 无机盐工业, 1992(6):15-18. |

| [3] | 谢伟胜. 溶剂萃取法制取硝酸钾研究进展[J]. 现代化工, 2008(6):32-36. |

| [4] | 秦炜, 李小松, 李跃, 等. 一种利用硝酸和氯化钾制备硝酸钾的方法:中国,103112876A[P]. 2013-05-22. |

| [5] | 史忠录, 杜佩英, 于雪峰, 等. 硝酸与氯化钾直接制取硝酸钾工艺研究[J]. 无机盐工业, 2019, 51(8):37-39. |

| [6] |

WANG H P, ZHOU Z Y, QIN W, et al. Study and modeling of the li-quid-solid equilibrium of the KCl-KNO3-HCl-H2O system at 283.15 K[J]. AIChE Journal, 2020, 66(1).Doi: 10.1002/aic.16750.

doi: 10.1002/aic.16750 |

| [7] | 杜芳林, 宫玉臻. 硝酸与氯化钾直接法制取硝酸钾[J]. 磷肥与复肥, 1997(5):13-15. |

| [8] | 马誉景, 金央, 李军, 等. 硝酸和氯化钾直接制备硝酸钾工艺研究及优化[J]. 无机盐工业, 2015, 47(3):31-34. |

| [9] | PORTELA L S. Process for obtaining potassium nitrate from potassi-um chloride and nitric acid:US,4668495[P]. 1987-05-26. |

| [10] | MANOR S, BAR-GURI M, ALEXANDRON A, et al. Process for the manufacture of potassium nitrate:US,4378342[P]. 1983-03-29. |

| [11] |

EYAL A, MIZRAHI J, BANIEL A. Potassium nitrate through solvent separation of strong acids[J]. Industrial & Engineering Chemistry Process Design and Development, 1985, 24(2):387-390.

doi: 10.1021/i200029a028 |

| [12] | 苏磊, 张海军, 汪瑾, 等. 反应萃取法制备熔盐级硝酸钾工艺探讨[J]. 无机盐工业, 2020, 52(5):35-39. |

| [13] | 费维扬. 萃取塔设备研究和应用的若干新进展[J]. 化工学报, 2013, 64(1):44-51. |

| [14] | 吴秋林, 王俊峰, 张天祥, 等. 核燃料后处理工程溶剂萃取设备[M]. 北京: 中国原子能出版社, 2012. |

| [15] | LADE V G, RATHOD V K, BHATTACHARYYA S, et al. Compar-ison of normal phase operation and phase reversal studies in a pu-lsed sieve plate extraction column[J]. Chemical Engineering Re-search and Design, 2013, 91(6):1133-1144. |

| [16] |

SARKAR S, SEN N, SINGH K K, et al. Effect of operating and geo-metric parameters on dispersed phase holdup in pulsed disc and doughnut and pulsed sieve plate columns:A comparative study[J]. Chemical Engineering and Processing:Process Intensification, 2017, 118:131-142.

doi: 10.1016/j.cep.2017.04.016 |

| [17] |

SEN N, SARKAR S, SINGH K K, et al. Regime transition and hol-dup in pulsed sieve-plate and pulsed disc and doughnut columns:A comparative study[J]. Solvent extraction and ion exchange, 2018, 36(1):66-83.

doi: 10.1080/07366299.2017.1415672 |

| [18] |

TORAB-MOSTAEDI M, GHAEMI A, ASADOLLAHZADEH M. Flooding and drop size in a pulsed disc and doughnut extraction column[J]. Chemical Engineering Research and Design, 2011, 89(12):2742-2751.

doi: 10.1016/j.cherd.2011.06.006 |

| [19] |

KHAJENOORI M, HAGHIGHI-ASL A, SAFDARI J, et al. Predic-tion of drop size distribution in a horizontal pulsed plate extraction column[J]. Chemical Engineering and Processing:Process Intensification, 2015, 92:25-32.

doi: 10.1016/j.cep.2015.03.021 |

| [20] |

YI H, WANG Y, SMITH K H, et al. Hydrodynamic performance of a pulsed solvent extraction column with novel ceramic internals:Holdup and drop size[J]. Industrial & Engineering Chemistry Research, 2017, 56(4):999-1007.

doi: 10.1021/acs.iecr.6b03324 |

| [21] |

TAN B, LAN M, LI L X, et al. Drop size correlation and population balance model for an agitated-pulsed solvent extraction column[J]. AIChE Journal, 2020, 66(8).Doi: 10.1002/aic.16279.

