Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (11): 51-58.doi: 10.19964/j.issn.1006-4990.2024-0003

• New energy battery materials • Previous Articles Next Articles

Effect of annealing temperature on phase structure and electrochemical performance of hydrogen storage alloys for automotive batteries

HU Wenjuan1,2( ), SHEN Xiaozhong1,2, WANG Rujia3, LU Lu1,2, ZOU Lianli4

), SHEN Xiaozhong1,2, WANG Rujia3, LU Lu1,2, ZOU Lianli4

- 1.Department of Intelligent Equipment and Automotive Engineering,Wuxi Vocational Institute of Commerce,Wuxi 214153,China

2.Jiangsu Province Engineering Research Center of Key Components for New Energy Vehicle,Wuxi 214153,China

3.School of automobile and traffic engineering,Jiangsu University of Technology,Changzhou 213001,China

4.Institute for Advanced Materials,School of Materials Science and Engineering,Jiangsu University,Zhenjiang 212013,China

-

Received:2024-01-03Online:2024-11-10Published:2024-11-27

CLC Number:

Cite this article

HU Wenjuan, SHEN Xiaozhong, WANG Rujia, LU Lu, ZOU Lianli. Effect of annealing temperature on phase structure and electrochemical performance of hydrogen storage alloys for automotive batteries[J]. Inorganic Chemicals Industry, 2024, 56(11): 51-58.

share this article

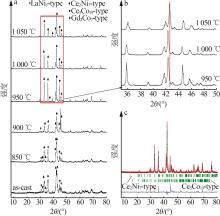

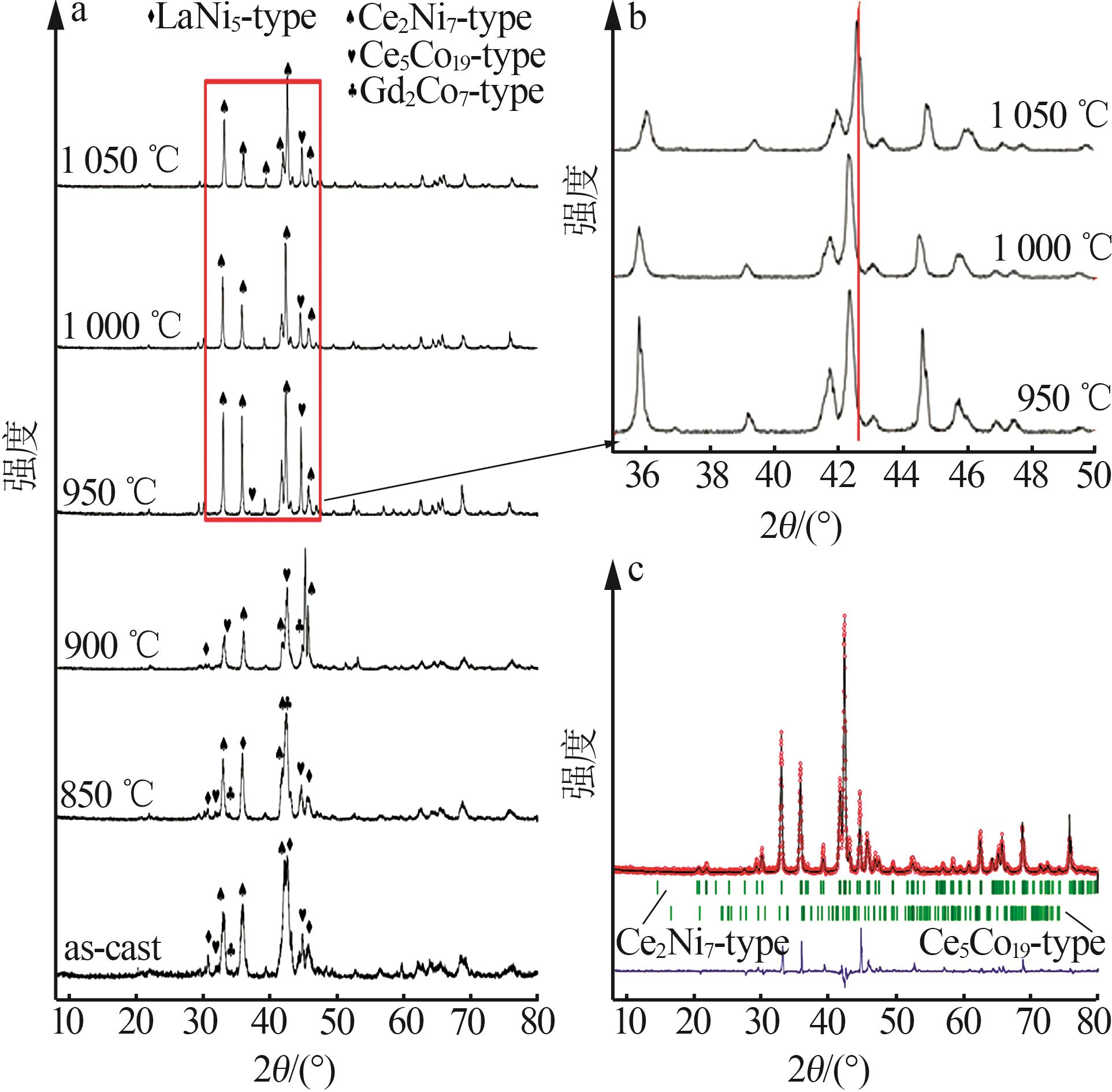

Table 1

Phase structure and parameters of Y0.2La0.8Ni3.2Al0.2Mn0.2 hydrogen storage alloys in as-cast and annealed states"

