Inorganic Chemicals Industry ›› 2022, Vol. 54 ›› Issue (10): 121-126.doi: 10.19964/j.issn.1006-4990.2022-0019

• Environment·Health·Safety • Previous Articles Next Articles

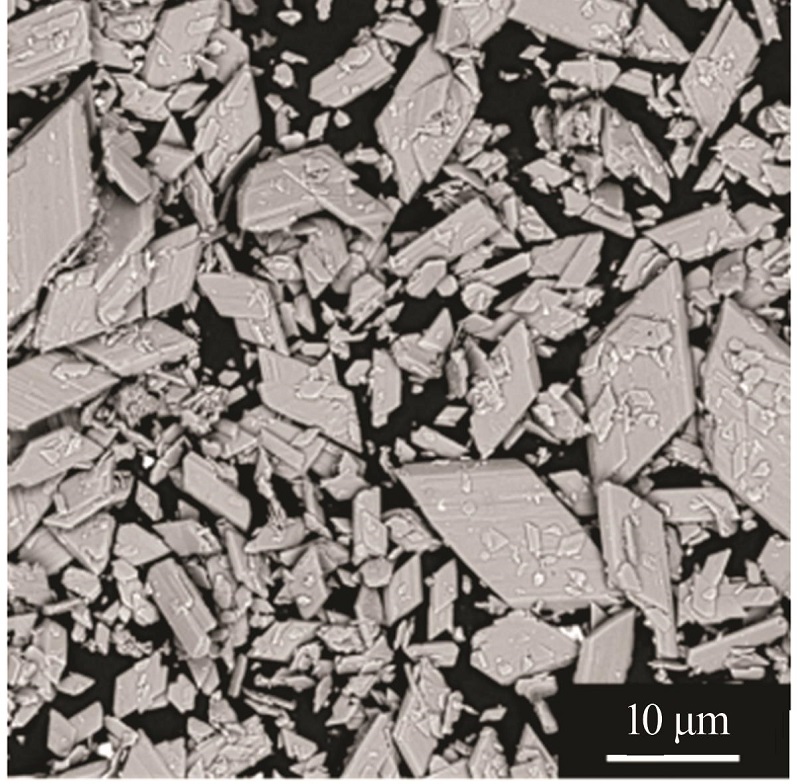

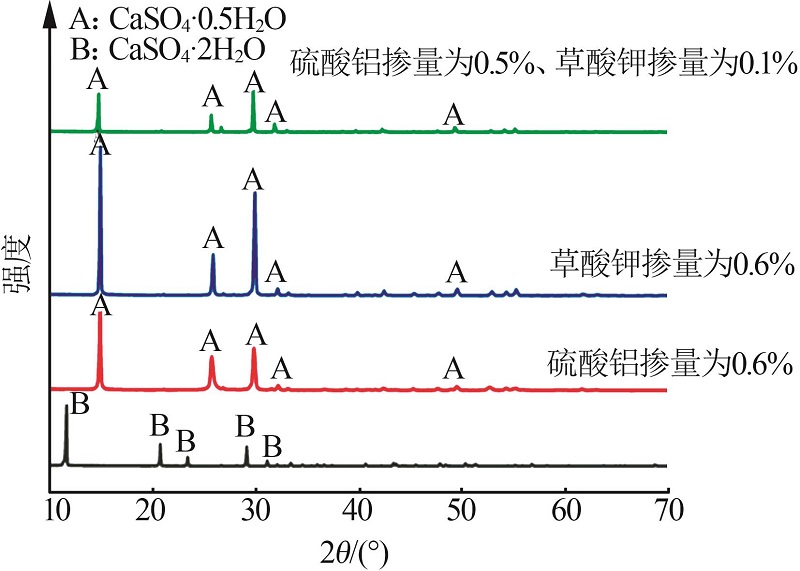

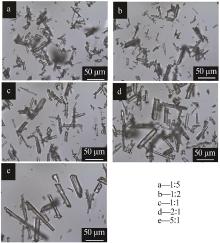

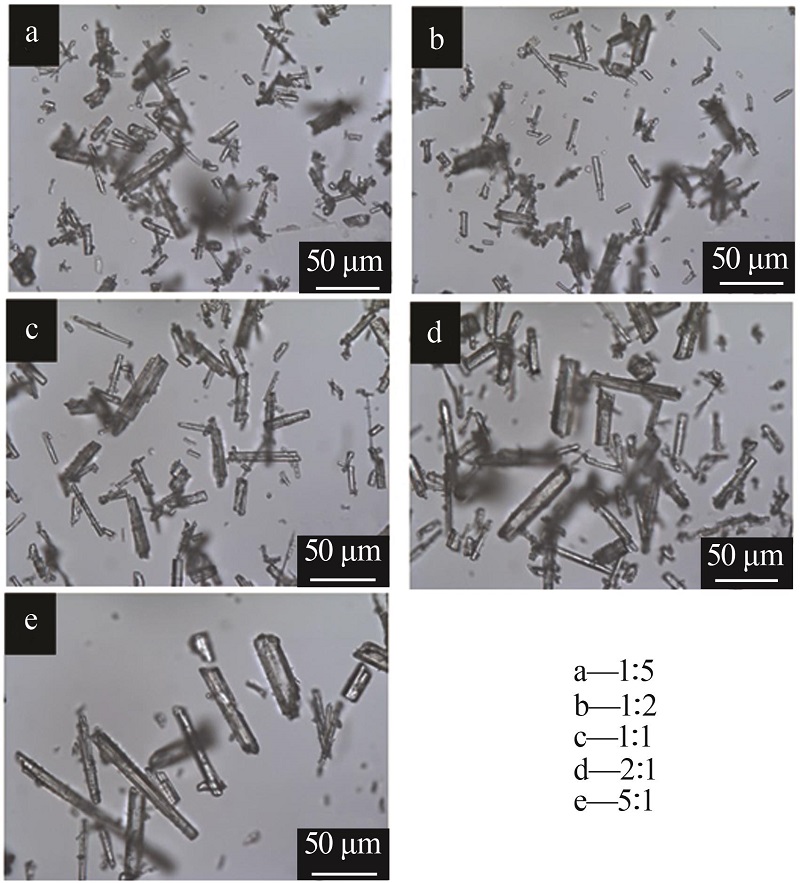

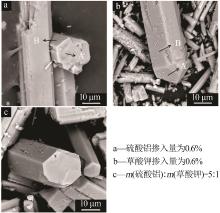

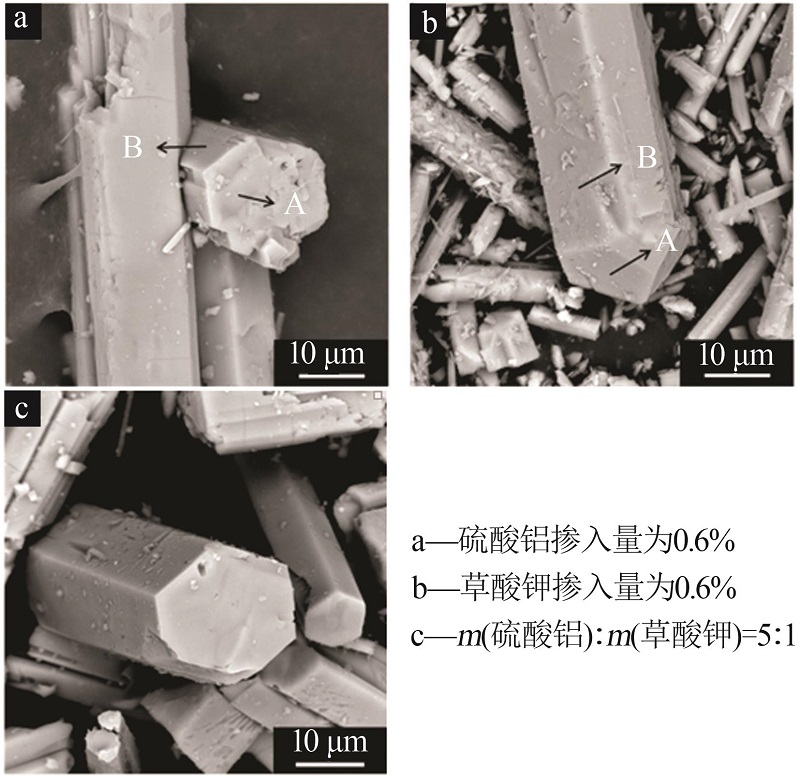

Effect of potassium oxalate and aluminum sulfate and their compounds on preparation and properties of α-hemihydrate gypsum

JIANG Hanning( ),LI Yuping(

),LI Yuping( ),WANG Zhiyun,WEN Huimin,YE Baoquan

),WANG Zhiyun,WEN Huimin,YE Baoquan

- School of materials science and Engineering,Hunan University,Changsha 410006,China

-

Received:2022-03-12Online:2022-10-10Published:2022-11-03 -

Contact:LI Yuping E-mail:13855605291@163.com;liypli@hnu.edu.cn

