| [1] |

LIU Kailong, ZHU Kongyi, GUO Chunlei, MA Xiaobiao, WANG Yujian, SHENG Qiang, LI Xiang, WANG Yinbin, JIN Fengying.

Effects of process condition on performance of diesel aromatic to light aromatic

[J]. Inorganic Chemicals Industry, 2024, 56(6): 139-146.

|

| [2] |

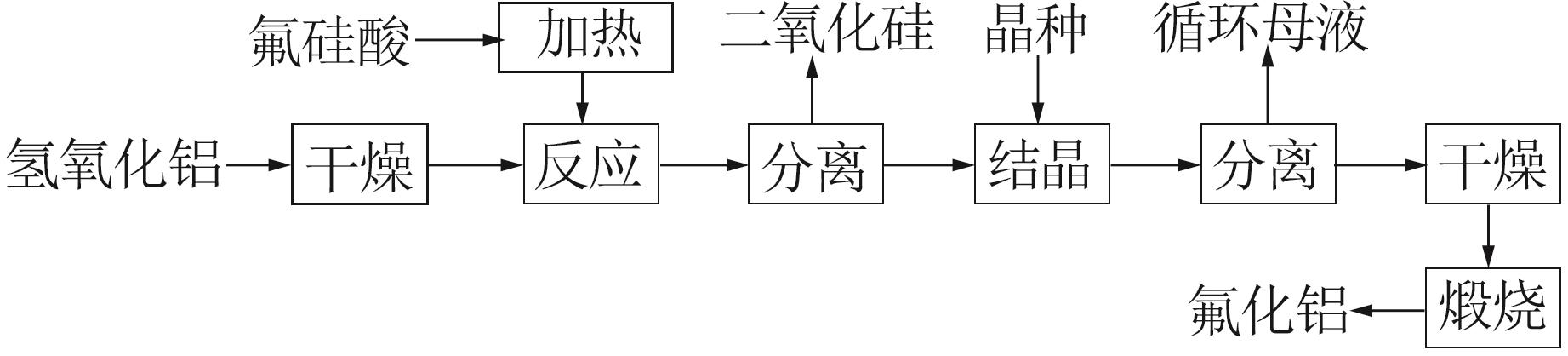

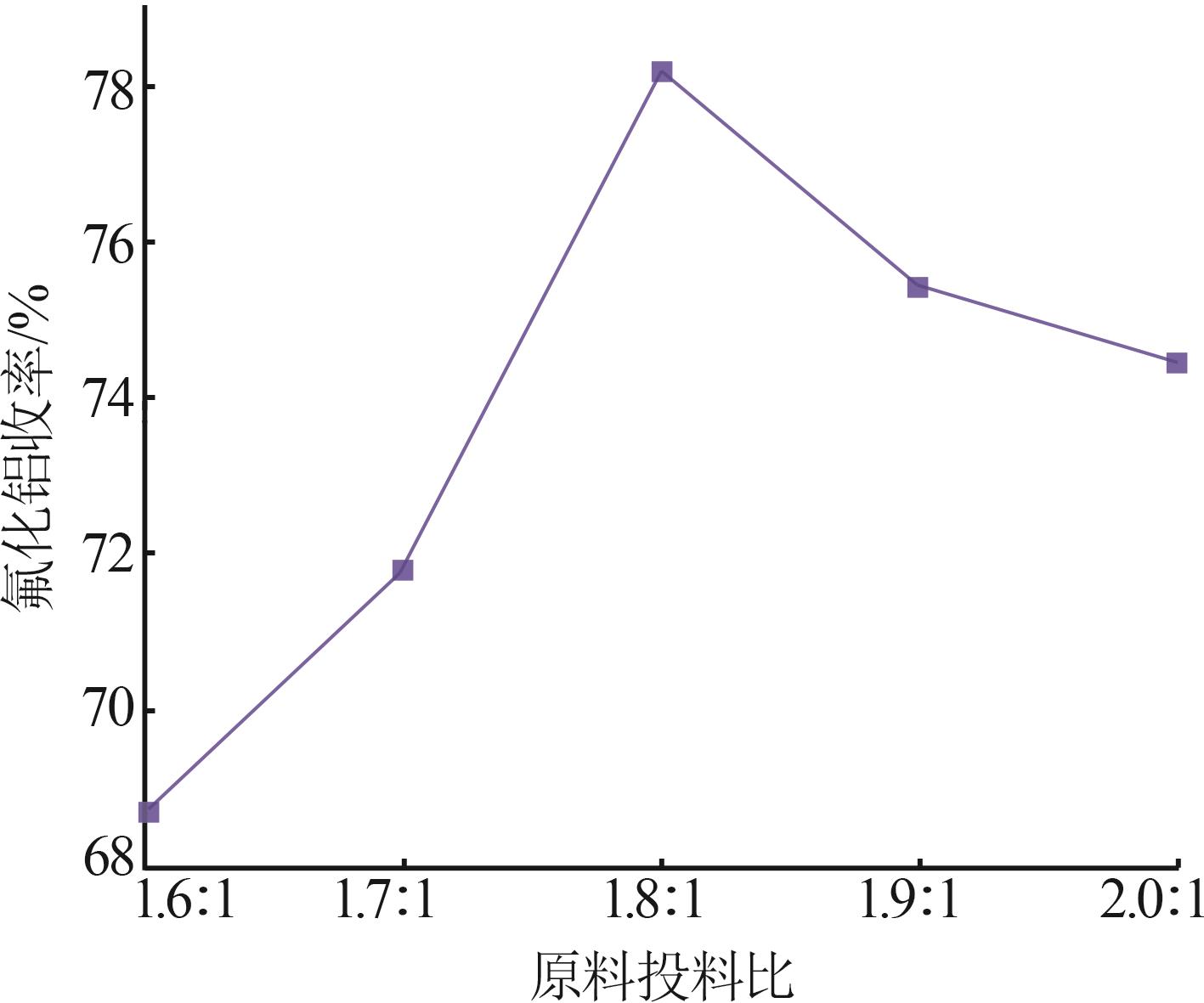

WANG Jianping, XUE Xujin, XUE Fengfeng.

