Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (7): 18-24.doi: 10.19964/j.issn.1006-4990.2022-0557

• Reviews and Special Topics • Previous Articles Next Articles

Research progress of deep calcium removal process of battery-grade lithium carbonate

WANG Hang1,2( ), XU Chuan1,2, YAN Xinxing1,2, TU Mingjiang1,2, CHEN Xin1,2

), XU Chuan1,2, YAN Xinxing1,2, TU Mingjiang1,2, CHEN Xin1,2

- 1. Tianqi Lithium(Shehong) Co. ,Ltd. ,Shehong 629200,China

2. Key Laboratory of Lithium Resources and Materialsof Sichuan Province,Tianqi Lithium Industry Co. ,Ltd. ,Chengdu 610000,China

-

Received:2022-09-15Online:2023-07-10Published:2023-07-13

CLC Number:

Cite this article

WANG Hang, XU Chuan, YAN Xinxing, TU Mingjiang, CHEN Xin. Research progress of deep calcium removal process of battery-grade lithium carbonate[J]. Inorganic Chemicals Industry, 2023, 55(7): 18-24.

share this article

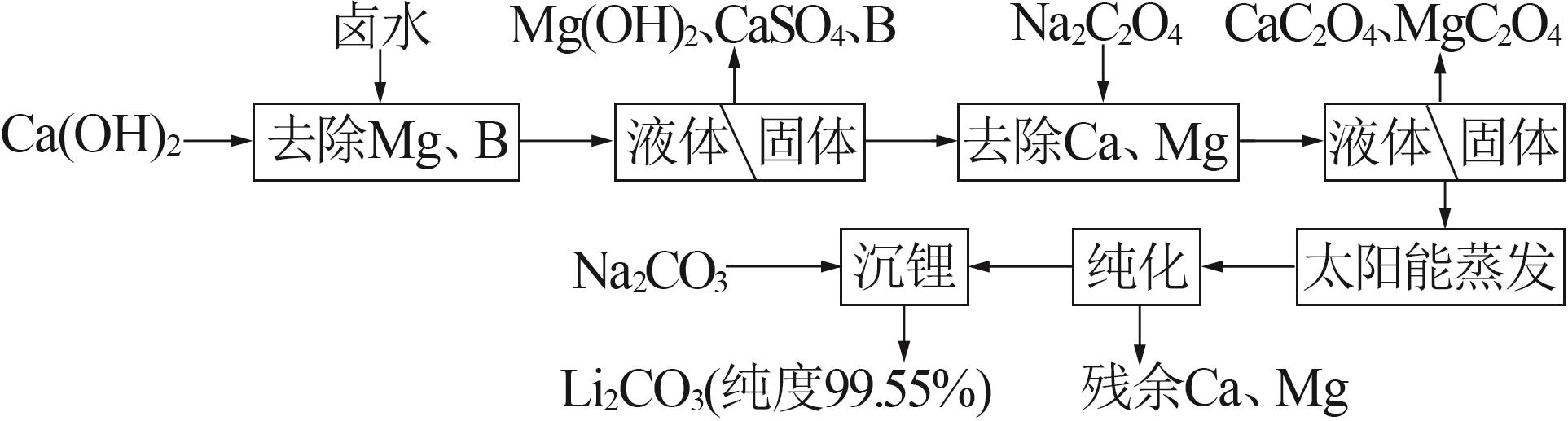

Table 1

Advantages and disadvantages of different calcium removal processes"

| 除钙工艺 | 优点 | 缺点 |

|---|---|---|

| 化学沉淀法 | 工艺成熟、成本低、母液可循环、效率高 | 引入Na和K杂质、收率低、难以深度除钙、污染环境 |

| 氢化分解法 | 不引入杂质、工艺成 熟 | 伴随Ca(HCO3)2进入产物、 CO2利用率低、生产周期长 |

| 络合法 | 减少试剂用量、工艺 简单、成本低 | 络合物伴随进入产物、影响晶型、产品发黑 |

| 离子交换法 | 深度除钙、循环使用、环保 | 循环寿命低、需反复活化、成本高、周期较长、引入Na离子 |

| 电解法 | 选择性高、综合利用 率高 | 成本高、受配套基础设施影 响、周期长、产生有害气体、杂质残留 |

| 1 | 赵春龙,孙峙,郑晓洪,等.碳酸锂的制备及其纯化过程的研究进展[J].过程工程学报,2018,18(1):20-28. |

| ZHAO Chunlong, SUN Sun, ZHENG Xiaohong,et al.Research progress of lithium carbonate preparation and purification proce- | |

