Inorganic Chemicals Industry ›› 2025, Vol. 57 ›› Issue (10): 24-31.doi: 10.19964/j.issn.1006-4990.2025-0019

• Research & Development • Previous Articles Next Articles

Study on recovery of metals from spent NCA-type lithium-ion power batteries

LI Yanqiang1( ), WANG Dahui1(

), WANG Dahui1( ), CHEN Huaijing2, PENG Xiaoping1, SONG Xiaolong1

), CHEN Huaijing2, PENG Xiaoping1, SONG Xiaolong1

- 1. State Key Laboratory of Advanced Processing and Recycling of Nonferrous Metals,Lanzhou University of Technology,Lanzhou 730050,China

2. College of Science,Lanzhou University of Technology,Lanzhou 730050,China

-

Received:2025-01-06Online:2025-10-10Published:2025-05-27 -

Contact:WANG Dahui E-mail:3204893178@qq.com;wangdh@lut.edu.cn

CLC Number:

Cite this article

LI Yanqiang, WANG Dahui, CHEN Huaijing, PENG Xiaoping, SONG Xiaolong. Study on recovery of metals from spent NCA-type lithium-ion power batteries[J]. Inorganic Chemicals Industry, 2025, 57(10): 24-31.

share this article

| [1] | WANG Qingsong, MAO Binbin, STOLIAROV S I,et al.A review of lithium ion battery failure mechanisms and fire prevention strategies[J].Progress in Energy and Combustion Science,2019,73:95-131. |

| [2] | 唐迪,王俊雄,陈稳,等.退役锂离子电池正极材料直接回收的研究现状和展望[J].无机盐工业,2023,55(1):15-25. |

| TANG Di, WANG Junxiong, CHEN Wen,et al.Research status and prospect on direct regeneration of cathode materials from retired lithium-ion batteries[J].Inorganic Chemicals Industry,2023,55(1):15-25. | |

| [3] | ALI H, KHAN H A, PECHT M.Preprocessing of spent lithium-ion batteries for recycling:Need,methods,and trends[J].Renewable and Sustainable Energy Reviews,2022,168:112809. |

| [4] | SRINIVASAN S, SHANTHAKUMAR S, ASHOK B.Sustainable lithium-ion battery recycling:A review on technologies,regulatory approaches and future trends[J].Energy Reports,2025,13:789- 812. |

| [5] | HUANG Tao, LIU Longfei, ZHANG Shuwen.Recovery of cobalt,lithium,and manganese from the cathode active materials of spent lithium-ion batteries in a bio-electro-hydrometallurgical process[J].Hydrometallurgy,2019,188:101-111. |

| [6] | GUO Hui, KUANG Ge, WAN Hao,et al.Enhanced acid treatment to extract lithium from lepidolite with a fluorine-based chemical method[J].Hydrometallurgy,2019,183:9-19. |

| [7] | XIA Heyi, LIU Cheng, SHEN Lu,et al.Structure and thermal stability of LiNi0.8Co0.15Al0.05O2 after long cycling at high temperatu-re[J].Journal of Power Sources,2020,450:227695. |

| [8] | KOUIHEN F EL, KHARBOUCH Z, FAIK A.Review:Advancements in synthesis methods for nickel-rich NCA cathode materials:Optimizing synthesis conditions and their impact on electrochemical performances for next-generation lithium batteries[J].Journal of the Electrochemical Society,2023,170(10):100520. |

| [9] | 李园园,席儒恒,蓝兹炜,等.高镍三元镍钴铝酸锂正极材料研究进展[J].化工新型材料,2022,50(10):57-62. |

| LI Yuanyuan, XI Ruheng, LAN Ziwei,et al.Research progress on LiNi x Co y Al1- x- y O2 cathode material with high Ni[J].New Chemical Materials,2022,50(10):57-62. | |

| [10] | NONAKA T, OKUDA C, SENO Y,et al. In situ XAFS and micro-XAFS studies on LiNi0.8Co0.15Al0.05O2 cathode material for lithium-ion batteries[J].Journal of Power Sources,2006,162(2):1329-1335. |

| [11] | LI Li, BIAN Yifan, ZHANG Xiaoxiao,et al.Process for recycling mixed-cathode materials from spent lithium-ion batteries and kinetics of leaching[J].Waste Management,2018,71:362-371. |

| [12] | MENG Xiangqi, HAO Jie, CAO Hongbin,et al.Recycling of LiNi1/3Co1/3Mn1/3O2 cathode materials from spent lithium-ion batteries using mechanochemical activation and solid-state sinter- ing[J].Waste Management,2019,84:54-63. |

