Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (1): 64-73.doi: 10.19964/j.issn.1006-4990.2022-0605

• Development and utilization of lithium resources • Previous Articles Next Articles

Study on lithium separation from brine by aluminum-based adsorbent in fixed bed

CHEN Jun1,2( ),ZHONG Jing1,2,LIN Sen1,2(

),ZHONG Jing1,2,LIN Sen1,2( ),YU Jianguo1,2(

),YU Jianguo1,2( )

)

- 1. National Engineering Research Center for Integrated Utilization of Salt Lake Resources,East China University of Science and Technology,Shanghai 200237,China

2. Joint International Laboratory for Potassium and Lithium Strategic Resources,East China University of Science and Technology,Shanghai 200237,China

-

Received:2022-10-12Online:2023-01-10Published:2023-01-17 -

Contact:LIN Sen,YU Jianguo E-mail:jchen_2020@163.com;linsen@ecust.edu.cn;jgyu@ecust.edu.cn

CLC Number:

Cite this article

CHEN Jun,ZHONG Jing,LIN Sen,YU Jianguo. Study on lithium separation from brine by aluminum-based adsorbent in fixed bed[J]. Inorganic Chemicals Industry, 2023, 55(1): 64-73.

share this article

Table 7

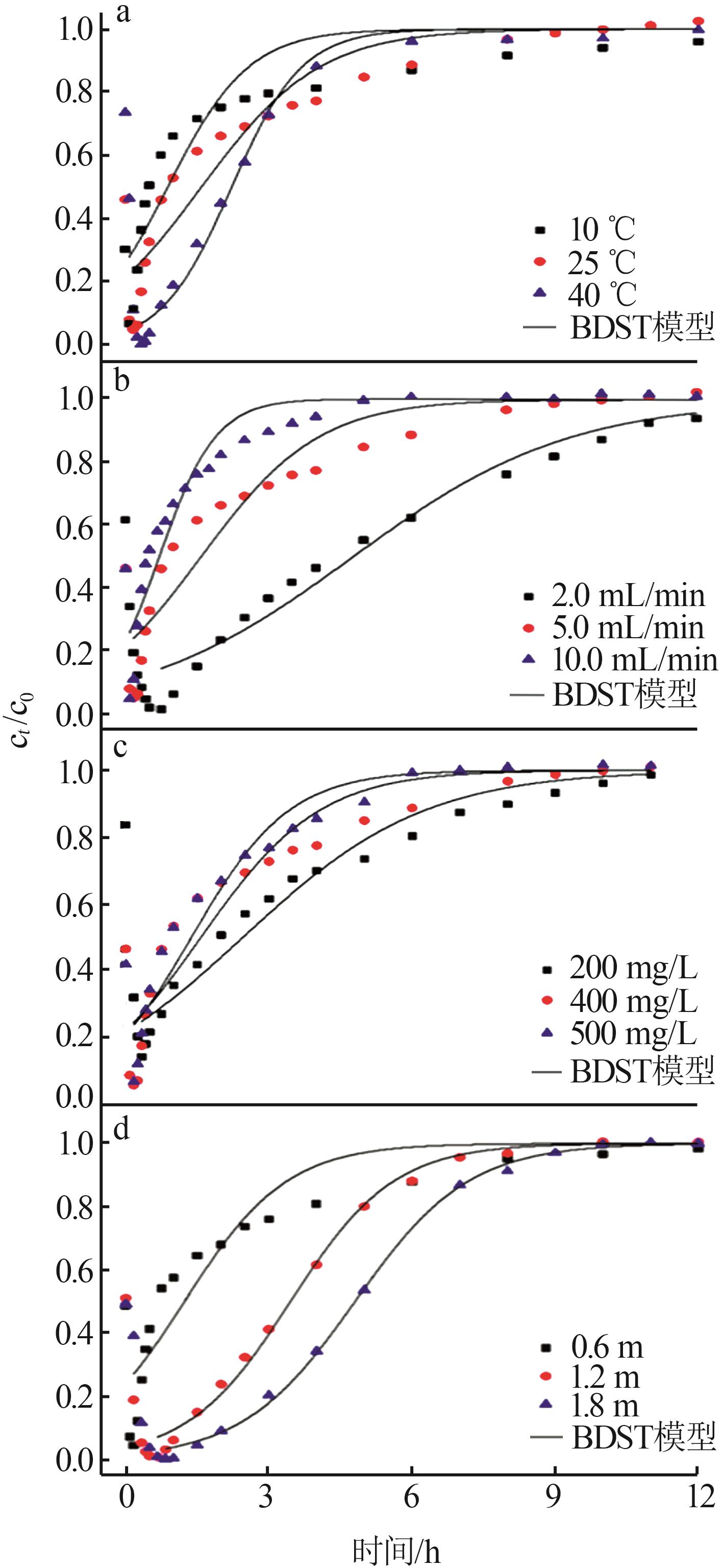

BDST model fitting parameters for Li+breakthrough curves"

