| [1] |

周功耀, 罗军. 3D打印基础教程[M]. 北京: 东方出版社, 2016.

|

| [2] |

徐晓燕, 赵永武, 卞达. 碳纳米管的功能化处理及其对胶黏陶瓷涂层抗腐蚀性能的影响[J]. 表面技术, 2018,47(12):223-230.

|

| [3] |

邱琳, 郭璞, 冯妍卉, 等. 纳米涂层增强碳纳米管阵列界面热输运[J]. 工程热物理学报, 2019,40(9):2109-2114.

|

| [4] |

辛兆鹏, 方伟, 赵雷, 等. 泡沫碳/碳纳米管复合电极材料制备及其电化学性能[J]. 无机盐工业, 2018,50(9):14-18.

|

| [5] |

Hsieh C T, Tzou D Y, Lee W Y, et al. Deposition of MnO2 nanonee-dles on carbon nanotubes and graphene nanosheets as electrode materials for electrochemical capacitors[J]. Journal of Alloys and Compounds, 2016,660:99-107.

doi: 10.1016/j.jallcom.2015.11.021

|

| [6] |

陈林, 刘虹财, 严磊, 等. 碳纳米管功能化改性聚偏氟乙烯介电复合材料的结构及性能[J]. 材料导报, 2020,34(4):126-131.

|

| [7] |

王鹏, 李昭, 周颖梅, 等. 碳纳米管改性g-C3N4提升可见光催化降解性能[J]. 无机化学学报, 2019,35(2):217-224.

|

| [8] |

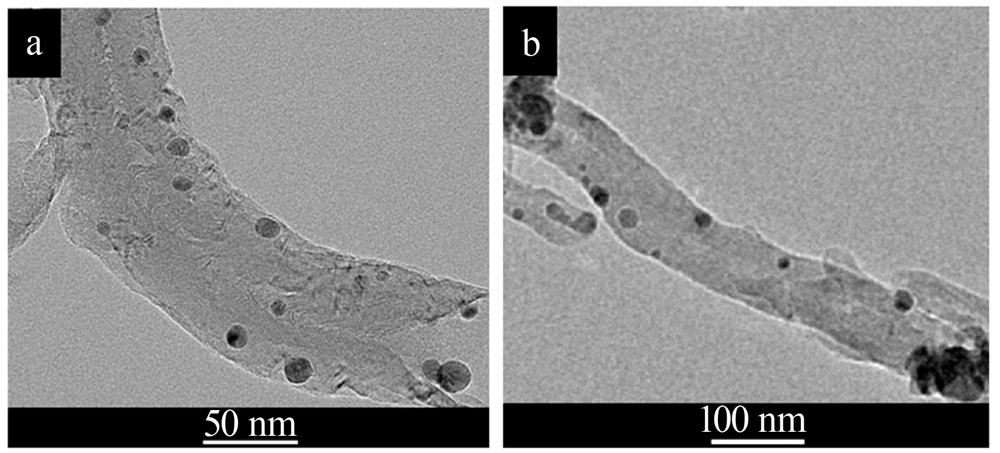

张景成, 朱金剑, 宋国良, 等. 硫化型NiMoS/CNTs加氢催化剂的制备与性能研究[J]. 无机盐工业, 2019,51(10):89-92.

|

| [9] |

Ning L N, Liu X H, Deng M, et al. Palladium-based nanocatalysts anchored on CNT with high activity and durability for ethanol electro-oxidation[J]. Electrochimica Acta, 2019,297:206-214.

doi: 10.1016/j.electacta.2018.11.188

|

| [10] |

李军芳, 毛学锋, 钟金龙, 等. 碳纳米管负载NiMoP催化剂在煤直接液化油加氢中的催化性能[J]. 石油学报:石油加工, 2019,35(6):1167-1174.

|

| [11] |

邢亚娟, 陈宏源, 陈名海, 等. 碳纳米管在热管理材料中的应用[J]. 科学通报, 2014,59(28):2840-2850.

|

| [12] |

白彦江, 李京超, 张茜, 等. 碳纳米管束与炭黑并用对天然橡胶导热性能和动态力学性能的影响[J]. 北京化工大学学报:自然科学版, 2020,47(4):30-38.

|

),Sun Guanhua2,Sun Yanmin1,Zhu Jinjian1,Nan Jun1,Xiao Han1,Zhang Jingcheng1,Song Guoliang1

),Sun Guanhua2,Sun Yanmin1,Zhu Jinjian1,Nan Jun1,Xiao Han1,Zhang Jingcheng1,Song Guoliang1