| [1] |

WANG Mengdi, LUO Jin, WU Wei, ZHOU Jinghui, WANG Jing, SUN Yanmin, YU Haibin.

Study on preparation of γ-Al2O3 by microreaction and its properties for methyl orange adsorption

[J]. Inorganic Chemicals Industry, 2023, 55(9): 66-74.

|

| [2] |

LUO Wenbo, LI Heng, LÜ Jun, YANG Linguang, ZHAO Xingfan, LONG Xiao.

Study on recovery of silicon and aluminum from industrial silicon slag

[J]. Inorganic Chemicals Industry, 2023, 55(9): 94-99.

|

| [3] |

KANG Le, JING Maoxiang, LI Donghong, HU Xinyu, JIA Chunyan.

Study on preparation and electrochemical performance of lithium aluminate nanorods modified solid electrolyte

[J]. Inorganic Chemicals Industry, 2023, 55(8): 65-70.

|

| [4] |

PANG Fei, XU Yingrui, CHAI Chunling, SHEN Jingjing, BAI Liguang, ZHAO Xiaodong.

Overview on recycling of waste activated alumina in production of hydrogen peroxide by anthraquinone process

[J]. Inorganic Chemicals Industry, 2023, 55(6): 1-7.

|

| [5] |

XU Jingyao,ZHOU Xiaoli,SUN Jinghui,CAO Alin,QING Peilin.

Study on preparation of flake α-alumina based on mixed molten salt at low temperature

[J]. Inorganic Chemicals Industry, 2023, 55(2): 73-78.

|

| [6] |

TIAN Peng, XU Jingang, XU Qianjin, LIU Kunji, PANG Hongchang, NING Guiling.

Preparation of nano-alumina slurry and its application in modifying lithium-ion battery cathode material

[J]. Inorganic Chemicals Industry, 2023, 55(12): 43-49.

|

| [7] |

XIONG Shuang, YAN Jinsheng, ZHOU Zhou, ZHOU Baodi, CHEN Xiaopeng, TONG Zhangfa.

Effect of reaction conditions of quicklime digestion on properties of calcium hydroxide

[J]. Inorganic Chemicals Industry, 2023, 55(12): 50-58.

|

| [8] |

JIANG Demin, LI Shunmei, Li Qingqing, Chen Yuxin, LIU Daijun.

Hydrothermal synthesis of basic magnesium sulfate whiskers from magnesium hydroxide and magnesium sulfate heptahydrate

[J]. Inorganic Chemicals Industry, 2023, 55(12): 74-81.

|

| [9] |

LI Yunfei, LIU Shuqing, TANG Shengwei, ZHANG Tao.

Preparation of α-hemihydrate gypsum in Mg-Na mixed salt solution system under atmospheric pressure

[J]. Inorganic Chemicals Industry, 2023, 55(11): 100-106.

|

| [10] |

GUO Xueqin, DENG Xiaochuan, ZHU Chaoliang, FU Xin, WANG Ruirui, MA Wanxia, FAN Jie, ZUO Fangtao, QING Binju.

Study on preparation of modified diatomite loaded ammonium phosphomolybdate composite adsorbent and its adsorption performance of Cs+

[J]. Inorganic Chemicals Industry, 2023, 55(11): 19-26.

|

| [11] |

TIAN Peng, ZHOU Ruohui, XU Qianjin, LIU Kunji, PANG Hongchang, NING Guiling.

Synthesis and dehydration dynamics of boehmite microcrystalline with different particle sizes

[J]. Inorganic Chemicals Industry, 2023, 55(11): 27-36.

|

| [12] |

GUO Jianye, WANG Dong, SU Lijun, LI Wenjing.

Effect of aerogel doping on thermal insulation performance of glass fiber felt

[J]. Inorganic Chemicals Industry, 2023, 55(11): 53-57.

|

| [13] |

YANG Hongjun, WANG Min, GE Haiwen, QIAO Youmin, QIAO Ziyang.

Study on recycling process of potassium from calcium aluminate fly ash

[J]. Inorganic Chemicals Industry, 2023, 55(10): 121-127.

