Inorganic Chemicals Industry ›› 2020, Vol. 52 ›› Issue (4): 79-83.doi: 10.11962/1006-4990.2019-0333

• Environment·Health·Safety • Previous Articles Next Articles

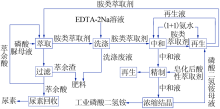

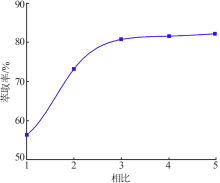

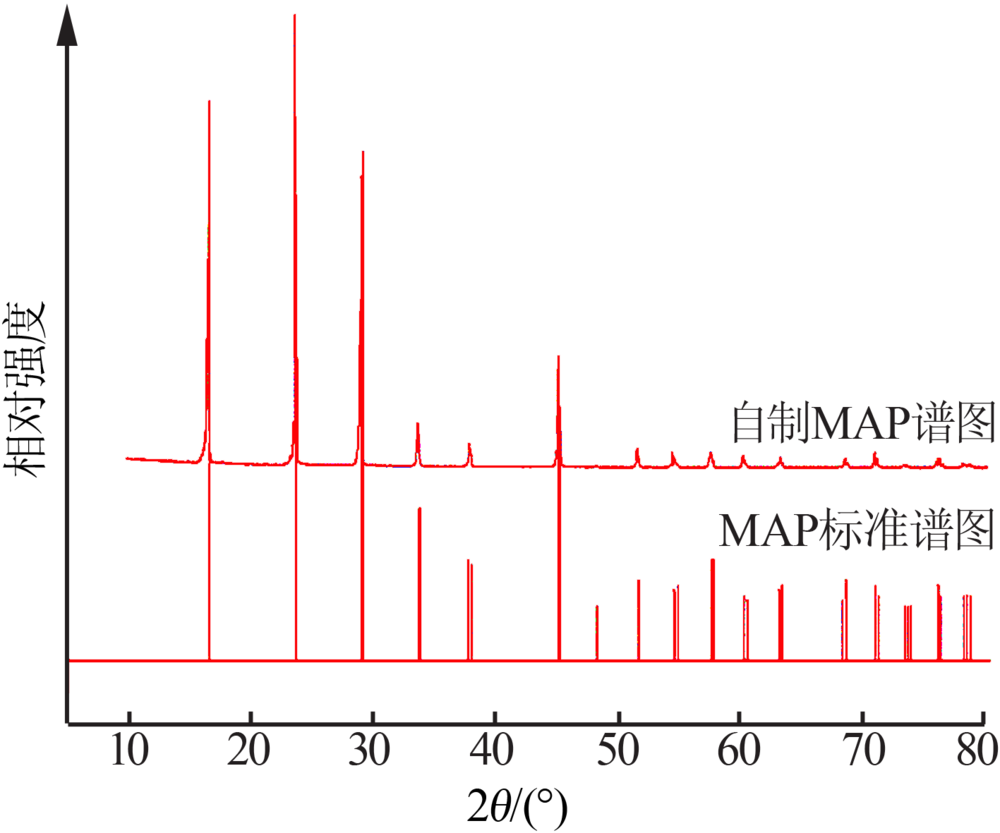

Process study on preparation of industrial grade ammonium dihydrogen phosphate from urea phosphate mother liquor

Liao Xiaoting,Li Jun( ),Chen Ming

),Chen Ming

- School of Chemical Engineering,Sichuan University,Chengdu 610065,China

-

Received:2019-10-14Online:2020-04-10Published:2020-04-22 -

Contact:Li Jun E-mail:lijun@scu.edu.cn

CLC Number:

Cite this article

Liao Xiaoting,Li Jun,Chen Ming. Process study on preparation of industrial grade ammonium dihydrogen phosphate from urea phosphate mother liquor[J]. Inorganic Chemicals Industry, 2020, 52(4): 79-83.

share this article

| [1] | 罗珍 . 湿法磷酸溶剂萃取副产萃余酸制磷酸脲和磷镁肥实验研究[D]. 昆明:昆明理工大学, 2015. |

| [2] | 周兆安, 唐瑜钟, 慎义勇 , 等. 化学抛光废磷酸处理方法和磷酸一铵的制备方法:中国, 107089650A[P]. 2017-08-25. |

| [3] | 林晶, 党亚固, 费德君 , 等. 磷酸二氢铵结晶介稳区的研究[J]. 无机盐工业, 2007,39(10):21-23. |

| [4] | Chen Ming, Li Jun, Jin Yang , et al. Efficient solvent extraction of phosphoric acid with dibutyl sulfoxide[J]. Journal of Chemical Tech-nology & Biotechnology, 2018,93(2):467-475. |

