| [1] |

LIU Jie, SHI Xueru, WEI Shubing, CAO Xinxin.

Artificial interface layer construction and sodium storage performance of P2-type layered oxide cathode

[J]. Inorganic Chemicals Industry, 2024, 56(3): 39-44.

|

| [2] |

WANG Yansu, LIU Guozhu, YU Haibin.

Research progress of platinum-based propane dehydrogenation catalysts

[J]. Inorganic Chemicals Industry, 2023, 55(7): 1-9.

|

| [3] |

HAN Hongjing, ZHANG Jingze, LAMAO Zhuoma, HAN Jizhe, WU Yongmin, TANG Weiping.

Preparation of Al-Co co-doped lithium manganese oxide and its adsorption performance of lithium

[J]. Inorganic Chemicals Industry, 2023, 55(7): 38-44.

|

| [4] |

TIAN Yuling, CHENG Yang, HAN Rong, ZHOU Mei, WANG Chengjie, GE Qiangru.

Effect of CaO on heavy metals stability and adsorption properties of sludge-derived biochar

[J]. Inorganic Chemicals Industry, 2023, 55(6): 124-129.

|

| [5] |

LUO Zhibo, WANG Huaiyou, WANG Min, DU Baoqiang.

Effect of purity on thermo-physical properties of 60% NaNO3-40% KNO3 binary molten salt

[J]. Inorganic Chemicals Industry, 2023, 55(6): 43-49.

|

| [6] |

WANG Yansu, LIU Guozhu, YU Haibin.

Research progress of non-precious metal catalysts for propane dehydrogenation

[J]. Inorganic Chemicals Industry, 2023, 55(12): 1-11.

|

| [7] |

JI Ying, ZHANG Ying, HOU Xuechao, ZHU Xiaofeng, JIANG Run, PENG Wenjuan, SUN Guangdong, LÜ Long.