CLC Number:

Cite this article

JIANG Hanning,LI Yuping,WANG Zhiyun,WEN Huimin,YE Baoquan. Effect of potassium oxalate and aluminum sulfate and their compounds on preparation and properties of α-hemihydrate gypsum[J]. Inorganic Chemicals Industry, 2022, 54(10): 121-126.

share this article

| [1] | 张厚记, 宗炜, 郑武西, 等. 工业固废磷石膏复合稳定基层材料研究[J].武汉理工大学学报, 2021, 43(12): 7-12. |

| ZHANG Houji, ZONG Wei, ZHENG Wuxi, et al.Composite stabilized base material research of industrial solid waste phosphogypsum[J].Journal of Wuhan University of Technology, 2021, 43(12): 7-12. | |

| [2] | 龚丽, 何宾宾, 姜威, 等. 简述磷石膏制备半水石膏的工艺及应用[J].磷肥与复肥, 2019, 34(12): 27-29. |

| GONG Li, HE Binbin, JIANG Wei, et al.Review of production process of hemihydrate gypsum from phosphogypsum and its application[J].Phosphate & Compound Fertilizer, 2019, 34(12): 27-29. | |

| [3] | 刘伟, 刘永秀, 王琰沛.利用不同磷石膏制备α型半水石膏的研究[J].山东化工, 2019, 48(14): 59-61. |