| ss[J].The Chinese Journal of Process Engineering,2018,18(1):20-28. | |

| 2 | XU Xin, CHEN Yongmei, WAN Pingyu,et al.Extraction of lithium with functionalized lithium ion-sieves[J].Progress in Materials Science,2016,84:276-313. |

| 3 | LIU Gui, ZHAO Zhongwei, GHAHREMAN A.Novel approaches for lithium extraction from salt-lake brines:A review[J].Hydrometallurgy,2019,187:81-100. |

| 4 | 张苏江,崔立伟,孔令湖,等.国内外锂矿资源及其分布概述[J].有色金属工程,2020,10(10):95-104. |

| ZHANG Sujiang, CUI Liwei, KONG Linghu,et al.Summarize on the lithium mineral resources and their distribution at home and abroad[J].Nonferrous Metals Engineering,2020,10(10):95-104. | |

| 5 | 苏彤,郭敏,刘忠,等.全球锂资源综合评述[J].盐湖研究,2019,27(3):104-111. |

| SU Tong, GUO Min, LIU Zhong,et al.Comprehensive review of global lithium resources[J].Journal of Salt Lake Research,2019,27(3):104-111. | |

| 6 | 任沁沁.我国新能源汽车保有量突破1000万辆[N].新华每日电讯,2022-07-07(3). |

| 7 | 黄开成.电池级锂盐钙杂质的来源及深度除钙工艺研究[J].中氮肥,2022(4):74-76,80. |

| HUANG Kaicheng.Study on the source of calcium impurities in battery-grade lithium salt and the deep calcium removal process[J].M-Sized Nitrogenous Fertilizer Progress,2022(4):74-76,80. | |

| 8 | 孔祥宇,张永生.锂资源:新能源革命的源动力[J].人民论坛·学术前沿,2022(13):76-81. |

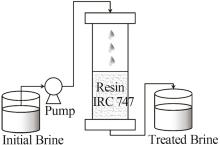

| KONG Xiangyu, ZHANG Yongsheng.Lithium resource:The motive force of new energy revolution[J].Frontiers,2022(13):76- 81. | |

| 9 | YAN Qunxuan, LI Xinhai, WANG Zhixing,et al.Extraction of lithium from lepidolite by sulfation roasting and water leaching[J].International Journal of Mineral Processing,2012,110/111:1-5. |

| 10 | LUONG V T, KANG Dongjun, AN J W,et al.Iron sulphate roasting for extraction of lithium from lepidolite[J].Hydrometallurgy,2014,141:8-16. |

