Inorganic Chemicals Industry ›› 2022, Vol. 54 ›› Issue (12): 10-18.doi: 10.19964/j.issn.1006-4990.2022-0057

• Reviews and Special Topics • Previous Articles Next Articles

Application status and development direction of wet flue gas desulfurization technology

- 1. Xi′an Center of Geological Survey,China Geological Survey,Xi'an 710054,China

2. Baoji Thermal Power Co. ,Ltd.

-

Received:2022-03-04Online:2022-12-10Published:2022-12-19 -

Contact:Lü Ruiliang E-mail:245099651@qq.com;524886206@qq.com

CLC Number:

Cite this article

HUA Wen,LÜ Ruiliang. Application status and development direction of wet flue gas desulfurization technology[J]. Inorganic Chemicals Industry, 2022, 54(12): 10-18.

share this article

Table 1

Comparison of technical characteristics of different wet desulfurization"

| 项目 | 吸收剂 | 脱硫 效率/% | 运行 成本 | 副产物 | 二次 污染 | 副产物 利用 | 优点 | 缺点 | 应用现状 |

|---|---|---|---|---|---|---|---|---|---|

石灰石-石 灰法[ | 石灰、石灰石 | 约90 | 高 | 石膏 | 固废、 废水 | 建筑 材料 | 脱硫效果好,吸收剂廉价易得 | 系统易结垢,可靠性差,占地面积大 | 广泛应用 |

| 镁法[ | 氧化镁 | >90 | 较高 | 硫酸镁 | 固废、 废水 | 镁肥 | 脱硫率高,适用范围广,副产物资源化技术多元化 | 吸收剂受区域性限制 | 市场占有率不足1% |

| 氨法[ | 氨水 | 90~99 | 较高 | 硫酸铵 | 气溶胶 | 氨肥 | 脱硫效率高,副产物附加值高 | 系统安全性要求高,且易发生二次污染 | 市场占有率为2% |

| 海水法[ | 海水 | 90 | 低 | 无 | 无 | 无 | 吸收剂充裕,运行成本低廉,目前无二次污染问题 | 吸收剂受区域性限制 | 市场占有率为3% |

离子液循环 法[ | 有机阴、阳离子 | >98 | 高 | 高纯SO2 | 废水 | 制酸、 硫磺 | 脱硫效率高,副产物附加值高 | 易腐蚀,能耗高 | 实验室阶段 |

| 钠碱法[ | 钠盐、碱液 | 98 | — | 高纯SO2 | 无 | 高纯 SO2 | 脱硫效率高,吸收剂可循环利用,副产物附加值高 | 氧化副反应易发生,投资成本高 | 部分应用 |

| 氨酸法[ | 氨水 | 95~99 | 高 | 硫酸铵、 硫酸 | 无 | 制酸、 氨肥 | 脱硫效率高,副产物附加值高 | 投资成本高 | 低浓度SO2行业广泛应用 |

膜气体吸收 法[ | 海水、氨水 | 98 | — | 硫酸铵 | 无 | 氨肥 | 脱硫效率高,副产物附加值高 | 投资运行成本高 | 实验室阶段 |

Table 1

| 1 | 郝吉明, 马广大. 大气污染控制工程[M]. 2版. 北京:高等教育出版社, 2010. |

| 2 | 中华人民共和国生态环境部. 中国生态环境统计年报•2019[M].北京:中国环境出版集团, 2021. |

| 3 | 马林. 国外烟气脱硫技术应用进展回顾[J]. 化工管理, 2015(31):119. |

| MA Lin. Review of application progress of flue gas desulfurization technology abroad[J]. Chemical Enterprise Management, 2015(31):119 | |

| 4 | 金平, 王昊辰, 李磊, 等. 烟气脱硫技术现状及展望[J]. 当代化工, 2019, 48(1):119-121, 126. |

| JIN Ping, WANG Haochen, LI Lei, et al. Status and prospect of flue gas desulfurization[J]. Contemporary Chemical Industry, 2019, 48(1):119-121, 126. | |