| LIU Wei, LIU Yongxiu, WANG Yanpei.Study on using different phosphogypsum prepared α-hemihydrate gypsum[J].Shandong | |

| Industry Chemical, 2019, 48(14): 59-61. | |

| [4] | 张凡凡, 陈超, 相利学.基于磷石膏的半干法制备α半水石膏试验[J].现代矿业, 2016, 32(10): 72-74, 77. |

| [5] | 耿庆钰, 李建锡, 韩伟明, 等. 磷石膏蒸压制备半水硫酸钙晶须[J].人工晶体学报, 2016, 45(7): 1892-1897, 1905. |

| GENG Qingyu, LI Jianxi, HAN Weiming, et al.Preparation of calcium sulfate hemihydrate whisker by phosphogypsum autoclave method[J].Journal of Synthetic Crystals, 2016, 45(7): 1892-1897, 1905. | |

| [6] | 韩康, 管学茂, 王燕峰, 等. 加压水溶液法制备工艺对α型高强石膏性能的影响[J].硅酸盐通报, 2021, 40(5): 1620-1630, 1645. |

| HAN Kang, GUAN Xuemao, WANG Yanfeng, et al.Effect of preparation process of pressurized aqueous solution method on properties of α-high strength gypsum[J].Bulletin of the Chinese Ceramic Society, 2021, 40(5): 1620-1630, 1645. | |