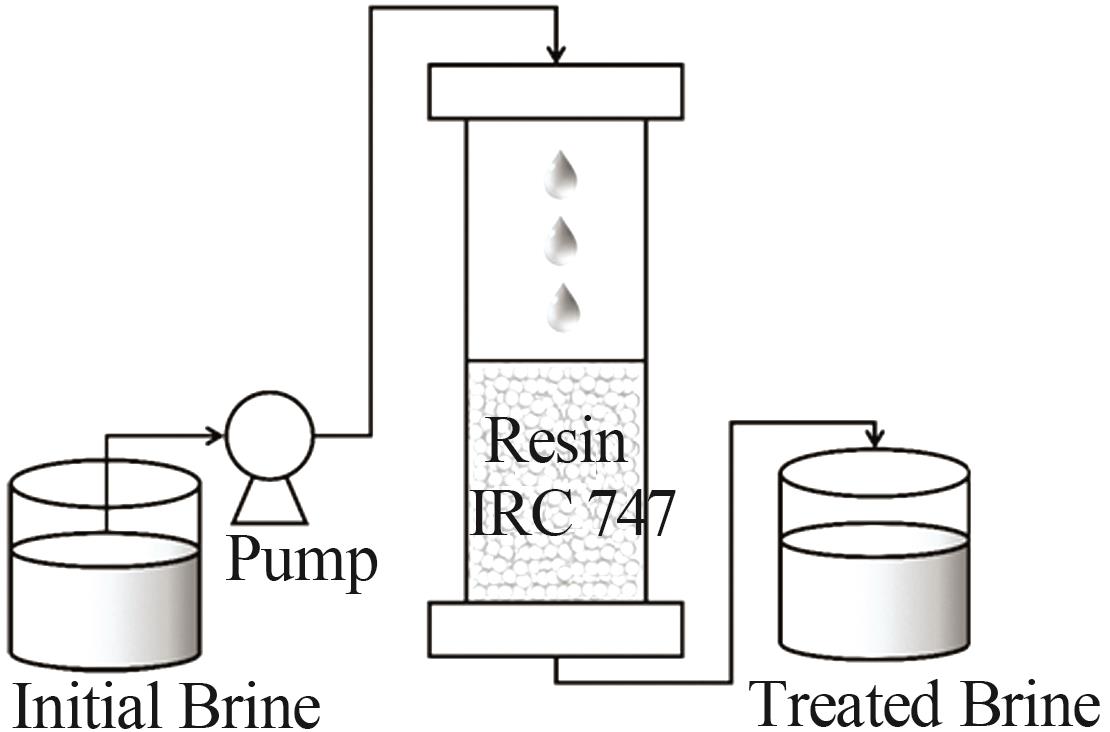

| 11 | 张选旭.宜春锂云母采用硫酸盐法制取碳酸锂工艺净化除杂试验[J].江西有色金属,1995(1):45-47. |

| ZHANG Xuanxu.Experiment on purification and impurity removal of lithium carbonate from Yichun lepidolite by sulfate met- | |

| hod[J].Nonferrous Metals Science and Engineering,1995(1):45-47. | |

| 12 | 谭博,刘香环,刘旭东,等.锂辉石浸出液提锂除杂规律研究[J].无机盐工业,2021,53(4):56-60. |

| TAN Bo, LIU Xianghuan, LIU Xudong,et al.Study on law of lithium extraction and impurity removal from spodumene leaching solution[J].Inorganic Chemicals Industry,2021,53(4):56- 60. | |

| 13 | 张亮,杨卉芃,柳林,等.全球提锂技术进展[J].矿产保护与利用,2020,40(5):24-31. |

| ZHANG Liang, YANG Huipeng, LIU Lin,et al.Global technology trends of lithium extraction[J].Conservation and Utilization of Mineral Resources,2020,40(5):24-31. | |

| 14 | AN J W, KANG Dongjun, TRAN K T,et al.Recovery of lithium from uyuni salar brine[J].Hydrometallurgy,2012,117/118:64- 70. |

| 15 | 刘东帆,孙淑英,于建国.盐湖卤水提锂技术研究与发展[J].化工学报,2018,69(1):141-155. |

| LIU Dongfan, SUN Shuying, YU Jianguo.Research and development on technique of lithium recovery from salt lake brine[J].CIESC Journal,2018,69(1):141-155. | |

| 16 | 李青林.柴达木盆地油田卤水提锂实验研究[J].化工矿物与加工,2006(8):16-17. |

| LI Qinglin.Extraction of lithium from oil field brine in Chaidamu basin[J].Industrial Minerals & Processing,2006(8):16-17. | |

| 17 | 谈庆光,李银兰.察尔汗盐湖卤水制取碳酸锂除杂技术探讨[J].科技创新与应用,2012(27):15. |

| TAN Qingguang, LI Yinlan.Discussion on impurity removal technology of preparing lithium carbonate from brine in Chaerhan salt lake[J].Technology Innovation and Application,2012(27): 15. | |

| 18 | 邓姝皓,杨子萱,杨佳逸,等.由扎布耶盐湖粗盐制备高纯碳酸锂新工艺研究[J].无机盐工业,2016,48(4):26-30. |

| DENG Shuhao, YANG Zixuan, YANG Jiayi,et al.New process for preparation of high purity lithium carbonate from coarse salt in Zabuye salt lake[J].Inorganic Chemicals Industry,2016,48(4):26-30. | |