| 5 | 王文飚, 许月阳, 薛建明, 等. 燃煤电厂脱硫技术研究进展及建议[J]. 电力科技与环保, 2020, 36(3):1-5. |

| WANG Wenbiao, XU Yueyang, XUE Jianming, et al. The research progress and suggestions of desulfurization technology in coal-fired power plants[J]. Electric Power Technology and Environmental Protection, 2020, 36(3):1-5. | |

| 6 | 杜家芝, 曹顺安. 湿法烟气脱硫技术的现状与进展[J]. 应用化工, 2019, 48(6):1495-1500. |

| DU Jiazhi, CAO Shunan. Research status and progress of wet flue gas desulfurization technology[J]. Applied Chemical Industry, 2019, 48(6):1495-1500. | |

| 7 | 李存杰, 张军, 张涌新, 等. 基于pH值分区控制的湿法烟气脱硫增效研究[J]. 环境科学学报, 2015, 35(12):4081-4087. |

| LI Cunjie, ZHANG Jun, ZHANG Yongxin, et al. Removal efficiency of high sulfur dioxide in WFGD based on dual-pH value control[J]. Acta Scientiae Circumstantiae, 2015, 35(12):4081-4087. | |

| 8 | QIN Mingchen, DONG Yong, CUI Lin, et al. Pilot-scale experiment and simulation optimization of dual-loop wet flue gas desulfurization spray scrubbers[J]. Chemical Engineering Research and Design, 2019, 148: 280-290. |

| 9 | 张赢丹, 丁俊, 丁宏. 单塔双区脱硫技术在燃煤电厂中的应用[J]. 浙江电力, 2018, 37(3):73-76. |

| ZHANG Yingdan, DING Jun, DING Hong. Application of single tower and double zone desulphurization technology in coal-fired power plants[J]. Zhejiang Electric Power, 2018, 37(3):73-76. | |

| 10 | 李乐. 浅析石灰石-石膏湿法烟气脱硫吸收塔选型及设计[J]. 中国设备工程, 2021(22):146-148. |

| LI Le. Analysis on selection and design of limestone-gypsum wet flue gas desulfurization absorption tower[J]. China Plant Engineering, 2021(22):146-148. | |

| 11 | 何红博, 刘岩. 浅析浆液冷却系统对湿法脱硫的影响[J]. 化工管理, 2015(20):54. |

| HE Hongbo, LIU Yan. Analysis of influence of slurry cooling system on wet desulfurization[J]. Chemical Enterprise Management, 2015(20):54. | |

| 12 | 金侃. 燃煤电站环保装备运行成本效益研究[D].杭州:浙江大学, 2016. |

| JIN Kan. Study on cost-benefit of envrionmental protection equipment in coal-fired power plants[D].Hangzhou:Zhejiang University, 2016. | |

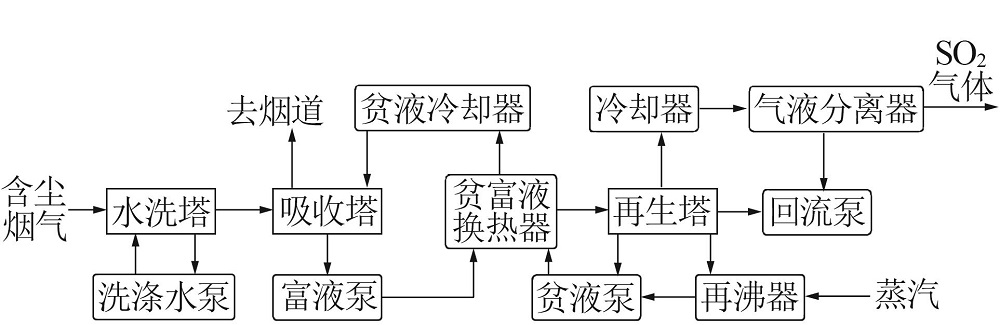

| 13 | 蒋婷, 田浩臣, 蔡琳, 等. 燃煤电厂湿法脱硫故障数据及可靠性分析[J]. 锅炉技术, 2017, 48(4):68-73. |

| JIANG Ting, TIAN Haochen, CAI Lin, et al. Analysis on fault data and reliability of wet desulphurization of coal-fired power plants[J]. Boiler Technology, 2017, 48(4):68-73. | |