| 试样 | 相结构 | 晶格常数 | 相丰度/% | ||

|---|---|---|---|---|---|

| a/Å | c/Å | V/Å3 | |||

| 铸态 | CaCu5 | 5.020 | 3.986 | 86.5 | 22.25 |

| Ce2Ni7 | 5.001 | 24.467 | 527.6 | 41.61 | |

| Gd2Co7 | 5.048 | 36.339 | 799.2 | 20.22 | |

| Ce5Co19 | 4.936 | 48.831 | 1 025.6 | 15.92 | |

| 850 ℃退火态 | CaCu5 | 5.032 | 4.002 | 87.3 | 11.69 |

| Ce2Ni7 | 5.021 | 24.364 | 529.4 | 58.57 | |

| Gd2Co7 | 5.026 | 36.588 | 794.7 | 18.65 | |

| Ce5Co19 | 4.999 | 47.691 | 1 027.6 | 11.08 | |

| 900 ℃退火态 | CaCu5 | 5.180 | 3.981 | 86.7 | 9.67 |

| Ce2Ni7 | 5.029 | 24.334 | 530.6 | 72.97 | |

| Gd2Co7 | 5.025 | 36.228 | 788.8 | 9.02 | |

| Ce5Co19 | 4.957 | 48.864 | 1 035.4 | 8.35 | |

| 950 ℃退火态 | Ce2Ni7 | 5.026 | 24.358 | 532.5 | 93.29 |

| Ce5Co19 | 4.987 | 48.612 | 1 042.5 | 6.71 | |

| 1 000 ℃退火态 | Ce2Ni7 | 5.025 | 24.420 | 530.7 | 86.96 |

| Ce5Co19 | 4.944 | 48.880 | 1 030.2 | 13.04 | |

| 1 050 ℃退火态 | Ce2Ni7 | 4.993 | 24.303 | 522.4 | 77.97 |

