| [1] |

BAR M, ALAGIRUSAMY R,DAS A.Flame retardant polymer composites[J].Fibers and Polymers,2015,16(4):705-717.

|

| [2] |

SALMEIA K A, GAAN S.An overview of some recent advances in DOPO-derivatives:Chemistry and flame retardant applications[J].Polymer Degradation and Stability,2015,113:119-134.

|

| [3] |

韩森森.二维纳米杂化阻燃剂制备及阻燃聚合物的性能与机理研究[D].合肥:中国科学技术大学,2024.

|

|

HAN Sensen.Research on the preparation of two-dimensional nano-hybrid flame retardants and the properties and mechanisms of flame-retarded polymers[D].Hefei:University of Science and Tech-nology of China,2024.

|

| [4] |

靳昕怡,魏丽菲,窦娟,等.无卤阻燃剂在聚合物阻燃中的应用研究进展[J].高科技纤维与应用,2022,47(6):67-73.

|

|

JIN Xinyi, WEI Lifei, DOU Juan,et al.Research on the application of halogen-free flame retardants in polymer flame retardan-ts[J].Hi-Tech Fiber and Application,2022,47(6):67-73.

|

| [5] |

王清硕,惠岚峰,张宜宜,等.新型无卤素阻燃剂研究及应用进展[J].现代化工,2024,44(6):35-40.

|

|

WANG Qingshuo, HUI Lanfeng, ZHANG Yiyi,et al.Research and application progress on novel halogen-free flame retardant[J].Modern Chemical Industry,2024,44(6):35-40.

|

| [6] |

马立群,肖添远,孟爽,等.磷系阻燃剂在常用塑料中的应用进展[J].工程塑料应用,2017,45(11):136-139.

|

|

MA Liqun, XIAO Tianyuan, MENG Shuang,et al.Application progress of phosphorous flame retardant in common plastics[J].Engineering Plastics Application,2017,45(11):136-139.

|

| [7] |

王淼.氢氧化镁透明分散体及其聚合物基阻燃材料的制备和性能研究[D].北京:北京化工大学,2016.

|

|

WANG Miao.Research on the preparation and properties of transparent magnesium hydroxide dispersions and their polymer-based flame-retardant materials[D].Beijing:Beijing University of Che-mical Technology,2016.

|

| [8] |

刘立平.微化反应器在制备阻燃剂氢氧化镁上的应用[J].镁化合物科技(生产)信息,2017(1/2):71-79.

|

|

LIU Liping.Application of micro-reactor in the preparation of magnesium hydroxide flame retardant[J].Magnesium Compound Technology(Production) Information,2017(1/2):71-79.

