Inorganic Chemicals Industry ›› 2022, Vol. 54 ›› Issue (4): 88-93.doi: 10.19964/j.issn.1006-4990.2021-0591

• Research & Development • Previous Articles Next Articles

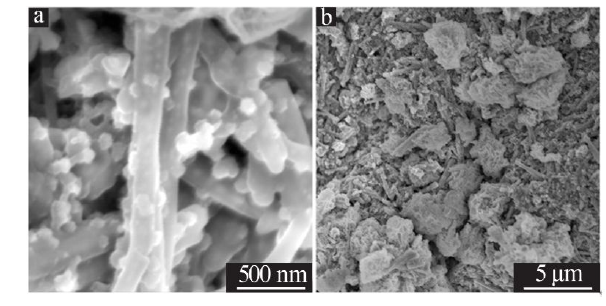

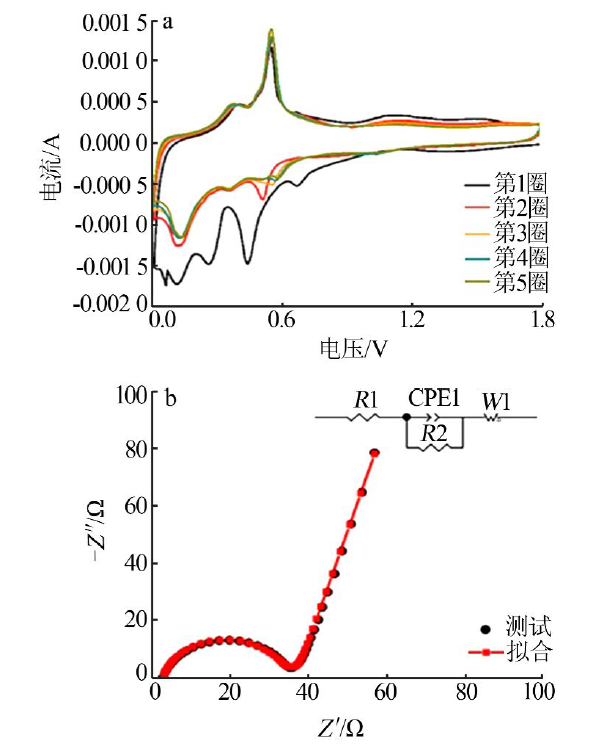

Nanoconfined encapsulation of iron-germanium alloy anode and its lithium ion storage performance

LI Fangkun( ),WANG Xinyi,XU Xijun,WU Yiwen,YANG Yan,LIU Jun(

),WANG Xinyi,XU Xijun,WU Yiwen,YANG Yan,LIU Jun( )

)

- Guangdong Provincial Key Laboratory of Advanced Energy Storage Materials,School of Materials Science and Engineering,South China University of Technology,Guangzhou 510641,China

-

Received:2021-09-29Online:2022-04-10Published:2022-04-18 -

Contact:LIU Jun E-mail:1827518710@qq.com;msjliu@scut.edu.cn

CLC Number:

Cite this article

LI Fangkun,WANG Xinyi,XU Xijun,WU Yiwen,YANG Yan,LIU Jun. Nanoconfined encapsulation of iron-germanium alloy anode and its lithium ion storage performance[J]. Inorganic Chemicals Industry, 2022, 54(4): 88-93.

share this article

| [1] |

SHEN J, XU X, LIU J, et al. Unraveling the catalytic activity of Febased compounds toward Li2Sx in Li-S chemical system from d-p bands[J]. Advanced Energy Materials, 2021, 11(26).Doi: 10.1002/aenm.202100673.

doi: 10.1002/aenm.202100673 |

| [2] |

LI F, LIU Z, SHEN J, et al. A nanorod-like Ni-rich layered cathode with enhanced Li+ diffusion pathways for high-performance lithium-ion batteries[J]. Journal of Materials Chemistry A, 2021, 9(5):2830-2839.

doi: 10.1039/D0TA10608A |

| [3] |

ZHANG N, SUN C, HUANG Y, et al. Tuning electrolyte enables microsized Sn as an advanced anode for Li-ion batteries[J]. Journal of Materials Chemistry A, 2021, 9(3):1812-1821.

doi: 10.1039/D0TA10861H |

| [4] |

XU X, SHEN J, LI F, et al. Fe3O4@C nanotubes grown on carbon fabric as a free-standing anode for high-performance Li-ion batteries[J]. Chemistry-A European Journal, 2020, 26(64):14708-14714.

doi: 10.1002/chem.202002938 |

| [5] |

JUNG S C, KIM H-J, KANG Y-J, et al. Advantages of Ge anode for Na-ion batteries:Ge vs.Si and Sn[J]. Journal of Alloys and Compounds, 2016, 688:158-163.