| Ce5Co19 | 4.943 | 48.743 | 1 026.7 | 22.03 | |

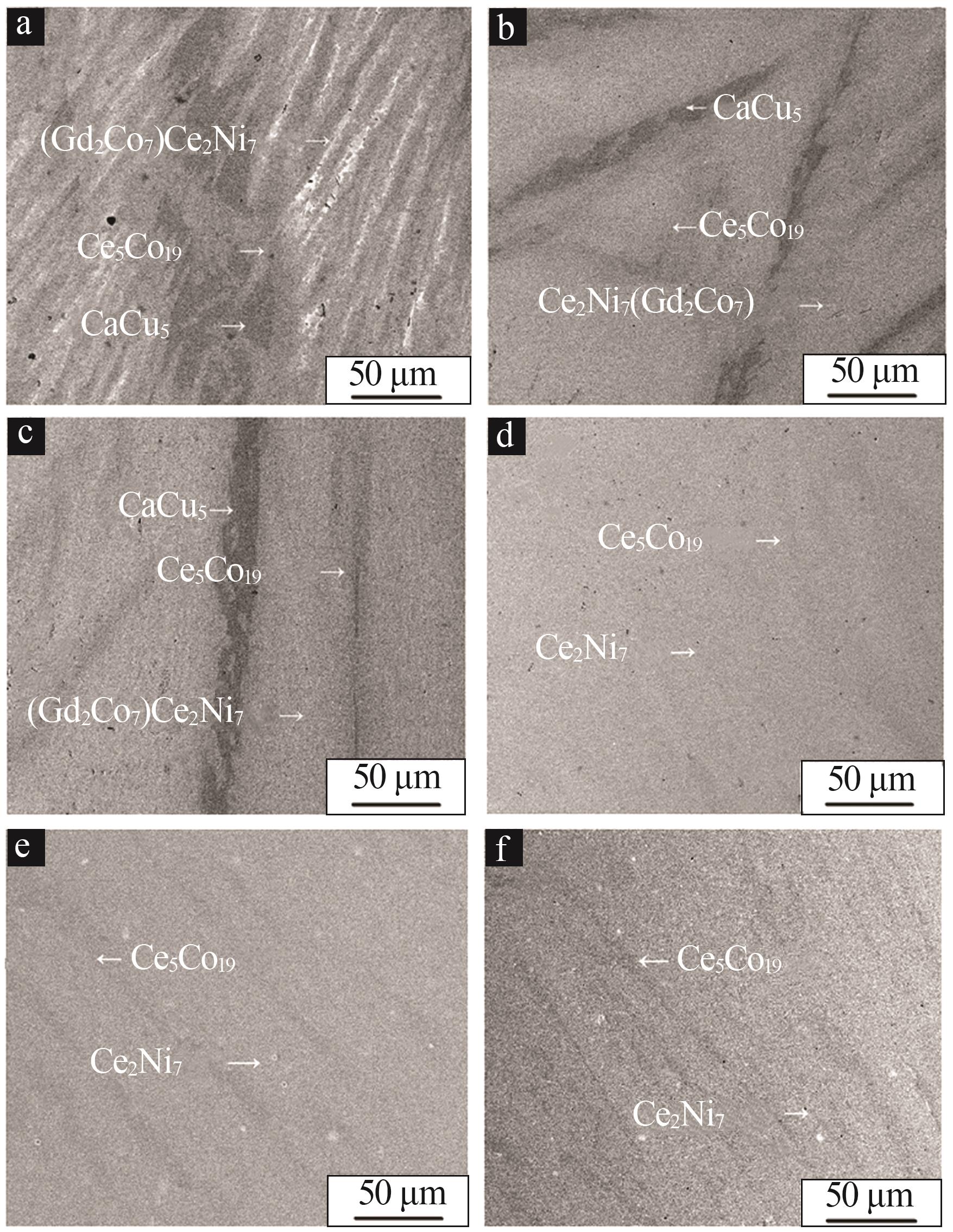

Table 2

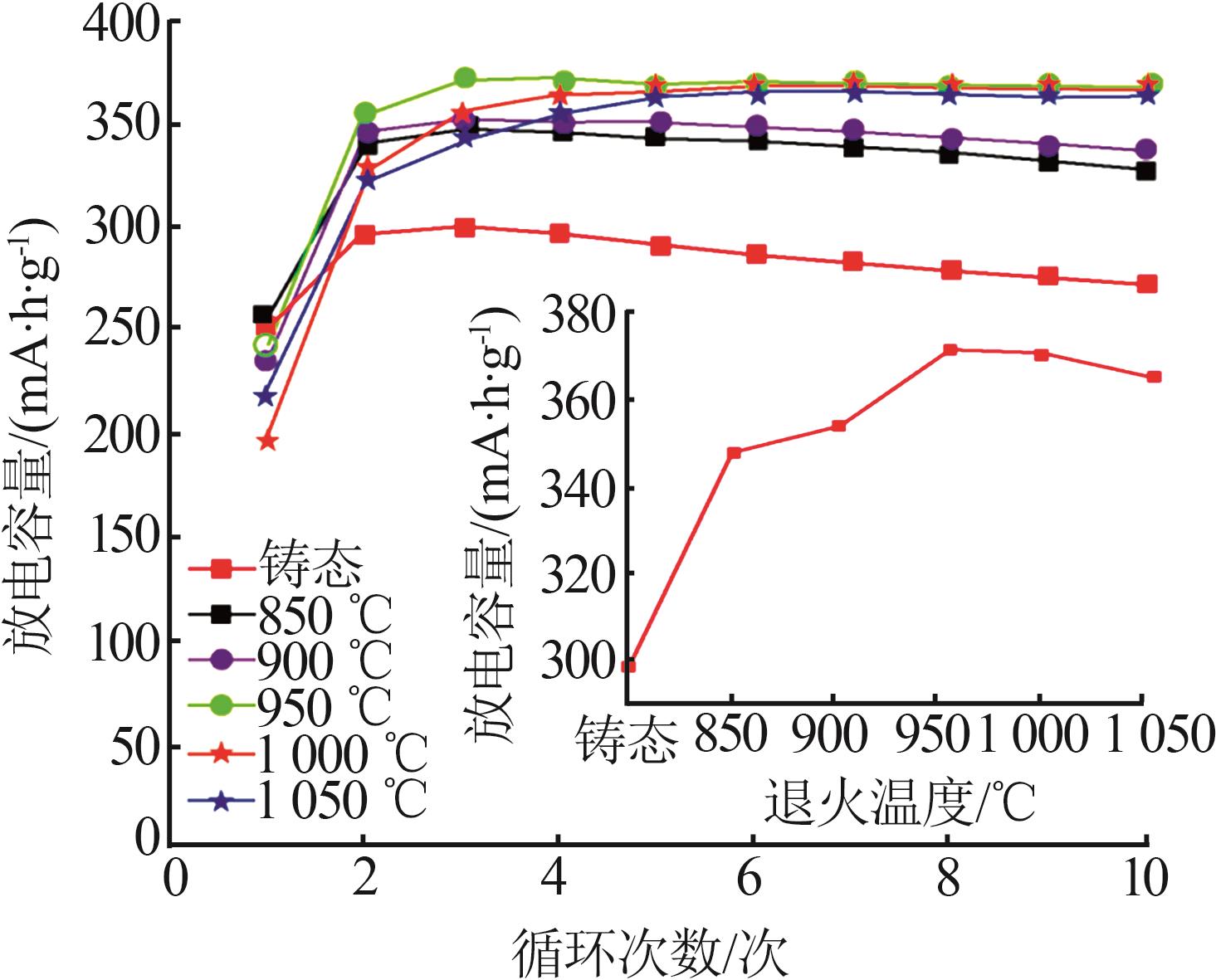

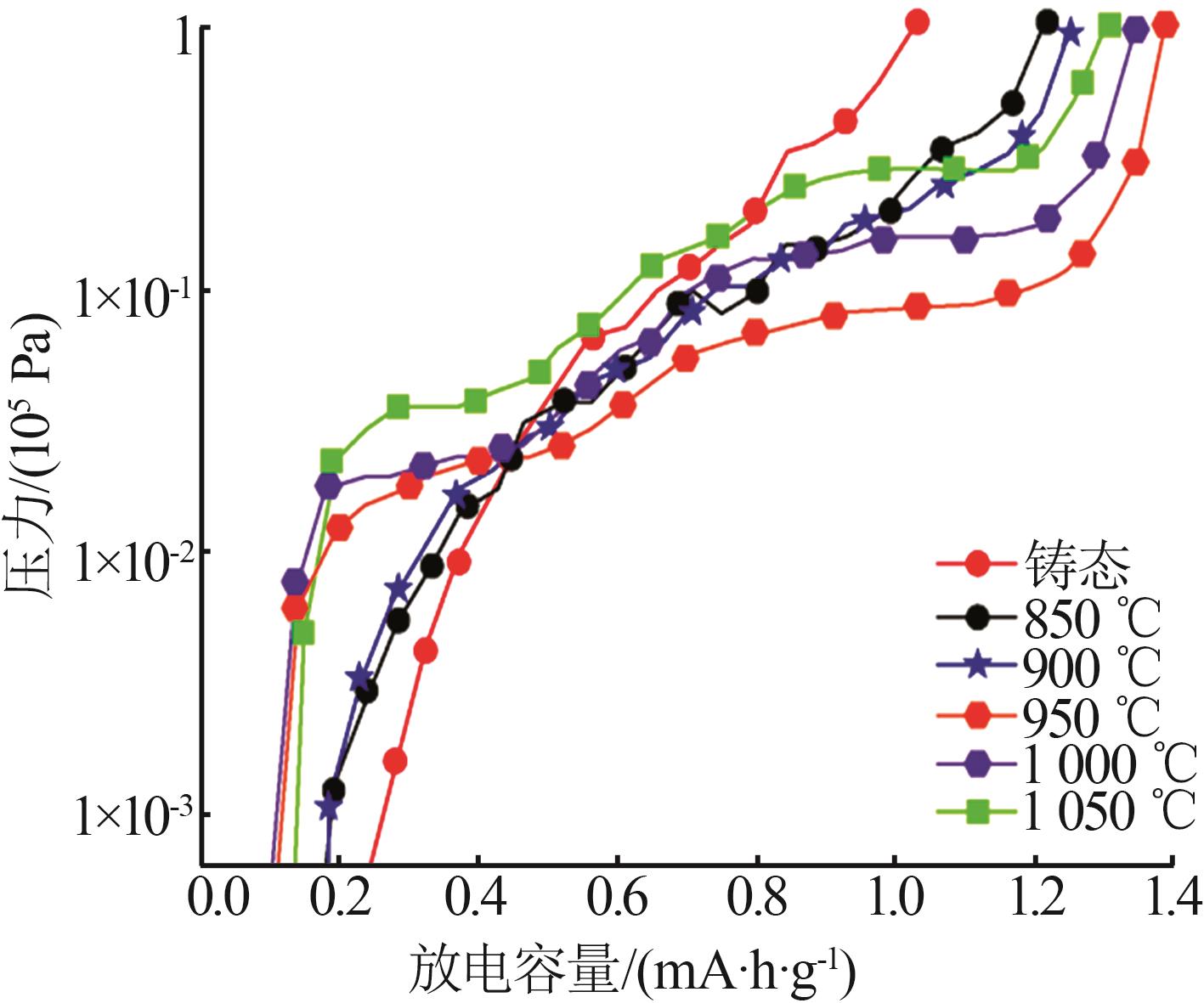

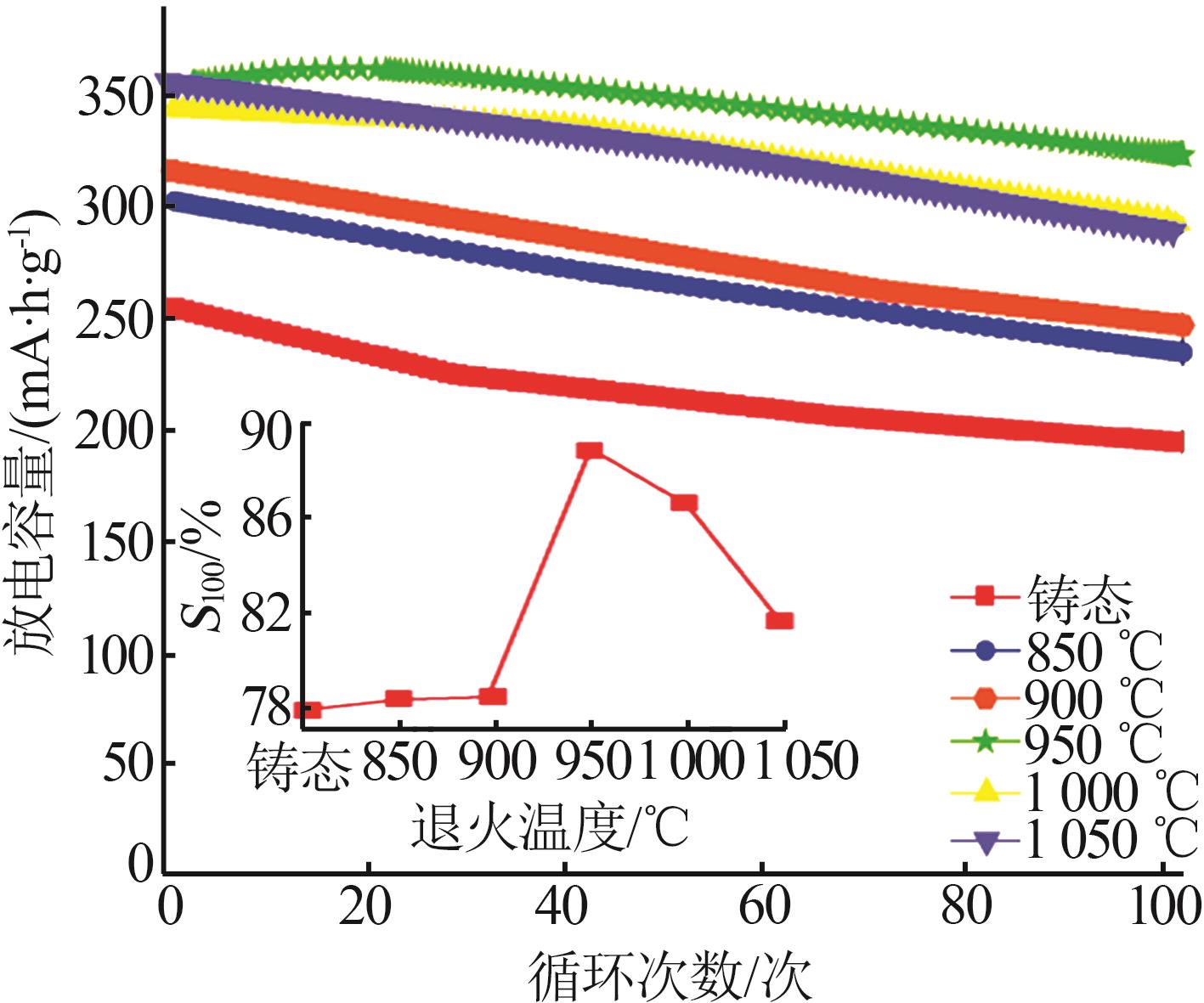

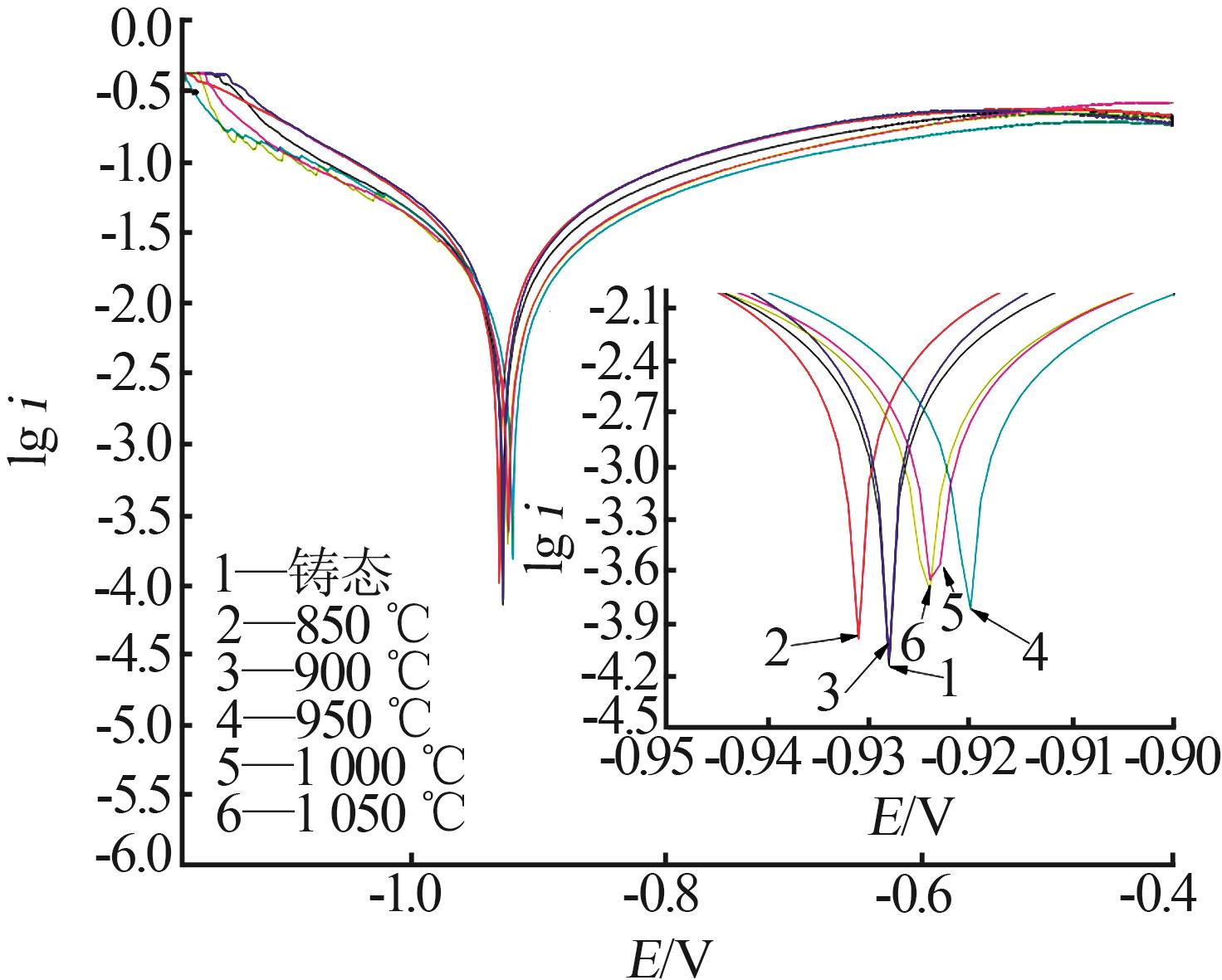

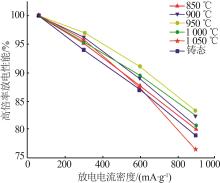

Statistical results of electrochemical parameters of Y0.2La0.8Ni3.2Al0.2Mn0.2 hydrogen storage alloys in different states"