| 编号 | K0/10-3 (L·g-1·h-1) | N0/102 (mg·L-1) | R2 | SSE |

|---|---|---|---|---|

| 1 | 3.11 | 4.48 | 0.816 3 | 0.223 2 |

| 2 | 2.13 | 8.07 | 0.897 4 | 0.174 1 |

| 3 | 3.58 | 11.31 | 0.989 9 | 0.019 1 |

| 4 | 1.16 | 60.68 | 0.966 2 | 0.043 2 |

| 5 | 4.45 | 1.80 | 0.922 0 | 0.148 1 |

| 6 | 2.51 | 22.68 | 0.962 5 | 0.048 8 |

| 7 | 2.30 | 6.27 | 0.942 2 | 0.101 8 |

| 8 | 2.45 | 8.80 | 0.994 1 | 0.011 3 |

| 9 | 2.23 | 8.16 | 0.998 1 | 0.003 9 |

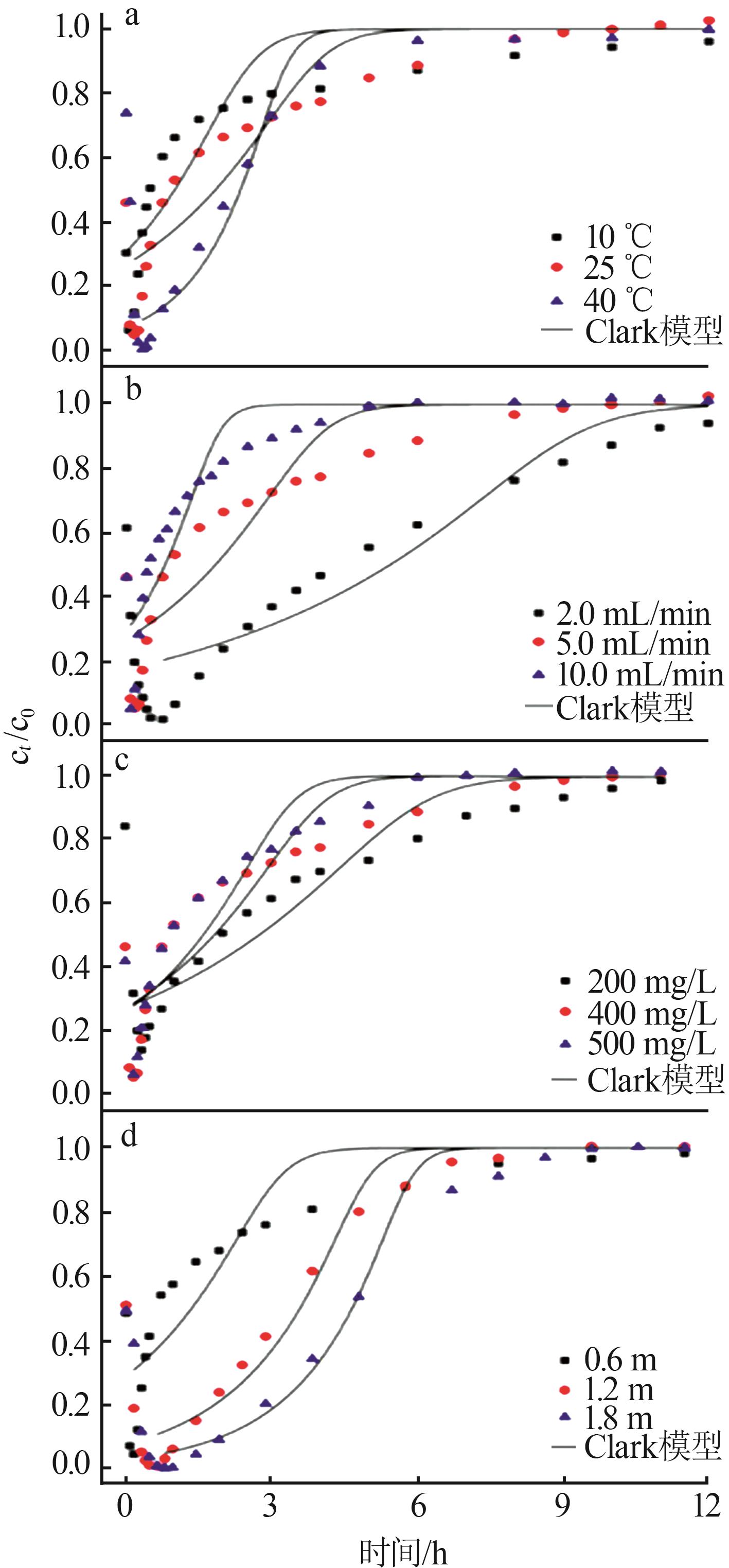

Table 8

Clark model fitting parameters for lithium breakthrough curves"