| [7] | 郑万荣, 高洋, 高飞, 等. 加压水溶液法制备α半水石膏技术的几个问题[J].非金属矿, 2007, 30(4): 4-7. |

| ZHENG Wanrong, GAO Yang, GAO Fei, et al.Some questions on preparation of α-hemihydrate gypsum with hydrothermal method in pressure[J].Non-Metallic Mines, 2007, 30(4): 4-7. | |

| [8] | LI Xianbo, ZHANG Qin, SHEN Zhihui, et al.L-aspartic acid:A crystal modifier for preparation of hemihydrate from phosphogypsum in CaCl2 solution[J].Journal of Crystal Growth, 2019, 511: 48-55. |

| [9] | 丁峰, 窦焰, 郑之银, 等. 常压盐溶液-丁二酸转晶体系中pH对α-CaSO4·0.5H2O的影响[J].无机盐工业, 2020, 52(1): 82-86, 98. |

| DING Feng, DOU Yan, ZHENG Zhiyin, et al.Effect of pH on α-CaSO4·0.5H2O in salt solution at atmospheric pressure-succinic acid crystal transfer system[J].Inorganic Chemicals Industry, 2020, 52(1): 82-86, 98. | |

| [10] | SINGH N B, MIDDENDORF B.Calcium sulphate hemihydrate hydration leading to gypsum crystallization[J].Progress in Crystal Growth and Characterization of Materials, 2007, 53(1): 57-77. |

| [11] |

SHAO Duoduo, ZHAO Bin, ZHANG Hongqi, et al.Preparation of large-grained α-high strength gypsum with FGD gypsum[J].Crystal Research and Technology, 2017, 52(7).Doi:10.1002/crat. 201700078 .

doi: 10.1002/crat. 201700078 |

| [12] | 张稼祥, 徐玲玲.EDTA对脱硫石膏制备α-半水石膏晶体生长的影响[J].南京工业大学学报:自然科学版, 2018, 40(2): 90-94, 131. |

| ZHANG Jiaxiang, XU Lingling.Effects of EDTA on crystal growth of α-hemihydrate gypsum prepared by flue gas desulphurization gypsum[J].Journal of Nanjing Tech University:Natural Science Edition, 2018, 40(2): 90-94, 131. | |

| [13] | 胡成, 向玮衡, 陈平, 等. 丁二酸对水热合成α-半水脱硫石膏微晶形貌及力学强度的影响[J].无机盐工业, 2021, 53(4): 76-80. |

| HU Cheng, XIANG Weiheng, CHEN Ping, et al.Effects of succinic acid on crystallite morphology and mechanical strength of α-hemihydrate desulfurized gypsum synthesized by hydrothermal method[J].Inorganic Chemicals Industry, 2021, 53(4): 76-80. | |

| [14] | 张巨松, 孙蓬, 鞠成, 等. 转晶剂对脱硫石膏制备α-半水石膏形貌及强度的影响[J].沈阳建筑大学学报:自然科学版, 2009, 25(3): 521-525. |

| ZHANG Jusong, SUN Peng, JU Cheng, et al.Influence of crystal modifier on morphology and strength of α-hemihydrate gypsum prepared by desulfurization gypsum[J].Journal of Shenyang Jianzhu University:Natural Science, 2009, 25(3): 521-525. | |

| [15] | DUAN Zhengyang, LI Jianxi, LI Tianguo, et al.Influence of crystal modifier on the preparation of α-hemihydrate gypsum from phosphogypsum[J].Construction and Building Materials, 2017, 133: 323-329. |

| [1] | HU Cheng, LIU Meng, XIANG Weiheng, CHEN Ping, WANG Neng, LU Guanju, ZHOU Jinlan. Preparation of α-hemihydrous gypsum from CaCl2 and MgCl2 and their composite solution [J]. Inorganic Chemicals Industry, 2024, 56(7): 112-117. |

| [2] | HU Cheng, LIU Meng, XIANG Weiheng, DUAN Pengxuan, LI Shunkai, MING Yang, WANG Neng, LU Guanju. Effect of NaCl solution concentration on transcrystallization behavior of α-hemihydrate gypsum from phosphogypsum [J]. Inorganic Chemicals Industry, 2024, 56(6): 87-93. |

