Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (12): 66-73.doi: 10.19964/j.issn.1006-4990.2023-0055

• Research & Development • Previous Articles Next Articles

Synthesis of sodium titanate anode from industrial titanium liquid and its sodium storage performance

ZHANG Rui( ), WANG Zhenghao, CHEN Liang, GUO Xiaodong, LUO Dongmei(

), WANG Zhenghao, CHEN Liang, GUO Xiaodong, LUO Dongmei( )

)

- School of Chemical Engineering,Sichuan University,Chengdu 610065,China

-

Received:2023-02-07Online:2023-12-10Published:2023-12-14 -

Contact:LUO Dongmei E-mail:2515541008@qq.com;dmluo@scu.edu.cn

CLC Number:

Cite this article

ZHANG Rui, WANG Zhenghao, CHEN Liang, GUO Xiaodong, LUO Dongmei. Synthesis of sodium titanate anode from industrial titanium liquid and its sodium storage performance[J]. Inorganic Chemicals Industry, 2023, 55(12): 66-73.

share this article

Table 4

Comparison of electrochemical performance of mixed with sodium titanate prepared in this paper with that prepared by other methods"

| 制备方法 | 原料 | 产物物相 | 电流密度/循环次数/放电比容量 |

|---|---|---|---|

| 水热法[ | 锐钛TiO2,NaOH | Na2Ti3O7/Na2Ti6O13 | 20 mA/g,100次,约80 mA·h/g;2 000 mA/g, 4 000次,19.45 mA·h/g |

| 溶胶-凝胶法[ | 丁醇钛,NaOH | Na2Ti3O7;Na2Ti3O7/MWCNT | 0.2C,50次,8 mA·h/g;0.2C,50次,160 mA·h/g |

喷雾干燥法[ 1 000 ℃,8 h) | TiO2,Na2CO3 | 800 ℃:Na2Ti3O7; 1 000 ℃:Na2Ti3O7 | 35.6 mA/g,500次,44 mA·h/g;178 mA/g, 500次,32 mA·h/g |

| 高温固相法[ | TiO2和Na2CO3·H2O,TiO2和NaOH | 24 h:CO-Na2Ti3O7; 20 h:OH-Na2Ti3O7 | 0.1C,100次,<10 mA·h/g;0.1C,100次,约 76.9 mA·h/g |

| 高温固相法[ | TiO2(锐钛与金红石混合)和Na2CO3 | m-Na2Ti3O7;t-Na2Ti3O7 | 20 mA/g,20次,35.5 mA·h/g;20 mA/g,20次, 约92 mA·h/g |