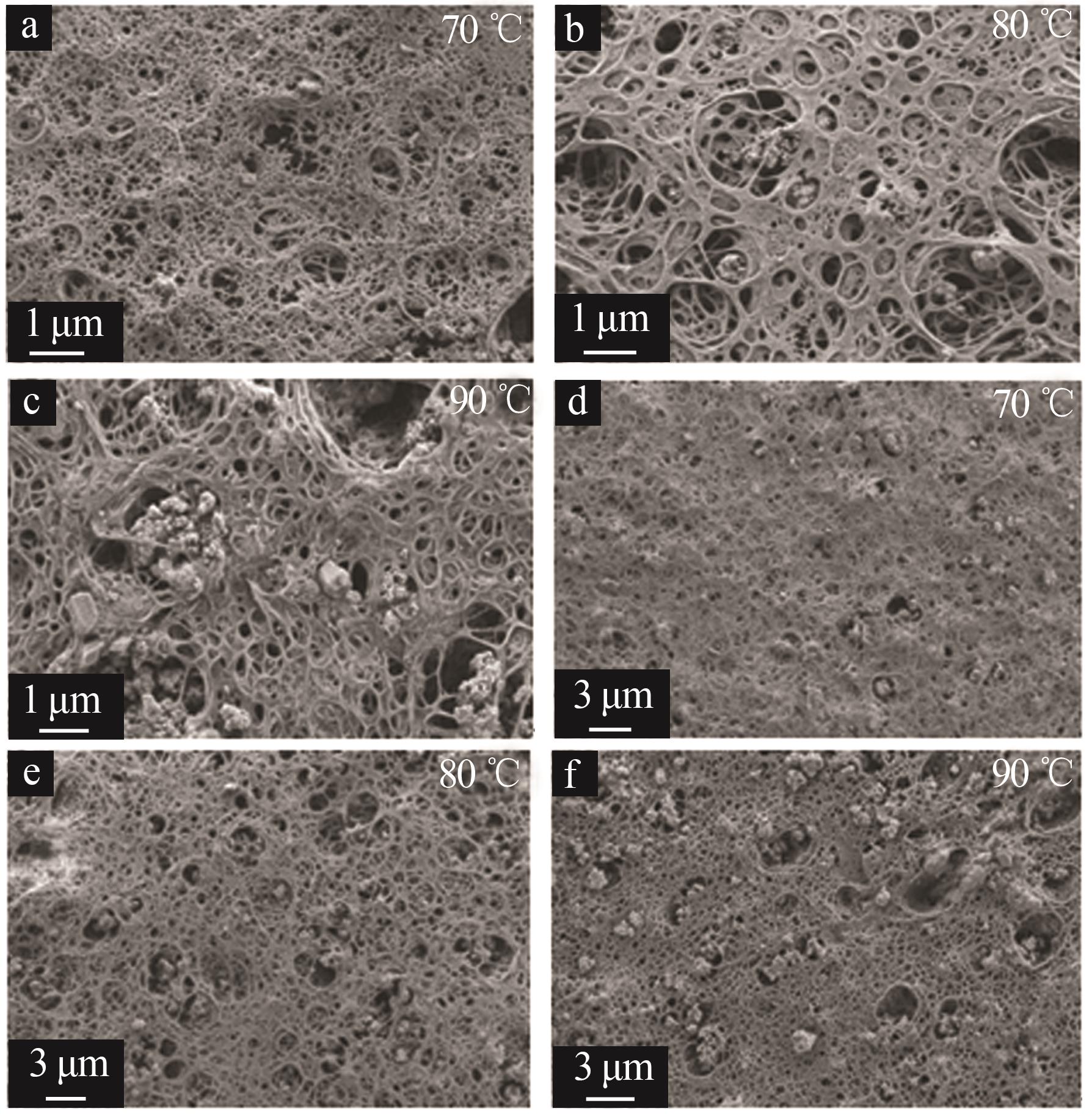

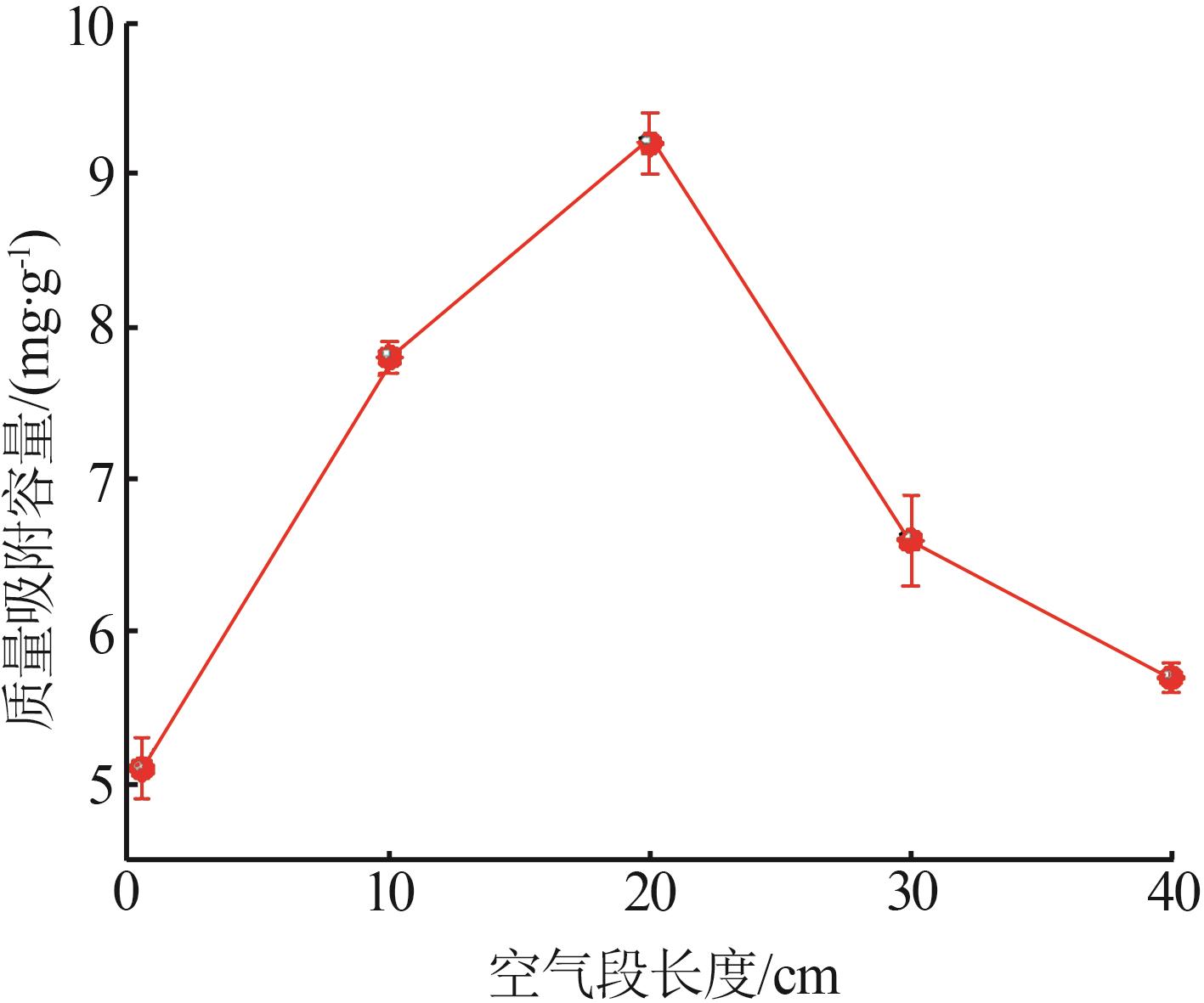

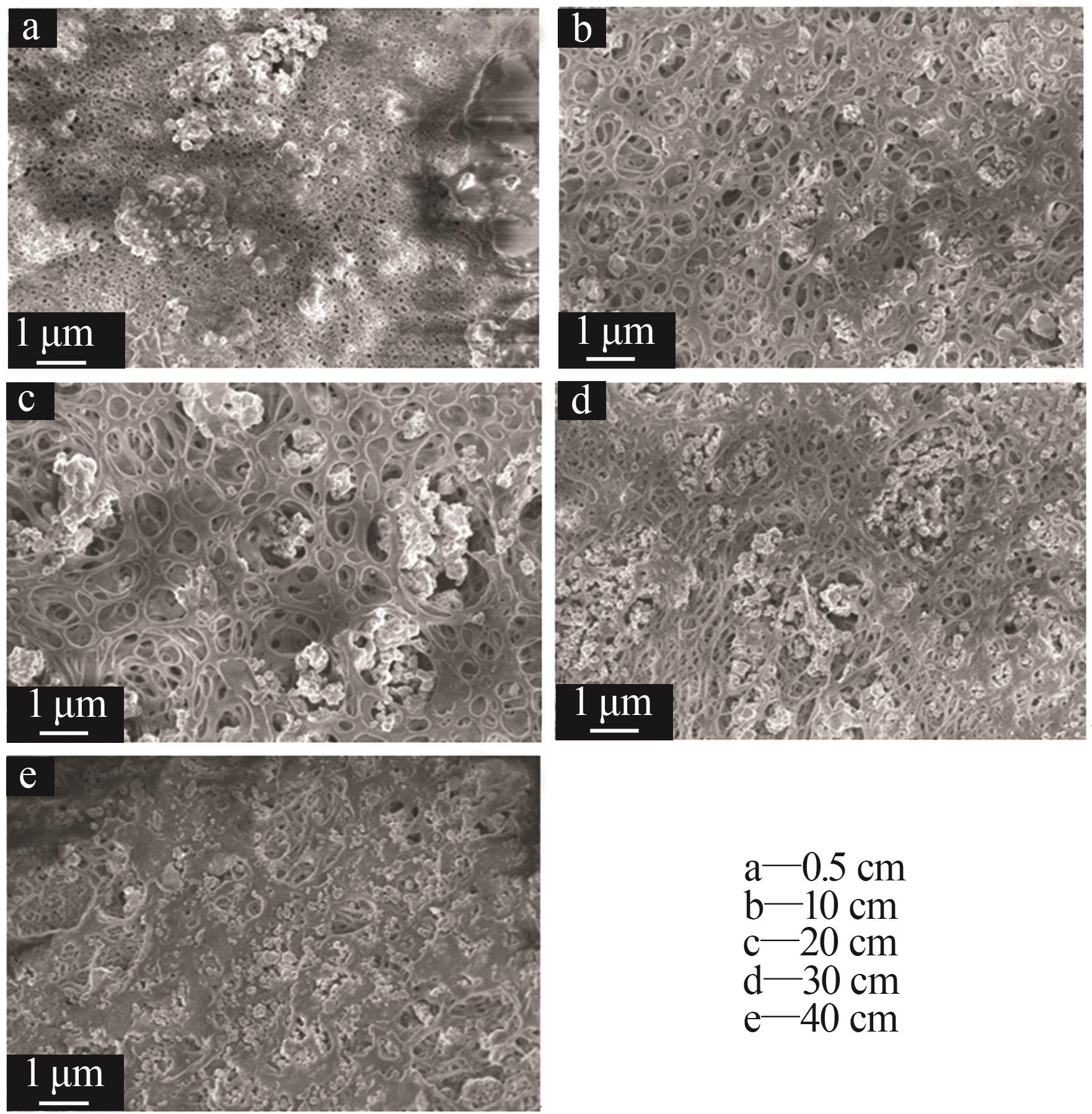

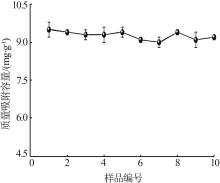

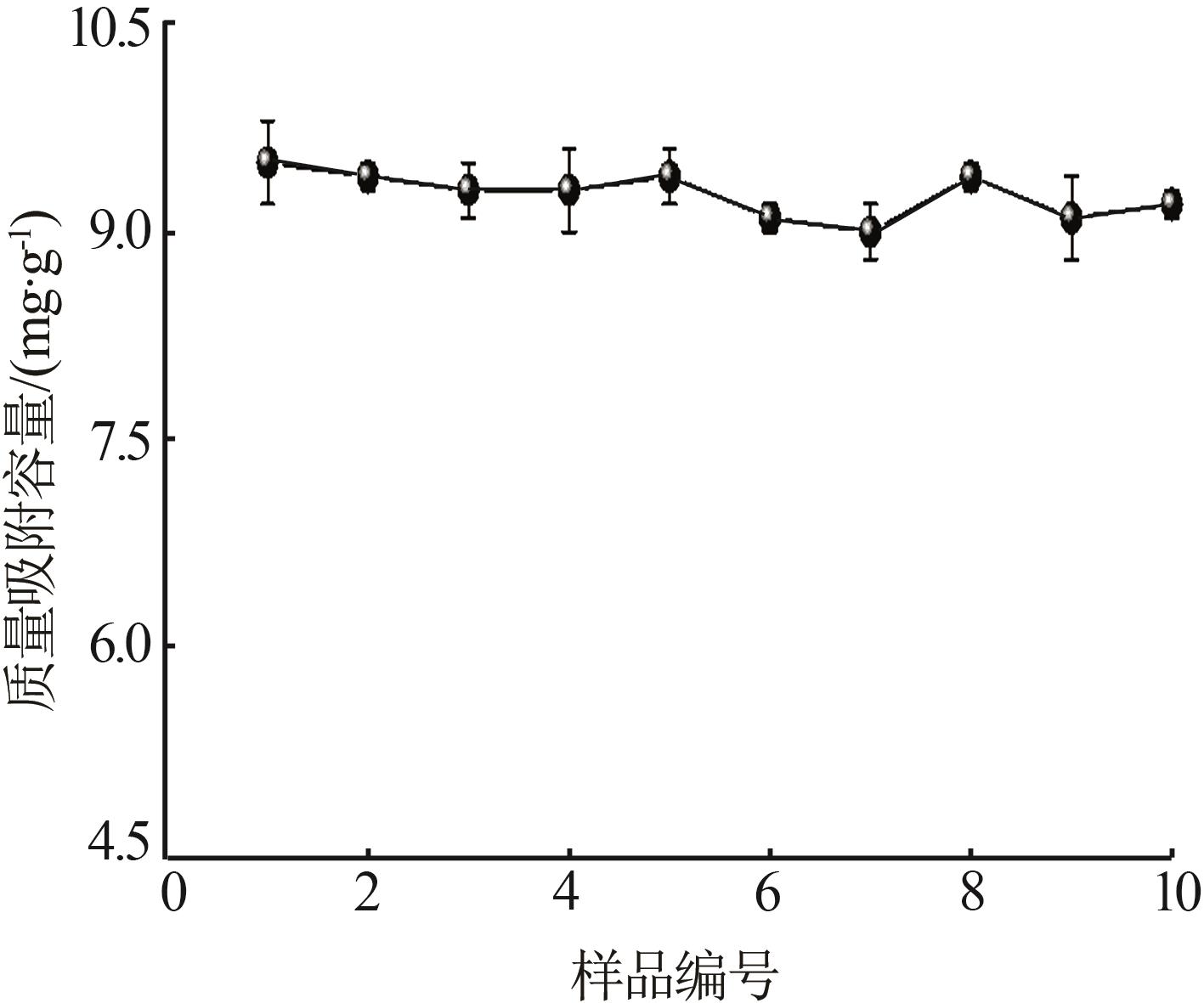

Application research of titanium adsorbent of carbonate-type salt lake in Tibet

[J]. Inorganic Chemicals Industry, 2023, 55(11): 70-77.

|

| [8] |

LI Sen, WANG Jin, WANG Yingying, CAI Mingfang.

Synthesis and modification of NaA zeolite and its application in polyurethane system

[J]. Inorganic Chemicals Industry, 2023, 55(10): 78-85.

|

| [9] |

LIN Yuqing,ZHANG Yiren,QIU Yulong,ZHANG Jiayu,YU Jianguo.

Progress and prospect of membrane technology in lithium extraction from salt lake brine

[J]. Inorganic Chemicals Industry, 2023, 55(1): 33-45.

|

| [10] |

HAN Hongjing,WU Yongmin,CAO Yongsheng,HAN Tingting,TANG Weiping.

