Inorganic Chemicals Industry ›› 2025, Vol. 57 ›› Issue (2): 98-104.doi: 10.19964/j.issn.1006-4990.2024-0192

• Industrial Techniques • Previous Articles Next Articles

Discussion on application of post-treatment process in fixed bed hydrogen peroxide production process

CHENG Xiaoqiang( ), MA Jun, FENG Bin, BAI Liguang, ZHAO Xiaodong

), MA Jun, FENG Bin, BAI Liguang, ZHAO Xiaodong

- Liming Research and Design Institute of Chemical Industry Co. ,Ltd. ,Luoyang 471000,China

-

Received:2024-04-07Online:2025-02-10Published:2025-02-20

CLC Number:

Cite this article

CHENG Xiaoqiang, MA Jun, FENG Bin, BAI Liguang, ZHAO Xiaodong. Discussion on application of post-treatment process in fixed bed hydrogen peroxide production process[J]. Inorganic Chemicals Industry, 2025, 57(2): 98-104.

share this article

Table 4

Compositions of working fluid"

| 序号 | 采样 位置 | ρ(EAQ)/ (g·L-1) | ρ(THEAQ)/ (g·L-1) | ρ(AQ)/ (g·L-1) | AR含量/ (mL·L-1) | TOP含量/ (mL·L-1) | TBU含量/ (mL·L-1) | 总有效蒽醌 增量/(g·L-1) |

|---|---|---|---|---|---|---|---|---|

| 1 | 碱塔前 | 111.21 | 53.47 | 164.68 | 661.64 | 130.05 | 54.04 | 2.08 |

| 碱塔后 | 112.21 | 54.50 | 166.71 | 664.51 | 128.58 | 54.26 | ||

| 2 | 碱塔前 | 111.12 | 53.51 | 164.63 | 663.73 | 129.31 | 52.12 | 2.12 |

| 碱塔后 | 112.18 | 54.57 | 166.75 | 664.69 | 128.41 | 52.75 | ||

| 3 | 碱塔前 | 113.57 | 54.68 | 168.25 | 660.43 | 129.88 | 54.41 | 1.62 |

| 碱塔后 | 113.44 | 56.34 | 169.78 | 662.67 | 128.56 | 54.76 |

| 1 | 杨盟飞,冯彬,白立光,等.蒽醌法制过氧化氢技术研究进展[J].化学推进剂与高分子材料,2024,22(1):25-32. |

| YANG Mengfei, FENG Bin, BAI Liguang,et al.Research progress in technology preparing hydrogen peroxide by anthraquinone process[J].Chemical Propellants & Polymeric Materials,2024,22(1):25-32. | |

| 2 | 成小强,李鹏翔,冯彬,等.蒽醌法制备过氧化氢用钯催化剂的再生及科学使用探讨[J].化学推进剂与高分子材料,2022,20(6):25-30. |

| CHENG Xiaoqiang, LI Pengxiang, FENG Bin,et al.Discussion on regeneration and scientific use of palladium catalysts for preparation of hydrogen peroxide by anthraquinone process[J].Chemical Propellants & Polymeric Materials,2022,20(6):25-30. | |

| 3 | 潘智勇,邢定峰.过氧化氢市场现状和技术发展趋势[J].现代化工,2021,41(4):11-16. |

| PAN Zhiyong, XING Dingfeng.Market status and technology development trend of hydrogen peroxide[J].Modern Chemical Industry,2021,41(4):11-16. | |

| 4 | 沈冲,庞飞,柴春玲,等.磷酸三辛酯的合成工艺概况[J].化学推进剂与高分子材料,2021,19(6):1-7. |

| SHEN Chong, PANG Fei, CHAI Chunling,et al.Overview of synthesis process of trioctyl phosphate[J].Chemical Propellants & Polymeric Materials,2021,19(6):1-7. | |