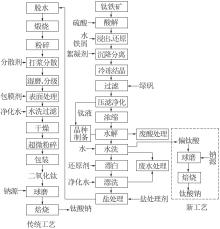

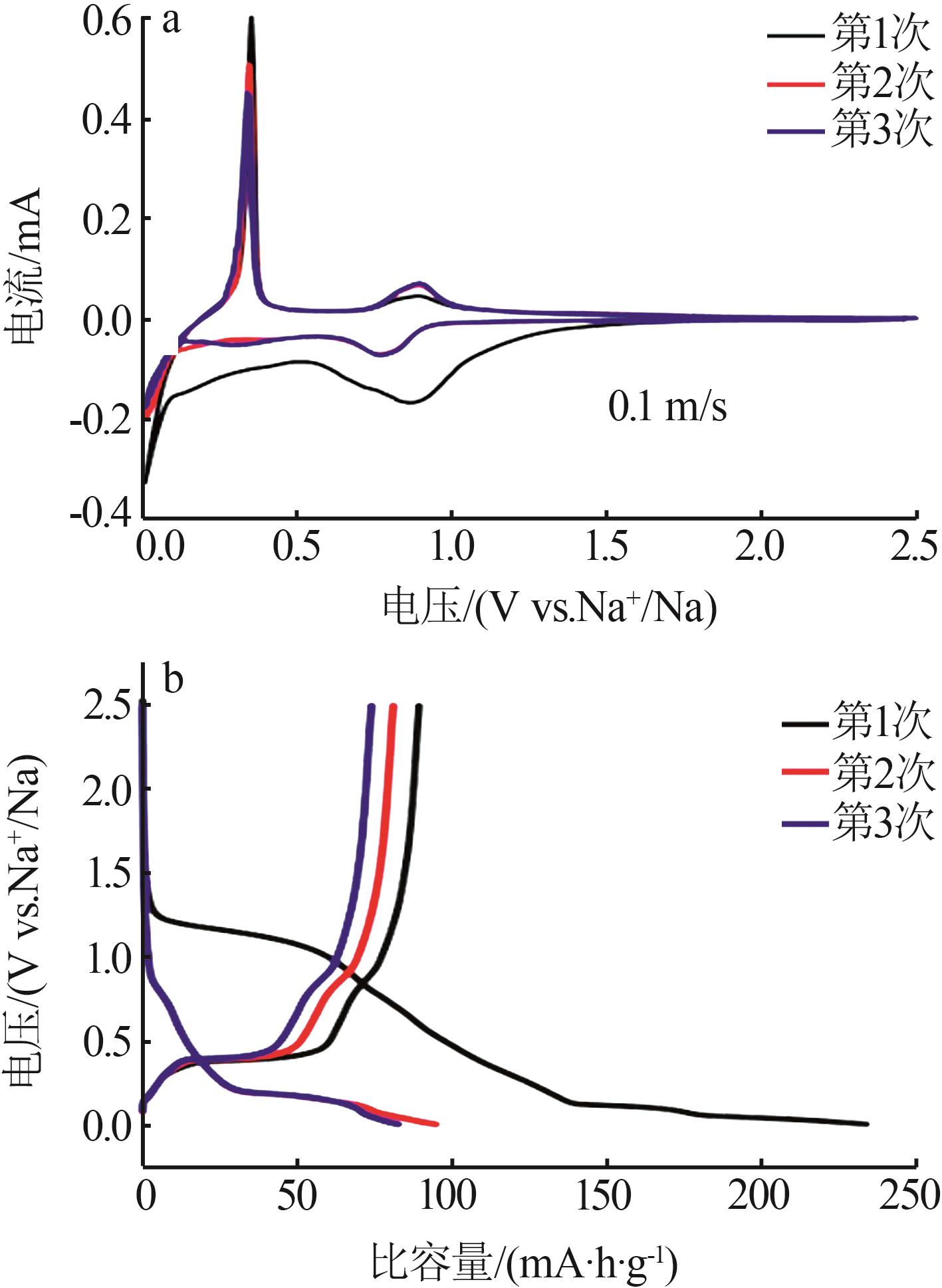

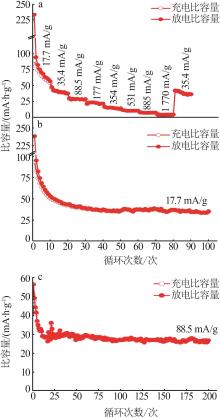

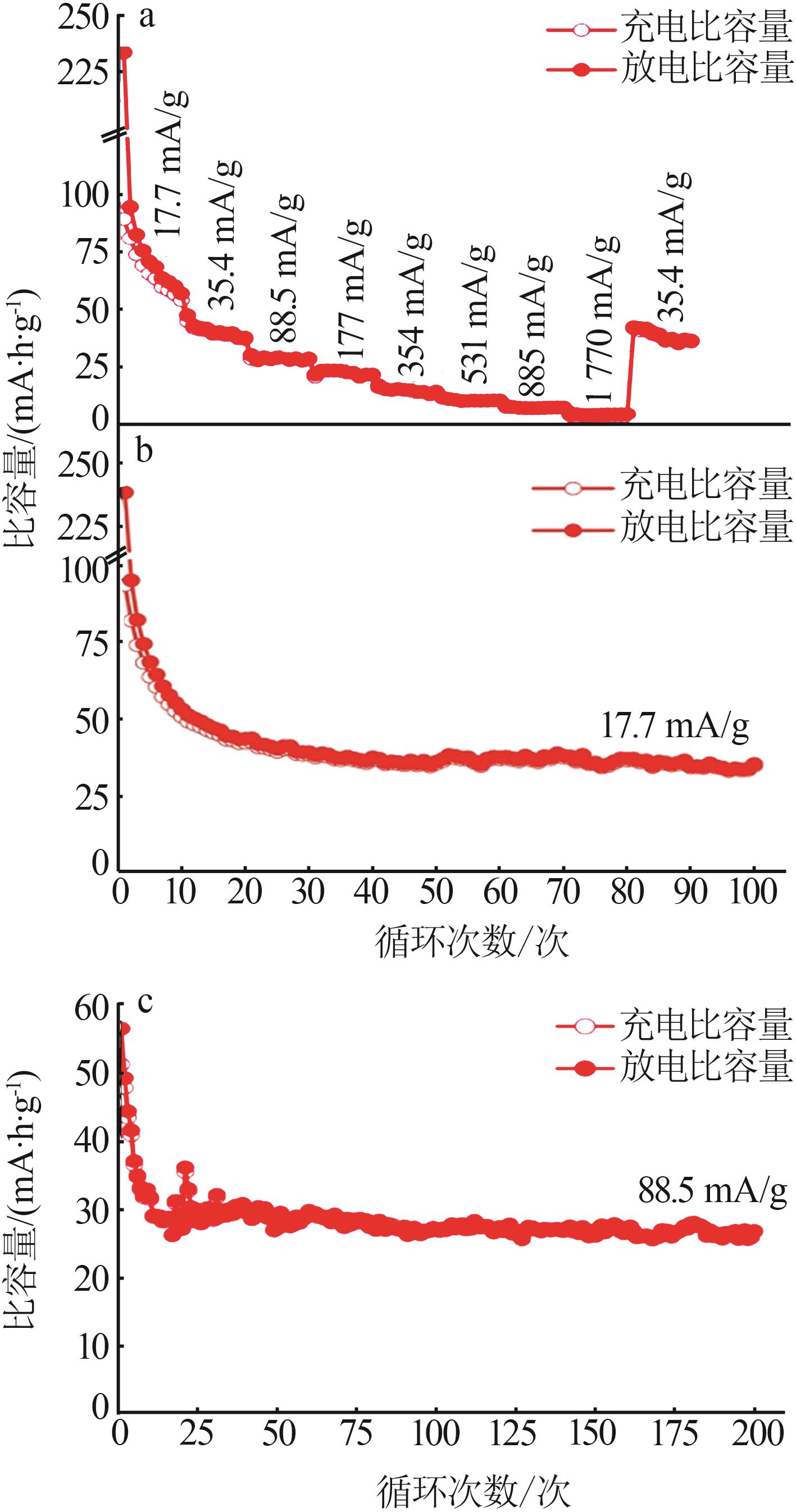

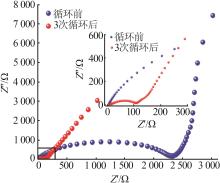

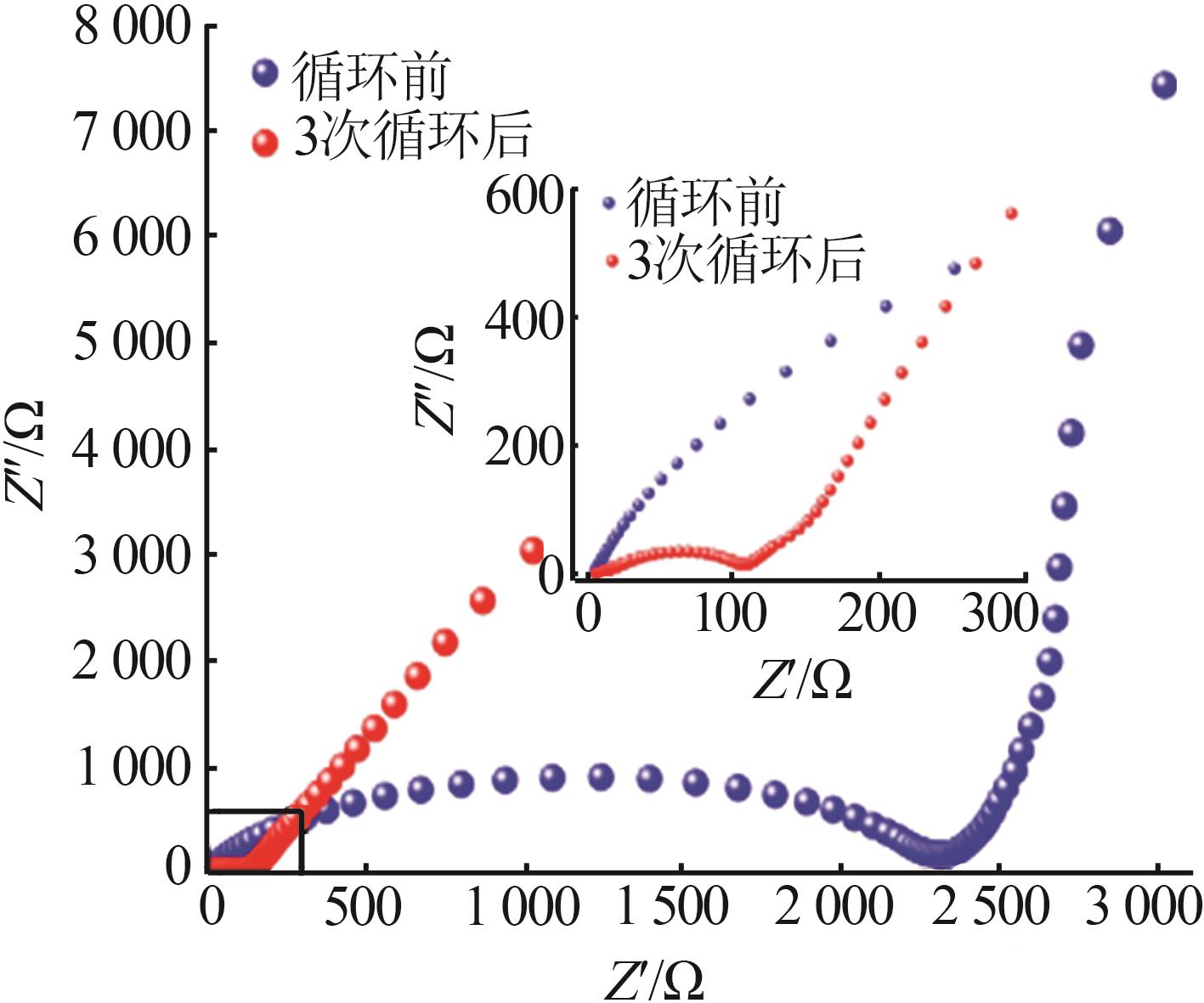

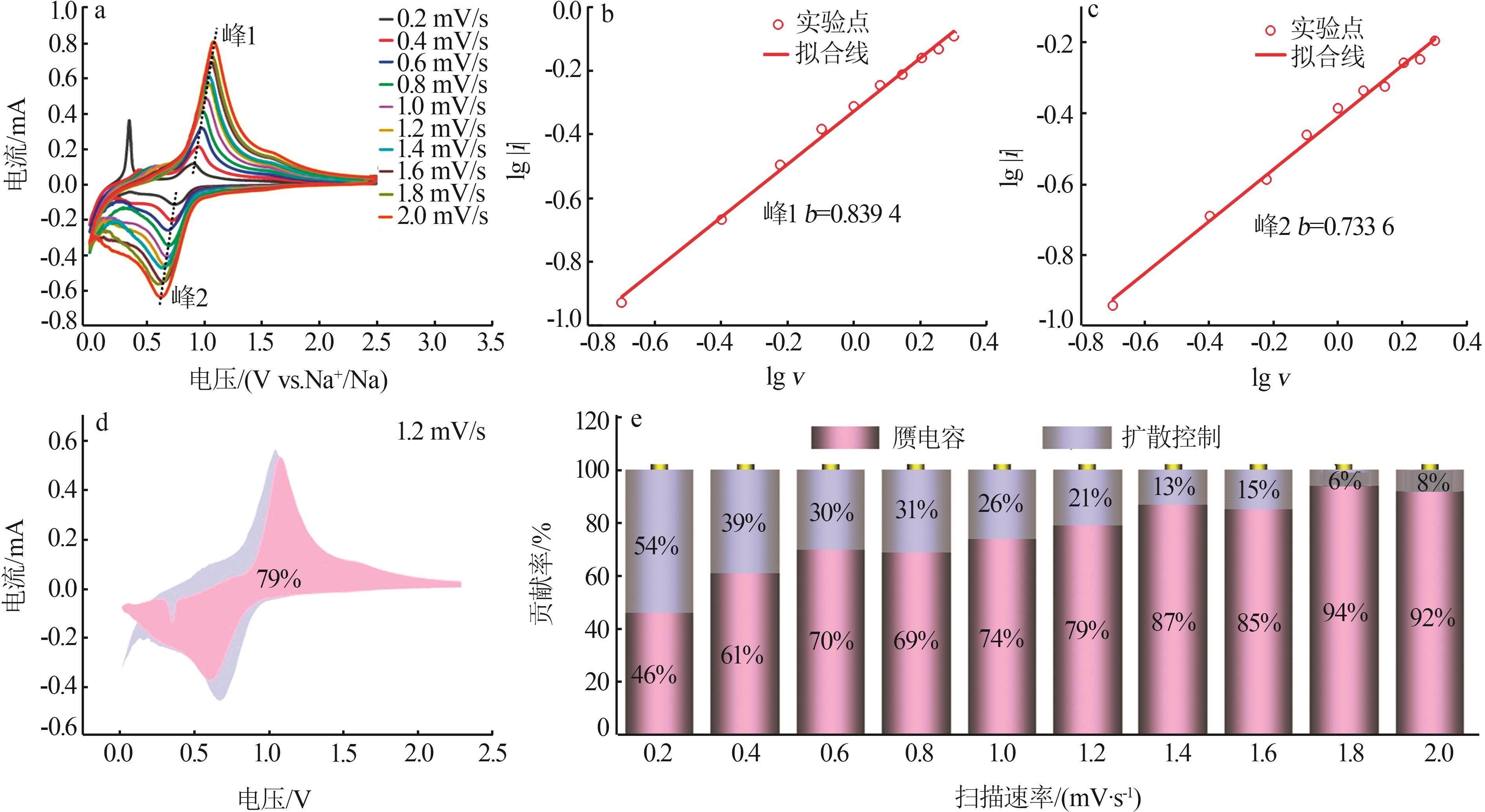

| 高温固相法(800 ℃,20 h) | 工业钛液水解得到的偏钛酸,Na2CO3 | Na2Ti3O7/Na2Ti6O13 | 88.5 mA/g,200次,26.87 mA·h/g |