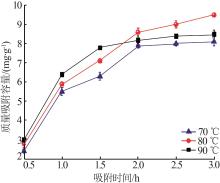

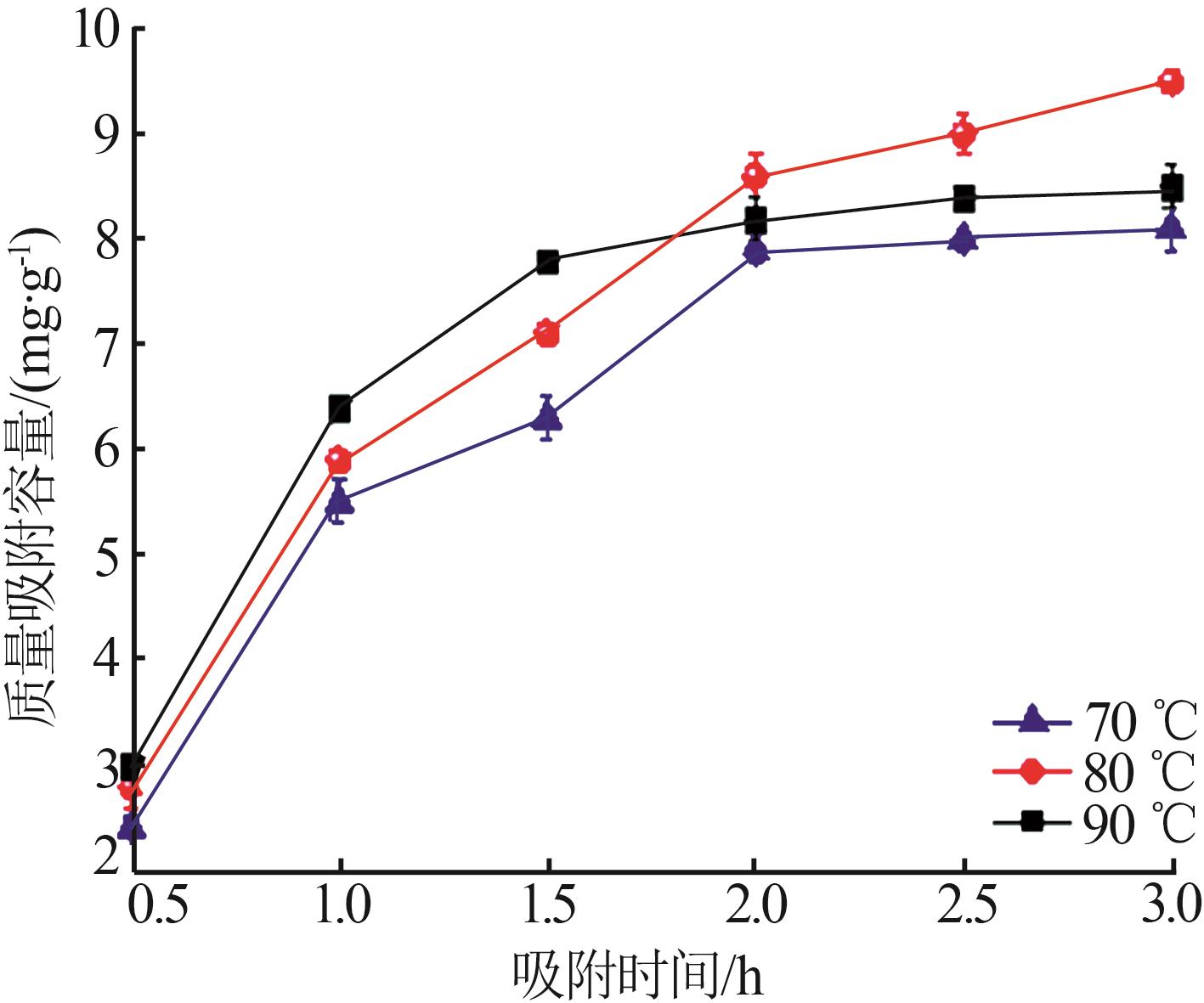

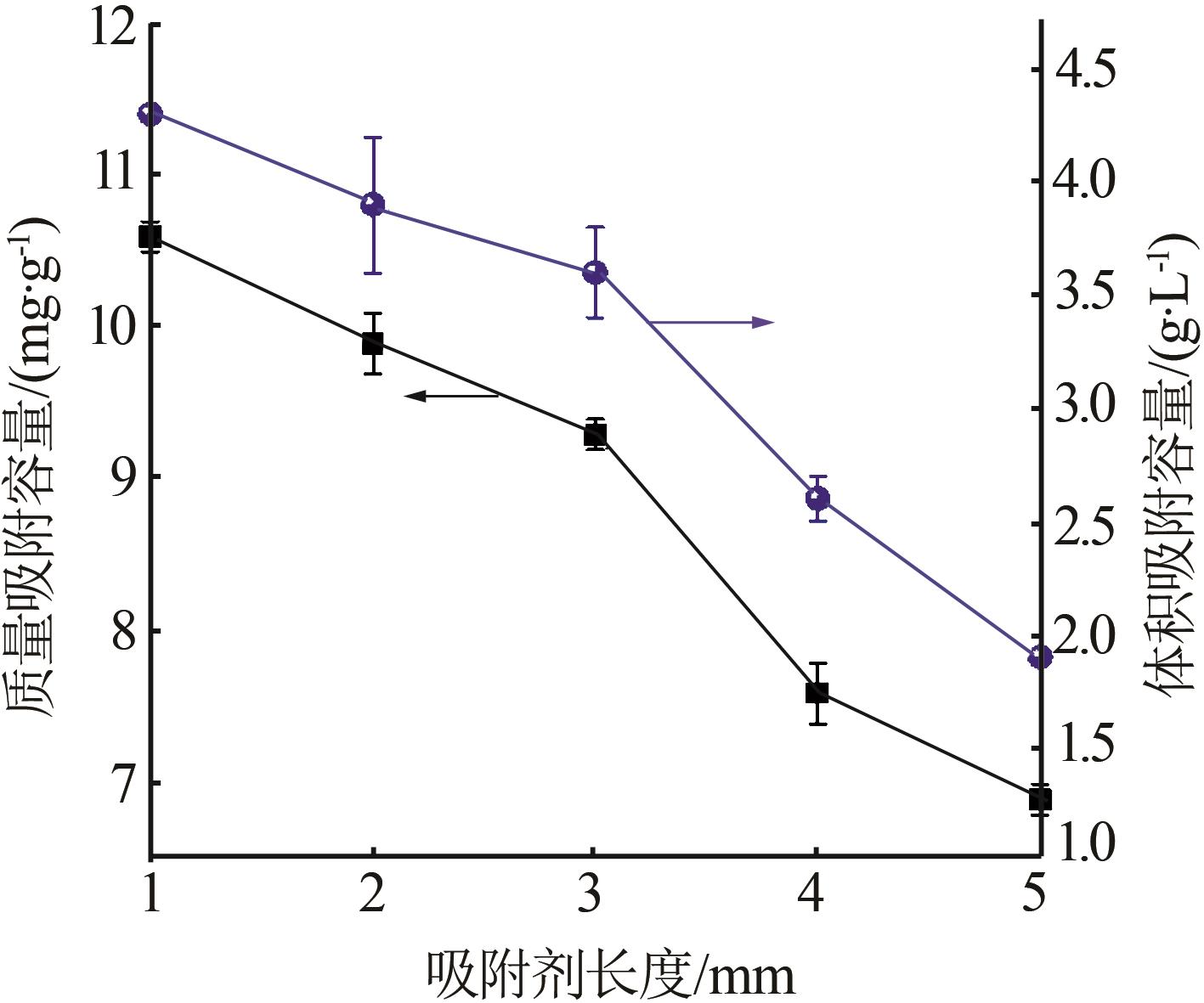

Preparation of nano?flake polyhedral manganese based lithium ion sieve and its adsorption and desorption characteristic for Li+

[J]. Inorganic Chemicals Industry, 2022, 54(8): 59-65.

|

| [11] |

ZHAO Zhanyi,ZHONG Yongheng,LIU Jia,LI Xiaoyan,YONG Meijing.

Research on global patent distribution and development countermeasures of lithium industry

[J]. Inorganic Chemicals Industry, 2022, 54(7): 10-17.

|

| [12] |

ZHENG Yangzi,JIN Mingshang.

Strategy to improve catalytic performance of Pt-based core-shell catalysts for fuel cells

[J]. Inorganic Chemicals Industry, 2022, 54(11): 1-7.

|

| [13] |

Wang Chenxin,Chen Meili,Tian Mengkui,Yang Wanliang.

Study on preparation of hollow α-Fe2O3 nanobelts and their photocatalytic properties

[J]. Inorganic Chemicals Industry, 2021, 53(6): 185-189.

|

| [14] |

Jin Qingqing,Liang Xiaoyi,Zhang Jia′nan,Zhou Xiaolong.

Study on adsorption performance of modified spherical activated carbon for ammonia

[J]. Inorganic Chemicals Industry, 2021, 53(4): 61-66.

|

| [15] |

Liu Yuhe,Wu Mingsong,Wang Xinshu,Huang Nannan,Zhou Xiuyan.

Review of basic properties and influence factors related to stability of chlorine dioxide

[J]. Inorganic Chemicals Industry, 2021, 53(3): 18-23.

|

), MO Hengliang1(

), MO Hengliang1( ), LI Tianyu1, PENG Wenjuan1, SUN Guangdong1,2, XIAO Hongkang1, CHEN Yili1, LI Suoding1, TANG Yang3

), LI Tianyu1, PENG Wenjuan1, SUN Guangdong1,2, XIAO Hongkang1, CHEN Yili1, LI Suoding1, TANG Yang3