Inorganic Chemicals Industry ›› 2025, Vol. 57 ›› Issue (8): 87-93.doi: 10.19964/j.issn.1006-4990.2024-0440

• Environment·Health·Safety • Previous Articles Next Articles

Effect of compound magnesium salt on performance of desulfurized building gypsum

TIAN Bo( ), HAO Jianying(

), HAO Jianying( ), WANG Shengchang

), WANG Shengchang

- School of Materials Science and Engineering,Taiyuan University of Science and Technology,Taiyuan 030024,China

-

Received:2024-08-06Online:2025-08-10Published:2024-12-29 -

Contact:HAO Jianying E-mail:102499701@qq.com;haojy2006@163.com

CLC Number:

Cite this article

TIAN Bo, HAO Jianying, WANG Shengchang. Effect of compound magnesium salt on performance of desulfurized building gypsum[J]. Inorganic Chemicals Industry, 2025, 57(8): 87-93.

share this article

Table 3

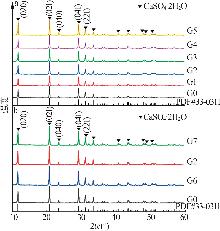

Lattice parameters of building gypsum crystal"

| 试样 | a/nm | b/nm | c/nm | α、γ/ (°) | β/ (°) |

|---|---|---|---|---|---|

半水石膏 (PDF#41-0224) | 12.028 0 | 6.932 0 | 12.691 0 | 90 | 90.183 |

| G0 | 11.972 1 | 6.973 7 | 12.555 6 | 90 | 90.150 |

| G1 | 11.983 2 | 6.932 2 | 12.662 7 | 90 | 90.180 |

| G2 | 11.989 5 | 6.923 6 | 12.634 8 | 90 | 90.250 |

| G3 | 11.994 5 | 6.916 6 | 12.646 3 | 90 | 90.050 |

| G4 | 11.994 6 | 6.921 4 | 12.638 5 | 90 | 90.200 |

| G5 | 11.983 8 | 6.921 9 | 12.645 0 | 90 | 90.090 |

Table 4

Diffraction data of main crystal plane of building gypsum samples"

| 样品 | 晶面(400) | 晶面(204) | |||||

|---|---|---|---|---|---|---|---|

| 2θ/(°) | FWHM | 高度/nm | 2θ/(°) | FWHM | 高度/nm | ||

| G0 | 29.580 | 0.204 | 364 | 31.935 | 0.217 | 449 | |

| G1 | 29.720 | 0.213 | 380 | 31.940 | 0.248 | 470 | |

| G2 | 29.782 | 0.220 | 412 | 31.960 | 0.219 | 512 | |

| G3 | 29.783 | 0.202 | 374 | 31.980 | 0.224 | 469 | |

| G4 | 29.786 | 0.182 | 370 | 31.990 | 0.229 | 466 | |

| G5 | 29.791 | 0.208 | 368 | 32.040 | 0.226 | 460 | |

| [1] | CÓRDOBA P.Status of Flue Gas Desulphurisation(FGD) systems from coal-fired power plants:Overview of the physic-chemical control processes of wet limestone FGDs[J].Fuel,2015,144:274- 286. |

| [2] | 刘显丽.燃煤电厂脱硫石膏的产生及综合利用[J].化工设计通讯,2022,48(6):152-154. |

| LIU Xianli.Production and comprehensive utilization of desulfurization gypsum in coal-fired powerplant[J].Chemical Design Bulletin,2022,48(6):152-154. | |

| [3] | 黎涛,于亮,宋文吉,等.烟气脱硫石膏粉化学物相分析[J].冶金分析,2013,33(2):28-32. |

| LI Tao, YU Liang, SONG Wenji,et al.Chemical phase analysis of flue gas desulfurization gypsum powder[J].Metallurgical Analysis,2013,33(2):28-32. | |

| [4] | LIU Sen, LIU Wei, Jiao Fen,et al.Production and resource utilization of flue gas desulfurized gypsum in China-A review[J].Environmental Pollution,2021,288:117799. |

| [5] | 周佳佳,迟慧芳,夏宝林.脱硫石膏作水泥缓凝剂的若干问题分析[J].水泥技术,2024(3):86-88. |

| ZHOU Jiajia, CHI Huifang, XIA Baolin.Analysis of several issues on desulfurized gypsum as cement retarder[J].Cement Technology,2024(3):86-88. | |

| [6] | 孙振平,金惠玲,杨海静,等.工业副产石膏制备高强石膏的方法及其应用技术[J].混凝土世界,2024,(1):74-81. |

| SUN Zhenping, JIN Huiling, YANG Haijing,et al.Method for preparing high-strength gypsum from industrial by-product gypsum and application technology of high-strength gypsum[J].Concrete World,2024(1):74-81. | |