|

| [9] |

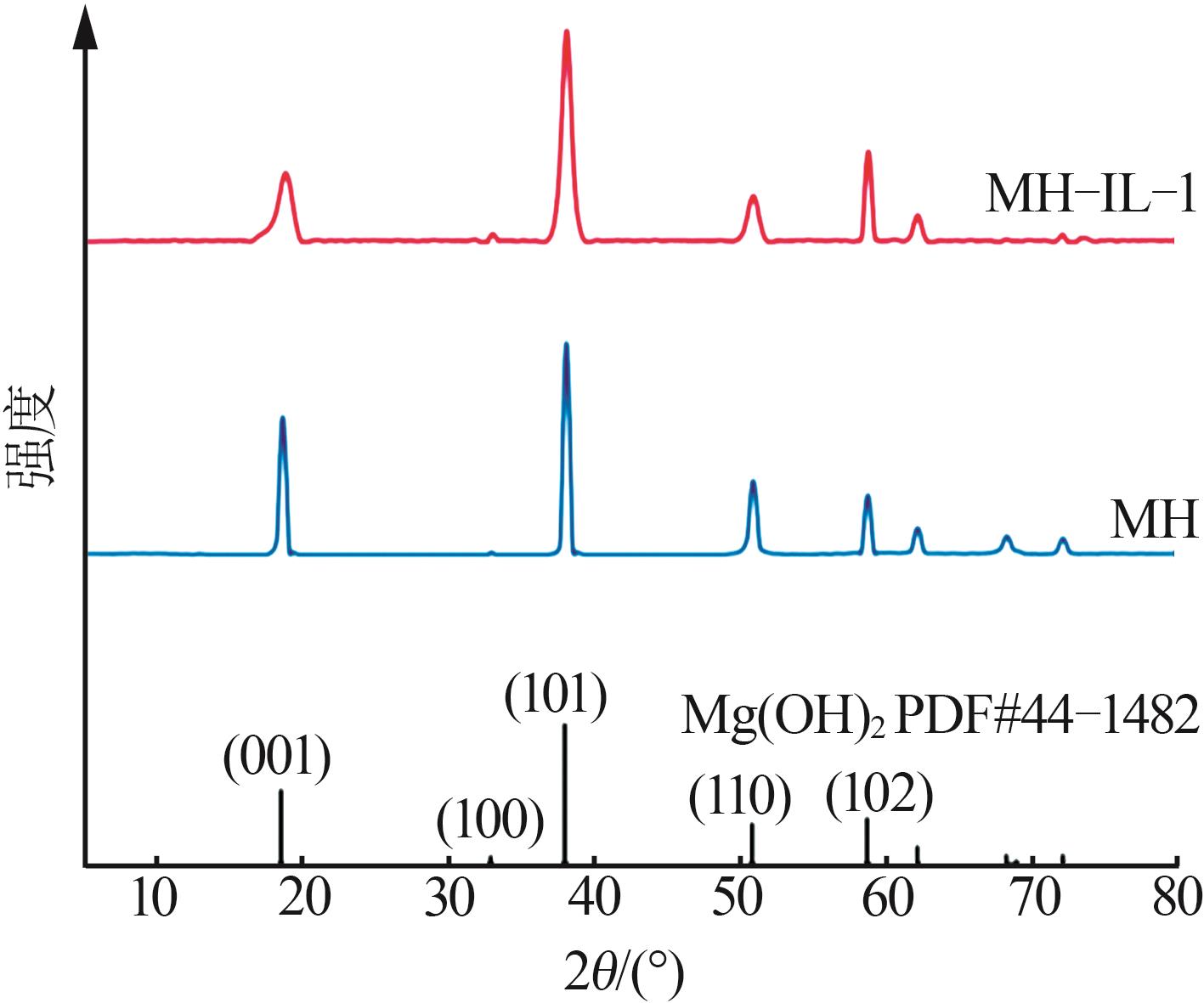

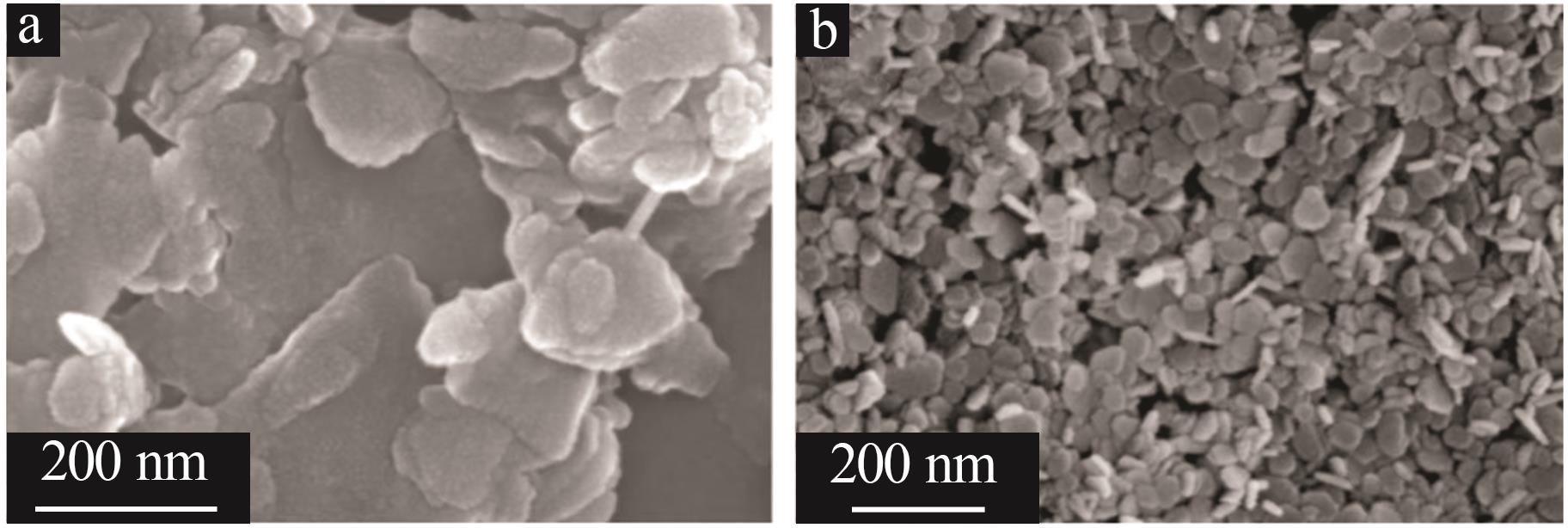

申纯宇,李翠利,汤建伟,等.纳米氢氧化镁制备及其阻燃应用进展[J].化工进展,2024,43(9):4980-4995.

|

|

SHEN Chunyu, LI Cuili, TANG Jianwei,et al.Progress in preparation and flame retardant application of nano magnesium hydroxi-de[J].Chemical Industry and Engineering Progress,2024,43(9):4980-4995.