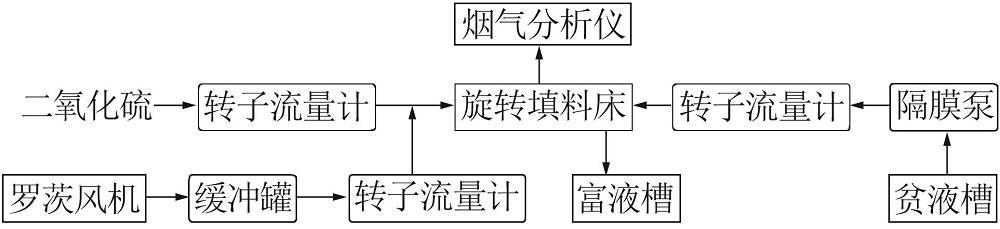

| 14 |

WANG Qunkui, LIU Jing, XUE Fangming. Case analysis and preventive measures of limestone-gypsum wet flue gas desulfurization slurry poisoning for 320 MW unit[J]. IOP Conference Series:Earth and Environmental Science, 2021, 651(2).Doi:10.1088/1755-1315/651/2/022079 .

doi: 10.1088/1755-1315/651/2/022079 |

| 15 |

SONG Da, MA Ying, XUE Fangming, et al. Research on countermeasures against slurry foaming and poisoning of desulphurization system in coal-fired power plants[J]. IOP Conference Series:Earth and Environmental Science, 2021, 651(2).Doi:10.1088/1755-1315/651/2/022069 .

doi: 10.1088/1755-1315/651/2/022069 |

| 16 | 庞子涛, 黄思齐, 宋永吉, 等. 燃煤烟气同时脱硫脱硝技术研究现状与展望[J]. 现代化工, 2019, 39(1):56-60. |

| PANG Zitao, HUANG Siqi, SONG Yongji, et al. Research status and prospect for simultaneous desulfurization and denitrification of coal-fired flue gas[J]. Modern Chemical Industry, 2019, 39(1):56-60. | |

| 17 | 王睿, 王连勇, 崔家新, 等. 燃煤烟气同时脱硫脱硝技术研究现状[C]// 第十一届全国能源与热工学术年会论文集. 沈阳: 中国金属学会能源与热工分会, 2021:26-34. |

| 18 | 沙成豪, 张冬冬, 谭波, 等. 湿法烟气脱硫系统协同脱汞研究进展[C]// 中国环境科学学会2021年科学技术年会——环境工程技术创新与应用分会场论文集(三). 北京: 中国环境科学学会环境工程分会, 2021:154-158,244. |

| 19 |

WU Qirong, GU Min, DU Yungui, et al. Synergistic removal of dust using the wet flue gas desulfurization systems[J]. Royal Society Open Science, 2019, 6(7).Doi:10.1098/rsos.181696 .

doi: 10.1098/rsos.181696 |

| 20 |

ZHANG Shanshan, WU Qiaoling, JIN Yinjia, et al. Study on biological treatment of limestone-gypsum wet desulfurization wastewater[J]. IOP Conference Series:Materials Science and Engineering, 2019, 563(2).Doi:10.1088/1757-899X/563/2/022007 .

doi: 10.1088/1757-899X/563/2/022007 |

| 21 | 项飞鹏, 陈锡炯, 刘春红, 等. 火电脱硫石膏资源化利用研究进展[J]. 新型建筑材料, 2021, 48(6):25-30. |

| XIANG Feipeng, CHEN Xijiong, LIU Chunhong, et al. Research status on resource utilization of power plant desulfurization gypsum[J]. New Building Materials, 2021, 48(6):25-30. | |

| 22 |

DENG Yongqiang, ZOU Peng, WU Fayuan, et al. Discussion on the cause of scaling in wet desulfurization system of large coal-fired power plants[J]. IOP Conference Series:Earth and Environmental Science, 2018, 199.Doi:10.1088/1755-1315/199/5/052021 .