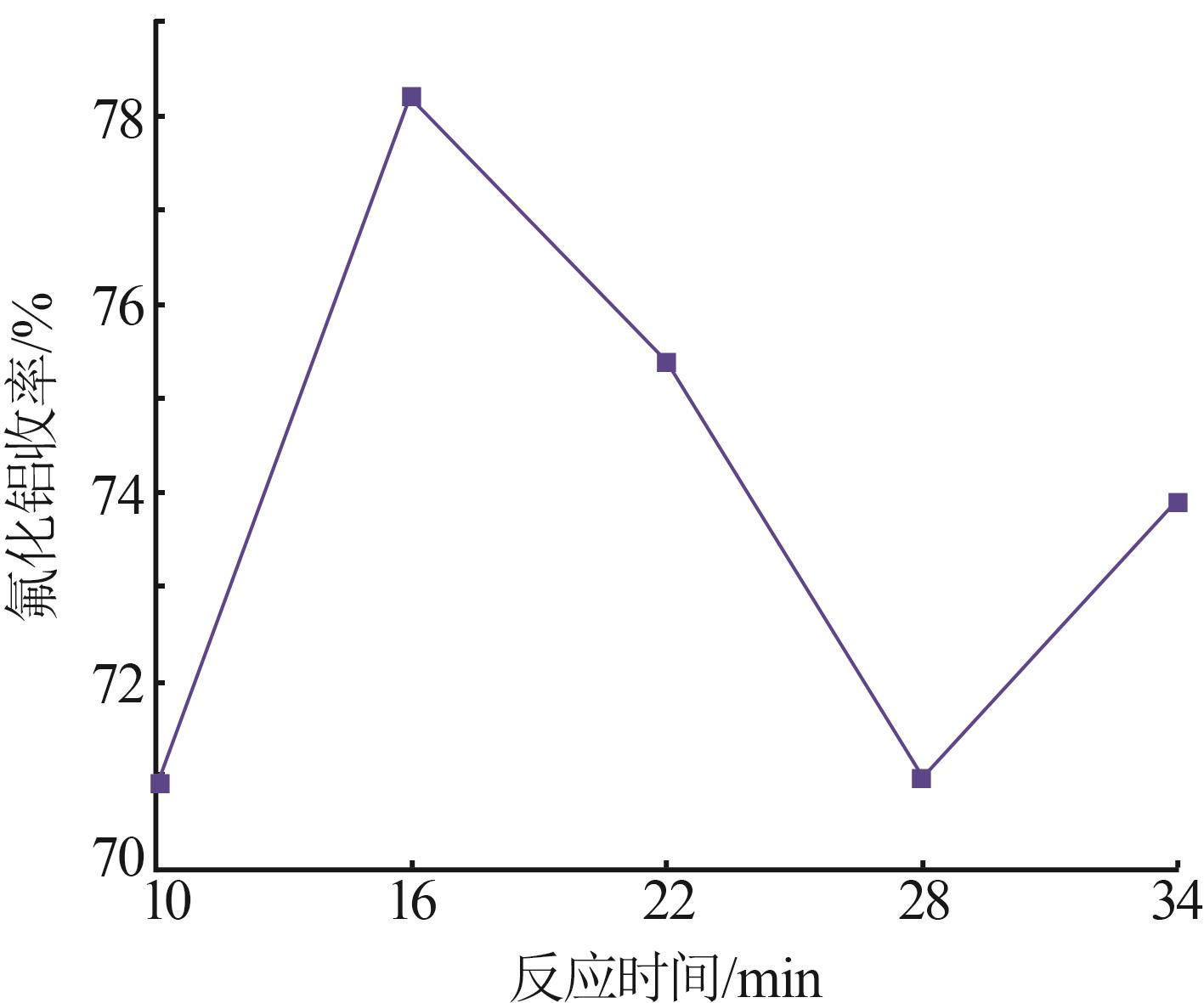

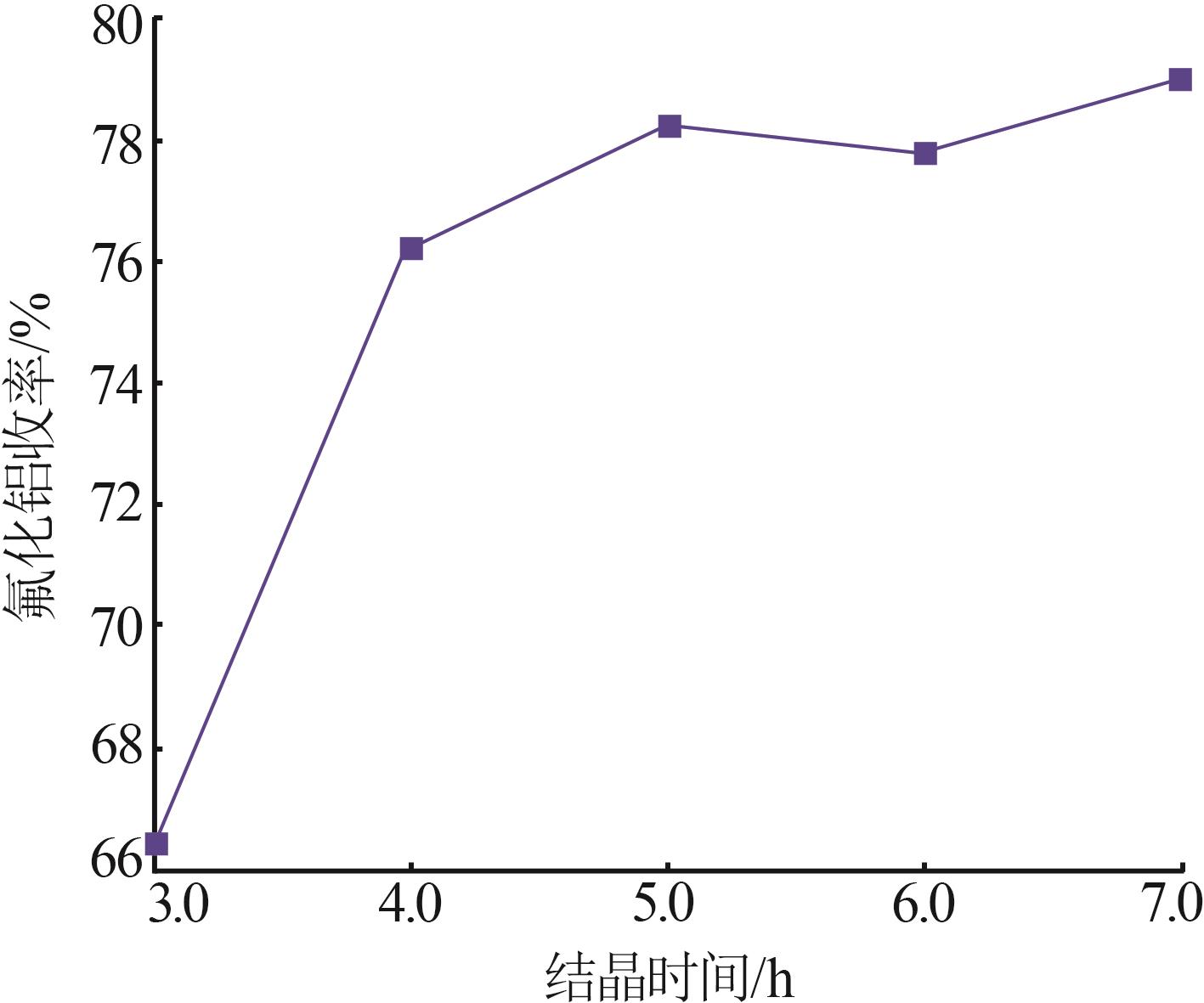

Study on new process of preparing high-purity aluminium fluoride from fluorosilicic acid

[J]. Inorganic Chemicals Industry, 2024, 56(3): 86-90.

|

| [3] |

YANG Yong, CHEN Haiyang, LI Yukun, FAN Zongliang, LI Guixian, DUAN Zhiqiang, ZHAO Yu, WANG Dongliang.

Progress of process development and industrial application for anhydrous hydrogen fluoride and aluminum fluoride

[J]. Inorganic Chemicals Industry, 2023, 55(9): 17-25.

|

| [4] |

YUAN Jinghua, WU Junhu, YANG XiuShan, XU Dehua, ZHANG Zhiye.

Research on process of production ammonium dihydrogen phosphate by ammonia purification of nitro-phosphoric acid

[J]. Inorganic Chemicals Industry, 2023, 55(9): 50-56.

|

| [5] |

FANG Weicheng,CHENG Xingxing,SUN Changrong.

Optimization of preparation of sludge/fly ash composite ceramsite filler materials by response surface methodology

[J]. Inorganic Chemicals Industry, 2022, 54(9): 119-125.

|

| [6] |

QIE Zhijia,DONG Weibing,DU Jingling,MA Shengkui,WANG Gang.