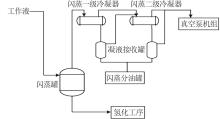

| 5 | 刘向来.真空脱水在双氧水生产中的应用[J].无机盐工业,2014,46(7):47-50. |

| LIU Xianglai.Application of vacuum dehydration in hydrogen peroxide production[J].Inorganic Chemicals Industry,2014,46(7):47-50. | |

| 6 | 陈四海,蔡志伟,龚凌,等.四丁基脲代替磷酸三辛酯用于过氧化氢生产[J].石油化工,2003,32(6):470-473. |

| CHEN Sihai, CAI Zhiwei, GONG Ling,et al.Tetra-n-butyl urea substituted for tri-iso-octyl phosphate to manufacture H2O2 [J].Petrochemical Technology,2003,32(6):470-473. | |

| 7 | 许颖睿,庞飞,申敬敬,等.一种过氧化氢生产用萃取塔:中国,116236813A[P].2023-06-09. |

| 8 | 初铭玥,吴美岩,唐春,等.过氧化氢工作液中蒽醌降解物再生剂研究现状[J].无机盐工业,2018,50(11):7-10. |

| CHU Mingyue, WU Meiyan, TANG Chun,et al.Recent advances in regenerant of anthraquinone degradation products in working solution of hydrogen peroxide[J].Inorganic Chemicals Industry,2018,50(11):7-10. | |

| 9 | 邓明杨,张晓昕,宗保宁.蒽醌加氢法生产过氧化氢工业催化剂中的科学问题[J].中国科学:化学,2021,51(7):896-904. |

| DENG Mingyang, ZHANG Xiaoxin, ZONG Baoning.Scientific issues in industrial catalysts for anthraquinone hydrogenation to produce hydrogen peroxides[J].Scientia Sinica Chimica,2021,51(7):896-904. | |

| 10 | 庞飞,许颖睿,柴春玲,等.蒽醌法过氧化氢生产工艺中废弃活性氧化铝的回收利用研究概况[J].无机盐工业,2023,55(6):1-7,49. |

| PANG Fei, XU Yingrui, CHAI Chunling,et al.Overview on recycling of waste activated alumina in production of hydrogen peroxide by anthraquinone process[J].Inorganic Chemicals Industry,2023,55(6):1-7,49. | |

| 11 | 周伟,王红琴,安霓虹,等.过氧化氢生产中新型氧化铝再生剂工业应用实验[J].无机盐工业,2018,50(12):44-46. |

| ZHOU Wei, WANG Hongqin, AN Nihong,et al.Industrial application of new alumina regenerant for hydrogen peroxide working solution[J].Inorganic Chemicals Industry,2018,50(12):44-46. | |

| 12 | 庞飞,许颖睿,柴春玲,等.蒽醌法过氧化氢生产工艺中废弃活性氧化铝的回收利用研究概况[J].无机盐工业,2023,55(6):1-7,49. |

| PANG Fei, XU Yingrui, CHAI Chunling,et al.Overview on recycling of waste activated alumina in production of hydrogen peroxide by anthraquinone process[J].Inorganic Chemicals Industry,2023,55(6):1-7,49. | |

| 13 | 赵珒,袁恩先,王莅.氧化镁/γ-氧化铝催化蒽醌法工艺降解物再生过程研究[J].无机盐工业,2015,47(6):70-73. |

| ZHAO Jin, YUAN Enxian, WANG Li.Regenerations of degradation products in anthraquinone process of hydrogen peroxide production over MgO/γ-Al2O3 catalysts[J].Inorganic Chemicals Industry,2015,47(6):70-73. | |

| 14 | 陈振.蒽醌降解物再生固体碱催化剂制备及性能研究[D].北京:北京化工大学,2019. |

| 15 | 程义,梁希慧,朱朝莹,等.CaO和MnO2双修饰的γ-Al2O3催化再生乙基蒽醌工作液[J].化学反应工程与工艺,2018,34(5):431-439. |

| CHENG Yi, LIANG Xihui, ZHU Chaoying,et al.CaO and MnO2-modified γ-Al2O3 catalyzed the regeneration of ethyl anthraquinone working solution[J].Chemical Reaction Engineering and Technology,2018,34(05):431-439. | |