| 19 | LINNEEN N, BHAVE R, WOERNER D.Purification of industrial grade lithium chloride for the recovery of high purity battery grade lithium carbonate[J].Separation and Purification Technology,2019,214:168-173. |

| 20 | 吴鉴,姚耀春,龙萍.循环氢化对电池级碳酸锂制备中钙镁去除的影响[J].材料导报,2013,27(S1):150-153. |

| WU Jian, YAO Yaochun, LONG Ping.Effect of cyclic carbonation on the removal of calcium and magnesium in preparation of battery-grade lithium carbonate[J].Materials Review,2013,27(S1):150-153. | |

| 21 | 吴鉴,赵泉峰,龙萍,等.电池级碳酸锂制备过程中磷酸锂除钙的研究[J].电源技术,2016,40(11):2110-2111,2147. |

| WU Jian, ZHAO Quanfeng, LONG Ping,et al.Research of removing calcium using lithium phosphate in preparation process of battery-grade lithium carbonate[J].Chinese Journal of Power So- | |

| urces,2016,40(11):2110-2111,2147. | |

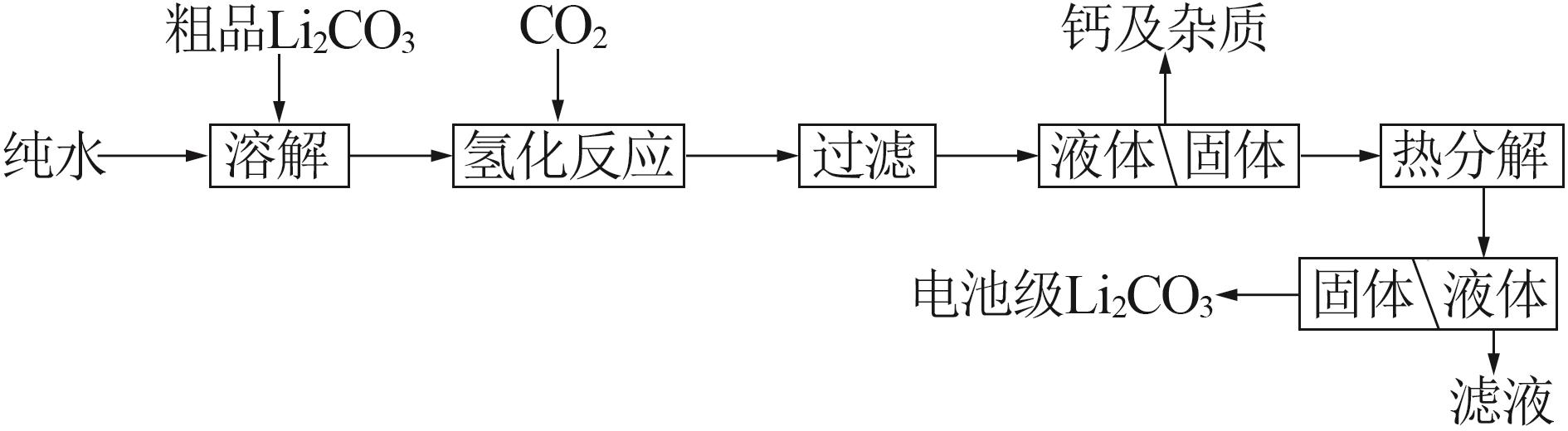

| 22 | 周晓东,叶华,郭晴,等.碳化分解法提纯碳酸锂粗品[J].有色金属(冶炼部分),2018(4):42-45. |

| ZHOU Xiaodong, YE Hua, GUO Qing,et al.Purification of lithi- | |

| um carbonate by carbonation-decomposition method[J].Nonferrous Metals(Extractive Metallurgy),2018(4):42-45. | |