| [7] | 王升昌,郝建英,陈佳宁,等.添加硫酸铝钾煅烧对脱硫石膏制备建筑石膏性能的影响[J].无机盐工业,2024,56(4):105- 111. |

| WANG Shengchang, HAO Jianying, CHEN Jianing,et al.Effect of calcination on properties of calcined gypsum prepared from desulphurization gypsum with potassium aluminum sulfate[J].Inorganic Chemicals Industry,2024,56(4):105-111. | |

| [8] | 周旭,井敏,武吉伟,等.脱硫建筑石膏制备石膏晶须及其应用研究[J].山东建筑大学学报,2024,39(1):81-90. |

| ZHOU Xu, JING Min, WU Jiwei,et al.Preparation and application of gypsum whiskers from desulfurized building gypsum[J].Journal of Shandong University of Architecture,2024,39(1):81-90. | |

| [9] | WANG Haoqiao, WANG Feifei, Qin Weiran,et al.A critical review on the use of flue gas desulfurization gypsum to ameliorate saline-alkali soils and its prospect for reducing carbon emissions[J].Science of The Total Environment,2024:174053. |

| [10] | 高志刚,王靖宇,罗纯仁,等.我国脱硫石膏的综合利用现状与展望[J].工业安全与环保,2024,50(1):103-106. |

| GAO Zhigang, WANG Jingyu, LUO Chunren,et al.Present situation and prospect of comprehensive utilization of desulfurization gypsum in China[J].Industrial Safety and Environmental Protection,2024,50(1):103-106. | |

| [11] | 秦颖,刘新庄,桑海风.工业副产石膏在建材领域的资源化利用现状及展望[J].中国建材科技,2023,32(5):23-25. |

| QIN Ying, LIU Xinzhuang, Haifeng SAN.Current situation and prospect of resource utilization of industrial by-product gypsum in the field of building materials[J].China Building Materials Technology,2023,32(5):23-25. | |

| [12] | SINGH N, MIDDENDORF B.Calcium sulphate hemihydrate hydration leading to gypsum crystallization[J].Progress in crystal growth and characterization of materials,2007,53(1):57-77. |

| [13] | 朱桂华,何宾宾,杨文娟,等. α-半水石膏生产工艺与应用研究进展[J].磷肥与复肥,2023,38(5):23-28. |

| ZHU Guihua, HE Binbin, YANG Wenjuan,et al.Research progress of production technology and application of α-hemihydrate gypsum[J].Phosphorus Fertilizer and Compound Fertilizer,2023, 38(5):23-28. | |

| [14] | 苏文康,赵波,郭文程,等.不同羧酸钠盐对磷石膏转晶制备α-CaSO4·0.5H2O的影响[J].安徽化工,2019,45(5):47- 49. |

| SU Wenkang, ZHAO Bo, GUO Wencheng,et al.Effects of different sodium carboxylates on the preparation of α-CaSO4·0.5H2O by phosphogypsum crystallization[J].Anhui Chemical Industry,2019,45(5):47-49. | |

| [15] | LIU Dongmei, WANG Qing, XU Gang,et al.Effect of modifiers on crystalizing habit and mechanical strength of α-hemihydrate gypsum prepared from PG by an autoclaved method[J].Construction and Building Materials,2023,366:130114. |

| [16] | 应翔,郭文程,肖钧,等.不同硫酸盐对磷石膏转晶制备α-CaSO4·0.5H2O的影响[J].安徽化工,2019,45(5):43-46. |

| YING Xiang, GUO Wencheng, XIAO Jun,et al.Effects of different sulfates on conversion of phosphogypsum α-CaSO4·0.5H2O [J].Anhui Chemical Industry,2019,45(5):43-46. | |

| [17] | DUAN Zhengyang, LI Jianxi, LI Tianguo,et al.Influence of crystal modifier on the preparation of α-hemihydrate gypsum from phosphogypsum[J].Construction and Building Materials,2017,133:323-329. |

| [18] | 陈燕,岳文海,董若兰.石膏建筑材料[M].中国建材工业出版社,2003. |

| CHEN Yan, YUE Wenhai, DONG Ruolan.Gypsum building materials[M].China Building Material Industry Press,2003. | |

| [19] | 郝建英,王升昌,陈佳宁,等.复合转晶剂对建筑石膏性能的影响[J].硅酸盐通报,2023,42(11):4027-4034. |

| HAO Jianying, WANG Shengchang, CHEN Jianing,et al.Effects of composite crystal modifiers on properties of calcined gypsum[J].Bulletin of Chiness Ceramic Society,2023,42(11):4027-4034. | |

