| [1] |

ZHAO Runze, QIAN A′niu.

Research progress of lithium recovery for spent lithium-ion batteries and preparation in battery-grade lithium carbonate

[J]. Inorganic Chemicals Industry, 2024, 56(12): 70-78.

|

| [2] |

CHENG Chunchun, LI Yulong, ZHANG Zhiqiang, ZUO Shuo, QIN Donglan, ZHOU Na, WANG Jiaqin.

Study on agglomeration phenomenon and regulation method of lithium carbonate crystal prepared from potassium carbonate

[J]. Inorganic Chemicals Industry, 2024, 56(10): 47-54.

|

| [3] |

WANG Hang, XU Chuan, YAN Xinxing, TU Mingjiang, CHEN Xin.

Research progress of deep calcium removal process of battery-grade lithium carbonate

[J]. Inorganic Chemicals Industry, 2023, 55(7): 18-24.

|

| [4] |

LI Yan,WANG Yansong,CHENG Huaigang,KANG Jin,LI Enze,LÜ Hongzhou,LIU Qian.

Rapid quality inspection of high-purity lithium carbonate based on determination of magnesium by water-soluble probe method

[J]. Inorganic Chemicals Industry, 2023, 55(1): 87-92.

|

| [5] |

GUO Chunping,ZHOU Youchi,WEN Xiaoqiang,LIU Wenwen,HONG Kan,HUANG Yetian.

Study on preparation process of battery-grade lithium carbonate from slag containing lithium phosphate

[J]. Inorganic Chemicals Industry, 2022, 54(3): 82-86.

|

| [6] |

Wang Bin,Deng Xiaochuan,Shi Yifei,Dong Chaochao,Fan Faying,Zhu Chaoliang,Fan Jie.

Online determination of the solubility of lithium carbonate in water and NaCl-KCl solution system

[J]. Inorganic Chemicals Industry, 2021, 53(7): 73-79.

|

| [7] |

Tan Bo,Liu Xianghuan,Liu Xudong,Yi Meigui.

Study on law of lithium extraction and impurity removal from spodumene leaching solution

[J]. Inorganic Chemicals Industry, 2021, 53(4): 56-60.

|

| [8] |

Wu Zhaomin,Yang Lin,Wang Xinlong,Zhuang Haibo,Ye Runzhou,Wang Ye,Li Yaoji.

Study on process of dynamic ion-exchange for etching waste acid containing aluminum in electronic industry

[J]. Inorganic Chemicals Industry, 2021, 53(2): 61-65.

|

| [9] |

HU Yue,XU Lele,ZHOU Yanfang,XU Zhe,TIAN Shoushuai,LIAO Fan,YANG Xiaojun.

Research progress on alkaline substance on surface of nickel-rich ternary cathode materials

[J]. Inorganic Chemicals Industry, 2021, 53(12): 74-79.

|

| [10] |

Zhang Yan,Zhao Zhenzhong,Ma Zhaohui,Zhao Yancai,Chen Zhiyu,Ma Zhengqiang.

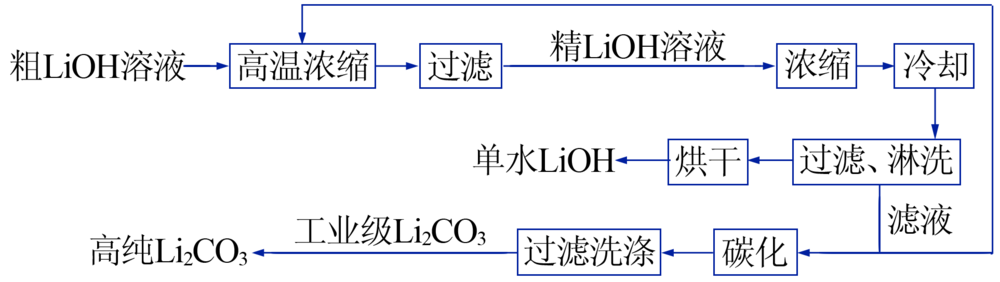

Optimization of process for preparation of battery grade lithium carbonate by carbonization

[J]. Inorganic Chemicals Industry, 2020, 52(3): 68-71.

|

| [11] |

Hu Min,Gong Hanzhang,Wu Huadong,Guo Jia,Zhang Linfeng,Zhou Yuxin.

Preparation of battery-grade lithium carbonate from lithium-containing industrial waste

[J]. Inorganic Chemicals Industry, 2020, 52(3): 80-84.

|

| [12] |

Liu Gousheng,Wang Linlin,Liu Yuelong.

Preparation of lithium carbonate from medium-and low-grade lithium clay by ammonium sulfate process

[J]. Inorganic Chemicals Industry, 2020, 52(10): 125-129.

|

| [13] |

Chen Jie,Chen Xia.

Crystallization process optimization for preparation of lithium carbonate

[J]. Inorganic Chemicals Industry, 2019, 51(8): 29-32.

|

| [14] |

Liu Guowang,Zhou Xiaojun,Zhang Shichun,Yang Shangming,Dong Shoulong,Li Binshou.

Recycle method of lithium extracted mother solution and phase diagram analysis

[J]. Inorganic Chemicals Industry, 2019, 51(6): 38-40.

|

| [15] |

Yin Jishuai,Sun Wenliang,Hao Rusi,Wang Xiao.

Study on the influence of lithium deposition reaction conditions on purity and impurities of lithium carbonate

[J]. Inorganic Chemicals Industry, 2019, 51(3): 29-33.

|