| 1 |

田原宇,乔英云,刘欣梅,等.碳中和约束下的石油炼制技术与产业发展动向及展望[J].中外能源,2022,27(7):9-16.

|

|

TIAN Yuanyu, QIAO Yingyun, LIU Xinmei,et al.Development trends and prospects of petroleum refining technology and industry under the constraints of carbon neutrality[J].Sino-Global Energy,2022,27(7):9-16.

|

| 2 |

郭春垒,万馨,秦培尧.全球首创:柴油吸附分离技术实现成功应用让成品油不过剩[J].中国石油石化,2020(15):56-57.

|

|

GUO Chunlei, WAN Xin, QIN Peiyao.The first in the world:The successful application of diesel oil adsorption separation technology makes the refined oil not surplus[J].China Petrochem,2020(15):56-57.

|

| 3 |

郭春垒,范景新,臧甲忠,等.柴油高值化综合利用技术发展现状及分析[J].化工进展,2018,37(11):4205-4213.

|

|

GUO Chunlei, FAN Jingxin, ZANG Jiazhong,et al.Development of high-value utilization technologies of diesel[J].Chemical Industry and Engineering Progress,2018,37(11):4205-4213.

|

| 4 |

PENG Chong, ZHOU Zhiming, FANG Xiangchen,et al.Thermodynamics and kinetics insights into naphthalene hydrogenation over a Ni-Mo catalyst[J].Chinese Journal of Chemical Engineering,2021,39:173-182.

|

| 5 |

BIE Shiquan, JIANG Hongbo, WANG Wei,et al.Kinetics of naphthalene catalytic hydrogenation under high temperature and high pressure[J].Petroleum Science and Technology,2020,38(3):266-270.

|

| 6 |

SHAN Shufeng, ZENG Xingye, WU Yuesong,et al.Synergism between Mo/Ni and acidic sites on NiMoS/ZSM-5 for heavy aromatic hydrodealkylation[J].Catalysis Letters,2022,152(11):3375-3387.

|

| 7 |

KIM T, KIM G P, JANG J,et al.An investigation on the selective hydrodealkylation of C9 + aromatics over alkali-treated Pt/H-ZSM-5 zeolites[J].Catalysis Science & Technology,2016,6(14):5599-5607.

|

| 8 |

SHAN Shufeng, TIAN Yiting, CHEN Feifei,et al.Acidity,crystallite size and pore structure as key factors influencing 1,3,5-trimethylbenzene hydrodealkylation performance of NiMoS/ZSM-5[J].Catalysis Surveys from Asia,2022,26(1):35-45.

|

| 9 |

陈俊森,彭冲,方向晨,等.NiMo/HY催化剂上四氢萘加氢裂化反应网络与热力学平衡分析[J].化工学报,2018,69(2):709-717.

|

|

CHEN Junsen, PENG Chong, FANG Xiangchen,et al.Reaction network and thermodynamic equilibrium for tetralin hydrocracking over Ni Mo/HY catalyst[J].CIESC Journal,2018,69(2):709-717.

|

| 10 |

LAREDO G C, PÉREZ-ROMO P, VEGA-MERINO P M,et al.Effect of the catalytic system and operating conditions on BTX formation using tetralin as a model molecule[J].Applied Petrochemical Research,2019,9(3):185-198.