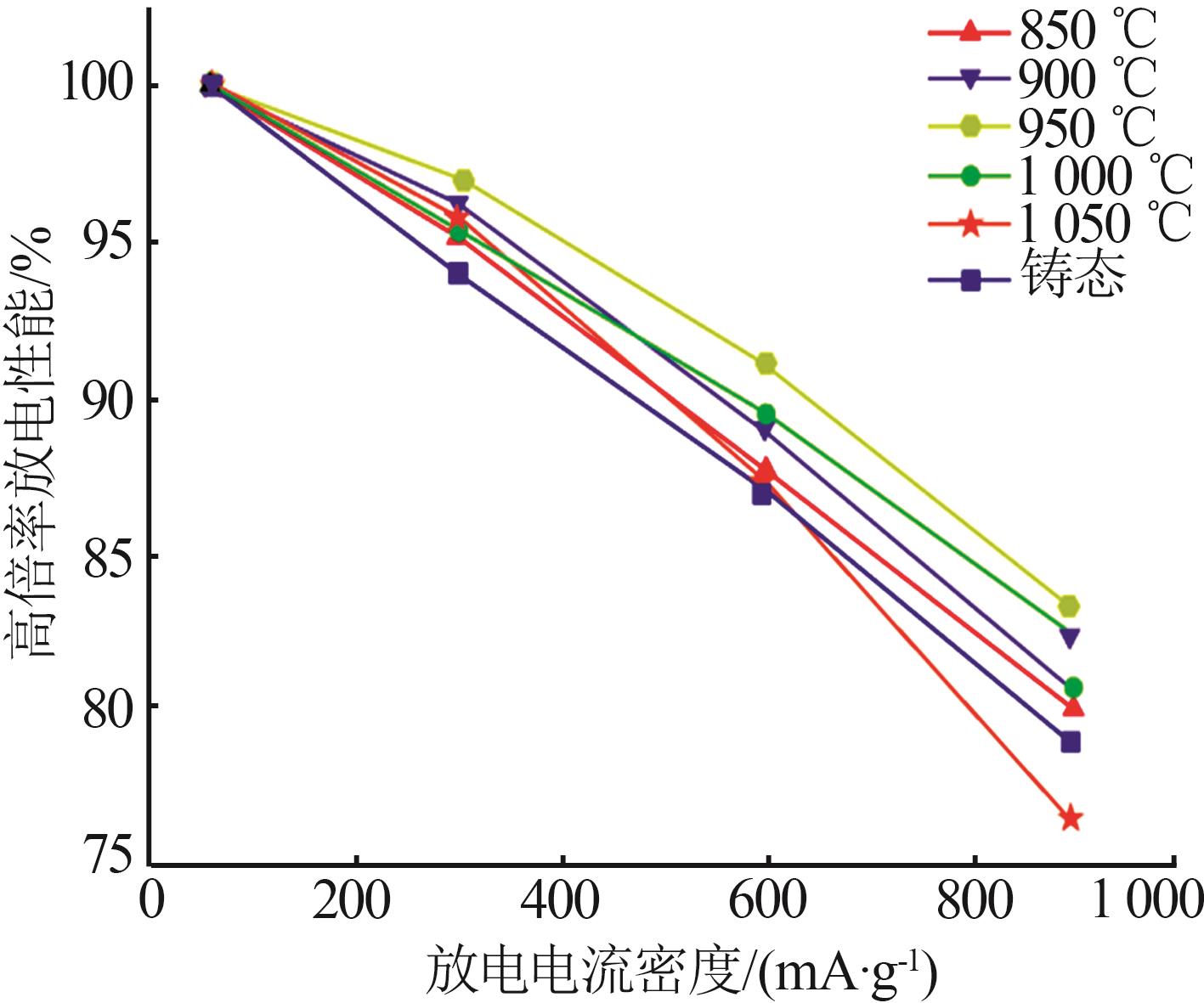

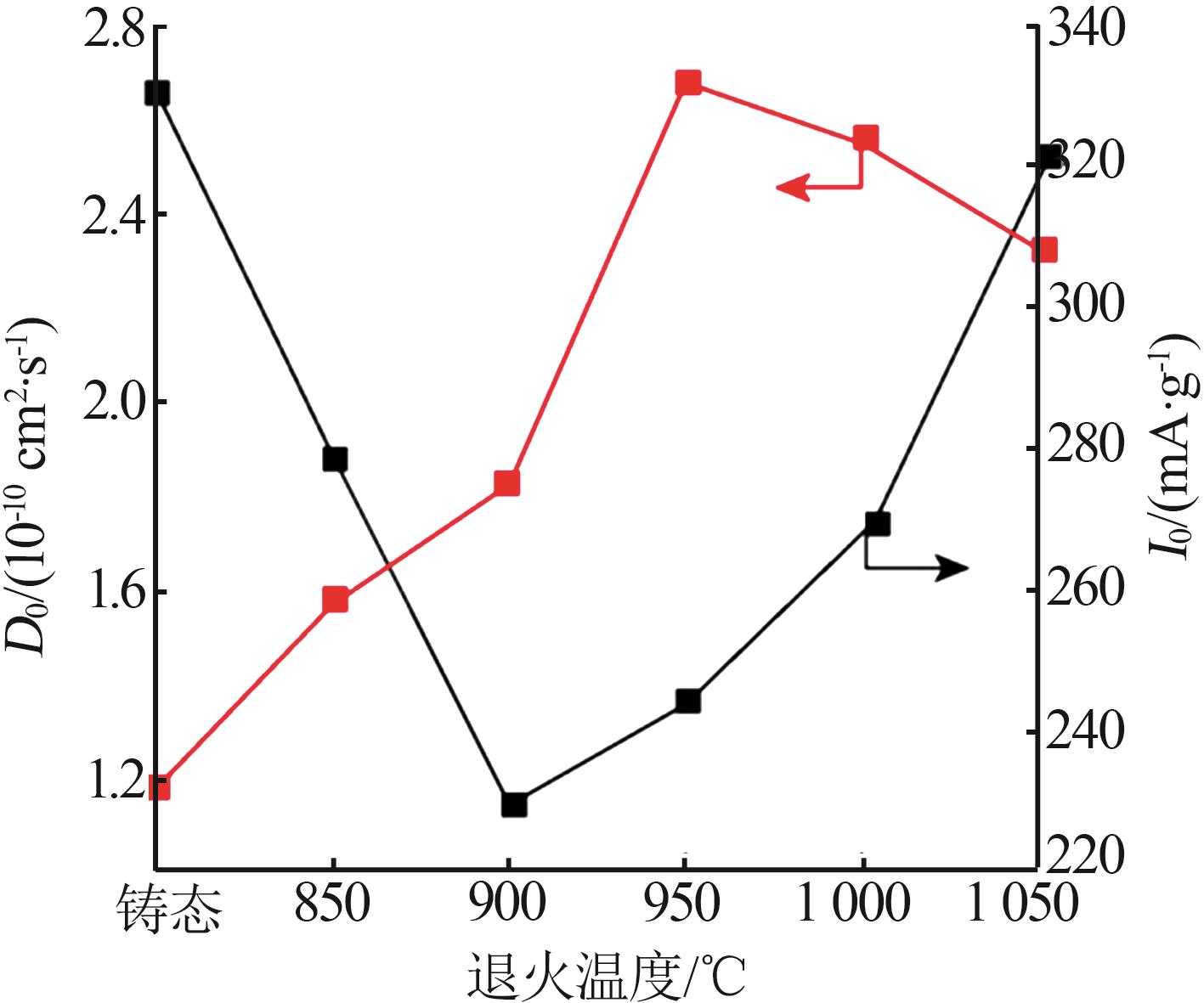

| 试样 | 活化次 数Na | 最大放电 容量Cmax/ (mA·h·g-1) | 循环稳 定性 S100/% | 高倍率放 电性能HRD900/% | 氢扩散系数D0 /(10-10 cm2·s-1) | 交换电流密度I0/(mA·g-1) |

|---|---|---|---|---|---|---|

| 铸态 | 3 | 299.3 | 78.8 | 79.9 | 1.29 | 332.0 |

850 ℃ 退火态 | 3 | 348.3 | 79.3 | 81.4 | 1.68 | 279.7 |

900 ℃ 退火态 | 3 | 354.4 | 79.4 | 83.4 | 1.93 | 231.0 |

950 ℃ 退火态 | 3 | 372.6 | 90.0 | 84.5 | 2.79 | 244.6 |

1 000 ℃ 退火态 | 5 | 371.5 | 87.6 | 81.7 | 2.67 | 270.2 |

1 050 ℃ 退火态 | 6 | 366.3 | 82.6 | 77.5 | 2.43 | 322.6 |

| 1 | LI Ruyue, LU Hang, PAN Xiangyu,et al.Improvement on cyclic stability of AB4-type La-Mg-Ni-based hydrogen storage alloys via merging Y element for nickel-metal hydride batteries[J].International Journal of Hydrogen Energy,2023,48(84):32849-32859. |

| 2 | 陶炳全,张华,杨星焕,等.汽车氢镍电池负极材料的热处理与性能研究[J].电源技术,2020,44(11):1642-1646. |

| TAO Bingquan, ZHANG Hua, YANG Xinghuan,et al.Study on heat treatment and performance of negative electrode material for vehicle NiMH battery[J].Chinese Journal of Power Sources,2020,44(11):1642-1646. | |

| 3 | 范庆科,孟庆华.汽车用La0.79Mg0.21Ni3.95储氢合金的制备与电化学性能研究[J].无机盐工业,2022,54(3):71-76. |

| FAN Qingke, MENG Qinghua.Study on preparation and electrochemical properties of La0.79Mg0.21Ni3.95 hydrogen storage alloy for vehicles[J].Inorganic Chemicals Industry,2022,54(3):71-76. | |

| 4 | 李媛,陈康莉,王文凤,等.La-Mg-Ni系A2B7型合金相结构与储氢性能研究进展[J].中国材料进展,2023,42(1):30-38,46. |

| LI Yuan, CHEN Kangli, WANG Wenfeng,et al.Investigation on phase structure and hydrogen storage properties of La-Mg-Ni-based A2B7-type alloys[J].Materials China,2023,42(1):30-38,46. | |