doi: 10.1016/j.jallcom.2016.07.201 |

| [6] |

HE Y, JIANG L, CHEN T, et al. Progressive growth of the solid-electrolyte interphase towards the Si anode interior causes capacity fading[J]. Nature Nanotechnology, 2021.Doi: 10.1038/s41565-02100947-8.

doi: 10.1038/s41565-02100947-8 |

| [7] |

SENG K H, PARK M H, GUO Z P, et al. Self-assembled germanium/ carbon nanostructures as high-power anode material for the lithiumion battery[J]. Angewandte Chemie International Edition, 2012, 51(23):5657-5661.

doi: 10.1002/anie.201201488 |

| [8] |

RAHMAN M M, SULTANA I, YANG T, et al. Lithium germinate (Li2GeO3):A high-performance anode material for lithium-ion batteries[J]. Angewandte Chemie International Edition, 2016, 55(52):16059-16063.

doi: 10.1002/anie.201609343 |

| [9] |

SHIN J H, PARK D H, LEE W J, et al. Coffee waste-derived one-step synjournal of a composite structure with Ge nanoparticles surrounded by amorphous carbon for Li-ion batteries[J]. Journal of Alloys and Compounds, 2022, 889.Doi: 10.1016/j.jallcom.2021.161685.

doi: 10.1016/j.jallcom.2021.161685 |

| [10] |

CHAN C K, ZHANG X F, CUI Y. High capacity Li ion battery anodes using Ge nanowires[J]. Nano Letters, 2008, 8(1):307-309.

doi: 10.1021/nl0727157 |

| [11] | CHOCKLA A M, KLAVETTER K C, MULLINS C B, et al. Solutiongrown germanium nanowire anodes for lithium-ion batteries[J]. ACS Applied Materials & Interfaces, 2012, 4(9):4658-4664. |

| [12] |

GAVRILIN I M, KUDRYASHOVA Y O, KUZ′MINA A A, et al. High-rate and low-temperature performance of germanium nanowires anode for lithium-ion batteries[J]. Journal of Electroanalytical Chemistry, 2021, 888.Doi: 10.1016/j.jelechem.2021.115209.

doi: 10.1016/j.jelechem.2021.115209 |

| [13] |

LIU J, SONG K, ZHU C, et al. Ge/C nanowires as high-capacity and long-life anode materials for Li-ion batteries[J]. ACS Nano, 2014, 8(7):7051-7059.

doi: 10.1021/nn501945f |

| [14] |

WANG B, JIN J, WEN Z. In situ synjournal of core-shell structured Ge@NC hybrids as high performance anode material for lithiumion batteries[J]. Chemical Engineering Journal, 2019, 360:1301-1309.

doi: 10.1016/j.cej.2018.09.113 |

| [15] |

CHEN Y, MA L, SHEN X, et al. In-situ synjournal of Ge/reduced graphene oxide composites as ultrahigh rate anode for lithium-ion battery[J]. Journal of Alloys and Compounds, 2019, 801:90-98.

doi: 10.1016/j.jallcom.2019.06.074 |

| [16] |

WANG X, XU X, LIU J, et al. Facile synjournal of peapod-like Cu3Ge/Ge@C as a high-capacity and long-life anode for Li-ion batteries[J]. Chemistry-A European Journal, 2019, 25(49):11486-11493.

doi: 10.1002/chem.201901629 |

| [17] |

MAO E, FU L, LIU W, et al. Encapsulating hetero-Cu3Ge/Ge into nitrogen-doped carbon matrix for advanced lithium storage[J]. Journal of Alloys and Compounds, 2021, 850.Doi: 10.1016/j.jallcom.2020.156815.

doi: 10.1016/j.jallcom.2020.156815 |

| [18] |

ZHONG X, HUAN H, LIU X, et al. Facile synjournal of porous germanium-iron bimetal oxide nanowires as anode materials for lithium-ion batteries[J]. Nano Research, 2018, 11(7):3702-3709.

doi: 10.1007/s12274-017-1938-z |

| [19] |

GAO Q, CHEN P, ZHANG Y, et al. Synjournal and characterization of organic-inorganic hybrid GeOx/ethylenediamine nanowires[J]. Advanced Materials, 2008, 20(10):1837-1842.

doi: 10.1002/adma.200701646 |

| [20] |

YU L, ZOU R, ZHANG Z, et al. A Zn2GeO4-ethylenediamine hybrid nanoribbon membrane as a recyclable adsorbent for the highly efficient removal of heavy metals from contaminated water[J]. Chemical Communications, 2011, 47(38):10719-10721.

doi: 10.1039/c1cc14159g |

| [21] |

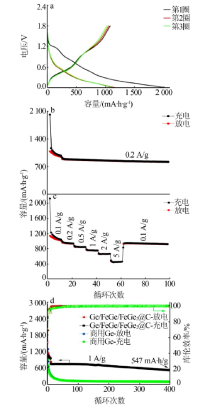

WEI D, ZENG S, LI H, et al. Multiphase Ge-based Ge/FeGe/FeGe2/C composite anode for high performance lithium ion batteries[J]. Electrochimica Acta, 2017, 253:522-529.