| 编号 | A | r/h-1 | R2 | SSE |

|---|---|---|---|---|

| 1 | 184.72 | 2.19 | 0.762 4 | 0.289 7 |

| 2 | 2 131.60 | 1.98 | 0.856 7 | 0.267 1 |

| 3 | 78 527.71 | 3.53 | 0.974 6 | 0.048 2 |

| 4 | 25 454.78 | 1.13 | 0.913 9 | 0.110 0 |

| 5 | 1 259.00 | 3.93 | 0.879 0 | 0.229 9 |

| 6 | 2 119.74 | 1.32 | 0.909 5 | 0.118 4 |

| 7 | 2 772.06 | 2.43 | 0.902 4 | 0.176 8 |

| 8 | 3.332 7×106 | 2.94 | 0.973 7 | 0.050 0 |

| 9 | 7.212 5×108 | 3.37 | 0.984 4 | 0.032 2 |

Table 9

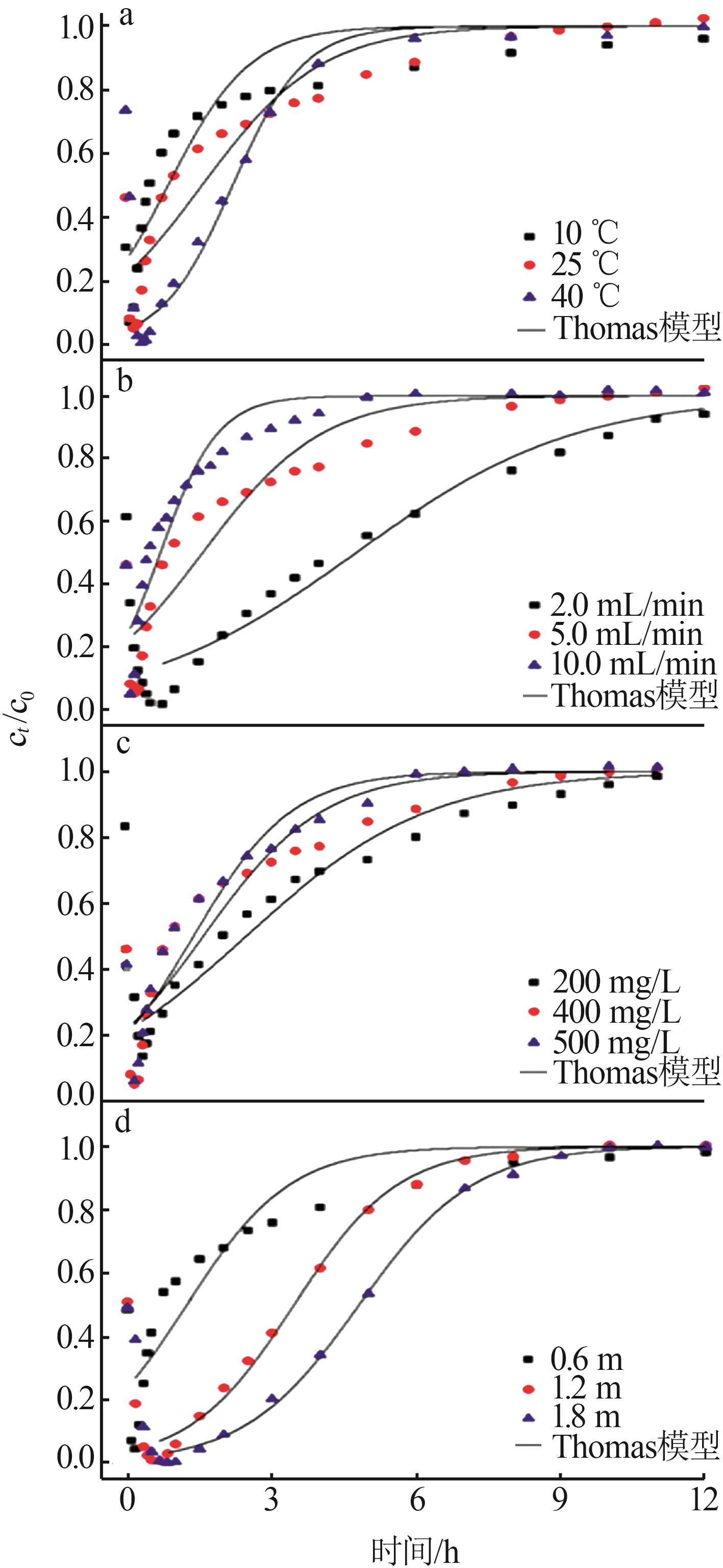

Thomas model fitting parameters for lithium breakthrough curves"