|

| [14] |

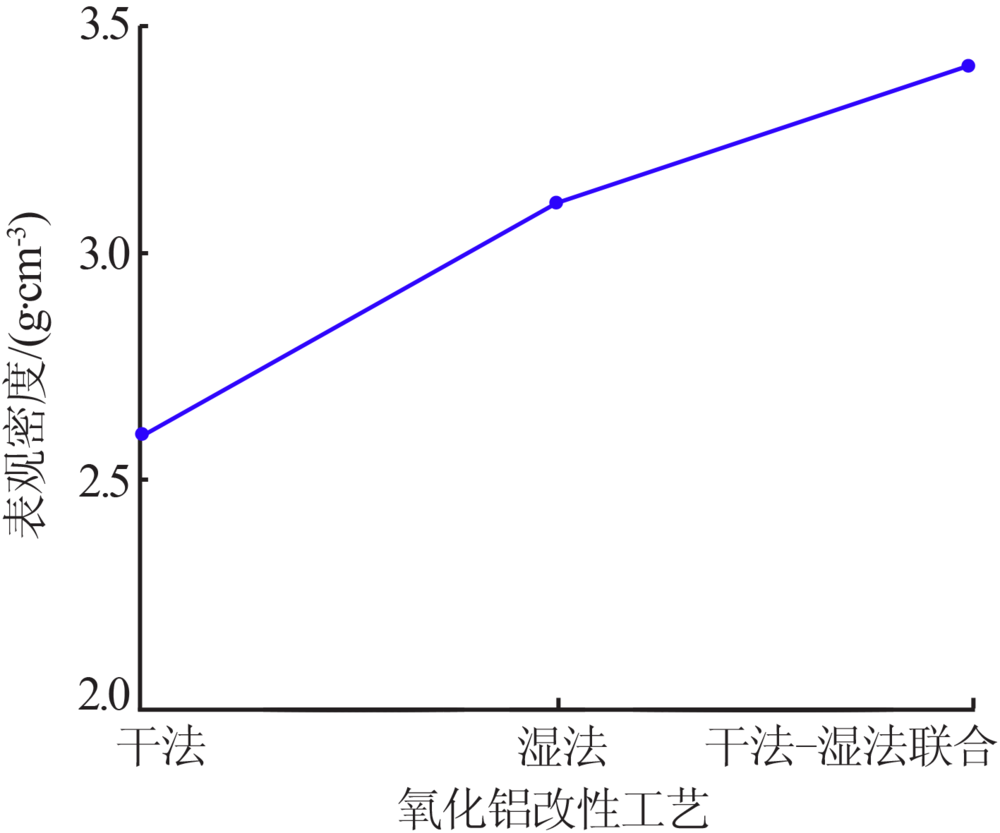

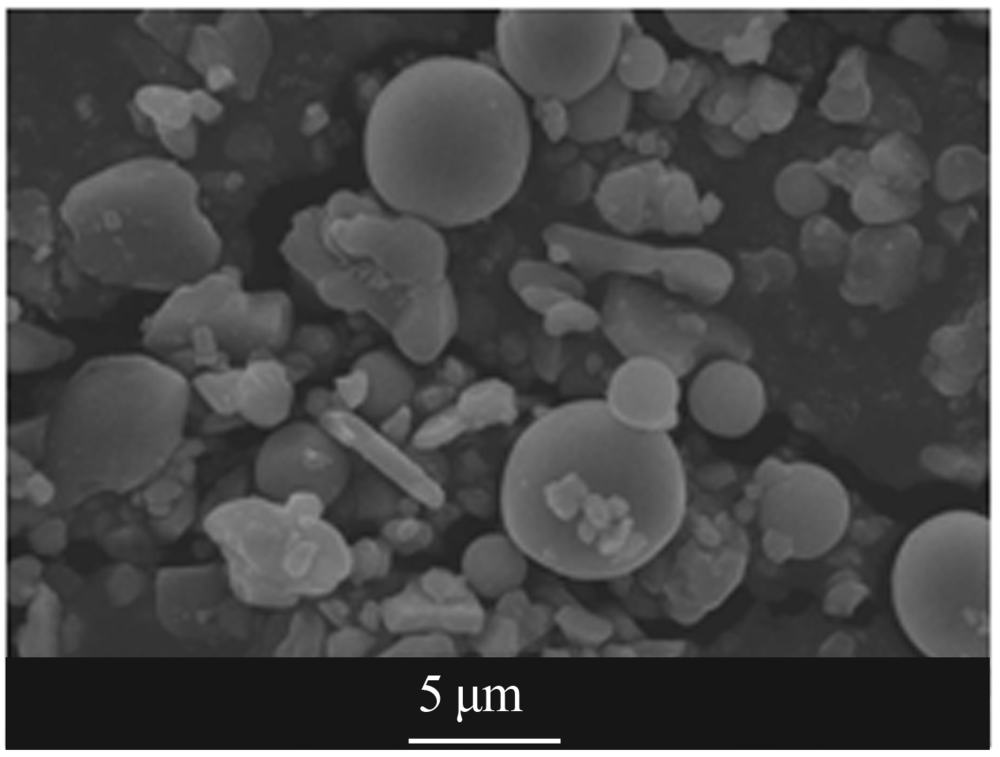

XU Qianjin,XU Jingang,TIAN Peng,LIU Kunji,GAO Tingting,NING Guiling.

Research progress of alumina coated cathode materials for lithium-ion batteries

[J]. Inorganic Chemicals Industry, 2023, 55(1): 46-55.

|

| [15] |

CHEN Mingsheng,LIU Peng,KONG Dewen,LI Yuan,YU Ke,HUANG Yansen,WU Ningbo,CHANG Juanjuan.

Effect of external admixtures on mechanical and thermal conductivity of phosphogypsum composite cementitious materials

[J]. Inorganic Chemicals Industry, 2022, 54(9): 113-118.

|