| 5 | 李亚琴,尚宏伟,查文珂,等.La-Mg-Ni系A2B7型电极材料的研究进展[J].电池,2022,52(6):698-702. |

| LI Yaqin, SHANG Hongwei, ZHA Wenke,et al.Research progress in La-Mg-Ni system A2B7-type electrode materials[J].Battery Bimonthly,2022,52(6):698-702. | |

| 6 | JIANG Weiqing, CHEN Yujie, HU Mengru,et al.Rare earth-Mg-Ni-based alloys with superlattice structure for electrochemical hydrogen storage[J].Journal of Alloys and Compounds,2021,887:161381. |

| 7 | 伏康康,赵鑫,可丹丹,等.Ce替代La对合金LaNi4.5Al0.5储氢性能及热力学的影响[J].稀土,2023,44(2):86-92. |

| FU Kangkang, ZHAO Xin, KE Dandan,et al.Effect of Ce substitution for La on the hydrogen storage properties and thermodynamics of alloy LaNi4.5Al0.5 [J].Chinese Rare Earths,2023,44(2):86-92. | |

| 8 | 肖冬玲,郭飞,李强.NiCo比对La0.8Mg0.2(Ni,Co)3.8储氢合金性能的影响[J].电池,2023,53(2):191-195. |

| XIAO Dongling, GUO Fei, LI Qiang.Effect of ratio between Ni and Co on the performance of La0.8Mg0.2(Ni,Co)3.8 hydrogen storage alloys[J].Battery Bimonthly,2023,53(2):191-195. | |

| 9 | 熊玮,周淑娟,赵玉园,等.不同化学计量比La-Y-Ni系储氢合金的研究Ⅱ:氢化反应与电极反应特性[J].稀土,2022,43(4):29-36. |

| XIONG Wei, ZHOU Shujuan, ZHAO Yuyuan,et al.Study on La-Y-Ni hydrogen storage alloys with different stoichiometric ratios Ⅱ:Hydrogenation and electrode reaction characteristics[J].Chinese Rare Earths,2022,43(4):29-36. | |

| 10 | 邓剑锋,孔凡校,朱立宗,等.添加剂REMg2Ni对Mg2Ni储氢材料性能的影响研究[J].电源技术,2022,46(11):1261-1264. |

| DENG Jianfeng, KONG Fanxiao, ZHU Lizong,et al.Effect of additive REMg2Ni on properties of Mg2Ni hydrogen storage materi-al[J].Chinese Journal of Power Sources,2022,46(11):1261-1264. | |

| 11 | DENG Anqiang, LUO Yongchun, ZHOU Jianfei,et al.Effect of Mn element on the structures and properties of A2B7-type La-Y-Ni-based hydrogen storage alloys[J].Metals,2022,12(7):1122. |

| 12 | 纪铭悦,田晓,刘昕瑀,等.铸态和快淬态La-Mg-Ni储氢合金的电化学性能及其对BH4 -的催化氧化性能[J].金属功能材料,2022,29(4):56-63. |

| JI Mingyue, TIAN Xiao, LIU Xinyu,et al.Electrochemical properties and catalytic oxidation properties for BH4 - of the as-cast and rapid quenched La-Mg-Ni hydrogen storage alloys[J].Metallic Functional Materials,2022,29(4):56-63. | |

| 13 | 齐颖,李宏鑫,万初斌.元素替代在La-Mg-Ni系储氢合金中应用的研究进展[J].稀土,2023,44(5):117-126. |

| QI Ying, LI Hongxin, WAN Chubin.Research progress of element substitution applied in La-Mg-Ni hydrogen storage al-loy[J].Chinese Rare Earths,2023,44(5):117-126. | |

| 14 | 郑波,刘雯雯,任权兵,等.不同Mn含量对A2B7型La-Y-Ni储氢合金性能的影响[J].有色金属(冶炼部分),2023(8):82-88. |

| ZHENG Bo, LIU Wenwen, REN Quanbing,et al.Effect of different Mn contents on properties of A2B7-type La-Y-Ni hydrogen storage alloy[J].Nonferrous Metals(Extractive Metallurgy), 2023(8):82-88. | |

| 15 | WANG Wenfeng, LIU Xiaoxue, ZHANG Lu,et al.The electrochemical characteristics of AB4-type rare earth-Mg-Ni-based superlattice structure hydrogen storage alloys for nickel metal hydride battery[J].Journal of Magnesium and Alloys,2021,9(6):2039-2048. |

| 16 | 程丽群,左付山.新能源汽车电池用无镁储氢合金的制备与性能研究[J].无机盐工业,2021,53(11):71-76. |

| CHENG Liqun, ZUO Fushan.Study on preparation and properties of magnesium free hydrogen storage alloys for new energy vehicle batteries[J].Inorganic Chemicals Industry,2021,53(11):71-76. | |

| 17 | 张旭,王利,李宝犬,等.Cu对La-Y-Ni系A2B7型储氢合金微观结构及电化学性能的影响[J].稀有金属,2021,45(12):1438-1447. |

| ZHANG Xu, WANG Li, LI Baoquan,et al.Effects of substituting Ni with Cu on microstructure and electrochemical performance of A2B7-type La-Y-Ni-based hydrogen storage alloy[J].Chinese Journal of Rare Metals,2021,45(12):1438-1447. | |

| 18 | 王姗姗,裴婷,张新庄,等.La0.7Mg0.3Ni2.5- x Co0.6Mn0.4Cu x( x=0~0.20)储氢合金的制备及电化学性能研究[J].石油化工应用,2023,42(9):96-98,102. |

| WANG Shanshan, PEI Ting, ZHANG Xinzhuang,et al.Preparation and electrochemical properties of La0.7Mg0.3Ni2.5- x Co0.6Mn0.4Cu x( x=0~0.20) hydrogen storage alloy[J].Petrochemical Industry Application,2023,42(9):96-98, 102. | |

| 19 | DING Xin, CHEN Ruirun, ZHANG Jiaxin,et al.Achieving superior hydrogen storage properties via in situ formed nanostructures:A high-capacity Mg-Ni alloy with La microalloying[J].International Journal of Hydrogen Energy,2022,47(10):6755-6766. |

| 20 | 李通,罗新宇,陈子然.退火温度对汽车镍氢电池用储氢合金电化学性能的影响[J].稀土,2022,43(5):93-101. |

| LI Tong, LUO Xinyu, CHEN Ziran.Effect of annealing temperature on electrochemical properties of hydrogen storage alloys for Ni-MH battery[J].Chinese Rare Earths,2022,43(5):93-101. | |