|

| 11 |

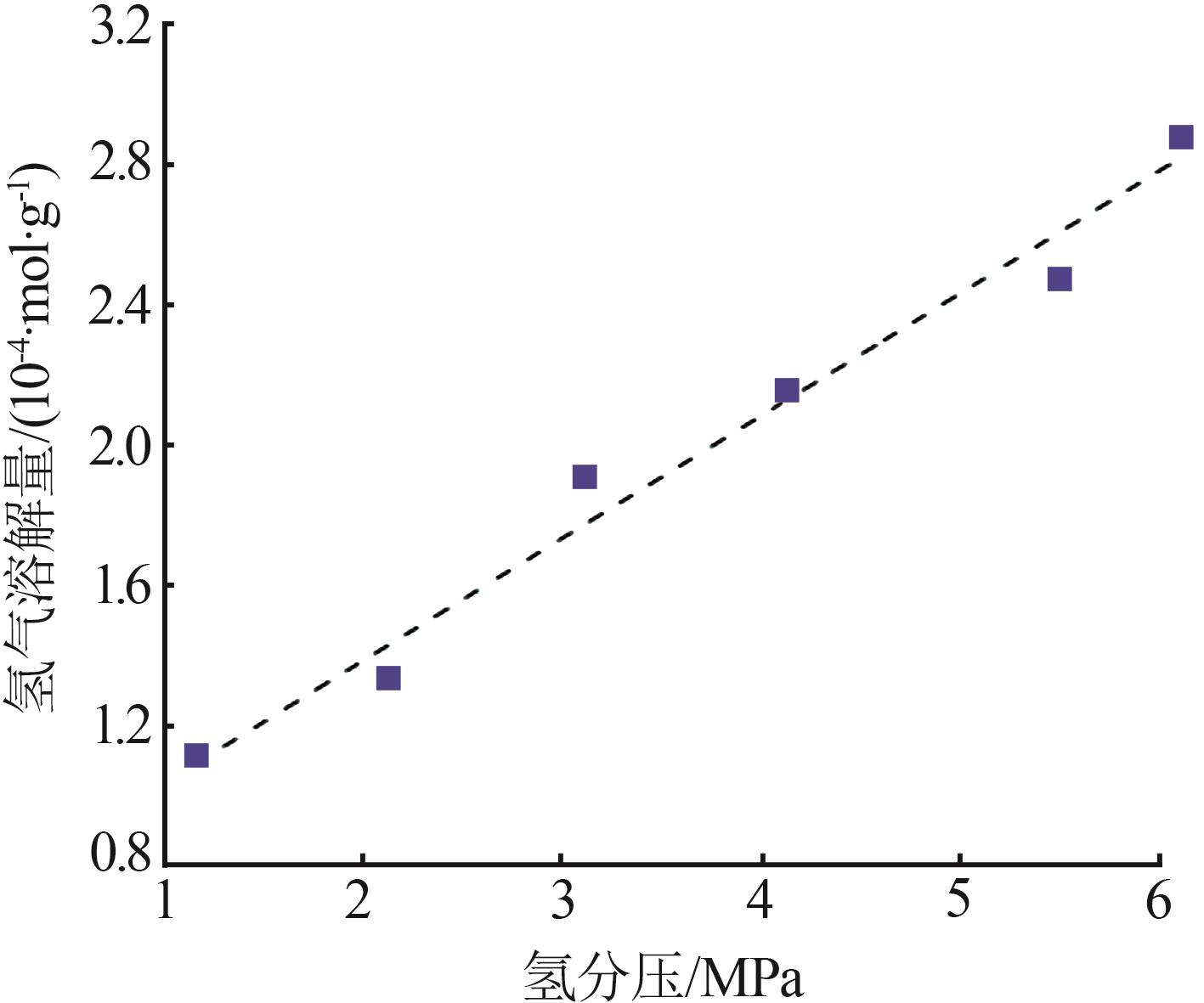

徐旋,宋奇,姜向东,等.加氢饱和C10 +重芳烃的轻质化反应工艺考察[J].化学反应工程与工艺,2017,33(3):261-268.

|

|

XU Xuan, SONG Qi, JIANG Xiangdong,et al.Investigation on process of conversion of hydrogenation saturated C10 + heavy aromatics to light aromatics[J].Chemical Reaction Engineering and Technology,2017,33(3):261-268.

|

| 12 |

靳凤英,于海斌,王亚权,等.镍对Pt/γ-Al2O3催化剂稠环芳烃选择性加氢性能的影响[J].无机盐工业,2022,54(10):141-148.

|

|

JIN Fengying, YU Haibin, WANG Yaquan,et al.Effect of Ni on selective hydrodegenation of polyaromatic hydrocarbons of Pt/γ-Al2O3 catalyst[J].Inorganic Chemicals Industry,2022,54(10):141-148.

|

| 13 |

梁金鹏,徐国峰,郭雷.C10 +重质芳烃轻质化工艺技术研究[J].化学工程,2022,50(2):75-78.

|

|

LIANG Jinpeng, XU Guofeng, GUO Lei.Study on conversion process of C10 + heavy aromatics to light aromatics[J].Chemical Engineering (China),2022,50(2):75-78.

|

| 14 |

KOSTYNIUK A, BAJEC D, LIKOZAR B.Catalytic hydrocracking reactions of tetralin as aromatic biomass tar model compound to benzene/toluene/xylenes(BTX) over zeolites under ambient pressure conditions[J].Journal of Industrial and Engineering Chemistry,2021,96:130-143.

|

| 15 |

JIN T, XIA D H, XIANG Y Z,et al.The effect of metal introduced over ZSM-5 zeolite for C9 heavy aromatics hydrodealkylation[J].Petroleum Science and Technology,2009,27(16):1821-1835.

|

| 16 |

刘航,臧甲忠,范景新,等.重芳烃轻质化催化剂n(Ni)/n(Ni+Mo)的优化与分析[J].无机盐工业,2021,53(12):140-145.

|

|

LIU Hang, ZANG Jiazhong, FAN Jingxin,et al.Optimization and analysis of n(Ni)/n(Ni+Mo) of heavy aromatics to light aromatics catalyst[J].Inorganic Chemicals Industry,2021,53(12):140-145.

|

| 17 |

刘航,臧甲忠,范景新,等.Sn和Zn对重芳烃轻质化NiMo/β催化剂性能的影响[J].化工进展,2021,40(7):3909-3914.