| 编号 | kT/10-3 (L·g-1·h -1) | q0/ (mg·g-1) | R2 | SSE |

|---|---|---|---|---|

| 1 | 3.11 | 2.108 9 | 0.816 3 | 0.223 2 |

| 2 | 2.13 | 3.726 4 | 0.897 4 | 0.101 8 |

| 3 | 3.58 | 5.167 8 | 0.989 9 | 0.019 1 |

| 4 | 1.16 | 4.569 3 | 0.966 2 | 0.043 2 |

| 5 | 4.45 | 3.296 2 | 0.922 0 | 0.148 1 |

| 6 | 2.51 | 3.222 9 | 0.962 5 | 0.174 1 |

| 7 | 2.30 | 3.655 8 | 0.942 2 | 0.048 8 |

| 8 | 2.45 | 4.043 8 | 0.994 1 | 0.011 3 |

| 9 | 2.23 | 3.780 1 | 0.998 1 | 0.003 9 |

Table 10

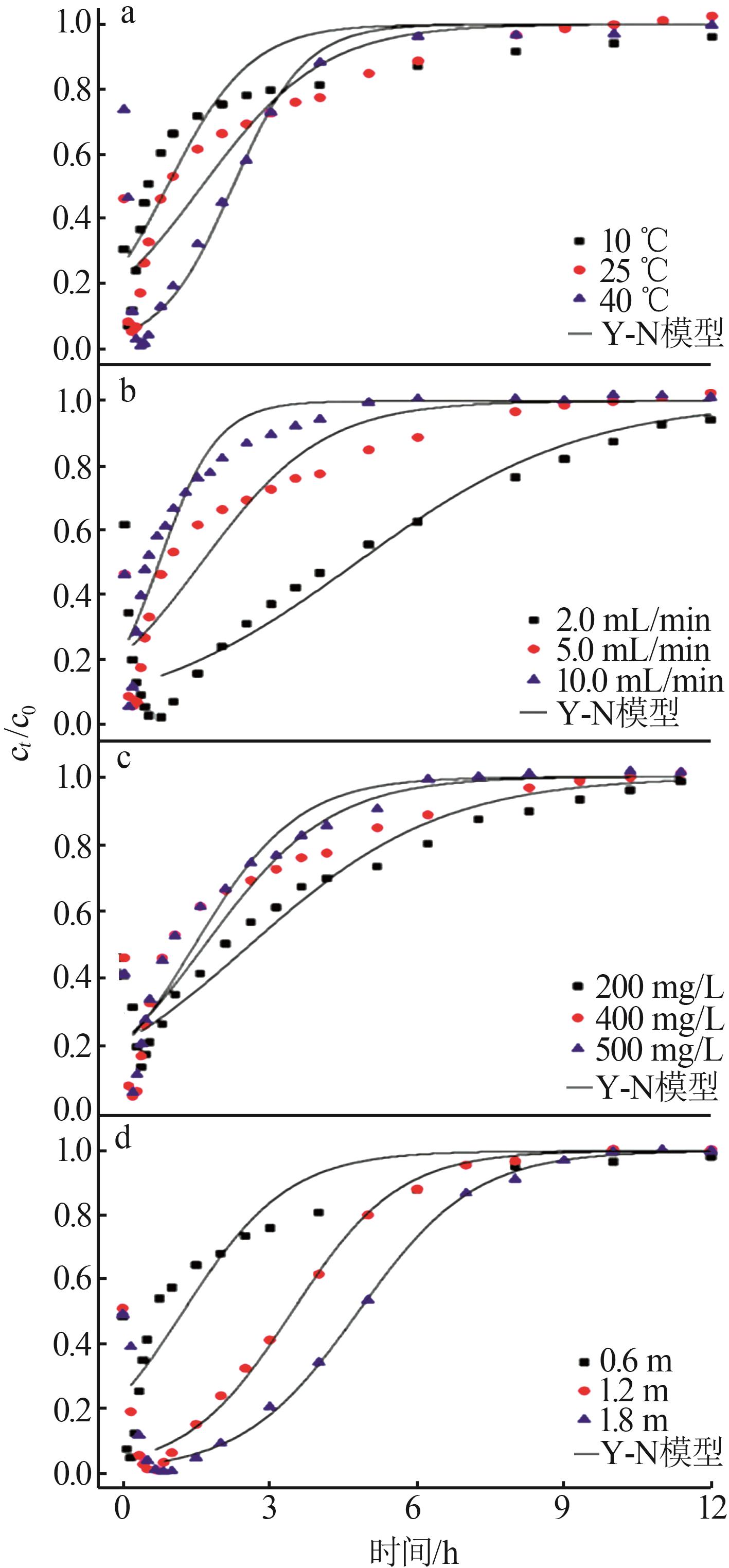

Yoon-Nelson model fitting parameters for lithium breakthrough curves"