| 1 |

DONG Shengyang, LV Nan, WU Yulin, et al. Titanates for sodium-ion storage[J]. Nano Today, 2022, 42:101349.

doi: 10.1016/j.nantod.2021.101349 |

| 2 |

DELMAS C. Sodium and sodium-ion batteries:50 years of resear-ch[J]. Advanced Energy Materials, 2018, 8(17):1703137.

doi: 10.1002/aenm.v8.17 |

| 3 |

PLACKE T, KLOEPSCH R, DÜHNEN S, et al. Lithium ion,lithium metal,and alternative rechargeable battery technologies:The odyssey for high energy density[J]. Journal of Solid State Electrochemistry, 2017, 21(7):1939-1964.

doi: 10.1007/s10008-017-3610-7 |

| 4 | MATSUMOTO K, HWANG J, KAUSHIK S, et al. Advances in sodium secondary batteries utilizing ionic liquid electrolytes[J]. Energy & Environmental Science, 2019, 12(11):3247-3287. |

| 5 |

LIBICH J, MINDA J, SEDLAŘÍKOVÁ M, et al. Sodium-ion batteries:Electrochemical properties of sodium titanate as negative electrode[J]. Journal of Energy Storage, 2020, 27:101150.

doi: 10.1016/j.est.2019.101150 |

| 6 |

HASA I, MARIYAPPAN S, SAUREL D, et al. Challenges of today for Na-based batteries of the future:From materials to cell metri-cs[J]. Journal of Power Sources, 2021, 482:228872.