doi: 10.1016/j.electacta.2017.09.105 |

| [22] |

ZHANG C, LIN Z, YANG Z, et al. Hierarchically designed germanium microcubes with high initial coulombic efficiency toward highly reversible lithium storage[J]. Chemistry of Materials, 2015, 27(6):2189-2194.

doi: 10.1021/acs.chemmater.5b00218 |

| [1] | ZHANG Yu, ZHAO Zhichao, ZHAO Cuilian, SUN Nannan. Study on effect of MTMS modification on weatherability of SiO2 anti-reflective coating [J]. Inorganic Chemicals Industry, 2024, 56(3): 64-69. |

| [2] | LI Yaguang, HAN Dongzhan, QI Lijuan. Recent research on pretreatment of waste lithium-ion batteries and electrolyte recovery technology [J]. Inorganic Chemicals Industry, 2024, 56(2): 1-10. |

| [3] | CHEN Tiandong, ZHAO Guangzhao, HAI Chunxi, DONG Shengde, HE Xin, XU Qi, FENG Hang, YUAN Shaoxiong, MA Luxiang, ZHOU Yuan. Research and industrialization progress on coating and doping modification of lithium-rich manganese-based materials [J]. Inorganic Chemicals Industry, 2023, 55(9): 1-8. |

| [4] | PAN Xiaoxiao, ZHUANG Shuxin, SUN Yuqing, SUN Gaoxing, REN Yan, JIANG Shengyu. Research progress of modified-LiFePO4 as cathode materials for lithium ion batteries [J]. Inorganic Chemicals Industry, 2023, 55(6): 18-26. |

| [5] | ZHANG Lijie,SUN Yanmin,LI He,ZENG Xianjun,LIN Xiaodong,HUANG Guihong. Research progress of catalyst coating process [J]. Inorganic Chemicals Industry, 2023, 55(2): 19-25. |

| [6] | TIAN Yu, ZHANG Zheng, ZHANG Xingran, CHEN Jie, WANG Yan, PENG Hao. Research progress of trivalent chromium electrodeposition process [J]. Inorganic Chemicals Industry, 2023, 55(12): 26-35. |

| [7] | ZHOU Min. Preparation of PANI/TIO composites and their application in polyurethane coatings [J]. Inorganic Chemicals Industry, 2023, 55(1): 112-117. |

| [8] | ZHOU Shiyu,HE Ting,FU Tongtong,GUO Zirui,GU Shuai,YU Jianguo. Life cycle and economic assessment of recycling spent lithium-ion batteries with hydrometallurgical process [J]. Inorganic Chemicals Industry, 2023, 55(1): 26-32. |

| [9] | XU Qianjin,XU Jingang,TIAN Peng,LIU Kunji,GAO Tingting,NING Guiling. Research progress of alumina coated cathode materials for lithium-ion batteries [J]. Inorganic Chemicals Industry, 2023, 55(1): 46-55. |

| [10] | LIU Zhuoqin,ZHOU Xiaochong,MO Liangjun. Study on modification of spinel lithium manganate coated with lithium borate [J]. Inorganic Chemicals Industry, 2022, 54(9): 90-95. |

| [11] | TANG Jianping,WANG Guosheng. Study on preparation technology and waterproof property of fused magnesia coating [J]. Inorganic Chemicals Industry, 2022, 54(5): 90-95. |

| [12] | ZHOU Kai,PAN Guoxiang,LI Jinhua,XIA Shengjie,XU Minhong,SHEN Hui,KOSO Aoki. Study on preparation and heat resistance of iron oxide yellow coated with double layer Al(OH)3@Zn(OH)2 [J]. Inorganic Chemicals Industry, 2022, 54(2): 50-53. |

| [13] | HE Ting,KONG Jiao,CUI Jingzhi,CHEN Zhihao,FU Tongtong,GUO Zirui,GU Shuai,YU Jianguo. Study on leaching and thermodynamic of spent lithium-ion batteries with electrochemical reduction [J]. Inorganic Chemicals Industry, 2022, 54(12): 34-43. |

| [14] | HUANG Liying,LU Dongchu,NING Yuxue,HU Tingting,CHEN Qing,HUANG Guoxin,SU Jing,WEN Yanxuan. Preparation and electrochemical performance of Nb-doped LiNiO2 cathode material for lithium-ion batteries [J]. Inorganic Chemicals Industry, 2022, 54(11): 52-58. |

| [15] | WANG Wei,LIU Wei,WU Yang,YANG Shenshen. Research progress on molybdenum disulfide-based anode materials for lithium-ion batteries [J]. Inorganic Chemicals Industry, 2022, 54(10): 87-95. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||