| 编号 | kYN/h-1 | τ/h | R2 | SSE |

|---|---|---|---|---|

| 1 | 1.17 | 0.88 | 0.816 3 | 0.223 2 |

| 2 | 0.80 | 1.58 | 0.897 4 | 0.174 1 |

| 3 | 1.35 | 2.22 | 0.989 9 | 0.019 1 |

| 4 | 0.44 | 4.76 | 0.966 2 | 0.043 2 |

| 5 | 1.68 | 0.71 | 0.922 0 | 0.148 1 |

| 6 | 0.53 | 2.47 | 0.962 5 | 0.048 8 |

| 7 | 0.98 | 1.38 | 0.942 2 | 0.101 8 |

| 8 | 0.92 | 3.45 | 0.994 1 | 0.011 3 |

| 9 | 0.84 | 4.81 | 0.998 1 | 0.003 9 |

Table 11

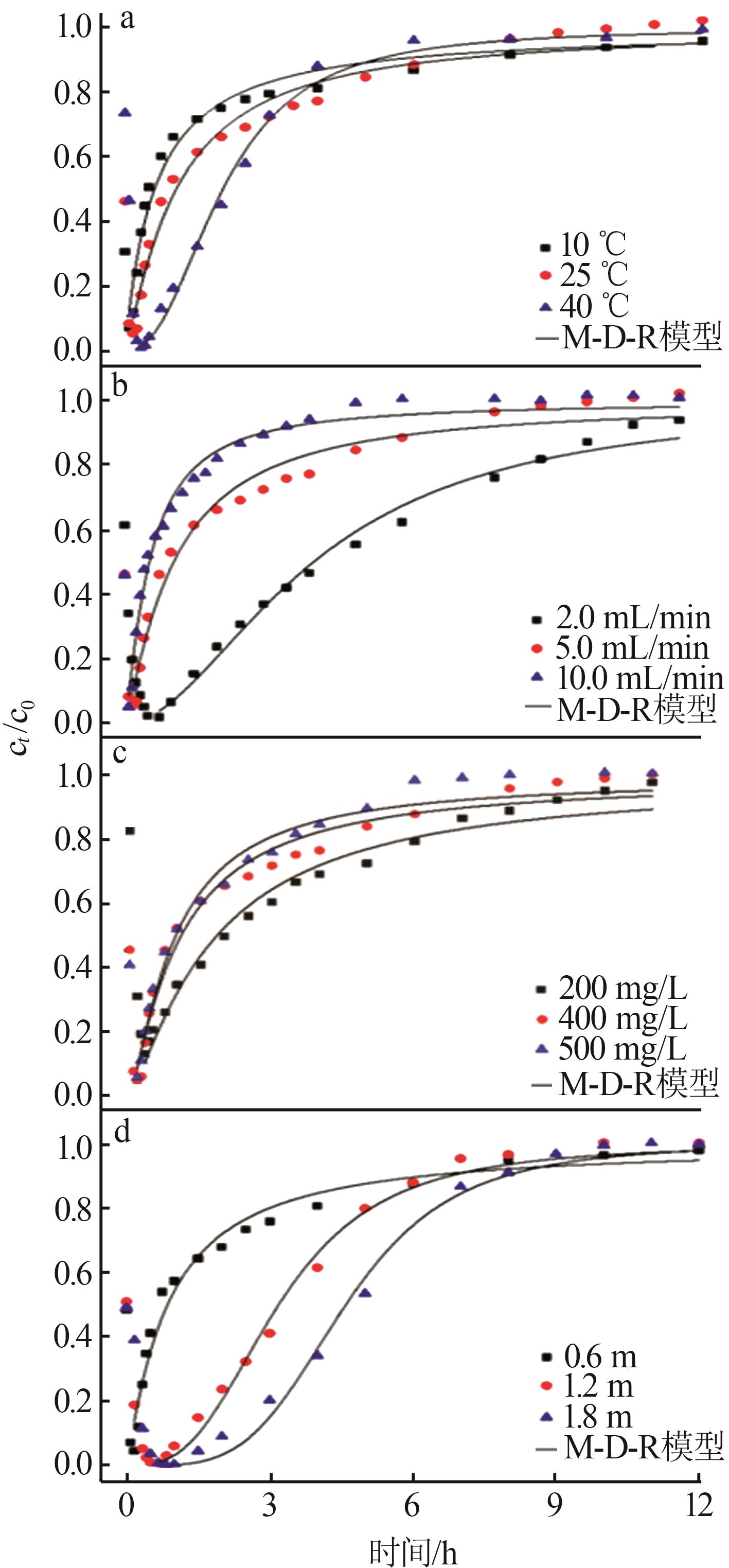

M-D-R model fitting parameters for lithiumbreakthrough curves"

| 编号 | aY | qY/(mg·g-1) | R2 | SSE |

|---|---|---|---|---|

| 1 | 1.01 | 1.4641 | 0.9751 | 0.0303 |

| 2 | 1.20 | 2.4995 | 0.9754 | 0.1018 |

| 3 | 2.37 | 4.7292 | 0.9945 | 0.0104 |

| 4 | 1.89 | 3.9112 | 0.9879 | 0.0154 |

| 5 | 1.29 | 2.4820 | 0.9841 | 0.0303 |

| 6 | 1.22 | 2.3466 | 0.9778 | 0.0417 |

| 7 | 1.30 | 2.5197 | 0.9834 | 0.0488 |

| 8 | 2.94 | 3.7289 | 0.9924 | 0.0144 |

| 9 | 4.05 | 3.6124 | 0.9930 | 0.0145 |

| 1 | Survey U.S.Geological. Mineral commodity summaries 2022[R].Reston,VA:U.S.Geological Survey, 2022. |

| 2 | 马珍. 盐湖锂资源高效分离提取技术研究进展[J].无机盐工业, 2022, 54(10):22-29. |

| MA Zhen. Research progress on efficient separation and extraction technology of lithium resources in salt lakes[J].Inorganic Chemicals Industry, 2022, 54(10):22-29. | |

| 3 |

ALESSIA A, ALESSANDRO B, MARIA V G, et al. Challenges for sustainable lithium supply:A critical review[J].Journal of Clean-

doi: 10.1016/j.jclepro.2021.126954 |

|