| [3] | WANG Mingshun, AO Xianquan, YUAN Xing, DONG Wenyan, CHEN Qianlin. Study on effect of crystallizer on preparation of anhydrous calcium sulfate from phosphogypsum [J]. Inorganic Chemicals Industry, 2024, 56(5): 101-107. |

| [4] | WANG Shengchang, HAO Jianying, CHEN Jianing, TIAN Bo. Effect of calcination on properties of calcined gypsum prepared from desulphurization gypsum with potassium aluminum sulfate [J]. Inorganic Chemicals Industry, 2024, 56(4): 105-111. |

| [5] | WANG Peixiong, GONG Xiaomei, DING Jiaqi, CAO Hong. Effect of crystal modifier on preparation of α-hemihydrates gypsum from industrial gypsum [J]. Inorganic Chemicals Industry, 2024, 56(4): 112-117. |

| [6] | YANG Fengling, QIAO Guoxin, YANG Pu, REN Lei, WANG Qiong, WU Haibin, CHENG Fangqin. Research progress and application of α-hemihydrate gypsum preparation from desulfurization gypsum [J]. Inorganic Chemicals Industry, 2024, 56(2): 11-20. |

| [7] | LI Peng, WANG Likun, MENG Qiuyan. Study on effect of α-hemihydrate gypsum on performance of cement mortar and its hydration mechanism [J]. Inorganic Chemicals Industry, 2023, 55(3): 98-103. |

| [8] | LI Yunfei, LIU Shuqing, TANG Shengwei, ZHANG Tao. Preparation of α-hemihydrate gypsum in Mg-Na mixed salt solution system under atmospheric pressure [J]. Inorganic Chemicals Industry, 2023, 55(11): 100-106. |

| [9] | LIU Chao, FAN Chuigang, LIU Runguo, YU Dongxue, LI Songgeng. Preparation of α-hemihydrate gypsum from phosphogypsum by flotation and atmospheric trans-crystallization in solution [J]. Inorganic Chemicals Industry, 2023, 55(11): 107-114. |

| [10] | LI Mingchuan,WEI Jiazhan,CHEN Ping,DUAN Pengxuan. Effect of crystal modifier and autoclave parameters on preparation of α-hemihydrate gypsum from phosphogypsum [J]. Inorganic Chemicals Industry, 2022, 54(8): 132-137. |

| [11] | XU Cheng,SHENG Jiefa,HAO Yuning,WU Binghui,MA Xiaoming,LIU Jianwu,YAN Shenghu,ZHANG Yue. Study on process of preparing α-hemihydrate gypsum by azeotropic reflux method [J]. Inorganic Chemicals Industry, 2022, 54(7): 117-123. |

| [12] | He Qingfeng,He Zhaohui,Yang Yumei,Wang Kaibao,Huang He,Liu Xiaofei,Gao Li,Li Yali,Li Jiaoyan. Current status and development trend of China′s aluminum and iron salt industry [J]. Inorganic Chemicals Industry, 2021, 53(6): 123-127. |

| [13] | YANG Zhuoying,YANG Fan,YI Meigui,XIANG Lan. Rule of hydrothermal hydrolysis of Mg/Al-bearing TiOSO4 solution [J]. Inorganic Chemicals Industry, 2021, 53(12): 113-116. |

| [14] | Chen Ping,Tian Yu,Hu Cheng. Effect of type and concentration of salt solution on synthesis of α-semi-water desulfurization gypsum [J]. Inorganic Chemicals Industry, 2020, 52(10): 130-134. |

| [15] | Zhao Xiaoli,Fang Li,Zhao Zesen,Cheng Huaigang,Cheng Fangqin. Study on crystal morphology in preparation of aluminum chloride hexahydrate by ammonium aluminum sulfate-hydrogen chloride reaction [J]. Inorganic Chemicals Industry, 2019, 51(5): 28-32. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||