| [1] |

范相虎, 周聪, 袁军, 等. 电子级磷酸研发现状及芯片级磷酸展望[J].研究报告与专论,2019(5):61-64.

|

| [2] |

李姗婷. 结晶法回收铝蚀刻废液中磷酸工艺研究[J].广东化工,2016(13):186-187.

|

| [3] |

周兆安, 唐瑜钟, 徐丽阳. 化学蚀刻废磷酸制备饲料级磷酸脲的研究[J]. 无机盐工业, 2018,50(10):67-69.

|

| [4] |

毕亚凡, 牟林琳, 徐俊虎, 等. 废刻蚀液与低品位磷矿为原料磷复肥的制备[J]. 武汉工程大学学报, 2013,35(7):27-31.

|

| [5] |

Leng X K, Zhong Y J, Xu D H, et al. Mechanism and kinetics study on removal of iron from phosphoric acid by cation exchange resin[J]. Chinese Journal of Chemical Engineering, 2018,27(5):1050-1057.

doi: 10.1016/j.cjche.2018.09.012

|

| [6] |

李竹琬. 离子交换法脱除磷酸中镁离子的工艺研究[D]. 成都:四川大学, 2018.

|

| [7] |

Yazdani M, Tuutijarrvi T, Bhatnagar A, et al. Adsorptive removal of arsenic(Ⅴ) from aqueous phase by Feldspars:Kinetics,mechani-sm,and thermodynamic aspects of adsorption[J]. Journal of Molec-ular Liquids, 2016,214:149-156.

|

| [8] |

王璐, 冯京京, 陶敏莉. 季铵离子化腈纶纤维对染料的动态吸附性能[J]. 化学工业与工程, 2019,37(2):73-79.

|

| [9] |

Naushad M, Alothman Z A, Kha M R, et al. Equilibrium,kinetics and thermodynamic studies for the removal of organophosphorus pesticide using amberlyst-15 resin:Quantitative analysis by liquid chromatography-mass spectrometry[J]. Journal of Industrial and En-gineering Chemistry, 2014,20(6):4393-4400.

|

| [10] |

Ferda H, Nazmiye K, Busra C E, et al. In situ preparation and pro- perties of sulfonic and phosphonic acid substituted polyphospha-zene/polyaniline composites[J]. Polymer, 2016,96:112-120.

doi: 10.1016/j.polymer.2016.05.008

|

| [11] |

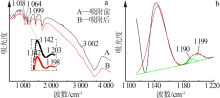

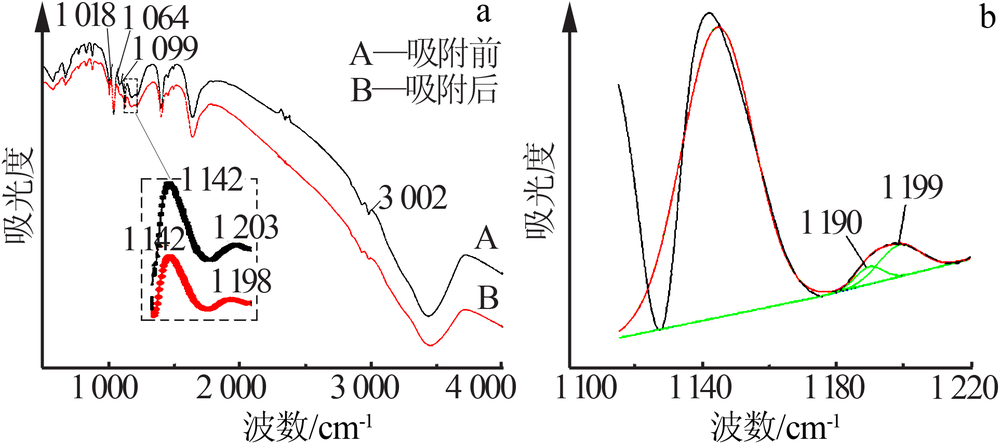

Lai Y M, Liang X F, Yang S Y, et al. Raman and FTIR spectra of iron phosphate glasses containing cerium[J]. Journal of Molecular Structure, 2011,992(1/2/3):84-88.

|

| [12] |

Zhang J B, Xu Z Q, Zong Y R, et al. Analysis of NMR and FT-IR spectra on the bis(substituted cyclopentadientyl)dichlorides of titanium and zirconium[J]. Spectrochimica Acta Part A Molecular & Biomolecular Spectroscopy, 2008,71(2):368-370.