| 23 | 许鑫,曾祖亮,廖文华,等.连续碳化——分解法制备高纯碳酸锂[Z].新余:江西赣锋锂业股份有限公司,2018. |

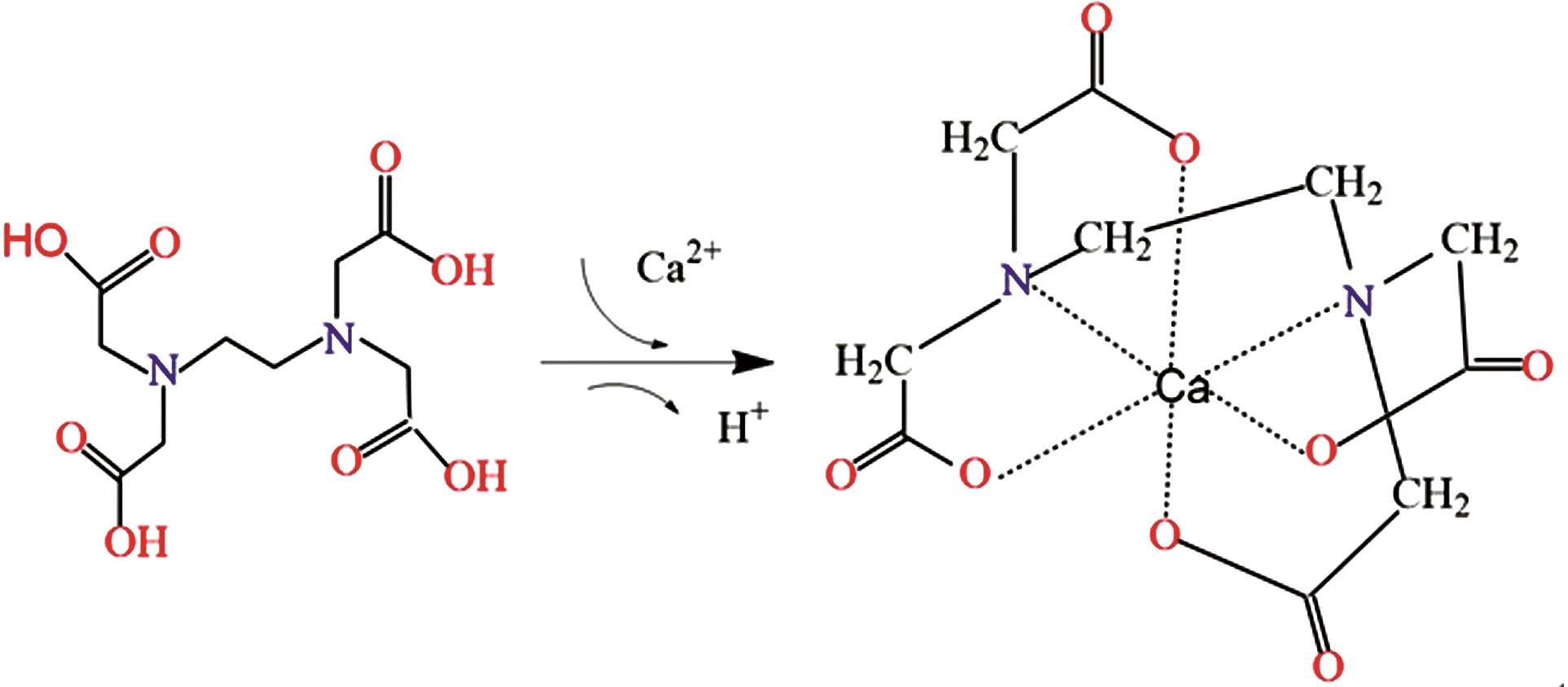

| 24 | GRIKO Y V.Energetics of Ca2+-EDTA interactions:Calorimetric study[J].Biophysical Chemistry,1999,79(2):117-127. |

| 25 | 周有池,王林生,刘帆,等.从含锂废渣中回收制备碳酸锂的工艺研究[J].稀有金属与硬质合金,2017,45(4):16-20,41. |

| ZHOU Youchi, WANG Linsheng, LIU Fan,et al.Study on preparation of lithium carbonate from lithium-containing residue[J].Rare Metals and Cemented Carbides,2017,45(4):16-20,41. | |

| 26 | 马爱军,鲁兴武,张恩玉,等.电池级碳酸锂生产中钙镁硼的络合分离试验研究[J].稀有金属与硬质合金,2015,43(1):36-38. |

| MA Aijun, LU Xingwu, ZHANG Enyu,et al.Experimental study on Ca-Mg-B complexation separation in the production of battery-grade lithium carbonate[J].Rare Metals and Cemented Carbides,2015,43(1):36-38. | |

