Inorganic Chemicals Industry ›› 2021, Vol. 53 ›› Issue (10): 28-35.doi: 10.19964/j.issn.1006-4990.2020-0612

• Reviews and Special Topics • Previous Articles Next Articles

Research progress on activation and mechanism of fly ash

Ma Pengchuan1( ),Li Xing2,Wen Zhenyu1,Meng Fanhui1,Li Zhong1(

),Li Xing2,Wen Zhenyu1,Meng Fanhui1,Li Zhong1( )

)

- 1. Key Laboratory of Coal Science and Technology of Ministry of Education and Shanxi Province,Institute of Coal Chemical Engineering,Taiyuan University of Technology,Taiyuan 030024,China

2. Shanxi Huairen Shifengshan Coal Industry Co.,Ltd.

-

Received:2020-11-13Online:2021-10-10Published:2021-10-11 -

Contact:Li Zhong E-mail:mapengzhuan@163.com;lizhong@tyut.edu.cn

CLC Number:

Cite this article

Ma Pengchuan,Li Xing,Wen Zhenyu,Meng Fanhui,Li Zhong. Research progress on activation and mechanism of fly ash[J]. Inorganic Chemicals Industry, 2021, 53(10): 28-35.

share this article

Table 3

Comparison of chemical excitation methods for fly ash"

| 激发方法 | 激发机理 | 优势 | 劣势 |

|---|---|---|---|

| 酸激发 | H+侵蚀粉煤灰玻璃体表面,释放活性SiO2、Al2O3,进而提高水化反应程度 | 可单独激发粉煤灰活性,并可通过改变酸 类型和强度对粉煤灰进行不同程度的激发 | 对设备腐蚀性强,目前技术尚未成熟, 仍处于研究阶段 |

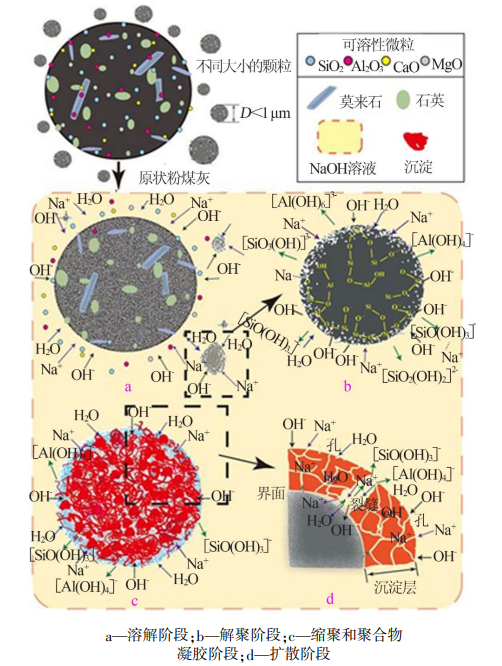

| 碱激发 | 通过OH-使得粉煤灰表面[AlO4]和[SiO4]发生解聚,破坏表面结构,释放玻璃体内的活性物质 | 可单独激发粉煤灰活性;可选用的激发剂 种类多,技术较成熟,可大规模使用 | 激发程度有限,碱过量会引发粉煤灰 材料内部发生碱集料反应,进而破坏 材料 |

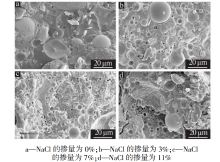

| 盐激发 | 在碱性条件下,Cl-和SO42-与粉煤灰中的活性物质反应生成胶凝性物质,加速了粉煤灰中活性物质的释放 | 可解决粉煤灰“先天缺钙”问题,应用成本 低,前景广阔 | 必须与碱配合使用才能激发活性; SO42-或Cl-过量对粉煤灰材料及其中的 钢筋有腐蚀 |

| 有机溶 剂激发 | 有机碱溶剂中的孤对电子与粉煤灰中的Fe、Al相发生络合,腐蚀粉煤灰表面,加速释放活性SiO2、Al2O3 | 对胶凝材料的早期激发效果好,可通过螯 合作用减少金属离子对土壤的影响 | 单一使用时效果差,需配合无机碱才 能有效激发粉煤灰活性;原料成本高 |

| [1] | 徐涛, 兰海平, 杨超, 等. 粉煤灰物理化学性质对比分析研究[J]. 无机盐工业, 2018, 50(7):65-68. |

| [2] |

Ding J, Ma S H, Shen S, et al. Research and industrialization progre-ss of recovering alumina from fly ash:A concise review[J]. Waste Management, 2017, 60(11):375-387.