doi: 10.1088/1755-1315/199/5/052021 |

| 23 | 马双忱, 徐昉, 徐东升, 等. 湿法脱硫吸收塔结垢原因分析与防治[J]. 电力科学与工程, 2019, 35(4):51-58. |

| MA Shuangchen, XU Fang, XU Dongsheng, et al. Cause analysis and prevention of scale formation in wet desulfurization absorption tower[J]. Electric Power Science and Engineering, 2019, 35(4):51-58. | |

| 24 | 李文鼎, 高惠华, 蔡文丰. 石灰石–石膏湿法脱硫吸收塔结垢分析及预防措施[J]. 发电技术, 2019, 40(1):51-55. |

| LI Wending, GAO Huihua, CAI Wenfeng. Scaling analysis and preventive measures of limestone-gypsum wet flue gas desulfurization[J]. Power Generation Technology, 2019, 40(1):51-55. | |

| 25 | 郭江源, 张志勇, 吴宇, 等. 石灰石-石膏湿法脱硫系统常见问题分析[C]//中国环境科学学会2019年科学技术年会——环境工程技术创新与应用分论坛论文集(四).北京:中国环境科学学会环境工程分会, 2019:389-393. |

| 26 | 窦吉平, 刘文武, 高志斗. 脱硫系统设备与管道的腐蚀与防护[J]. 冶金能源, 2018, 37(5):58-61. |

| DOU Jiping, LIU Wenwu, GAO Zhidou. Discussion and analysis of the corrosion and protection of the equipment and pipes in the desulfirization system[J]. Energy for Metallurgical Industry, 2018, 37(5):58-61. | |

| 27 | 刘林程, 左海滨, 许志强. 工业石膏的资源化利用途径与展望[J]. 无机盐工业, 2021, 53(10):1-9. |

| LIU Lincheng, ZUO Haibin, XU Zhiqiang. Resource utilization approach of industrial gypsum and its prospect[J]. Inorganic Chemicals Industry, 2021, 53(10):1-9. | |

| 28 |

NI Tingting, WANG Yunzhong, HUANG Chenghui, et al. Limestone-gypsum wet flue gas desulfurization wastewater treatment[J]. IOP Conference Series:Earth and Environmental Science, 2021, 651(4).Doi:10.1088/1755-1315/651/4/042034 .

doi: 10.1088/1755-1315/651/4/042034 |

| 29 | 山乐胜. 应用氧化镁法烟气脱硫工艺的可行性分析[J]. 山东电力技术, 2003(6):14-16. |

| SHAN Yuesheng. Feasibility study of application of magnesia FGD process[J]. Shandong Electric Power, 2003(6):14-16. | |

| 30 | 冯雅丽, 廖圣德, 李浩然, 等. 镁法脱硫及脱硫产物多元化利用研究现状[J]. 无机盐工业, 2019, 51(3):1-6. |

| FENG Yali, LIAO Shengde, LI Haoran, et al. Research status of magnesium desulphurization and diversified utilization of desulfurization products[J]. Inorganic Chemicals Industry, 2019, 51(3):1-6. | |

| 31 |

QU Litao, LI Caiting, LI Chao, et al. Evaluation of ultralow emission performance of magnesium oxide(MgO) wet flue gas desulfurization unit for coal-fired units[J]. IOP Conference Series:Earth and Environmental Science, 2019, 267(6).Doi:10.1088/1755-1315/267/6/062045 .

doi: 10.1088/1755-1315/267/6/062045 |

| 32 | 王昕竑, 周欣, 王中原, 等. 七水硫酸镁干燥脱水制取一水硫酸镁实验研究[J]. 无机盐工业, 2011, 43(10):45-47. |

| WANG Xinhong, ZHOU Xin, WANG Zhongyuan, et al. Study on preparation of magnesium sulfate monohydrate by dehydration of magnesium sulfate heptahydrate[J]. Inorganic Chemicals Industry, 2011, 43(10):45-47. | |