| 27 | 张海军,苏怡兵,杨瑛.一种除去电池级碳酸锂中钙、镁、铁、钠、钾阳离子杂质的方法:中国,102398910A[P].2014-07-16. |

| 28 | 李鹏武,尹晓刚,杨锦瑜,等.电池级碳酸锂精制工艺技术研究[J].无机盐工业,2018,50(6):51-54,62. |

| LI Pengwu, YIN Xiaogang, YANG Jinyu,et al.Study on purification technology of battery grade lithium carbonate[J].Inorganic Chemicals Industry,2018,50(6):51-54,62. | |

| 29 | 李鹏武,尹晓刚,程琥,等.氢化分解法制备电池级碳酸锂过程中钙、镁除杂工艺技术[J].稀有金属与硬质合金,2018,46(4):69-72,77. |

| LI Pengwu, YIN Xiaogang, CHENG Hu,et al.Technology of calcium and magnesium removal during preparation of battery grade lithium carbonate by hydrogenation decomposition[J].Rare Metals and Cemented Carbides,2018,46(4):69-72,77. | |

| 30 | 李良彬,胡耐根,黄学武,等.一种利用氯化锂溶液制备电池级碳酸锂的方法:中国,101609888A[P].2009-12-23. |

| 31 | 耿慧,许颖,戴晓虎,等.离子交换树脂在污泥处理中的应用及展望[J].中国环境科学,2022,42(11):5220-5228. |

| GENG Hui, XU Ying, DAI Xiaohu,et al.Overview and prospect of the application of ion exchange resin in treatment of sewage sludge[J].China Environmental Science,2022,42(11):5220-5228. | |

| 32 | GRÁGEDA M, GONZÁLEZ A, GRÁGEDA M,et al.Purification of brines by chemical precipitation and ion-exchange processes for obtaining battery-grade lithium compounds[J].International Journal of Energy Research,2018,42(7):2386-2399. |

| 33 | 王人杰,李明兴,李新义.基于氢化分解法的粗碳酸锂制备电池级碳酸锂工艺研究[J].化工设计通讯,2020,46(7):140- 142. |

| WANG Renjie, LI Mingxing, LI Xinyi.Study on preparation of battery-grade lithium carbonate from crude lithium carbonate based on hydrogenation decomposition method[J].Chemical Engineering Design Communications,2020,46(7):140-142. | |

| 34 | 张燕,赵振中,马朝辉,等.碳化法制备电池级碳酸锂工艺优化研究[J].无机盐工业,2020,52(3):68-71. |

| ZHANG Yan, ZHAO Zhenzhong, MA Zhaohui,et al.Optimization of process for preparation of battery grade lithium carbonate by carbonization[J].Inorganic Chemicals Industry,2020,52(3):68-71. | |

| 35 | YI Wentao, YAN Chunyan, MA Peihua.Removal of calcium and magnesium from LiHCO3 solutions for preparation of high-purity Li2CO3 by ion-exchange resin[J].Desalination,2009,249(2):729-735. |

| 36 | 盛亮.一种从工业级碳酸锂提取超纯度碳酸锂的方法及装置:中国,107055577B[P].2018-08-07. |

| 37 | 余心亮,李靖,詹稳,等.4N级高纯碳酸锂[Z].湖州:浙江天能新材料有限公司,2020. |

| 38 | DÍAZ NIETO C H, PALACIOS N A, VERBEECK K,et al.Membrane electrolysis for the removal of Mg2+ and Ca2+ from lithium rich brines[J].Water Research,2019,154:117-124. |

| 39 | 祝增虎,李法强,朱朝梁,等.电解法制备氢氧化锂的研究进展[J].无机盐工业,2014,46(8):6-9. |

| ZHU Zenghu, LI Faqiang, ZHU Chaoliang,et al.Research progress on preparation of lithium hydroxide by electrolysis[J].Inorganic Chemicals Industry,2014,46(8):6-9. | |

| 40 | TORRES W R, DÍAZ NIETO C H, PRÉVOTEAU A,et al.Lithium carbonate recovery from brines using membrane electrolysis[J].Journal of Membrane Science,2020,615:118416. |