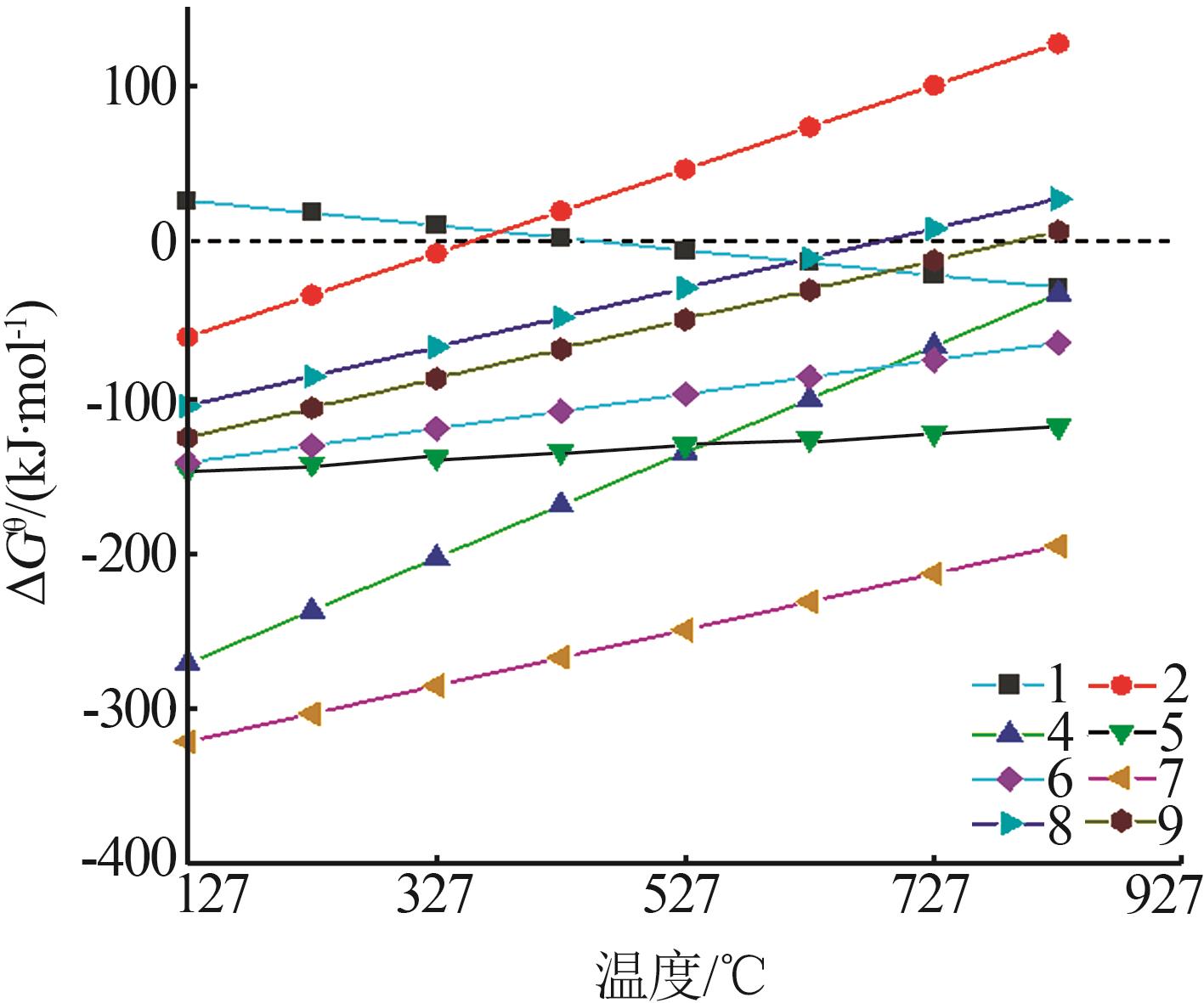

| [13] | WU Naiteng, WU Hao, YUAN Wei,et al.Facile synthesis of one-dimensional LiNi0.8Co0.15Al0.05O2 microrods as advanced cathode materials for lithium ion batteries[J].Journal of Materials Chemistry A,2015,3(26):13648-13652. |