doi: 10.1016/j.wasman.2016.06.009 |

| [3] | 姜龙. 燃煤电厂粉煤灰综合利用现状及发展建议[J]. 洁净煤技术, 2020, 26(4):31-39. |

| [4] |

Wang N N, Sun X Y, Zhao Q, et al. Leachability and adverse effects of coal fly ash:A review[J]. Journal of Hazardous Materials, 2020, 396(1).Doi: 10.1016/j.jhazmat.2020.122725.

doi: 10.1016/j.jhazmat.2020.122725 |

| [5] |

Yao Z T, Ji X S, Sarker P K, et al. A comprehensive review on the-applications of coal fly ash[J]. Earth-Science Reviews, 2015, 141(1):105-121.

doi: 10.1016/j.earscirev.2014.11.016 |

| [6] |

Tauanov Z, Azat S, Baibatyrova A. A mini-review on coal fly ash pro-perties,utilization and synjournal of zeolites[J]. International Journal of Coal Preparation and Utilization, 2020, 40(10).Doi: 10.1080/19392699.2020.1788545.

doi: 10.1080/19392699.2020.1788545 |

| [7] | Dar M I, Green I D, Naikoo M I, et al. Assessment of biotransfer and bioaccumulation of cadmium lead and zinc from fly ash amended soil in mustard-aphid-beetle food chain[J]. Science of the Total En-vironment, 2017,584- 585(1):1221-1229. |

| [8] |

Shi Y, Jiang K X, Zhang T A. Cleaner extraction of alumina from coal fly ash:Baking-electrolysis method[J]. Fuel, 2020, 273(2).Doi: 10.1016/j.fuel.2020.117697.

doi: 10.1016/j.fuel.2020.117697 |

| [9] | 肖翠微. 粉煤灰在水处理领域的应用进展[J]. 洁净煤技术, 2016, 22(4):45-51,67. |

| [10] | 张祥成, 孟永彪. 浅析中国粉煤灰的综合利用现状[J]. 无机盐工业, 2020, 52(2):1-5. |

| [11] | 周茗如, 孙耀峰, 乔宏霞. 不同品质粉煤灰在砂浆中减水效应及强度规律的研究[J]. 粉煤灰综合利用, 2011, 25(1):15-17,21. |

| [12] | 李辉, 曹敏丽, 张伟, 等. 大掺量超细粉煤灰高强混凝土研究[J]. 硅酸盐通报, 2014, 33(5):1028-1034. |

| [13] | Cho Y K, Jung S H, Choi Y C. Effects of chemical composition of fly ash on compressive strength of fly ash cement mortar[J]. Cons-truction and Building Materials, 2019, 204(2):255-264. |

| [14] |

Chen X M, Gao J M, Yan Y, et al. Investigation of expansion pro-perties of cement paste with circulating fluidized bed fly ash[J]. Construction and Building Materials, 2017, 157(2):1154-1162.

doi: 10.1016/j.conbuildmat.2017.08.159 |

| [15] |

Akshata G P, Shanmugharaj A M, Anandhan S. Interparticle intera-ctions and lacunarity of mechano-chemically activated fly ash[J]. Powder Technology, 2014, 272(1):241-249.

doi: 10.1016/j.powtec.2014.12.006 |

| [16] | Chen Z L, Lu S Y, Tang M H, et al. Mechanical activation of fly ash from MSWI for utilization in cementitious materials[J]. Waste Ma-nagement, 2019, 88(4):182-190. |

| [17] |

Sanjay K, Mucsi G, Feerenc K, et al. Mechanical activation of fly ash and its influence on micro and nano-structural behaviour of re-sulting geopolymers[J]. Advanced Powder Technology, 2017, 28(3):805-813.

