Inorganic Chemicals Industry ›› 2021, Vol. 53 ›› Issue (3): 73-77.doi: 10.11962/1006-4990.2020-0204

• Environment·Health·Safety • Previous Articles Next Articles

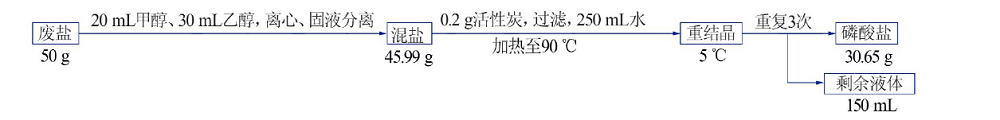

Study on purification of phosphorus waste salt produced by medicine

Li Ningyu1,2( ),Sun Xiaolei1,2,Zou Mingjing1,2,Sun Xiuyun1,2(

),Sun Xiaolei1,2,Zou Mingjing1,2,Sun Xiuyun1,2( ),Han Weiqing1,2,Wang Lianjun1,2(

),Han Weiqing1,2,Wang Lianjun1,2( )

)

- 1. Department of Environmental Science and Engineering,Nanjing University of Science and Technology,Nanjing 210094,China

2. Jiangsu Key Laboratory of Chemical Pollution Control and Resources Reuse