doi: 10.1002/aic.16279 |

| [22] |

KHANRAMAKI F, SAFDARI J, SHIRANI A S, et al. Experimen-tal study on hold-up,characteristic and slip velocities in a horizon-tal pulsed sieve-plate column and uranium reactive extraction con-dition in aqueous phase[J]. Progress in Nuclear Energy, 2018, 109:159-170.

doi: 10.1016/j.pnucene.2018.08.009 |

| [23] | WANG F, MAO Z S. Numerical and experimental investigation of liquid-liquid two-phase flow in stirred tanks[J]. Industrial & En-gineering Chemistry Research, 2005, 44(15):5776-5787. |

| [24] | SCHILLER L, NAUMANN A. Fundamental calculations in gravita-tional processing[J]. Zeitschrift Des Vereines Deutscher Ingenieu-re, 1933, 77:320-381. |

| [25] |

MORSI S A, ALEXANDER A J. An investigation of particle trajec-tories in two-phase flow systems[J]. Journal of Fluid Mechanics, 1972, 55(2):193-208.

doi: 10.1017/S0022112072001806 |

| [26] |

BARNEA E, MIZRAHI J. A generalised approach to the fluid dy-namics of particulate systems part 2:Sedimentation and fluidisa-tion of clouds of spherical liquid drops[J]. The Canadian Journal of Chemical Engineering, 1975, 53(5):461-468.

doi: 10.1002/cjce.v53:5 |

| [27] | AUGIER F, MASBERNAT O, GUIRAUD P. Slip velocity and drag law in a liquid-liquid homogeneous dispersed flow[J]. AIChE Jo-urnal, 2003, 49(9):2300-2316. |

| [28] |

KUMAR A, HARTLAND S. Gravity settling in liquid/liquid disper-sions[J]. The Canadian Journal of Chemical Engineering, 1985, 63(3):368-376.

doi: 10.1002/cjce.v63:3 |

| [29] | 李洲, 费维扬, 杨基础. 液-液萃取过程和设备[M]. 北京: 原子能出版社, 1985. |

| [30] | KUMAR A, HARTLAND S. Prediction of dispersed phase hold-upin pulsed perforated-plate extraction columns[J]. Chemical Engi-neering and Processing:Process Intensification, 1988, 23(1):41-59. |

| [31] |

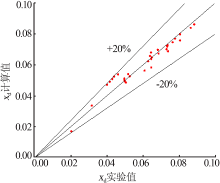

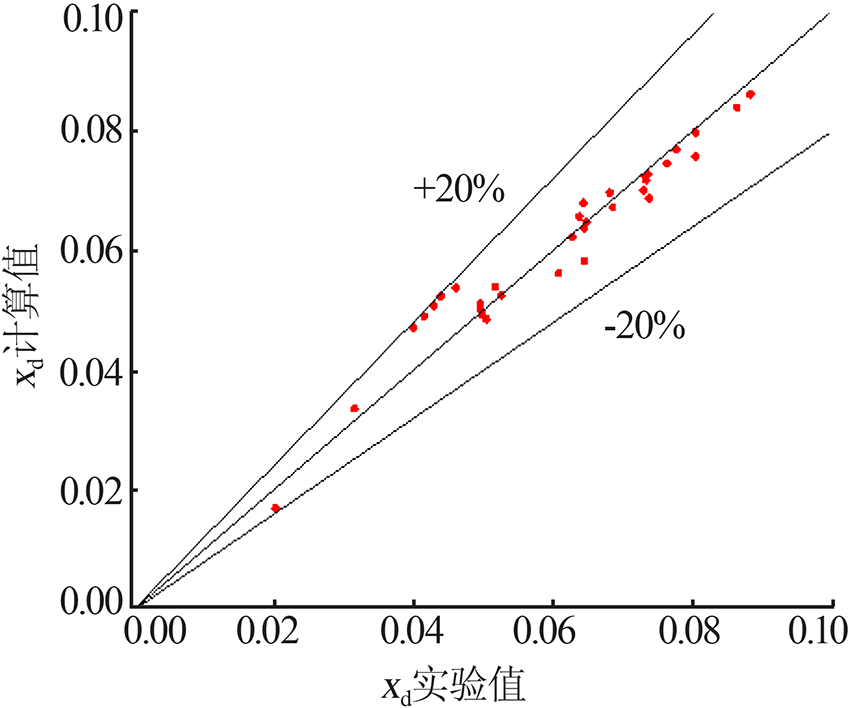

KUMAR A, HARTLAND S. Unified correlations for the prediction of drop size in liquid-liquid extraction columns[J]. Industrial & Engineering Chemistry Research, 1996, 35(8):2682-2695.