doi: 10.1016/j.apt.2016.11.027 |

| [18] | Patil A G, Anandhan S. Influence of planetary ball milling parame-ters on the mechano-chemical activation of fly ash[J]. Powder Te-chnology, 2015, 281(1):151-158. |

| [19] |

Craig S L. A tour of force[J]. Nature, 2012, 487(7406):176-177.

doi: 10.1038/487176a |

| [20] |

Mucsi G. Mechanical activation of power station fly ash by grinding-A review[J]. Epitoanyag-Journal of Silicate Based and Composite Materials, 2016, 68(2):56-61.

doi: 10.14382/epitoanyag-jsbcm.2016.10 |

| [21] |

Kumar S, Kumar R. Mechanical activation of fly ash:Effect on reac-tion,structure and properties of resulting geopolymer[J]. Ceramics International, 2011, 37(2):533-541.

doi: 10.1016/j.ceramint.2010.09.038 |

| [22] | Du Y T, Wang H F, Wang Z C, et al. Mineralogical and active me-chanical excitation characteristics of filled fly ash cementitious materials[J]. Journal of Wuhan University of Technology-Mater.Sci.Ed., 2017, 32(2):413-416. |

| [23] | 罗忠涛, 马保国, 李相国, 等. 水热碱性环境下粉煤灰水化进程研究[J]. 中国矿业大学学报, 2010, 66(2):275-278. |

| [24] |

Ma L J, Feng Y, Zhang M, et al. Mechanism study on green high-efficiency hydrothermal activation of fly ash and its application prospect[J]. Journal of Cleaner Production, 2020, 275(1).Doi: 10.1016/j.jclepro.2020.122977.

doi: 10.1016/j.jclepro.2020.122977 |

| [25] |

Hemalatha T, Ramaswamy A. A review on fly ash characteristics-Towards promoting high volume utilization in developing sustaina-ble concrete[J]. Journal of Cleaner Production, 2017, 147(1):546-559.

doi: 10.1016/j.jclepro.2017.01.114 |

| [26] |

Zhang J B, Li S P, Li H Q, et al. Acid activation for pre-desilicated high-alumina fly ash[J]. Fuel Processing Technology, 2016, 151(1):64-71.

doi: 10.1016/j.fuproc.2016.05.036 |

| [27] | Losey D J, Sihvonen S K, Veghte D P. et al. Acidic processing of fly ash:Chemical characterization,morphology,and immersion freez-ing[J]. Environmental Science:Processes & Impacts, 2018, 20(11):1581-1592. |

| [28] | 赵海君, 严云, 胡志华. 低钙粉煤灰活性激发技术的研究[J]. 水泥工程, 2008, 39(3):8-11. |

| [29] | 于继寿, 李仁福, 隋成飞, 等. 酸碱激活粉煤灰的研究[J]. 粉煤灰综合利用, 2000, 14(2):26-27. |

| [30] |

Yin B, Kang T H, Kang J T, et al. Analysis of active ion-leaching behavior and the reaction mechanism during alkali activation of low-calcium fly ash[J]. International Journal of Concrete Structures and Materials, 2018, 12(1).Doi: 10.1186/s40069-018-0282-3.

doi: 10.1186/s40069-018-0282-3 |

| [31] |

Velandia D F, Lynsdale C J, Provis J L. et al. Evaluation of activated high volume fly ash systems using Na2SO4,lime and quicklime in mortars with high loss on ignition fly ashes[J]. Construction and Building Materials, 2016, 128:248-255.

doi: 10.1016/j.conbuildmat.2016.10.076 |

| [32] | 杨晓凤, 彭龙贵, 张再勇. 强碱激发剂对高掺量粉煤灰水化活性的影响及表征[J]. 化工新型材料, 2011, 39(A1):100-103. |

| [33] | Duxson P, Fernández-Jiménez A, Provis J L, et al. Geopolymer technology:The current state of the art[J]. Journal of Materials Sci-ence, 2006, 42(9):2917-2933. |

| [34] | 王敏, 吴勇生, 李如燕, 等. 碱激发剂对铸造粉尘-粉煤灰基地质聚合物抗压强度的影响[J]. 硅酸盐通报, 2013, 34(6):1037-1042. |

| [35] |

Bignozzi M C, Manzi S, Natali M E, et al. Room temperature alkali activation of fly ash:The effect of Na2O/SiO2 ratio[J]. Construction and Building Materials, 2014, 69(2):262-270.