doi: 10.1016/j.jpowsour.2020.228872 |

| 7 | LI Shiyou, WEN Shuxiang, DING Hao, et al. Improve the electrochemical performance of Na2Ti3O7 nanorod through pitch coat-ing[J]. ACS Sustainable Chemistry & Engineering, 2022, 10(13):4247-4257. |

| 8 | MUKHERJEE A, DAS D, BANERJEE S, et al. Synthesis and electrochemical performance of in situ and ex-situ carbon-coated Na2Ti3O7,as a promising anode for sodium-ion batteries[J]. Electrochemical Science Advances, 2022. Doi:10.1002/elsa.202100118 . |

| 9 | 张希, 杨军, 乔志军, 等. 炭负极材料储钠机理的研究进展[J]. 化工新型材料, 2023, 51(1):51-55. |

| ZHANG Xi, YANG Jun, QIAO Zhijun, et al. Application progress of carbon anode materials in sodium-ion batteries[J]. New Chemical Materials, 2023, 51(1):51-55. | |

| 10 | 王祺. 钠离子电池负极材料的研究进展[J]. 化工技术与开发, 2022, 51(8):52-54,5. |

| WANG Qi. Research progress of anode materials for sodium ion batteries[J]. Technology & Development of Chemical Industry, 2022, 51(8):52-54,5. | |

| 11 | 马存双, 万延华, 许永开, 等. 超薄氮硫掺杂碳包覆二硫化铁的制备及储钠性能[J]. 无机盐工业, 2022, 54(6):55-60. |

| MA Cunshuang, WAN Yanhua, XU Yongkai, et al. Preparation and sodium storage properties of ultra-thin N and S doped carbon coated FeS2 [J]. Inorganic Chemicals Industry, 2022, 54(6):55-60. | |

| 12 | 包科杰, 路凌然. 新能源汽车电池负极材料的制备与性能研究[J]. 无机盐工业, 2021, 53(3):54-59. |

| BAO Kejie, LU Lingran. Study on preparation and performance of negative electrode materials for batteries of new energy vehicl-es[J]. Inorganic Chemicals Industry, 2021, 53(3):54-59. | |

| 13 | 李凡群, 赵星星. 钠离子电池负极材料的研究现状[J]. 电池, 2017, 47(2):120-122. |

| LI Fanqun, ZHAO Xingxing. Research status quo of anode materials for sodium ion battery[J]. Battery Bimonthly, 2017, 47(2):120-122. | |

| 14 | 朱子翼, 张英杰, 董鹏, 等. 高性能钠离子电池负极材料的研究进展[J]. 化工进展, 2019, 38(5):2222-2232. |

| ZHU Ziyi, ZHANG Yingjie, DONG Peng, et al. Research progress of anode materials for high performance sodium-ion batteries[J]. Chemical Industry and Engineering Progress, 2019, 38(5):2222-2232. | |

| 15 | 党荣彬, 陆雅翔, 容晓晖, 等. 钠离子电池关键材料研究及工程化探索进展[J]. 科学通报, 2022, 67(30):3546-3564. |

| DANG Rongbin, LU Yaxiang, RONG Xiaohui, et al. Research progress of key materials and engineering exploration for Na-ion batteries[J]. Chinese Science Bulletin, 2022, 67(30):3546-3564. | |

| 16 |

SENGUTTUVAN P, ROUSSE G, SEZNEC V, et al. Na2Ti3O7:Lowest voltage ever reported oxide insertion electrode for sodium ion batteries[J]. Chemistry of Materials, 2011, 23(18):4109-4111.

doi: 10.1021/cm202076g |

| 17 |

RUDOLA A, SARAVANAN K, DEVARAJ S, et al. Na2Ti6O13:A potential anode for grid-storage sodium-ion batteries[J]. Chemical Communications, 2013, 49(67):7451-7453.

doi: 10.1039/c3cc44381g |

| 18 | SHIRPOUR M, CABANA J, DOEFF M. New materials based on a layered sodium titanate for dual electrochemical Na and Li intercalation systems[J]. Energy & Environmental Science, 2013, 6(8):2538-2547. |

| 19 |

CECH O, VANÝSEK P, CHLADIL L, et al. Mixed sodium titanate as an anode for a sodium-ion battery[J]. ECS Transactions, 2016, 74(1):331-337.