| 33 | 亢万忠. 镁法烟气脱硫副产物资源化利用研究[D].上海:华东理工大学, 2011. |

| KANG Wanzhong. Research on resources utilization of by-product from flue gas desulfurization employing magnesium process[D]. Shanghai:East China University of Science and Technology, 2011. | |

| 34 | 高原, 王振平, 沈小瑞, 等. 工业锅炉钙、镁法烟气脱硫经济性分析[J]. 山东化工, 2021, 50(20):249-250. |

| GAO Yuan, WANG Zhenping, SHEN Xiaorui, et al. Analysis of dosage of calcium and magnesium flue gas desulfurization agents for industrial boilers[J]. Shandong Chemical Industry, 2021, 50(20):249-250. | |

| 35 | 王海风, 张春霞, 齐渊洪. 氨法脱硫研究进展[J]. 环境工程, 2010, 28(6):55-58, 62. |

| WANG Haifeng, ZHANG Chunxia, QI Yuanhong. Status of research on desulfurization by ammonia method[J]. Environmental Engineering, 2010, 28(6):55-58, 62. | |

| 36 | 丁红蕾, 苏秋凤, 张涌新, 等. 湿式氨法烟气脱硫工艺影响因素的试验研究[J]. 热力发电, 2014, 43(1):96-98, 136. |

| DING Honglei, SU Qiufeng, ZHANG Yongxin, et al. Experimental study on factors affecting the ammonia-based WFGD process[J]. Thermal Power Generation, 2014, 43(1):96-98, 136. | |

| 37 | LIAN Zhouyang, LUO Zhengwei, YUAN Lirui, et al. Corrosion inhibition of organic amine on Q235 steel in ammonium sulfate slurry of ammonia flue gas desulfurization system[J]. Anti-Corro- sion Methods and Materials, 2017, 64(4):432-442. |

| 38 | 祁晓晖, 冯想红. 氨法脱硫的硫酸铵结晶影响因素探究[C]//第二十五届大气污染防治技术研讨会论文集.北京:中国环境科学学会, 2021:271-275. |

| 39 | 聂鑫. 海水法烟气脱硫技术在爪哇7号工程中的应用[J]. 能源科技, 2021, 19(2):57-62. |

| NIE Xin. Application of seawater flue gas desulfurization technology in jawa No.7 project[J]. Energy Science and Technology, 2021, 19(2):57-62. | |

| 40 | 姜华, 薛军, 祝良燮. 我国火电厂烟气海水脱硫的发展建议[J]. 环境保护, 2014, 42(S1):69-71. |

| JIANG Hua, XUE Jun, ZHU Liangxie. Suggestions for development of flue gas seawater desulfurization in thermal power plants in China[J]. Environmental Protection, 2014, 42(S1):69-71. | |

| 41 | 郭娟, 袁东星, 陈进生, 等. 燃煤电厂海水脱硫工艺的排水对海域环境的影响[J]. 环境工程学报, 2008(5):707-711. |

| GUO Juan, YUAN Dongxing, CHEN Jinsheng, et al. Impact of discharge water from seawater flue gas desulfurization system of coal-fired power plant on the environment of surrounding sea area[J]. Chinese Journal of Environmental Engineering, 2008(5):707-711. | |

| 42 | 李枭鸣, 王圣, 姜艳靓, 等. 沿海燃煤电厂采用海水脱硫的环境影响适用性分析研究[J]. 环境科学与管理, 2015, 40(1):94-97. |

| LI Xiaoming, WANG Sheng, JIANG Yanliang, et al. Environmental impact feasibility of using seawater FGD process in coastal city[J]. Environmental Science and Management, 2015, 40(1):94-97. | |

| 43 | 顾晓薇, 张延年, 张伟峰, 等. 大宗工业固废高值建材化利用研究现状与展望[J]. 金属矿山, 2022(1):2-13. |

| GU Xiaowei, ZHANG Yannian, ZHANG Weifeng, et al. Research status and prospect of high value building materials utilization of bulk industrial solid waste[J]. Metal Mine, 2022(1):2-13. | |