doi: 10.1016/j.conbuildmat.2014.07.062 |

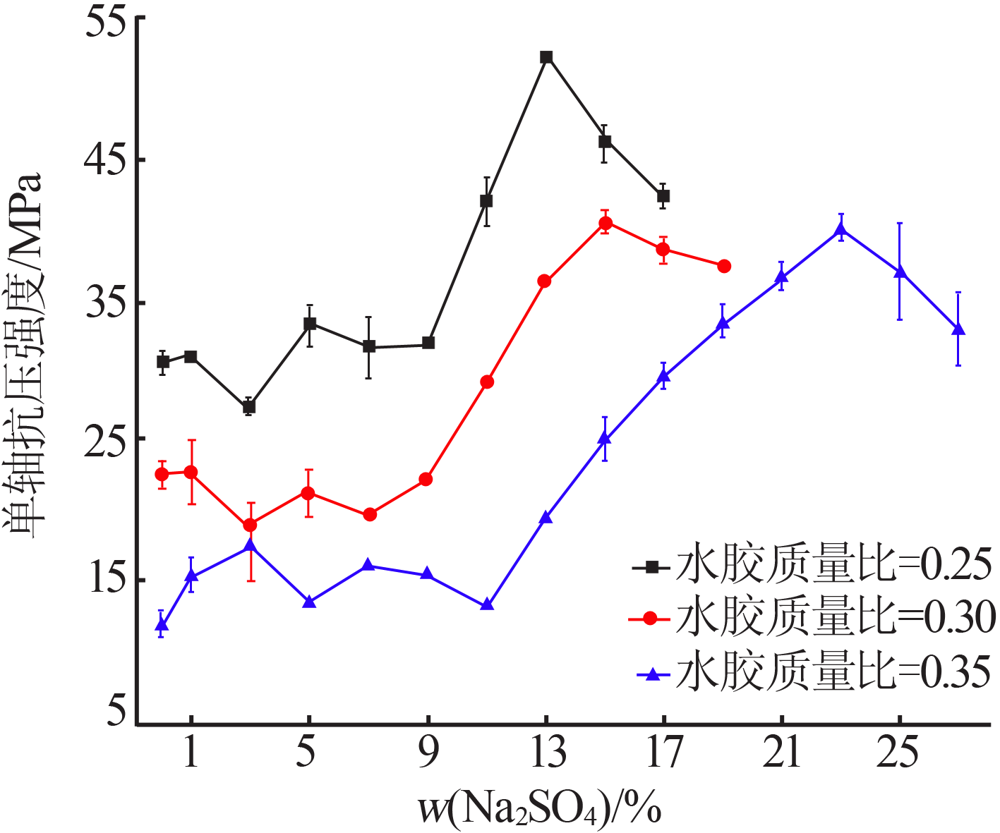

| [36] | Dakhane A, Tweedley S, Kailas S, et al. Mechanical and microstruc-tural characterization of alkali sulfate activated high volume fly ash binders[J]. Materials & Design, 2017, 122(1):236-246. |

| [37] | Nguyen H A. Utilization of commercial sulfate to modify early per-formance of high volume fly ash based binder[J]. Journal of Build-ing Engineering, 2018, 19(1):429-433. |

| [38] |

Sivapullaiah P V, Baig M A A. Gypsum treated fly ash as a liner for waste disposal facilities[J]. Waste Management, 2011, 31(2):359-369.

doi: 10.1016/j.wasman.2010.07.017 pmid: 20817503 |

| [39] | 柯国军, 杨晓峰, 彭红, 等. 化学激发粉煤灰活性机理研究进展[J]. 煤炭学报, 2005, 30(3):366-370. |

| [40] | 王智, 郑洪伟, 钱觉时, 等. 硫酸盐对粉煤灰活性激发的比较[J]. 粉煤灰综合利用, 1999, 13(3):15-18. |

| [41] |

Venkatarama Reddy B V, Gourav K. Strength of lime-fly ash com-pacts using different curing techniques and gypsum additive[J]. Materials and Structures, 2011, 44(10):1793-1808.