doi: 10.1021/ie950674w |

| [1] | ZHOU Qinglie, WANG Baoqi, ZHANG Zhiye, ZHANG Yinghu, WANG Jian, YANG Lin. Development of new process of removing metal cations from wet-process phosphoric acid by extraction [J]. Inorganic Chemicals Industry, 2023, 55(3): 84-91. |

| [2] | LI Huifang, WANG Xiao, BAI Youpeng, ZHANG Shixiang. Study on extraction of lithium from low grade high clay leaching solution by solvent extraction [J]. Inorganic Chemicals Industry, 2023, 55(10): 63-69. |

| [3] | KANG Jin,WEI Lina,CHENG Huaigang. Research progress on application of ionic liquids in extracting lithium from salt lakes [J]. Inorganic Chemicals Industry, 2022, 54(1): 1-6. |

| [4] | Zhang Shaojie,Tang Shengwei,Wang Yang,Zheng Dongyue,Zhong Benhe,Chen Yanxiao. Preliminary study on scrubbing and stripping operation of the extracted organic phase in wet phosphoric acid process by hydrochloric acid route [J]. Inorganic Chemicals Industry, 2021, 53(8): 36-43. |

| [5] | Wei Lina,Kang Jin,Li Hu,Li Enze,Cheng Huaigang,Cheng Fangqin. Research progress of lithium extractants and extraction systems from salt lakes [J]. Inorganic Chemicals Industry, 2021, 53(5): 21-25. |

| [6] | ZHAO Yuanfang,GAO Youfei,DU Zhaoxin. Experimental research on purification of wet process phosphoric acid by methyl isobutyl ketone in rotating disc column [J]. Inorganic Chemicals Industry, 2021, 53(12): 105-108. |

| [7] | Su Lei,Zhang Haijun,Wang Jin,Yu Xuefeng,Dong Changji,Sun Ze,Song Xingfu,Yu Jianguo. Study on preparation of molten salt grade potassium nitrate by reactive extraction method [J]. Inorganic Chemicals Industry, 2020, 52(5): 35-39. |

| [8] | Liao Xiaoting,Li Jun,Chen Ming. Process study on preparation of industrial grade ammonium dihydrogen phosphate from urea phosphate mother liquor [J]. Inorganic Chemicals Industry, 2020, 52(4): 79-83. |

| [9] | Zhang Yongxing,Ma Yameng,Zhang Lizhen,Zhang Xiufeng,Tan Xiumin. Experimental research on extracting lithium from concentrated salt lake brine [J]. Inorganic Chemicals Industry, 2019, 51(3): 38-40. |

| [10] | Zhou Xiumei,Sun Guixing. Optimization technology for stable operation of ammonium chloride crystal system in potassium dihydrogen phosphate production plant [J]. Inorganic Chemicals Industry, 2019, 51(12): 58-60. |

| [11] | CHEN Xi, LI Jun, JIN Yang, MO Shan, WU Shi-Qin. Research on demulsification by gravity sedimentation and stirring in emulsification solvent extraction process [J]. INORGANICCHEMICALSINDUSTRY, 2015, 47(5): 15-. |

| [12] | ZHANG Zhi-Qiang, ZHANG Cai-Mian, SUN Ying-Bo, TANG Qiang. Research on purification of wet process phosphoric acid by methyl isobutyl ketone [J]. INORGANICCHEMICALSINDUSTRY, 2014, 46(7): 20-. |

| [13] | JIANG Cai-Li, ZHENG Shao-Cong, ZHENG Yuan-Li, WANG Zhi-Juan. Preparation of potassium dihydrogen phosphate by triotylamine-isoamyl alcohol organic solvent extraction [J]. INORGANICCHEMICALSINDUSTRY, 2014, 46(2): 44-. |

| [14] | SUN Yi, LI Jun, ZHOU Kun, ZHANG Ya-Qing. Study on preparation of potassium dihydrogen phosphate from wet-process phosphoric acid by solvent extraction method [J]. INORGANICCHEMICALSINDUSTRY, 2013, 45(4): 34-. |

| [15] | ZHONG Ben-He, FANG Wei-Mao, LI Jun, YING Jian-Kang. Progress in purification technology(engineering) of wet process phosphoric acid in China [J]. INORGANICCHEMICALSINDUSTRY, 2013, 45(2): 8-. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||