Production er,2021, 300.Doi:10.1016/j.jclepro.2021.126954.

doi: 10.1016/j.jclepro.2021.126954 |

|

| 4 | VIKSTRÖM H, DAVIDSSON S, HÖÖK M. Lithium availability and future production outlooks[J].Applied Energy, 2013, 110:252-266. |

| 5 | KESLER S E, GRUBER P W, MEDINA P A, et al. Global lithium resources:Relative importance of pegmatite,brine and other deposits[J].Ore Geology Reviews, 2012, 48:55-69. |

| 6 | 韩佳欢, 乜贞, 方朝合, 等. 中国锂资源供需现状分析[J].无机盐工业, 2021, 53(12):61-66. |

| HAN Jiahuan, NIE Zhen, FANG Chaohe, et al. Analysis of existing circumstance of supply and demand on China's lithium resourc-es[J].Inorganic Chemicals Industry, 2021, 53(12):61-66. | |

| 7 | SWAIN B. Recovery and recycling of lithium:A review[J].Separation and Purification Technology, 2017, 172:388-403. |

| 8 | 刘东帆, 孙淑英, 于建国. 盐湖卤水提锂技术研究与发展[J].化工学报, 2018, 69(1):141-155. |

| LIU Dongfan, SUN Shuying, YU Jianguo. Research and development on technique of lithium recovery from salt lake brine[J].CIESC Journal, 2018, 69(1):141-155. | |

| 9 |

SUN Ying, WANG Qi, WANG Yunhao, et al. Recent advances in magnesium/lithium separation and lithium extraction technologies from salt lake brine[J].Separation and Purification Technology, 2021, 256.Doi:10.1016/j.seppur.2020.117807.

doi: 10.1016/j.seppur.2020.117807 |

| 10 |

ZHONG Jing, LIN Sen, YU Jianguo. Li+ adsorption performance and mechanism using lithium/aluminum layered double hydroxides in low grade brines[J].Desalination, 2021, 505.Doi:10.1016/j.desal.2021.114983.