doi: 10.1617/s11527-011-9738-5 |

| [42] |

Lv Q F, Wang Z S, Gu L Y, et al. Effect of sodium sulfate on stren-gth and microstructure of alkali-activated fly ash based geopoly-mer[J]. Journal of Central South University, 2020, 27(6):1691-1702.

doi: 10.1007/s11771-020-4400-4 |

| [43] | Jeon D, Yum W S, Jeong Y, et al. Properties of quicklime(CaO)-activated Class F fly ash with the use of CaCl2[J]. Cement and Co-ncrete Research, 2018, 111(1):147-156. |

| [44] | Li C, Zhu H B, Wu M X, et al. Pozzolanic reaction of fly ash modi-fied by fluidized bed reactor-vapor deposition[J]. Cement and Co-ncrete Research, 2017, 92(1):98-109. |

| [45] |

Saldanha R B, Scheuermann Filho H C, Ribeiro J L D, et al. Mode-lling the influence of density,curing time,amounts of lime and so-dium chloride on the durability of compacted geopolymers mono-lithic walls[J]. Construction and Building Materials, 2017, 136(1):65-72.

doi: 10.1016/j.conbuildmat.2017.01.023 |

| [46] | 王复生, 朱元娜, 张磊. 氯化钠对粉煤灰硅酸盐混合水泥活性激发能力和结合方式的试验研究[J]. 硅酸盐通报, 2009, 30(1):31-37. |

| [47] | 吕擎峰, 王子帅, 陈臆, 等. 氯化钠对碱激发地聚物强度影响机理研究[J]. 功能材料, 2020, 51(2):73-77,98. |

| [48] | 兰明章, 侯伟芳, 王亚丽. 醇胺对掺粉煤灰水泥基材料性能的影响[J]. 混凝土, 2015, 37(8):95-97. |

| [49] | Chen X, Zhu G R, Zhou M K, et al. Effect of organic polymers on the properties of slag-based geopolymers[J]. Construction and Buil-ding Materials, 2018, 167(2):216-224. |

| [50] | 杨萌, 孙正, 周卫兵, 等. 醇胺类助磨剂对粉煤灰水泥水化硬化过程的影响[J]. 水泥, 2011, 38(12):3-6. |

| [51] | 汤青青, 张丽娟, 孙国文, 等. 三乙醇胺-氢氧化钙对大掺量粉煤灰水泥胶凝体系早期活性激发[J]. 硅酸盐通报, 2018, 37(9):2737-2742. |

| [52] | Heinz D, Göbel M, Hilbig H, et al. Effect of TEA on fly ash solubili-ty and early age strength of mortar[J]. Cement and Concrete Rese-arch, 2010, 40(3):392-397. |

| [53] |

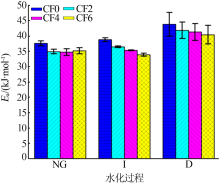

He J H, Long G C, Ma C, et al. Effect of triethanolamine on hydra-tion kinetics of cement-fly ash system at elevated curing tempera-ture[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(27).Doi: 10.1021/acssuschemeng.0c01763.

doi: 10.1021/acssuschemeng.0c01763 |

| [54] |

Sun G W, Tang Q Q, Zhang J J, et al. Early activation of high volu-me fly ash by ternary activator and its activation mechanism[J]. Journal of Environmental Management, 2020, 267(1).Doi: 10.1016/j.jenvman.2020.110638.