doi: 10.1149/07401.0331ecst |

| 20 |

WU Chunjin, HUA Weibo, ZHANG Zheng, et al. Design and synthesis of layered Na2Ti3O7 and tunnel Na2Ti6O13 hybrid structures with enhanced electrochemical behavior for sodium-ion batteri- es[J]. Advanced Science, 2018, 5(9):1800519.

doi: 10.1002/advs.v5.9 |

| 21 |

HWANG J, CAHYADI H S, CHANG W, et al. Uniform and ultrathin carbon-layer coated layered Na2Ti3O7 and tunnel Na2Ti6O13 hybrid with enhanced electrochemical performance for anodes in sodium ion batteries[J]. The Journal of Supercritical Fluids, 2019, 148:116-129.

doi: 10.1016/j.supflu.2019.03.006 |

| 22 |

CHANDEL S, LEE S, LEE S, et al. Hierarchically nanorod structured Na2Ti6O13/Na2Ti3O7 nanocomposite as a superior anode for high-performance sodium ion battery[J]. Journal of Electroanalytical Chemistry, 2020, 877:114747.

doi: 10.1016/j.jelechem.2020.114747 |

| 23 |

HO C K, LI C Y V, CHAN K Y. Scalable template-free synthesis of Na2Ti3O7/Na2Ti6O13 nanorods with composition tunable for synergistic performance in sodium-ion batteries[J]. Industrial & Engineering Chemistry Research, 2016, 55(38):10065-10072.

doi: 10.1021/acs.iecr.6b01867 |

| 24 |

BHARDWAJ H S, RAMIREDDY T, PRADEEP A, et al. Understanding the cyclic(In)stability and the effects of presence of a stable conducting network on the electrochemical performances of Na2Ti3O7 [J]. ChemElectroChem, 2018, 5(8):1219-1229.

doi: 10.1002/celc.v5.8 |

| 25 |

PIFFET C, VERTRUYEN B, HATERT F, et al. High temperature X-ray diffraction study of the formation of Na2Ti3O7 from a mixture of sodium carbonate and titanium oxide[J]. Journal of Energy Chemistry, 2022, 65:210-218.

doi: 10.1016/j.jechem.2021.05.050 |

| 26 |

ZARRABEITIA M, CASTILLO-MARTÍNEZ E, LÓPEZ DEL AMO J M, et al. Identification of the critical synthesis parameters for enhanced cycling stability of Na-ion anode material Na2Ti3O7 [J]. Acta Materialia, 2016, 104:125-130.

doi: 10.1016/j.actamat.2015.11.033 |

| 27 |

CAO Yang, YE Qi, WANG Fanfan, et al. A new triclinic phase Na2Ti3O7 anode for sodium-ion battery[J]. Advanced Functional Materials, 2020, 30(39):2003733.

doi: 10.1002/adfm.v30.39 |

| 28 |

PAN Jun, WANG Nana, Dan LÜ, et al. Layered structure Na2Ti3O7 as a promising anode material for sodium-ion batteri-es[J]. Advanced Energy and Sustainability Research, 2021, 2(6):2000095.

doi: 10.1002/aesr.v2.6 |

| 29 |

吴乾鑫, 刘磊, 孙晋蒙, 等. 磺酸基修饰石墨烯复合材料的储钠性能研究[J]. 材料工程, 2022, 50(4):36-43.

doi: 10.11868/j.issn.1001-4381.2020.001197 |

| WU Qianxin, LIU Lei, SUN Jinmeng, et al. Sodium ions storage performance of PSS-rGO composites[J]. Journal of Materials Engineering, 2022, 50(4):36-43. | |

| 30 |

CHEN Fuyu, YUAN Jing, ZHOU Minquan, et al. Compressible neuron-like 3D few-layered MoS2/N-doped graphene foam as freestanding and binder-free electrodes for high-performance lithium-ion batteries[J]. ACS Applied Energy Materials, 2022, 5(6):7249-7259.

