Inorganic Chemicals Industry ›› 2020, Vol. 52 ›› Issue (3): 98-100.doi: 10.11962/1006-4990.2019-0258

• Chemical Equipment and Design • Previous Articles Next Articles

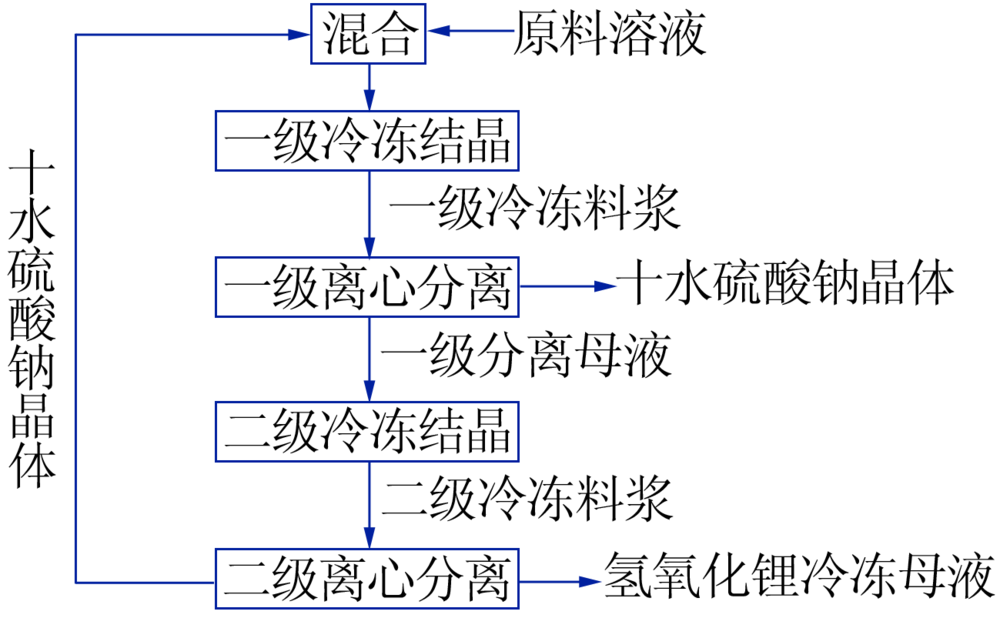

Instruction of production process and equipment for continuous freezing crystallization denitrification of lithium hydroxide

Han Tao,He Yanbin,Huang Shuaipeng

- Hebei Yanming Chemical Industry Equipment Co.,Ltd.,Shijiazhuang 050031,China