| 44 | 郭本凯, 夏瑞杰, 王吉营, 等. 硬石膏和脱硫石膏对低钙硫铝酸盐水泥熟料性能的影响[J]. 水泥工程, 2021(4):4-7, 15. |

| GUO Benkai, XIA Ruijie, WANG Jiying, et al. Effect of anhydrite and desulfurized gypsum on the properties of low calcium sulphoaluminate cement clinker[J]. Cement Engineering, 2021(4):4-7, 15. | |

| 45 | 秦萍, 肖国举, 罗成科, 等. 燃煤电厂脱硫石膏改良碱化土壤种植甜高粱的施用量研究[J]. 现代农业科学, 2008(12):32-35. |

| QIN Ping, XIAO Guoju, LUO Chengke, et al. Study on the application amount of desulfurized gypsum from coal-fired power plant in improving alkalized soil to plant sweet sorghum[J]. Modern Agricultural Sciences, 2008(12):32-35. | |

| 46 | 梁玲. 离子液循环吸收脱硫工程主要设备参数计算与选型[J]. 有色冶金节能, 2021, 37(1):62-66. |

| LIANG Ling. Parameters calculation and selection of main equipment for ionic liquid absorption cyclic desulfurization[J]. Energy Saving of Nonferrous Metallurgy, 2021, 37(1):62-66. | |

| 47 | 产文兵, 万皓, 宋桂东, 等. 钠碱法烟气脱硫工艺技术[J]. 上海大学学报:自然科学版, 2013, 19(5):474-478. |

| CHAN Wenbing, WAN Hao, SONG Guidong, et al. FGD process technology with sodium alkaline method[J]. Journal of Shanghai University:Natural Science, 2013, 19(5):474-478. | |

| 48 | 袁志国, 刘有智, 康晓峰, 等. 超重力-磷酸钠法脱除低浓度SO2 [J]. 环境工程学报, 2013, 7(11):4475-4480. |

| YUAN Zhiguo, LIU Youzhi, KANG Xiaofeng, et al. Removal of low concentration sulfur dioxide from gas by aqueous of sodium phosphate in high gravity[J]. Chinese Journal of Environmental Engineering, 2013, 7(11):4475-4480. | |

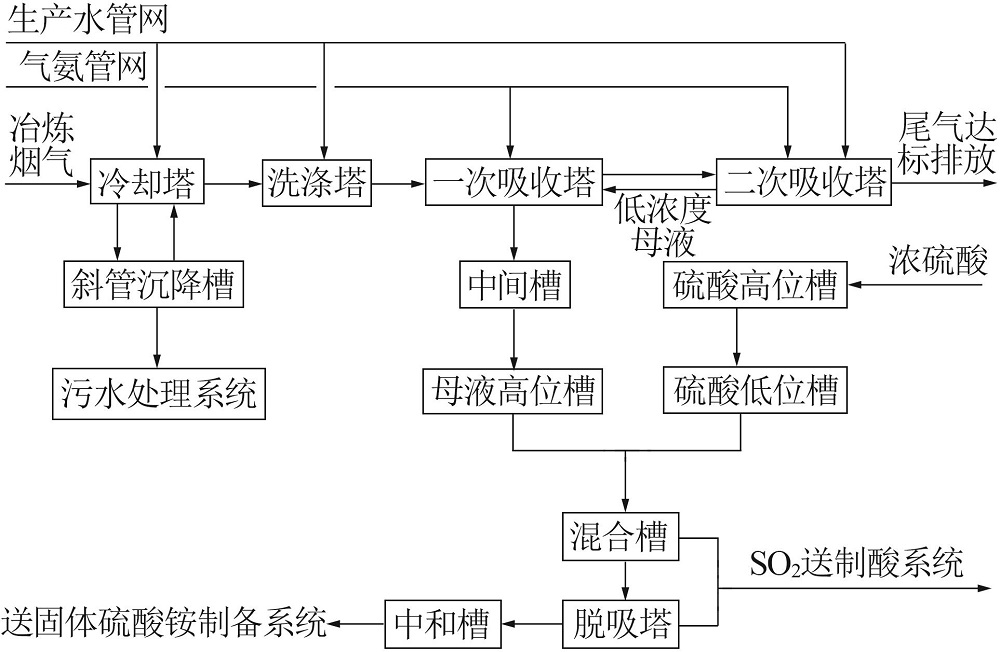

| 49 | 王亚. 烟气氨酸法脱硫技术在锌冶炼中的应用[J]. 中国金属通报, 2018(4):73-74. |

| WANG Ya. Application of flue gas ammonia acid desulfurization technology in zinc smelting[J]. China Metal Bulletin, 2018(4):73-74. | |