doi: 10.1016/j.jenvman.2020.110638 |

| [1] | LIU Xinlong, YANG Zhenyu, HAO He, LIU Shuxin, WU Chenyang, WANG Xingli, MA Qingqing. Study on shaped 4A zeolite synthesized with aluminum extraction residue by fly ash [J]. Inorganic Chemicals Industry, 2025, 57(3): 78-85. |

| [2] | LI Chao, WANG Liping, GAO Guimei, ZHANG Yunfeng, HONG Yu, LIU Darui, XU Lijun, CUI Yongjie. Study on reaction mechanism of acid leaching lithium from circulating fluidized bed fly ash [J]. Inorganic Chemicals Industry, 2025, 57(3): 101-107. |

| [3] | ZHAO Feiyan, ZHANG Xiaodong, DU Yanxia, WANG Qiang, LI Xiaoyan. Preparation technology and research progress of fly ash ceramsite [J]. Inorganic Chemicals Industry, 2024, 56(4): 16-23. |

| [4] | LI Kuai, LI Zhaoshuai, DONG Tingxuan, LI Dan, GUO Shengwei, HAN Fenglan. Study on effect of wet magnetic separation on distribution of Fe and heavy metal in fly ash [J]. Inorganic Chemicals Industry, 2024, 56(4): 98-104. |

| [5] | LI Qiaoyun, HUANG Xiuxing, WEI Wenye, CHEN Zhen. Study on adsorption of methylene blue by activated carbon with acid/alkali synergistically modified fly ash [J]. Inorganic Chemicals Industry, 2024, 56(3): 131-136. |

| [6] | ZHAO Shiyong, XIAO Yuchen, MA Qingqing, YANG Zhenni, WANG Jizhen, FAN Xiaoping. Study on adsorption of Cu(Ⅱ) on 4A zeolite synthesized by aluminum extraction residue by fly ash [J]. Inorganic Chemicals Industry, 2024, 56(10): 127-134. |

| [7] | LI Wen, WANG Wenxiang, FANG Hongsheng, WU Pingxiao. Study on effect mechanism of silicon-aluminum additives on stabilization of heavy metals in fly ash by mechanochemical stabilization method [J]. Inorganic Chemicals Industry, 2023, 55(4): 84-91. |

| [8] | SUN Zhigao, WU Yuan, YANG Xingchun, ZHANG Dongliang, WANG Mitang. Preparation and properties of high-magnesium nickel slag-fly ash based geopolymer [J]. Inorganic Chemicals Industry, 2023, 55(11): 139-146. |

| [9] | YANG Hongjun, WANG Min, GE Haiwen, QIAO Youmin, QIAO Ziyang. Study on recycling process of potassium from calcium aluminate fly ash [J]. Inorganic Chemicals Industry, 2023, 55(10): 121-127. |

| [10] | HE Wenchao,XUE Jing,WANG Wei. Research on strength and creep characteristics of concrete containing fly ash microbead [J]. Inorganic Chemicals Industry, 2023, 55(1): 124-128. |

| [11] | LIU Darui,XU Lijun,LI Shichun,CAO Kun,TU Ya,LI Wenqing,LIU Qingliang. Research progress of recovery of strategic metal lithium from fly ash [J]. Inorganic Chemicals Industry, 2023, 55(1): 56-63. |

| [12] | LEI Ming,ZHU Hanyu,LIU Zilong,CHEN Guopeng,YUAN Junsheng. Distribution and speciation of heavy metals in hardened solid of net slurry co?disposed by cement kiln [J]. Inorganic Chemicals Industry, 2022, 54(8): 107-113. |

| [13] | CUI Jiaxin,WANG Lianyong,LU Simeng,SUN Yanwen,WANG Rui,HE Yan,HAN Jianli. Research on performance of hydrothermally synthesized zeolite with fly ash from different producing areas [J]. Inorganic Chemicals Industry, 2022, 54(5): 96-100. |

| [14] | CUI Jiaxin,WANG Lianyong,LI Yao,HE Yan,WANG Rui,HAN Jianli. Preparation and properties characterization of water quenching slag-fly ash based 4A zeolite [J]. Inorganic Chemicals Industry, 2022, 54(4): 135-140. |

| [15] | LI Yajiao,ZHAO Yiwei,JU Kai,TANG Renlong,LI Longqing,SHAO Xiaoping,ZHANG Gaofeng,REN Wuang. Study on optimization of extraction conditions in process of determination of ammonia content in fly ash based on response surface method [J]. Inorganic Chemicals Industry, 2022, 54(4): 145-151. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||