|

| [10] |

牛跃同,李慧良,吴敬礼.氢氧化镁阻燃剂的研究应用[J].盐科学与化工,2023,52(11):1-3.

|

|

NIU Yuetong, LI Huiliang, WU Jingli.Research and application of magnesium hydroxide flame retardant[J].Journal of Salt Science and Chemical Industry,2023,52(11):1-3.

|

| [11] |

HE Wentao, SONG Pingan, YU Bin,et al.Flame retardant polymeric nanocomposites through the combination of nanomaterials and conventional flame retardants[J].Progress in Materials Science,2020,114:100687.

|

| [12] |

武俊,钱永芳,吕丽华,等.静电纺PVP/Mg(OH)2阻燃纳米纤维材料的制备及性能[J].上海纺织科技,2022,50(7):23-26,52.

|

|

WU Jun, QIAN Yongfang, Lihua LYU,et al.Preparation of electrospun PVP/Mg(OH)2 flame retardant nanofiber material and its performance[J].Shanghai Textile Science & Technology,2022,50(7):23-26,52.

|

| [13] |

马鸣杨.纳米氢氧化镁的制备与改性及阻燃性能研究[D].武汉:武汉工程大学,2023.

|

|

MA Mingyang.Research on Preparation,Modification and Flame-Retardant Properties of Nano-magnesium Hydroxide[D].Wuhan:Wuhan Institute of Technology,2023.

|

| [14] |

宋春雨,聂普选,马守涛,等.典型过程强化技术在纳米材料制备中的应用进展[J].过程工程学报,2021,21(4):373-382.

|

|

SONG Chunyu, NIE Puxuan, MA Shoutao,et al.Application progress of typical process intensification technologies applied for nanomaterials preparation[J].The Chinese Journal of Process Engineering,2021,21(4):373-382.

|

| [15] |

张靖,柯昌美,段国权,等.新型聚丙烯酸酯乳液对纳米氢氧化镁的改性研究[J].无机盐工业,2021,53(9):35-39.

|

|

ZHANG Jing, KE Changmei, DUAN Guoquan,et al.Study on modification of nano-magnesium hydroxide by new polyacrylate emulsion[J].Inorganic Chemicals Industry,2021,53(9):35-39.

|

| [16] |

叶欣然,吴赞,王海鸥,等.气液两相流体系下微反应器技术研究进展[J].过程工程学报,2024,24(9):1001-1015.

|

|

YE Xinran, WU Zan, WANG Haiou,et al.Research progress of microreactor technology in gas-liquid two-phase flow systems[J].The Chinese Journal of Process Engineering,2024,24(9):1001-1015.

|

| [17] |

周琳,杨炜,吕阳成.微反应器在含能材料合成中的应用及展望[J].含能材料,2024,32(3):325-344.

|

|

ZHOU Lin, YANG Wei, Yangcheng LÜ.Review on the application of microreactor in the synthesis processes of energetic materials[J].Chinese Journal of Energetic Materials,2024,32(3):325-344.

|

| [18] |

武向前,李伟波,高志强.微通道反应器制备纳米硫酸钡的工艺研究[J].盐科学与化工,2024,53(2):23-25.

|

|

WU Xiangqian, LI Weibo, GAO Zhiqiang.Study on the preparation of nano barium sulfate by micro-channel reactor[J].Journal of Salt Science and Chemical Industry,2024,53(2):23-25.

|

| [19] |

曹志军.金属离子液体调控制备功能性纳米复合材料及应用研究[D].无锡:江南大学,2023.

|

|

CAO Zhijun.Research on the preparation of functional nanocomposites via metal ionic liquid-mediated regulation and their applications[D].Wuxi:Jiangnan University,2023.

|

| [20] |

郑文君.离子液体在无机合成中的应用[J].大学化学,2024,39(8):163-168.

|

|

ZHENG Wenjun.Application in inorganic synthesis of ionic liquids[J].University Chemistry,2024,39(8):163-168.

|

| [21] |

江玮,王瑞,薛伟,等.离子液体辅助合成纳米金属氧化物的研究进展[J].石油化工,2024,53(1):105-114.

|

|

JIANG Wei, WANG Rui, XUE Wei,et al.Research progress in synthesis of nano metal oxides assisted by ionic liquids[J].Petrochemical Technology,2024,53(1):105-114.

|

), LI Xinqi1, BU Zhaoshuang1, GAO Xi1, ZHOU Yicheng2, SHEN Chunyu1, LI Cuili3, WANG Baoming1,4,5(

), LI Xinqi1, BU Zhaoshuang1, GAO Xi1, ZHOU Yicheng2, SHEN Chunyu1, LI Cuili3, WANG Baoming1,4,5( )

)