| [5] | 杨楠, 李军 . 胺类萃取剂萃取湿法磷酸中硫酸根的研究[J]. 无机盐工业, 2019,51(3):41-44. |

| [6] | 陈遵逵, 丁一刚, 龙秉文 , 等. 萃余酸制备工业级磷酸一铵的工艺优化[J]. 化学与生物工程, 2015,32(8):63-66. |

| [7] | 李军, 金央, 罗建洪 , 等. 用湿法磷酸制工业磷酸二氢铵工艺综述[J]. 磷肥与复肥, 2016,31(5):17-18,43. |

| [8] | 赵治华, 姜晓丽, 胡刚 . HEH[EHP]酸性络合萃取剂固体皂化性能研究[J]. 稀土, 2016,37(6):90-94. |

| [9] | 陈德清, 王娜, 张敏 , 等. 湿法磷酸净化生产工业磷酸一铵研究[J]. 无机盐工业, 2016,48(1):38-40. |

| [10] | 党亚固, 费德君, 林晶 . 湿法磷酸生产精细磷酸一铵结晶改善剂[J]. 无机盐工业, 2010,42(4):49-51. |

| [1] | Cao Weiwen,Li Jun,Chen Ming,Yu Yinrong,Liao Xiaoting. Study on agglomeration process during crystallization of calcium hydrogen phosphate and its main affecting impurity thereof [J]. Inorganic Chemicals Industry, 2021, 53(1): 50-53. |

| [2] | Liu Juexin,Zheng Chenggang,Ye Shichao. Determination and application of thermodynamic data of potassium dihydrogen phosphate crystal [J]. Inorganic Chemicals Industry, 2021, 53(1): 62-64. |

| [3] | Ma Yuming. Synthesis and application of sodium carbonate solution crystallization inhibitor [J]. Inorganic Chemicals Industry, 2020, 52(8): 63-65. |

| [4] | Shi Xingxing,Hu Kaibao,Wang Zhanhe,Pan Jingzhong,Cui Jingui,Luo Ruiyin,Du Wei,Tang Na. Study on salt crystallization law of brine frozen mirabilite and frozen mirabilite mother liquor evaporation in Jilantai Salt Lake [J]. Inorganic Chemicals Industry, 2020, 52(6): 54-58. |

| [5] | Wang Yanxia,Cheng Wenting,Fang Li,Cheng Fangqin. Study on preparation and growth mechanism of MgCO3·3H2O whiskers [J]. Inorganic Chemicals Industry, 2020, 52(5): 22-26. |

| [6] | Su Lei,Zhang Haijun,Wang Jin,Yu Xuefeng,Dong Changji,Sun Ze,Song Xingfu,Yu Jianguo. Study on preparation of molten salt grade potassium nitrate by reactive extraction method [J]. Inorganic Chemicals Industry, 2020, 52(5): 35-39. |

| [7] | Wang Haohao,Da Tao,Ye Shichao. Experimental study on crystallization process of ammonium chloride [J]. Inorganic Chemicals Industry, 2020, 52(4): 49-52. |

| [8] | Yin Haijiao,Xia Junjun,Quan Xiaoyu,Peng Tao,Tang Hao. Study on operation characteristics of mechanical flash cooling crystallization technology for titanium solution in summer [J]. Inorganic Chemicals Industry, 2020, 52(4): 93-95. |

| [9] | Han Tao,He Yanbin,Huang Shuaipeng. Instruction of production process and equipment for continuous freezing crystallization denitrification of lithium hydroxide [J]. Inorganic Chemicals Industry, 2020, 52(3): 98-100. |

| [10] | Chao Xiaoguang,Wang Hongbin,Cao Kun,Dai Yin,Song Litao,Zou Ping,Jia Min,Gao Guimei. Study on technology of recovering aluminum chloride from evaporation mother liquor in extraction of alumina from fly ash by hydrochloric acid method [J]. Inorganic Chemicals Industry, 2020, 52(12): 64-68. |

| [11] | Wang Baoming,Lü Zhonghao,Li Huiyong,Liu Yong,Hua Quanxian,Tang Jianwei. Research progress on preparation of urea phosphate with wet-process phosphoric acid [J]. Inorganic Chemicals Industry, 2020, 52(11): 1-5. |

| [12] | Liu Yanrui,Song Congcong,Shi Guizhen,Wang Kun. The study of double oxalate lithium borate preparation technology by aqueous phase method [J]. Inorganic Chemicals Industry, 2020, 52(10): 100-105. |

| [13] | Xiong Xiaoyun,Wei Zhaocheng,Wang Jiujiang,Gao Xionghou,Zhao Hongjuan,Hu Qingxun. Effect of synthesizing conditions on NaY zeolite prepared by in-situ crystallization from kaolin microspheres [J]. Inorganic Chemicals Industry, 2020, 52(1): 99-102. |

| [14] | Hao Jiantang. Study on aluminum fluoride pressurized crystallization technology [J]. Inorganic Chemicals Industry, 2019, 51(9): 57-60. |

| [15] | Zhang Hejie,Li Ping,Chen Xin,Wang Hongyan,Zheng Shili,Zhang Yi. New process research on removal of Fe and Al from MnSO4 leaching solutions of manganese metallurgy by in situ neutralization precipitation [J]. Inorganic Chemicals Industry, 2019, 51(9): 67-71. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|