doi: 10.1016/j.desal.2021.114983 |

| 11 | ISUPOV V P, KOTSUPALO N P, NEMUDRY A P, et al. Aluminium hydroxide as selective sorbent of lithium salts from brines and technical solutions[J].Studies in Surface Science and Catalysis, 1999, 120:621-652. |

| 12 |

SUN Ying, YUN Rongping, ZANG Yufeng, et al. Highly efficient lithium recovery from pre-synthesized chlorine-ion-intercalated LiAl-layered double hydroxides via a mild solution chemistry process[J].Materials:Basel, Switzerland,2019, 12(12).Doi:10.3390/ma12121968.

doi: 10.3390/ma12121968 |

| 13 | LIU Xuheng, ZHONG Maoli, CHEN Xingyu, et al. Separating lithium and magnesium in brine by aluminum-based materials[J].Hydrometallurgy, 2018, 176:73-77. |

| 14 | RYABTSEV A, MENZHERES L T,TEN A. Sorption of lithium from brine onto granular LiCl·2Al(OH)3·mH2O sorbent under dynamic conditions[J].Russian Journal of Applied Chemistry, 2002, 75:1069-1074. |

| 15 | PARANTHAMAN M P, LI Ling, LUO Jiaqi, et al. Recovery of lithium from geothermal brine with lithium-aluminum layered double hydroxide chloride sorbents[J].Environmental Science & Technology, 2017, 51(22):13481-13486. |

| 16 | WILLIAMS G R, O'HARE D. A kinetic study of the intercalation of lithium salts into Al(OH)3 [J].The Journal of Physical Chemistry.B, 2006, 110(22):10619-10629. |

| 17 |

WILLIAMS G R, O'HARE D. Towards understanding,control and application of layered double hydroxide chemistry[J].Che- mInform, 2006, 37(45).Doi:10.1002/chin.200645266.

doi: 10.1002/chin.200645266 |

| 18 | 吴志坚, 郭敏, 李权, 等. 氢氧化铝基锂吸附剂从卤水中吸附锂的机理[J].盐湖研究, 2018, 26(3):1-6. |

| WU Zhijian, GUO Min, LI Quan, et al. Adsorption mechanisms for the recovery of lithium from brines using aluminum hydroxide based adsorbent[J].Journal of Salt Lake Research, 2018, 26(3):1-6. | |

| 19 | 郭敏, 刘忠, 李权, 等. 铝基锂吸附剂从卤水中吸附提锂的研究及进展[J].青海科技, 2019, 26(3):16-20. |

| 20 | HU Fang, LIN Sen, LI Ping, et al. Quantitative effects of desorption intensity on structural stability and readsorption performance of lithium/aluminum layered double hydroxides in cyclic Li+ extraction from brines with ultrahigh Mg/Li ratio[J].Industrial & Engineering Chemistry Research, 2020, 59:13539-13548. |

| 21 |

ZHONG Jing, LIN Sen, YU Jianguo. Lithium recovery from ultrahigh Mg2+/Li+ ratio brine using a novel granulated Li/Al-LDHs adsorbent[J].Separation and Purification Technology, 2021, 256.Doi:10.1016/j.seppur.2020.117780.

doi: 10.1016/j.seppur.2020.117780 |

| 22 | 钟静, 陆旗玮, 林森, 等. 锂铝层状吸附剂超低品位卤水提锂冲洗和解吸过程[J].化工进展, 2021, 40(8):4638-4646. |

| ZHONG Jing, LU Qiwei, LIN Sen, et al. Washing and desorption procedures research on granulated lithium aluminum layered double hydroxides for lithium recovery from low-grade brine[J].Chemical Industry and Engineering Progress, 2021, 40(8):4638-4646. | |

| 23 | 张瑞, 钟静, 林森, 等. 盐湖铝系提锂吸附剂成型条件的影响研究[J].化工学报, 2021, 72(12):6291-6297. |

| ZHANG Rui, ZHONG Jing, LIN Sen, et al. Study on the influence of granulation conditions on Li/Al-LDHs for lithium recovery from low grade brine[J].CIESC Journal, 2021, 72(12):6291-6297. | |

| 24 | YAGUB M T, SEN T K, AFROZE S, et al. Fixed-bed dynamic column adsorption study of methylene blue(MB) onto pine cone[J].Desalination and Water Treatment, 2015, 55(4):1026-1039. |

| 25 | CLARK R M. Evaluating the cost and performance of field-scale granular activated carbon systems[J].Environmental Science & Technology, 1987, 21(6):573-580. |

| 26 | THOMAS H C. Heterogeneous ion exchange in a flowing syst-em[J].Journal of the American Chemical Society, 1944, 66(10):1664-1666. |

| 27 | RECEPOĞLU Y K, KABAY N, IPEK I Y, et al. Packed bed column dynamic study for boron removal from geothermal brine by a chelating fiber and breakthrough curve analysis by using mathematical models[J].Desalination, 2018, 437:1-6. |