|

|

LIU Hang, ZANG Jiazhong, FAN Jingxin,et al.Effects of Sn and Zn on the properties of heavy aromatic to light aromatic NiMo/β catalyst[J].Chemical Industry and Engineering Progress,2021,40(7):3909-3914.

|

| 18 |

赵闯,范景新,郭春垒,等.柴油芳烃吸附剂的失活研究[J].无机盐工业,2020,52(8):98-102.

|

|

ZHAO Chuang, FAN Jingxin, GUO Chunlei,et al.Study on deactivation of diesel aromatic adsorbent[J].Inorganic Chemicals Industry,2020,52(8):98-102.

|

| 19 |

王毅.Ni/γ-Al2O3还原条件的优化及其催化辛烯醛加氢反应性能研究[J].精细石油化工,2020,37(5):1-5.

|

|

WANG Yi.Optimization of reduction conditions of Ni/γ-Al2O3 and its catalytic performance for 2-ethyl-2-hexenal hydrogenation[J].Speciality Petrochemicals,2020,37(5):1-5.

|

| 20 |

柴磊昌,施岩,吉豪杰,等.还原条件对磷化镍催化剂的HDN性能影响[J].当代化工,2014,43(4):498-500.

|

|

CHAI Leichang, SHI Yan, JI Haojie,et al.Effect of reduction conditions on HDN performance of nickel phosphide catalyst[J].Contemporary Chemical Industry,2014,43(4):498-500.

|

| 21 |

段艳,王欣,侯凯湖.还原条件对Ni-Mo非负载催化剂选择性加氢脱氧的影响[J].高校化学工程学报,2016,30(6):1451-1457.

|

|

DUAN Yan, WANG Xin, HOU Kaihu.Effects of reduction conditions on unsupported Ni-Mo composite oxide catalysts for selective hydrodeoxygenation[J].Journal of Chemical Engineering of Chinese Universities,2016,30(6):1451-1457.

|

| 22 |

米星.萘加氢合成十氢萘γ-Al2O3负载镍催化剂催化性能的研究[D].北京:北京石油化工学院,2017.

|

|

MI Xing.Catalytic characteristics of Ni supported γ-Al2O3 catalysts for naphthalene hydrogenation to decalin[D].Beijing:Beijing Institute of Petrochemical Technology,2017.

|

| 23 |

万壮.直馏柴油加氢裂化多产乙烯料催化剂的制备及应用研究[D].北京:中国石油大学(北京),2021.

|

|

WAN Zhuang.Study on the preparation and application of catalyst for straight-Run diesel oil hydrocracking to ethylene cracking feedstock[D].Beijing:China University of Petroleum(Beijing),2021.

|

| 24 |

LAREDO SANCHEZ G C, QUINTANA SOLÓRZANO R, ARZATE BARBOSA E,et al.Impact of variables on the naphthalene hydrogenation for the tetralin formation towards BTX production[J].International Journal of Oil,Gas and Coal Technology,2020,23(4):504.

|

| 25 |

WANG Yuefa, MAO Zaisha, CHEN Jiayong.The relationship between hysteresis and liquid flow distribution in trickle beds[J].Chinese Journal of Chemical Engineering,1999,7(3):221-229.

|

| 26 |

ALSOLAMI B H, BERGER R J, MAKKEE M,et al.Catalyst performance testing in multiphase systems:Implications of using small catalyst particles in hydrodesulfurization[J].Industrial & Engineering Chemistry Research,2013,52(26):9069-9085.

|

| 27 |

方向晨.加氢裂化工艺与工程[M].2版.北京:中国石化出版社,2017.

|

| 28 |

白晓波,王胜,任富强,等.合成气完全甲烷化固定床反应器数值模拟[J].高校化学工程学报,2015,29(4):955-962.

|

|

BAI Xiaobo, WANG Sheng, REN Fuqiang,et al.Numerical simulation of a fixed-bed reactor for total methanation of syngas[J].Journal of Chemical Engineering of Chinese Universities,2015,29(4):955-962.

|

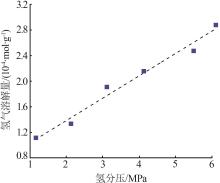

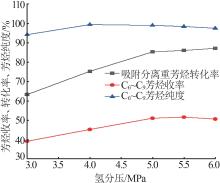

| 29 |

方向晨.氢分压对加氢裂化过程的影响[J].石油学报(石油加工),1999,15(5):6-13.

|

|

FANG Xiangchen.Effects of hydrogen partial pressure on hydrocracking process[J].Acta Petrolei Sinica(Petroleum Processing Section),1999,15(5):6-13.

|

), ZHU Kongyi3, GUO Chunlei1, MA Xiaobiao1, WANG Yujian1, SHENG Qiang2, LI Xiang2, WANG Yinbin1, JIN Fengying1

), ZHU Kongyi3, GUO Chunlei1, MA Xiaobiao1, WANG Yujian1, SHENG Qiang2, LI Xiang2, WANG Yinbin1, JIN Fengying1