| [14] | MA Liwen, LIU Guangyun, WANG Yuehua,et al.Preparation and performance of regenerated Al2O3-coated cathode material LiNi0.8Co0.15Al0.05O2 from spent power lithium-ion batteries[J].Molecules,2023,28(13):5165. |

| [15] | PENG Gang, YAO Xiayin, WAN Hongli,et al.Insights on the fundamental lithium storage behavior of all-solid-state lithium batteries containing the LiNi0.8Co0.15Al0.05O2 cathode and sulfide electrolyte[J].Journal of Power Sources,2016,307:724-730. |

| [16] | DONG Peng, XIA Shubiao, ZHANG Yingjie,et al.Influence of complexing agents on the structure and electrochemical properties of LiNi0.80Co0.15Al0.05O2 cathode synthesized by sol-gel meth-od:A comparative study[J].International Journal of Electrochemical Science,2017,12(1):561-575. |

| [17] | LI Li, QU Wenjie, ZHANG Xiaoxiao,et al.Succinic acid-based leaching system:A sustainable process for recovery of valuable metals from spent Li-ion batteries[J].Journal of Power Sources,2015,282:544-551. |

| [18] | ZENG Xianlai, LI Jinhui, LIU Lili.Solving spent lithium-ion battery problems in China:Opportunities and challenges[J].Renewable and Sustainable Energy Reviews,2015,52:1759-1767. |

| [19] | KU H, JUNG Y,JO M,et al.Recycling of spent lithium-ion battery cathode materials by ammoniacal leaching[J].Journal of Ha- zardous Materials,2016,313:138-146. |

| [20] | HE Lipo, SUN Shuying, SONG Xingfu,et al.Leaching process for recovering valuable metals from the LiNi1/3Co1/3Mn1/3O2 cathode of lithium-ion batteries[J].Waste Management,2017,64:171- 181. |

| [21] | MA Liwen, NIE Zuoren, XI Xiaoli,et al.Cobalt recovery from cobalt-bearing waste in sulphuric and citric acid systems[J].Hydrometallurgy,2013,136:1-7. |

| [22] | CHEN Xiangping, CHEN Yongbin, ZHOU Tao,et al.Hydrometallurgical recovery of metal values from sulfuric acid leaching liquor of spent lithium-ion batteries[J].Waste Management,2015,38:349-356. |

| [23] | JOULIÉ M, LAUCOURNET R, BILLY E.Hydrometallurgical process for the recovery of high value metals from spent lithium nickel cobalt aluminum oxide based lithium-ion batteries[J].Jo- urnal of Power Sources,2014,247:551-555. |

| [24] | JI Guanjun, Xing OU, ZHAO Ruirui,et al.Efficient utilization of scrapped LiFePO4 battery for novel synthesis of Fe2P2O7/C as candidate anode materials[J].Resources,Conservation and Recycling,2021,174:105802. |

| [25] | LI Li, LU Jun, ZHAI Longyu,et al.A facile recovery process for cathodes from spent lithium iron phosphate batteries by using oxalic acid[J].CSEE Journal of Power and Energy Systems,2018,4(2):219-225. |

| [26] | ALMEIDA J R, MOURA M N, BARRADA R V,et al.Composition analysis of the cathode active material of spent Li-ion batteries leached in citric acid solution:A study to monitor and assist recycling processes[J].Science of the Total Environment,2019,685:589-595. |

| [27] | DE CASTRO R H, ROMANO ESPINOSA D C, GOBO L A,et al.Design of recycling processes for NCA-type Li-ion batteries from electric vehicles toward the circular economy[J].Energy & Fuels,2024,38(6):5545-5557. |

| [28] | HU Juntao, ZHANG Jialiang, LI Hongxu,et al.A promising approach for the recovery of high value-added metals from spent lithium-ion batteries[J].Journal of Power Sources,2017,351:192-199. |

| [29] | YUAN Quan, ZENG Jing, SUI Qingxuan,et al.Thermodynamic and experimental analysis of lithium selectively recovery from spent lithium-ion batteries by in situ carbothermal reduction[J].Journal of Environmental Chemical Engineering,2023,11(5):111029. |

| [30] | 贾鹏升,王大辉,陈怀敬,等.LiFePO4-Na2CO3体系焙烧过程物相变化及Li、Fe回收研究[J].有色金属工程,2024,14(4):90-96. |

| JIA Pengsheng, WANG Dahui, CHEN Huaijing,et al.Study on phase transformation in LiFePO4-Na2CO3 roasting system and recovery of Li and Fe[J].Nonferrous Metals Engineering,2024,14(4):90-96. | |