| 28 | YAN G, VIRARAGHAVAN T. Heavy metal removal in a biosorption column by immobilized M.rouxii biomass[J].Bioresource Technology, 2001, 78(3):243-249. |

| 29 | YAN Guangyu, VIRARAGHAVAN T, CHEN Min. A new model for heavy metal removal in a biosorption column[J].Adsorption Science & Technology, 2001, 19(1):25-43. |

| 30 | 高灿, 郭探, 刘海宁, 等. 碱金属离子在树脂上的动态吸附行为[J].无机盐工业, 2015, 47(2):16-20. |

| GAO Can, GUO Tan, LIU Haining, et al. Dynamic adsorption of mixed alkali metal ions onto resins[J].Inorganic Chemicals Industry, 2015, 47(2):16-20. | |

| 31 | 吴赵敏, 杨林, 王辛龙, 等. 动态离子交换法处理电子行业蚀刻含铝废酸工艺研究[J].无机盐工业, 2021, 53(2):61-65, 70. |

| WU Zhaomin, YANG Lin, WANG Xinlong, et al. Study on process of dynamic ion-exchange for etching waste acid containing aluminum in electronic industry[J].Inorganic Chemicals Industry, 2021, 53(2):61-65, 70. | |

| 32 | 周为峰, 池勇志, 李恺雄, 等. 离子交换法脱除湿法冶金工业MVR冷凝废水中盐类的研究[J].无机盐工业, 2022, 54(4):152-158. |

| ZHOU Weifeng, CHI Yongzhi, LI Kaixiong, et al. Study on removal of salts from MVR condensate wastewater in the hydrometallurgical industry by ion exchange method[J].Inorganic Chemicals Industry, 2022, 54(4):152-158. | |

| 33 | WAN NGAH W S, TEONG L C, TOH R H, et al. Utilization of chitosan-zeolite composite in the removal of Cu(Ⅱ) from aqueous solution:Adsorption,desorption and fixed bed column studies[J].Chemical Engineering Journal, 2012, 209:46-53. |

| 34 |

CHU K H. Breakthrough curve analysis by simplistic models of fixed bed adsorption:In defense of the century-old bohart-adams model[J].Chemical Engineering Journal, 2020, 380.Doi:10.1016/j.cej.2019.122513.

doi: 10.1016/j.cej.2019.122513 |

| 35 |

HU Qili, XIE Yanhua, ZHANG Zhenya. Modification of breakthrough models in a continuous-flow fixed-bed column:Mathematical characteristics of breakthrough curves and rate profil-es[J].Separation and Purification Technology, 2020, 238.Doi:10.1016/j.seppur.2019.116399.

doi: 10.1016/j.seppur.2019.116399 |

| [1] | CHENG Xiaoqiang, MA Jun, FENG Bin, BAI Liguang, ZHAO Xiaodong. Discussion on application of post-treatment process in fixed bed hydrogen peroxide production process [J]. Inorganic Chemicals Industry, 2025, 57(2): 98-104. |

| [2] | ZHAN Sijin, LIU Shike, LIU Fei, YAO Mengqin, CAO Jianxin. Study on preparation and catalytic performance of ZnO-CeO2 [J]. Inorganic Chemicals Industry, 2024, 56(3): 137-143. |

| [3] | Cheng Penggao,Huang Chuanfeng,Gan Shantian,Gong Jingkuan,Xiang Jun,Tang Na. Preparation of aluminum-based lithium adsorbent and its application in extracting lithium from Taihe underground brine [J]. Inorganic Chemicals Industry, 2021, 53(6): 140-144. |

| [4] | Wu Zhaomin,Yang Lin,Wang Xinlong,Zhuang Haibo,Ye Runzhou,Wang Ye,Li Yaoji. Study on process of dynamic ion-exchange for etching waste acid containing aluminum in electronic industry [J]. Inorganic Chemicals Industry, 2021, 53(2): 61-65. |

| [5] | Zhuang Haibo,Yang Lin,Deng Qiang,Ye Runzhou,Wu Zhaomin. Study on dynamic adsorption of Mn 2+ from phosphoric acid by ion exchange technology [J]. Inorganic Chemicals Industry, 2021, 53(1): 18-23. |

| [6] | LIU Fei, JIE Tian, ZHENG Run, YANG Fan. Study on influencing factors of ammonium dihydrogen phosphate crystallization process [J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(3): 46-. |

| [7] | YAO Dong-Ling. Current situation and outlook of hydrogen peroxide production in China [J]. INORGANICCHEMICALSINDUSTRY, 2013, 45(9): 1-. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||