| 16 | 李亚北.新型固体镁基催化剂的构筑及其蒽醌降解物再生催化性能研究[D].北京:北京化工大学,2021. |

| 17 | 史振宇,孙小惠,张旭旺,等.一种用于蒽醌法制备双氧水工作液的再生剂及其应用:中国,112551541B[P].2022.10.11. |

| 18 | H·堺谷,井浦克弘,萩原猪佐夫,等.过含工作液再生工序的过氧化氢制造方法:中国,101421184B[P].2011-04-13. |

| 19 | 庞飞,许颖睿,马俊,等.一种蒽醌法生产过氧化氢用工作液的后处理新工艺:中国,114180773A[P].2022-03-15. |

| 20 | 卿光宗,杨华,刘光昌,等.蒽醌法全酸性工作液体系制备双氧水的方法:中国,103496674B[P].2015-02-18. |

| 21 | 张永泽,王珂.高效2-乙基蒽醌催化再生系统:中国,113045396A[P].2021-06-29. |

| [1] | QI Guoqing, LI Tong. Research progress of quality improvement plans for industrial hydrogen peroxide [J]. Inorganic Chemicals Industry, 2025, 57(1): 36-41. |

| [2] | Yang Jie,An Nihong,Wei Jianwei,Wang Hongqin,Xie Jiyang,Dai Yunsheng. Research progress of anthraquinone synthesis catalyst for hydrogen peroxide [J]. Inorganic Chemicals Industry, 2021, 53(4): 20-24. |

| [3] | Yu Tianhua,Huang Qipeng,Situ Cheng. Synthesis of dihydroxybenzenes by hydroxylation of phenol over Cu/ MS-1 with mesoporous [J]. Inorganic Chemicals Industry, 2021, 53(2): 94-99. |

| [4] | Zhu Hongwei, Jiang Jie, Sun Bing, Sun Feng, Xu Wei. Strategy on safety of hydrogen peroxide oxidation process [J]. Inorganic Chemicals Industry, 2021, 53(1): 77-81. |

| [5] | Yao Dongling,Zhang Xiaoping. Development progress and technical process of hydrogen peroxide production by anthraquinone process in China [J]. Inorganic Chemicals Industry, 2020, 52(6): 1-7. |

| [6] | Zhou Yi,Nie Xiaoyun. Determination method of some trace elements in hydrogen peroxide products [J]. Inorganic Chemicals Industry, 2020, 52(6): 80-82. |

| [7] | Wang Ben,Chen Mengmeng,Zhang Fan. Research progress on purification technology of hydrogen peroxide [J]. Inorganic Chemicals Industry, 2019, 51(6): 1-4. |

| [8] | RUAN Heng, WANG Fu-Li, HUANG Shi-Yong, GUO Zi-Tian, HUANG Shang-Shun, HUANG Mei, HUANG Qing-Ze, WANG Qiu-Ping. Regeneration of anthraquinone degradation products with organic alkali as catalyst [J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(6): 75-. |

| [9] | GUO Zi-Tian, RUAN Heng, WANG Fu-Li, HUANG Shi-Yong, HUANG Mei, HUANG Qing-Ze, WANG Qiu-Ping. Regeneration and physical-chemical properties of inactivated alumina in production of hydrogen peroxide [J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(5): 66-. |

| [10] | LIANG Yuan, WANG Hong. Determination of nitrate in hydrogen peroxide ion by ion chromatography [J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(12): 78-. |

| [11] | . Regenerations of degradation products in anthraquinone process of hydrogen peroxide production over MgO/γ-Al2O3 catalysts [J]. INORGANICCHEMICALSINDUSTRY, 2015, 47(6): 70-. |

| [12] | GAO Yuan, LUO Meng, ZHU Liu. Preparation of high purity boric oxide [J]. INORGANICCHEMICALSINDUSTRY, 2015, 47(2): 46-. |

| [13] | YAN Shao-Peng, MIAO Jun-Kui, JIANG Peng, LENG Kai-Liang, SUN Wei-Hong, XING Li-Hong, YU Yue-Qin. Study on new oxidation process for iodine ion in kelp soaking liquid [J]. INORGANICCHEMICALSINDUSTRY, 2014, 46(7): 27-. |

| [14] | LIU Xiang-Lai. Application of vacuum dehydration in hydrogen peroxide production [J]. INORGANICCHEMICALSINDUSTRY, 2014, 46(7): 47-. |

| [15] | LIU Xi-Xiang, 欧Yang-Hui-Xiang , XIE Yu-Qi, LING Shao-Ming, LAN Cui-Ling. Mimic enzyme catalytic spectrophotometric determination of trace hydrogen peroxide in foodstuff with Fe3O4 nanoparticles [J]. INORGANICCHEMICALSINDUSTRY, 2014, 46(5): 66-. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||