Inorganic Chemicals Industry ›› 2020, Vol. 52 ›› Issue (10): 135-139.doi: 10.11962/1006-4990.2019-0583

• Environment·Health·Safety • Previous Articles Next Articles

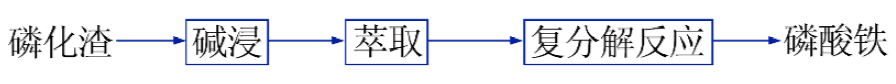

Preparation of battery grade iron phosphate from phosphating slag

Ou Xiaoju( ),Chai Qi,Li Zhengke,Wang Weiyan,Yang Yunquan(

),Chai Qi,Li Zhengke,Wang Weiyan,Yang Yunquan( )

)

- Xiangtan University,Xiangtan 411105,China

-

Received:2020-04-18Online:2020-10-10Published:2020-11-24 -

Contact:Yang Yunquan E-mail:1471759337@qq.com;yangyunquan@xtu.edu.cn

CLC Number:

Cite this article

Ou Xiaoju,Chai Qi,Li Zhengke,Wang Weiyan,Yang Yunquan. Preparation of battery grade iron phosphate from phosphating slag[J]. Inorganic Chemicals Industry, 2020, 52(10): 135-139.

share this article

| [1] | 张圣麟, 李红玲, 郑洪河, 等. 低温锌系磷化促进剂研究[J]. 涂料工业, 2005,35(9):60-61. |

| [2] | 武晓燕, 黄继承, 郎庆成, 等. 磷化渣资源化研究进展与展望[J]. 再生资源与循环经济, 2015(8):38-41. |

| [3] | 范洪强, 李淑英. 固废磷化渣的排放现状及资源化研究进展[J]. 现代化工, 2007,27(s1):97-99. |

| [4] | 范洪强, 李淑英, 焦扬. 固废磷化渣制备复合防锈颜料的研究[J]. 装备环境工程, 2008,5(2):83-86. |

| [5] |

Chiang Y M, Meethong N, Kao Y H. Reply to comment on“aliovalent substitutions in olivine lithium iron phosphate and impact on structure and properties”[J]. Advanced Functional Materials, 2010, 19(7):1060-1070.

doi: 10.1002/adfm.202000639 pmid: 32802013 |

| [6] | 冯国彪, 邓宏. 锂离子电池正极材料磷酸铁锂研究进展[J]. 无机盐工业, 2011,43(3):14-17. |

| [7] | Shao J, Li X, Wei J, et al. Synjournal of iron phosphate and their composites for lithium/sodium ion batteries[J]. Advanced Sustainable Systems, 2018,2(8/9):1700154. |

| [8] | Jugovic D, Uskokovic D. A review of recent developments in the synjournal procedures of lithium iron phosphate powders[J]. Journal of Power Sources, 2009,190(2):538-544. |

| [9] | Zhu Y, Tang S, Shi H, et al. Synjournal of FePO4·xH2O for fabricating submicrometer structured LiFePO4/C by a co-precipitation method[J]. Synjournal of FePO4·xH2O for fabricating 2014,40(2):2685-2690. |

| [10] | Peng C L, Shen C, Zhang B, et al. Effect of solution concentration on FePO4·2H2O precursor and performance of LiFePO4[J]. Journal of Central South University, 2010,41(5):1668-1673. |

| [11] | Okawa H, Yabuki J, Kawamura Y, et al. Synjournal of FePO4 cathode material for lithium ion batteries by asonochemical method[J]. Materials Research Bulletin, 2008,43(5):1203-1208. |

| [12] | Srinivasan V, Newman J. Discharge model for the lithium iron-phosphate electrode[J]. Journal of the Electrochemical Society, 2004,151(10):A1517-A1529. |

| [13] | 熊新宇, 熊天庆, 宋倩倩, 等. 金属表面处理磷化渣综合利用技术[J]. 冶金动力, 2015(2):43-45. |

| [14] | 范洪强, 李淑英, 蔡子达. 利用磷化渣配制复合磷化液[J]. 化工环保, 2008,28(2):165-168. |

| [15] | 马福波, 陈文兴, 田娟. 利用磷化废渣生产磷酸三钙技术[J]. 无机盐工业, 2015,47(9):60-61. |

| [16] | 崔国星, 严赤美, 张启卫. 溶剂萃取法分离锌锰金属离子的实验研究[J]. 无机盐工业, 2008,40(9):20-23. |

| [17] | Jiang D, Zhang X, Lu S, et al. Research on process of preparation and performance of iron phosphate as precusor of lithium iron phosphate[J]. Rare Metals, 2011,30(1):52-54. |

| [18] | Fu W, Fang Z, Hong W, et al. Effects of Ce+Gd on the structural features and thermal stability of iron-boron-phosphate glasses[J]. Materials Chemistry & Physics, 2017,201:170-179. |

| [19] |

Mahboobi E, Yourdkhani A, Poursalehi R. Liquid phase deposition of iron phosphate thin films[J]. CrystEngComm, 2018,20(35):10.1039/C8CE00632F.