| 21 | 朱晓梅,罗统钊,蒋志军,等.镁基储氢合金La0.47- x Sm0.53Mg x Ni3.35Al0.15的制备和退火工艺研究[J].稀土,2022,43(4):121-128. |

| ZHU Xiaomei, LUO Tongzhao, JIANG Zhijun,et al.Preparation and annealing technology of magnesium-based hydrogen storage alloy La0.47- x Sm0.53Mg x Ni3.35Al0.15 [J].Chinese Rare Earths,2022,43(4):121-128. | |

| 22 | LIN Shuangping, NIE Zuoren, HUANG Hui,et al.Annealing behavior of a modified 5083 aluminum alloy[J].Materials & Design,2010,31(3):1607-1612. |

| 23 | 李志强,郭正华,何玉汝.Zr/Mn元素替代及退火处理对汽车电池用储氢合金电化学性能的影响[J].无机盐工业,2023, 55(6):78-84. |

| LI Zhiqiang, GUO Zhenghua, HE Yuru.Effect of Zr/Mn element substitution and annealing treatment on electrochemical properties of hydrogen storage alloys for automotive batteries[J].Inorganic Chemicals Industry,2023,55(6):78-84. | |

| 24 | 刘雯雯,赖华生,王玉香,等.La/Y比对A2B7型La-Y-Ni储氢合金性能的影响[J].矿冶工程,2023,43(2):149-153. |

| LIU Wenwen, LAI Huasheng, WANG Yuxiang,et al.Effect of La/Y ratio on properties of A2B7-type La-Y-Ni hydrogen storage alloy[J].Mining and Metallurgical Engineering,2023,43(2):149-153. | |

| 25 | WAN Changpeng, ZHAO Shiqian, WANG Hui.Tuning phase structure and electrochemical hydrogen storage properties of A5B19-type La-Y-Ni-Mn-based superlattice alloys by partial Al substitution[J].International Journal of Hydrogen Energy,2024,49:51-58. |

| [1] | SU Baocai, ZHANG Qin, XIE Yuanjian, CAI Pingxiong, PAN Yuanfeng. Advances in synthesis methods and structural modification of LiMnFePO4 materials [J]. Inorganic Chemicals Industry, 2024, 56(7): 28-36. |

| [2] | LIU Jiasheng, LUO Xiaoqiang, HOU Cuihong, XUE Lingwei. Effects of fluorine doping on electrochemical behavior of LiMn0.8Fe0.2PO4/C cathode materials [J]. Inorganic Chemicals Industry, 2024, 56(11): 45-50. |

| [3] | WAN Feng, YAN Yingchun, FAN Zhuangjun. Research progress and prospect of halide solid electrolytes [J]. Inorganic Chemicals Industry, 2024, 56(11): 15-29. |

| [4] | PENG Weifeng, SHI Wei. Effect of Co replacing Ni on electrochemical performance of La0.8Mg0.2Ni3.8-x Co x hydrogen storage alloy for automotive batteries [J]. Inorganic Chemicals Industry, 2024, 56(11): 65-71. |

| [5] | CHEN Tiandong, ZHAO Guangzhao, HAI Chunxi, DONG Shengde, HE Xin, XU Qi, FENG Hang, YUAN Shaoxiong, MA Luxiang, ZHOU Yuan. Research and industrialization progress on coating and doping modification of lithium-rich manganese-based materials [J]. Inorganic Chemicals Industry, 2023, 55(9): 1-8. |

| [6] | LI Zhiqiang, GUO Zhenghua, HE Yuru. Effect of Zr/Mn element substitution and annealing treatment on electrochemical properties of hydrogen storage alloys for automotive batteries [J]. Inorganic Chemicals Industry, 2023, 55(6): 78-84. |

| [7] | QU Lian, LI Yuezhu, LI Mingya, WANG Zhaopei, CHEN Yanyu, LI Yineng. Study on effect of Fe2P on electrochemical performance of LiFePO4 [J]. Inorganic Chemicals Industry, 2023, 55(12): 88-94. |

| [8] | HOU Shunli,ZHAO Duan,ZHOU Geng,WEI Shishi,LI Jian,WANG Jiatai. Research progress on doping modification of high nickel ternary nickel-cobalt-aluminum cathode material [J]. Inorganic Chemicals Industry, 2022, 54(8): 40-46. |

| [9] | CHANG Chenggong,WEN Jing,DONG Jinmei,ZHENG Weixin,YAN Fengyun,XIAO Xueying. Effect of carbonization on evolution process of microstructure of magnesium oxychloride cement [J]. Inorganic Chemicals Industry, 2022, 54(6): 61-65. |

| [10] | ZHANG Xinyi,DI Yuli,DONG Qi,CHEN Xingyu,ZHANG Zhengdong. Research progress on preparation of Li3V2(PO4)3 cathode material for lithium-ion batteries [J]. Inorganic Chemicals Industry, 2022, 54(3): 38-44. |

| [11] | LU Zheng,CHEN Kunfeng,XUE Dongfeng. Study on large-scale preparation and electrochemical properties of high thermal stabilized α-Fe2O3 [J]. Inorganic Chemicals Industry, 2022, 54(3): 45-50. |

| [12] | FAN Qingke,MENG Qinghua. Study on preparation and electrochemical properties of La0.79Mg0.21Ni3.95 hydrogen storage alloy for vehicles [J]. Inorganic Chemicals Industry, 2022, 54(3): 71-76. |

| [13] | MA Caifu,YUAN Chuanlai,ZHAO Xueqi. Effect of ball milling time on electrochemical properties of graphene composites [J]. Inorganic Chemicals Industry, 2022, 54(12): 68-73. |

| [14] | WANG Wei,LIU Wei,WU Yang,YANG Shenshen. Research progress on molybdenum disulfide-based anode materials for lithium-ion batteries [J]. Inorganic Chemicals Industry, 2022, 54(10): 87-95. |

| [15] | Jian Mengqi,Zhang Kun,Xie Xin,Chen Xiyong. Research progress of LiMnPO4 cathode material for lithium ion batteries [J]. Inorganic Chemicals Industry, 2021, 53(9): 18-23. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||