| [1] | ZHAO Runze, QIAN A′niu. Research progress of lithium recovery for spent lithium-ion batteries and preparation in battery-grade lithium carbonate [J]. Inorganic Chemicals Industry, 2024, 56(12): 70-78. |

| [2] | CHENG Chunchun, LI Yulong, ZHANG Zhiqiang, ZUO Shuo, QIN Donglan, ZHOU Na, WANG Jiaqin. Study on agglomeration phenomenon and regulation method of lithium carbonate crystal prepared from potassium carbonate [J]. Inorganic Chemicals Industry, 2024, 56(10): 47-54. |

| [3] | LI Yan,WANG Yansong,CHENG Huaigang,KANG Jin,LI Enze,LÜ Hongzhou,LIU Qian. Rapid quality inspection of high-purity lithium carbonate based on determination of magnesium by water-soluble probe method [J]. Inorganic Chemicals Industry, 2023, 55(1): 87-92. |

| [4] | GUO Chunping,ZHOU Youchi,WEN Xiaoqiang,LIU Wenwen,HONG Kan,HUANG Yetian. Study on preparation process of battery-grade lithium carbonate from slag containing lithium phosphate [J]. Inorganic Chemicals Industry, 2022, 54(3): 82-86. |

| [5] | Wang Bin,Deng Xiaochuan,Shi Yifei,Dong Chaochao,Fan Faying,Zhu Chaoliang,Fan Jie. Online determination of the solubility of lithium carbonate in water and NaCl-KCl solution system [J]. Inorganic Chemicals Industry, 2021, 53(7): 73-79. |

| [6] | Tan Bo,Liu Xianghuan,Liu Xudong,Yi Meigui. Study on law of lithium extraction and impurity removal from spodumene leaching solution [J]. Inorganic Chemicals Industry, 2021, 53(4): 56-60. |

| [7] | HU Yue,XU Lele,ZHOU Yanfang,XU Zhe,TIAN Shoushuai,LIAO Fan,YANG Xiaojun. Research progress on alkaline substance on surface of nickel-rich ternary cathode materials [J]. Inorganic Chemicals Industry, 2021, 53(12): 74-79. |

| [8] | Xu Xinfang,Zhou Xiaoping,Liu Zhengfeng,Li Lei,Chen Hu,Li Changming. Study on causticization and purification of salt lake lithium ore and recovery of fluorine-containing lithium carbonate [J]. Inorganic Chemicals Industry, 2020, 52(7): 62-65. |

| [9] | Yao Yong,Guo Rui. Research progress of metal element doped spinel type MgGa2O4 [J]. Inorganic Chemicals Industry, 2020, 52(4): 23-28. |

| [10] | Zhang Yan,Zhao Zhenzhong,Ma Zhaohui,Zhao Yancai,Chen Zhiyu,Ma Zhengqiang. Optimization of process for preparation of battery grade lithium carbonate by carbonization [J]. Inorganic Chemicals Industry, 2020, 52(3): 68-71. |

| [11] | Hu Min,Gong Hanzhang,Wu Huadong,Guo Jia,Zhang Linfeng,Zhou Yuxin. Preparation of battery-grade lithium carbonate from lithium-containing industrial waste [J]. Inorganic Chemicals Industry, 2020, 52(3): 80-84. |

| [12] | Liu Gousheng,Wang Linlin,Liu Yuelong. Preparation of lithium carbonate from medium-and low-grade lithium clay by ammonium sulfate process [J]. Inorganic Chemicals Industry, 2020, 52(10): 125-129. |

| [13] | Dong Xiongbo,Zhang Xiangwei,Liu Xiaorui,Zheng Shuilin. Progress and development trend of inorganic coated titanium powder [J]. Inorganic Chemicals Industry, 2020, 52(10): 30-36. |

| [14] | Chen Jie,Chen Xia. Crystallization process optimization for preparation of lithium carbonate [J]. Inorganic Chemicals Industry, 2019, 51(8): 29-32. |

| [15] | Liu Guowang,Zhou Xiaojun,Zhang Shichun,Yang Shangming,Dong Shoulong,Li Binshou. Recycle method of lithium extracted mother solution and phase diagram analysis [J]. Inorganic Chemicals Industry, 2019, 51(6): 38-40. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||