Study on yield of KCl prepared by cold crystallization of low?sodium carnallite

[J]. Inorganic Chemicals Industry, 2022, 54(5): 72-78.

|

| [7] |

Zhang Xiaoxia.

Study on preparation process of silicon tetrafluoride from fluosilicic acid and electric lime

[J]. Inorganic Chemicals Industry, 2021, 53(9): 88-91.

|

| [8] |

Wang Xiheng,Sun Wenzhe,Zhang Ling.

Research progress in production process of silicon tetrafluoride

[J]. Inorganic Chemicals Industry, 2020, 52(1): 35-38.

|

| [9] |

Hao Jiantang.

Study on aluminum fluoride pressurized crystallization technology

[J]. Inorganic Chemicals Industry, 2019, 51(9): 57-60.

|

| [10] |

Hao Jiantang.

Study on producing anhydrous hydrogen fluoride by fluorosilicic acid and magnesium oxide and combined production of high quality magnesium sulfate

[J]. Inorganic Chemicals Industry, 2019, 51(8): 40-43.

|

| [11] |

ZHOU Jian-Min, CHEN Yu-Ning, TAN Li-Quan, LI Ze-Sheng, NIU Xian-Chun.

Study on process of alkaline leaching for acidic preparation of nano-silica by oil shale ash

[J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(2): 53-.

|

| [12] |

LI Xia.

Preparation of high purity potassium fluoride and silica by fluorosilicic acid

[J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(12): 55-.

|

| [13] |

MI Jun-Lin, HUANG Hui-Tao, SUN Xin-Hua.

Study on preparation of new lithium salt—lithium-difluoro(oxalato) borate

[J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(10): 32-.

|

| [14] |

ZHOU Jian-Min, TAN Li-Quan, YU Mei, NIU Xian-Chun, LIN Zhuo-Xian, WANG Jian.

Study on alkaline preparation of ultrafine silica from oil shale ash

[J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(10): 56-.

|

| [15] |

YANG Zhao-Juan, WANG Shun-Qiang, ZHAO Yan-Long, WANG Ji-Yang.

Research on preparation process of sodium carbonate monohydrate

from sodium carbonate decahydrate tailings

[J]. INORGANICCHEMICALSINDUSTRY, 2014, 46(4): 56-.

|

), LONG Bingwen1, ZHANG Yi1, DENG Fuli1, DAI Yafen1, LIU Shaofeng2, DING Yigang1(

), LONG Bingwen1, ZHANG Yi1, DENG Fuli1, DAI Yafen1, LIU Shaofeng2, DING Yigang1( )

)