Inorganic Chemicals Industry ›› 2021, Vol. 53 ›› Issue (9): 88-91.doi: 10.19964/j.issn.1006-4990.2021-0126

• Environment·Health·Safety • Previous Articles Next Articles

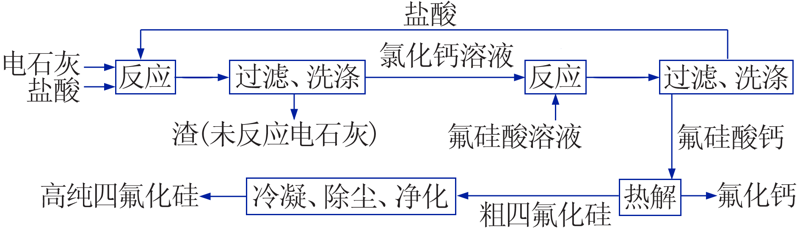

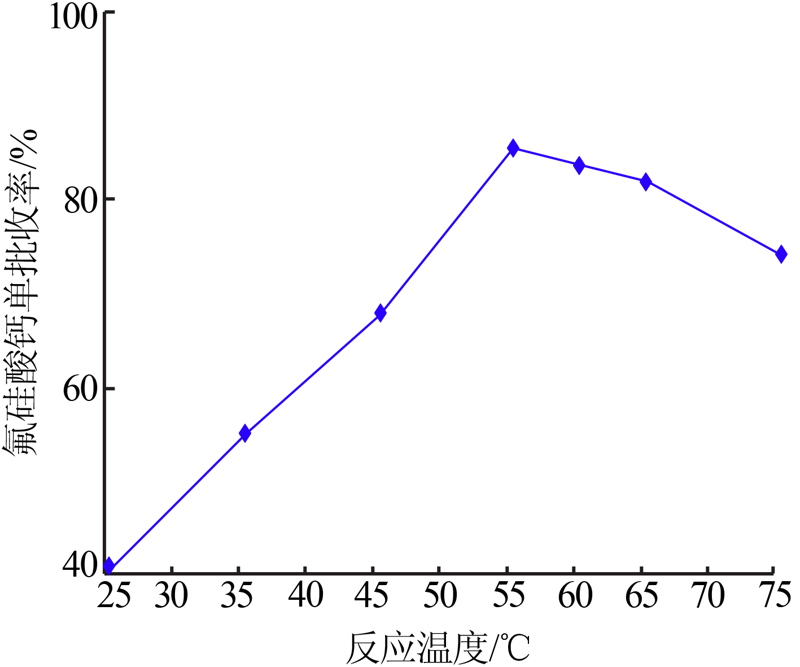

Study on preparation process of silicon tetrafluoride from fluosilicic acid and electric lime

- DO-Fluoride Chemicals Co.Ltd,Jiaozuo 454001,China