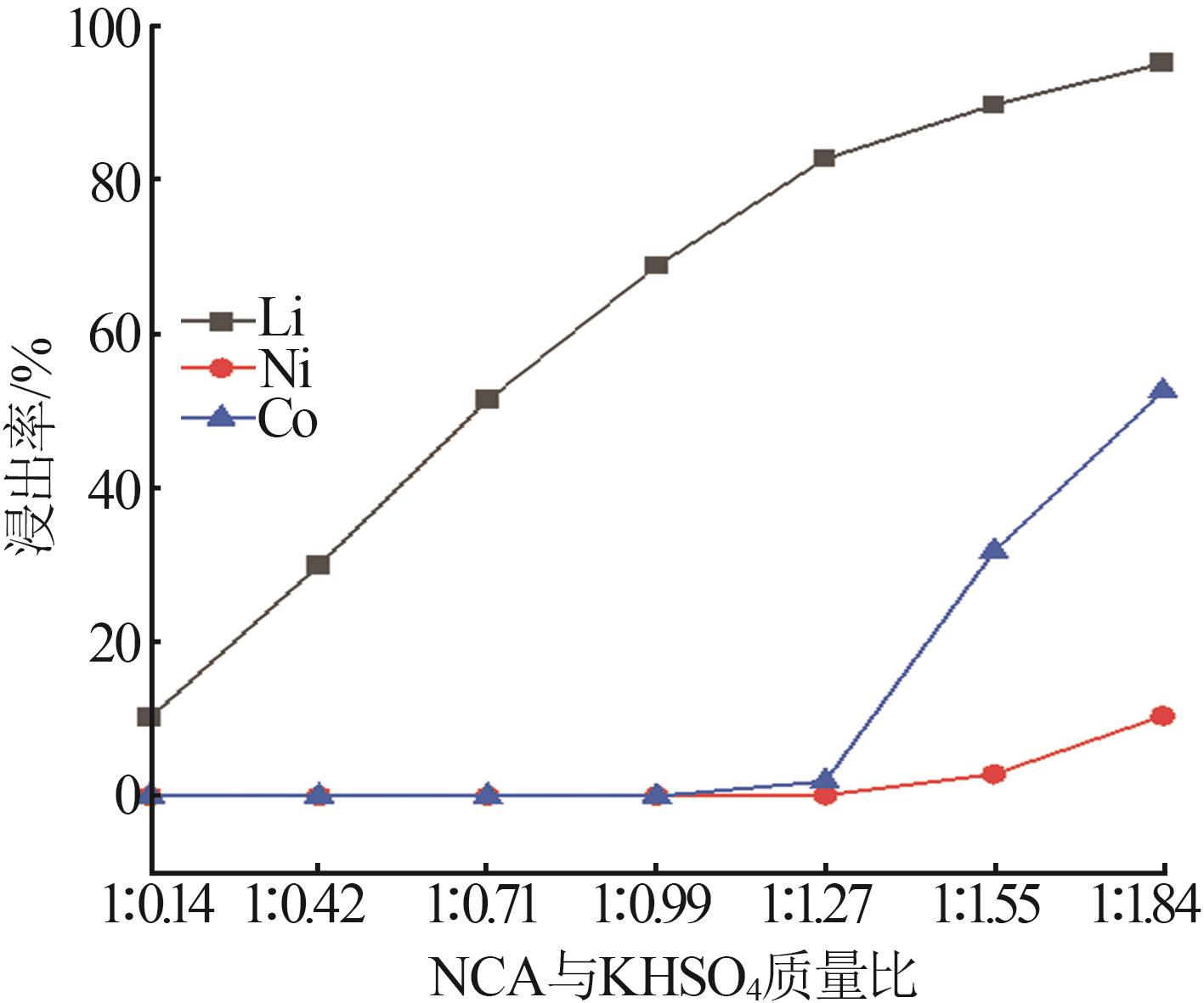

| [31] | 祁万虎,王大辉,陈怀敬,等.硫酸氢钾焙烧法回收NCM622正极材料中金属的研究[J].中国材料进展,2024,43(5):374- 379. |