doi: 10.1021/acsaem.2c00796 |

| 31 | 郑钧昊, 吴源基, 殷咏诗, 等. 高性能氮掺杂中空碳纳米盒的制备及其在钠离子负极中的应用[J]. 材料研究与应用, 2022, 16(5):804-811. |

| ZHENG Junhao, WU Yuanji, YIN Yongshi, et al. Preparation of high performance nitrogen doped hollow carbon box and their application in sodium anode[J]. Materials Research and Application, 2022, 16(5):804-811. |

| [1] | WANG Yizhou, HU Xiaomei, WANG Yongxiang, ZHANG Weimin. Study on preparation of nickel-iron-manganate sodium layered oxides and their properties [J]. Inorganic Chemicals Industry, 2024, 56(2): 57-64. |

| [2] | XU Enhao, WU Kaipeng. Research progress of preparation and application of nano-sized chromium oxide [J]. Inorganic Chemicals Industry, 2023, 55(10): 24-34. |

| [3] | LIU Jinhang,YANG Zhipeng,CHEN Xiudong,LUO Yuxuan,YU Langhua,WANG Yawei,ZHAN Changchao,CAO Xiaohua. Preparation of new porous carbon and its lithium storage performance [J]. Inorganic Chemicals Industry, 2022, 54(9): 85-89. |

| [4] | MA Cunshuang,WAN Yanhua,XU Yongkai,CHEN Weihua. Preparation and sodium storage properties of ultra?thin N and S doped carbon coated FeS2 [J]. Inorganic Chemicals Industry, 2022, 54(6): 55-60. |

| [5] | BAI Xiaojie,CAO Defu,WANG Junhui,LIU Hao,LIAO Libing. Research progress on semi-solid energy storage batteries [J]. Inorganic Chemicals Industry, 2022, 54(2): 6-15. |

| [6] | WANG Wei,LIU Wei,WU Yang,YANG Shenshen. Research progress on molybdenum disulfide-based anode materials for lithium-ion batteries [J]. Inorganic Chemicals Industry, 2022, 54(10): 87-95. |

| [7] | Jiang Yuncai,Li Xuemei,Wu Zhaoxian,Cao Changdie,Mei Yi,Lian Peichao. Research progress on preparation and application in energy storage of black phosphorus [J]. Inorganic Chemicals Industry, 2021, 53(6): 59-71. |

| [8] | Fan Zehui,Zhang Chen,Yuan Bo,Ling Guowei. Application progress of new type marine materials in energy storage field [J]. Inorganic Chemicals Industry, 2021, 53(5): 7-12. |

| [9] | Bao Kejie,Lu lingran. Study on preparation and performance of negative electrode materials for batteries of new energy vehicles [J]. Inorganic Chemicals Industry, 2021, 53(3): 54-59. |

| [10] | Liu Yang,Cai Zongying,Cao Weigang,Liu Yuzhao. Research progress on lithium sodium titanate for lithium ion batteries [J]. Inorganic Chemicals Industry, 2021, 53(10): 36-40. |

| [11] | Du Zhiqiang,Yao Guangyuan. Study on characteristics of novel low-melting binary inorganic salts for heat storage [J]. Inorganic Chemicals Industry, 2020, 52(1): 63-67. |

| [12] | Ye Jiaming,Li Changming. Research progress on anode material LiTi2(PO4)3 for lithium-ion batteries [J]. Inorganic Chemicals Industry, 2019, 51(5): 17-22. |

| [13] | Yang Yang1,He Liang1,Zhang Yanan1,Long Yunfei1,Su Jing1,3,4,Wen Yanxuan1,2,3,4. Preparation and lithium storage properties of Co-doped MnO by co precipitation method in micro channel reactor [J]. Inorganic Chemicals Industry, 2019, 51(12): 10-14. |

| [14] | YANG Jian-Wen, YOU Hai-Ping, DENG Xing-Shen, PAN Xiao-Jin, YANG Gui-Jun, ZHANG Ling-Zhi. Preparation and electrochemical performances of chiral porous sodium zinc phosphate as anode material [J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(2): 75-. |

| [15] | GUO Ai-Hong, TANG Xue-Jiao, ZHANG Bao-Gui- . Synthesis of high purity hypophosphorous acid by electrolysis of sodium hypophosphite with Ti-PbO2 anode [J]. INORGANICCHEMICALSINDUSTRY, 2013, 45(11): 18-. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||