|

| [13] |

Misra R, Jain S K, Khatri P K. Iminodiacetic acid functionalized cation exchange resin for adsorptive removal of Cr(Ⅵ),Cd(Ⅱ),Ni(Ⅱ) and Pb(Ⅱ) from their aqueous solution[J]. Journal of Ha-zardous Materials, 2010,185(2/3):1508-1512.

|

| [14] |

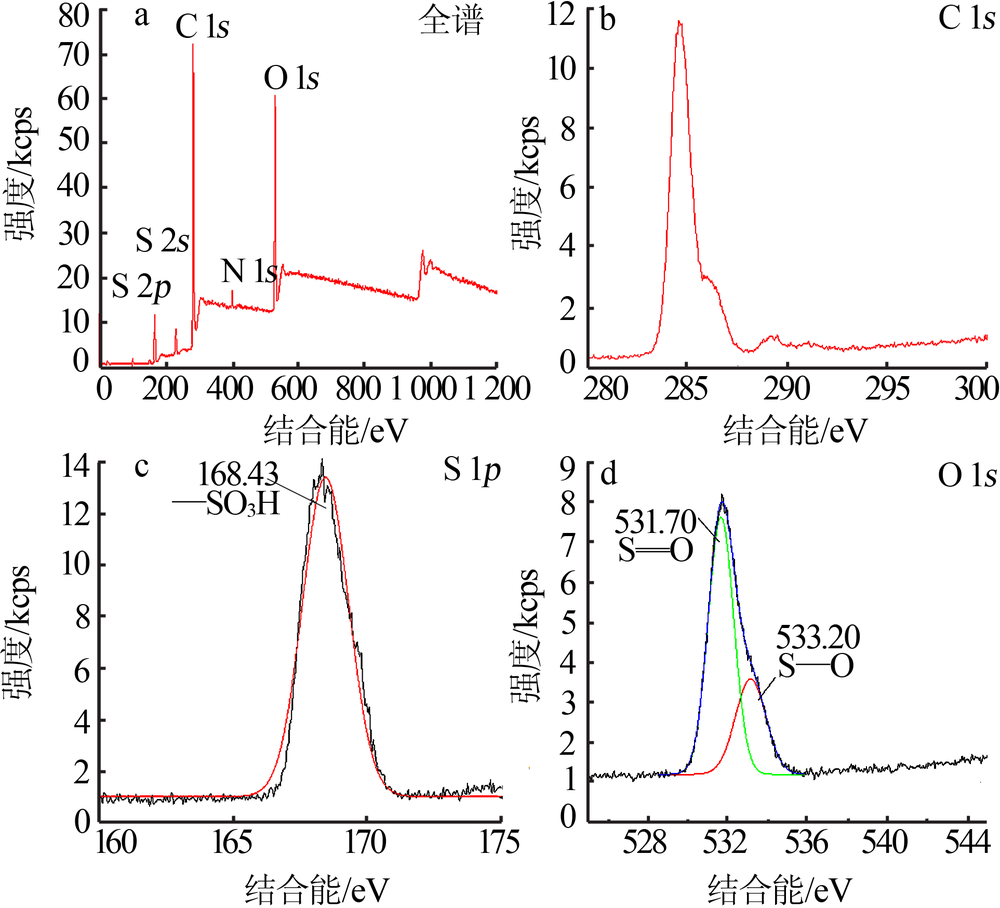

Nakhate A V, Yadav G D. Graphene-oxide-supported SO3H-func-tionalized imidazolium-based ionic liquid:Efficient and recyclable heterogenous catalyst for alcoholysis and aminolysis reactions[J]. Chemistry Select, 2018,16(3):4547-4556.

|

| [15] |

Lei H B, He D L, Guo Y N, et al. Synjournal and characterization of UV-absorbing fluorine-silicone acrylic resin polymer[J]. Applied Surface Science, 2018,442:71-77.

doi: 10.1016/j.apsusc.2018.02.134

|

),Yang Lin1(

),Yang Lin1( ),Wang Xinlong1(

),Wang Xinlong1( ),Zhuang Haibo1,Ye Runzhou1,Wang Ye1,2,Li Yaoji2

),Zhuang Haibo1,Ye Runzhou1,Wang Ye1,2,Li Yaoji2