| QI Wanhu, WANG Dahui, CHEN Huaijing,et al.Study on extraction of metal from NCM622 cathode material by potassium bisulfate roasting[J].Materials China,2024,43(5):374-379. | |

| [32] | SOHN J R.Correlation between acidic properties of nickel catalysts and catalytic activities for ethylene dimerization and butene isomerization[J].Catalysis Surveys from Asia,2004,8(4):249- 263. |

| [33] | LORENZ P, FINSTER J, WENDT G,et al.Esca investigations of some NiO/SiO2 and NiO:Al2O3/SiO2 catalysts[J].Journal of Electron Spectroscopy and Related Phenomena,1979,16(3):267- 276. |

| [34] | XIAO Peng, LV Tingjian, CHEN Xueping,et al.LiNi0.8Co0.15Al0.05O2:Enhanced electrochemical performance from reduced cationic disordering in Li slab[J].Scientific Reports,2017,7:1408. |

| [1] | FU Tongtong, HE Ting, ZHOU Shiyu, GU Shuai. Study on self-driven leaching of spent lithium-ion batteries cathodes and anodes with galvanic cell structure [J]. Inorganic Chemicals Industry, 2025, 57(7): 35-43. |

| [2] | ZHOU Shiyu,HE Ting,FU Tongtong,GUO Zirui,GU Shuai,YU Jianguo. Life cycle and economic assessment of recycling spent lithium-ion batteries with hydrometallurgical process [J]. Inorganic Chemicals Industry, 2023, 55(1): 26-32. |

| [3] | BAO Lingling,HOU Qianqian,WANG Kaifeng,JIANG Zipeng. Study on preparation and application of inorganic composite phase change materials for solar greenhouse [J]. Inorganic Chemicals Industry, 2022, 54(7): 61-69. |

| [4] | HE Ting,KONG Jiao,CUI Jingzhi,CHEN Zhihao,FU Tongtong,GUO Zirui,GU Shuai,YU Jianguo. Study on leaching and thermodynamic of spent lithium-ion batteries with electrochemical reduction [J]. Inorganic Chemicals Industry, 2022, 54(12): 34-43. |

| [5] | Shang Fangyu,Su Xuetong,Shang Suying. Study on recovery of barium from barium slag by chlorination roasting-water leaching process [J]. Inorganic Chemicals Industry, 2021, 53(3): 65-67. |

| [6] | Wang Zinan,Chen Kui,Zhu Jiawen,Zhang Yurong,Lin Farong,Zhou Xiaokui. Effects of crystal seeds and salt dopants on phase transformation of TiO2 in calcination process [J]. Inorganic Chemicals Industry, 2020, 52(3): 45-50. |

| [7] | Yang Quancheng,Gong Zhiming,Mao Yanyu,Li Xiaodong,Zhang Yancheng,Shi Changsheng,Zeng Ming. Preparation of mesoporous calcium silicate with alumina-extracted coal gangue by hydrothermal method [J]. Inorganic Chemicals Industry, 2020, 52(11): 86-90. |

| [8] | RONG 尔Yi, ZHU Jia-Wen, CHEN Kui, YAO Heng-Ping, ZHOU Xiao-Kui. Effects of calcining seed,phosphate,and magnesium on titanium dioxide crystal [J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(7): 21-. |

| [9] | CHEN Wen-Xing, TIAN Juan, ZHOU Chang-Ping. Preparation technology of potassium sulfate with insoluble potassium contained shale [J]. INORGANICCHEMICALSINDUSTRY, 2015, 47(7): 42-. |

| [10] | WU Shi-Qin, LI Jun, JIN Yang, MA Yu-Jing, CHEN Xi. Effect of Fe3+, Mg2+, and Al3+ on phase transformation process of CaSO4·2H2O to CaSO4·0.5H2O in CaCl2-HCl-H2O electrolyte solution [J]. INORGANICCHEMICALSINDUSTRY, 2015, 47(4): 30-. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||