| 50 | 李洪伟, 彭红寒, 袁红欣, 等. 铅锌冶炼烟气氨酸法脱硫技术的研究与运用[J]. 硫酸工业, 2017(1):29-32. |

| LI Hongwei, PENG Honghan, YUAN Hongxin, et al. Research and application of desulphurization method by ammonia in sulphuric acid plant based on lead and zinc smelting off-gases[J]. Sulphuric Acid Industry, 2017(1):29-32. | |

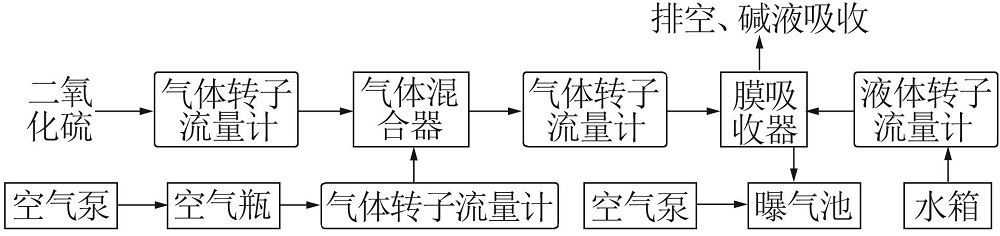

| 51 | 黄金凤. 膜吸收法烟气脱硫的研究[D].南京:南京理工大学, 2004. |

| 52 |

LIU Jie, DENG Mengxuan, YUAN Junsheng, et al. An aeration membrane absorption seawater flue gas desulfurization process intensified by combining dual-phase flow and oxidation reaction[J]. Chemical Engineering and Processing-Process Intensification, 2020, 153.Doi:10.1016/j.cep.2020.107935 .

doi: 10.1016/j.cep.2020.107935 |

| 53 | 刘铮, 关毅鹏, 曹震, 等. 膜气体吸收-氨法脱硫技术在煤化工废气处理中的应用[J]. 膜科学与技术, 2018, 38(2):106-110. |

| LIU Zheng, GUAN Yipeng, CAO Zhen, et al. Application of membrane gas absorption and ammonia desulphurization combination technique in the treatment of coal chemical waste gas[J]. Membrane Science and Technology, 2018, 38(2):106-110. | |

| 54 | 崔振东, 侯纯扬, 陈颖, 等. 膜吸收法浓海水烟气脱硫试验研究[J]. 膜科学与技术, 2011, 31(1):84-88. |

| CUI Zhendong, HOU Chunyang, CHEN Ying, et al. Study of concentrated seawater flue gas desulphurization by membrane absorption[J]. Membrane Science and Technology, 2011, 31(1):84-88. |

| [1] | SHEN Haiyan, LI Fangqin, REN Jianxing, WU Jiang, GUAN Zhenzhen, PAN Weiguo. Research progress on chemical absorption method for capturing carbon dioxide [J]. Inorganic Chemicals Industry, 2024, 56(5): 11-19. |

| [2] | LAI Xiaoling, ZHOU Wei, ZANG Jiazhong, DONG Zichao, HU Mingliang, SUN Shaochen. Research progress of low temperature cyclic sorption of carbon dioxide by calcium oxide-based sorbents [J]. Inorganic Chemicals Industry, 2023, 55(5): 16-23. |

| [3] | Liu Bingguang,Zu Xiaodong,Li Jiansheng,Lu Junfeng,Wang Zejiang. Research progress in supported lithium ion sieve absorbents [J]. Inorganic Chemicals Industry, 2019, 51(9): 12-16. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||