doi: 10.1039/C5CE01202C pmid: 26306076 |

| [20] | Zhu Y M, Ruan Z W, Tang S Z, et al. Research status in preparation of FePO4:a review[J]. Ionics, 2014,20(11):1501-1510. |

| [1] | Liu Peiwen,Dong Peng,Meng Qi,Yang Xuan,Zhou Siyuan. Research development of solid phase regeneration of cathode material of spent lithium iron phosphate batteries [J]. Inorganic Chemicals Industry, 2020, 52(9): 6-8. |

| [2] | Wang Guoping,Xu Xuhui,Li Gang,Qiu Xuhui,Liu Zhengwei. Identification and analysis of fouling composition of ammonium chloride evaporator [J]. Inorganic Chemicals Industry, 2020, 52(8): 81-83. |

| [3] | Guo Ju,Jia Shuangzhu. Study on the one-step hydrothermal synthesis of LiFePO4 and its properties [J]. Inorganic Chemicals Industry, 2020, 52(6): 36-40. |

| [4] | Wu Kang,Li Jun,Chen Ming. Synthesis and characterization of 3D nano/micro spherical iron phosphate in ethanol-water system [J]. Inorganic Chemicals Industry, 2020, 52(6): 41-45. |

| [5] | Guo Ju,Jia Shuangzhu. Study of the method for the preparation of spherical-like and low sulfur FePO4 [J]. Inorganic Chemicals Industry, 2020, 52(5): 31-34. |

| [6] | Hu Zengbin,Li Zongze,Li Shaohua,Cun Jie,Xu Yonge. ICP-AES determination of phosphorous content in iron phosphate for battery materials [J]. Inorganic Chemicals Industry, 2020, 52(5): 78-80. |

| [7] | Wang Jiatai,Zhao Duan,Ma Lianhua,Zhang Caihong. Research progress of LiFePO4 cathode materials for Li-ion battery [J]. Inorganic Chemicals Industry, 2020, 52(4): 18-22. |

| [8] | Chen Lei,Zhao Longtao,Chen Zhenyu,Li Guang. Preparation of spherical lithium iron phosphate material and its 18650 battery test [J]. Inorganic Chemicals Industry, 2019, 51(8): 25-28. |

| [9] | Mao Qiqi,Liu Chuanxin,Dong Wenjuan,Zhang Ximan,Chen Hongyu,Wu Suwen. Preparation and characterization of spheniscidite [J]. Inorganic Chemicals Industry, 2019, 51(5): 53-56. |

| [10] | BIAN Du-Cheng, LIU Shu-Lin, TIAN Yuan. Reusing of spent LiFePO4 cathode materials by solid phase lithium refilling method and electrochemical performance there of [J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(2): 71-. |

| [11] | MAO Jia-Yu, XIAO Yang. Research progress in doping modification of LiFePO4/C cathode materials [J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(1): 13-. |

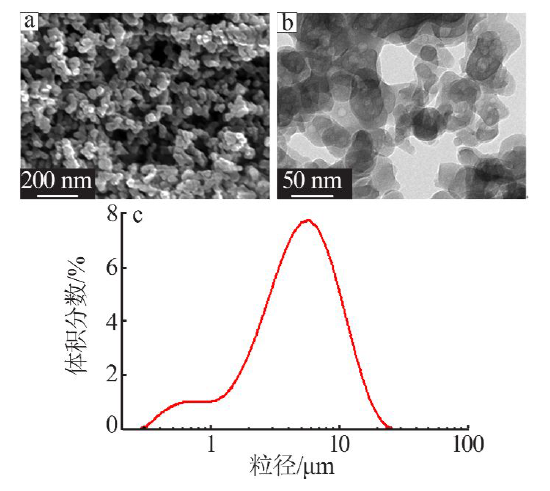

| [12] | ZHAO Feng-Yun, TIAN Bing-Long, WANG Jian-Ying, CUI Ji-Chao, ZHAO Hua, DUAN Xiao-Yu, HU Yong-Qi. Measurement of particle size of nano iron phosphate powder with laser particle size analyzer [J]. INORGANICCHEMICALSINDUSTRY, 2015, 47(7): 58-. |

| [13] | . Technology research progress of cathode material of lithium ion battery [J]. INORGANICCHEMICALSINDUSTRY, 2015, 47(6): 1-. |

| [14] | LIU Wan-Feng, XIAO Ren-Gui, LIN Qian, LIU Fei, PENG Xin. Amplification experiments of preparing battery-grade ferric phosphate by ferrophosphorus [J]. INORGANICCHEMICALSINDUSTRY, 2015, 47(5): 75-. |

| [15] | ZHANG Jun, LIU Heng, WANG Yan, ZHONG Ben-He, GAO Chao, WANG Wei, LI Jian-Long. Effect of precursor FePO4·2H2O on electrochemical properties of LiFePO4 [J]. INORGANICCHEMICALSINDUSTRY, 2013, 45(4): 60-. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|