| [20] | HAO Jianying, CHENG Guanji, HU Tao,et al.Preparation of high-performance building gypsum by calcining FGD gypsum adding CaO as crystal modifier[J].Construction and Building Materials,2021,306:124910. |

| [21] | 王青,刁华利,刘冬梅,等.Mg2+对半水硫酸钙晶须结晶习性的影响[J].人工晶体学报,2023,52(10):1897-1906. |

| WANG Qing, DIAO Huali, LIU Dongmei,et al.Effect of Mg2+ on crystallization habit of calcium sulfate hemihydrate whiskers[J].Journal of Artificial Crystallography,2023,52(10):1897-1906. | |

| [22] | 李德星,郭荣鑫,林志伟,等.磷石膏制备α半水石膏的研究现状[J].硅酸盐通报,2022,41(3):860-869. |

| LI Dexing, GUO Rongxin, LIN Zhiwei,et al.Research status of preparation of α-hemihydrate gypsum from phosphogypsum[J].Bulletin of Chiness Ceramic Society,2022,41(3):860-869. |

| [1] | WANG Feng, SONG Yu, HE Zhaoyi, XIA Yuhua, BI Yanli, FENG Hao, CAO Dongwei. Study on mechanical properties and microscopic characterization of phosphogypsum composite cementitious materials [J]. Inorganic Chemicals Industry, 2025, 57(5): 93-99. |

| [2] | LONG Qijun, WU Qin, TAO Jia, CHEN Chuanxiang, WANG Jianxiang, YU Fang. Study on mechanical properties of high content modified hemihydrate phosphogypsum wall materials [J]. Inorganic Chemicals Industry, 2025, 57(4): 89-96. |

| [3] | HAN Yingming, SUN Ruize, SUN Yining, SONG Xingfei. Study on properties of modified magnesia sulfide cement by calcined coal gangue powder [J]. Inorganic Chemicals Industry, 2025, 57(4): 97-104. |

| [4] | LIU Cijun, WU Ziyang, CHENG Shukai, CHEN Xuyong. Effect of recycled fine aggregate on mechanical properties and autogenous shrinkage of ultra-high performance concrete [J]. Inorganic Chemicals Industry, 2024, 56(9): 75-81. |

| [5] | LUO Tong, YE Jianzhou, CHEN Shangwei, YANG Houwen, CHEN Fuping. Study on effect of ash calcium on properties of phosphorus building gypsum doped with PCE [J]. Inorganic Chemicals Industry, 2024, 56(8): 116-122. |

| [6] | ZHANG Ruijun, CHEN Guoliang, SONG Chuncao, ZHU Yafei. Effects of graphene oxide on mechanical properties and chloride penetration resistance of ultra⁃high performance concrete incorporating recycled sand [J]. Inorganic Chemicals Industry, 2024, 56(8): 54-59. |

| [7] | LI Keke, XUE Jiangwei, WANG Luwei, GUAN Xuemao. Effect of MgAl-layered double hydroxides on properties of high-iron low-calcium portland cement [J]. Inorganic Chemicals Industry, 2024, 56(4): 57-63. |

| [8] | YU Zhou, HE Zhaoyi, TANG Liang, HE Sheng, XIAO Haixin, XIAO Yixun. Study on preparation and microscopic properties of typical sulfate solid waste composite cementitious materials [J]. Inorganic Chemicals Industry, 2024, 56(4): 90-97. |

| [9] | CUI Gengyin, XIE Lang, LU Yuexian, KONG Dewen, WANG Lingling. Optimization of mechanical properties of basalt fiber reinforced phosphogypsum-based composites based on RSM [J]. Inorganic Chemicals Industry, 2023, 55(8): 116-123. |

| [10] | WANG Yue, FANG Guoxiang, ZHANG Daoming, WANG Weicheng. Effect of nanosilica on gelling properties of hydraulic lime [J]. Inorganic Chemicals Industry, 2023, 55(7): 75-80. |

| [11] | XU Li, FANG Keneng, BI Yongxiang, YANG Min, CHEN Qianlin. Preparation of modified granular-like CaSO4 and its application in polyvinyl chloride [J]. Inorganic Chemicals Industry, 2023, 55(3): 104-112. |

| [12] | ZHANG Yanru, REN Changzai, SONG Zhanlong, ZHU Jianjun, ZHAO Baofeng, XIE Hongzhang, WANG Zhenjiang, QI Xiaole. Study on performance of biomass power plant ash as alternative to cement clinker in blended cements [J]. Inorganic Chemicals Industry, 2023, 55(10): 128-135. |

| [13] | CHEN Mingsheng,LIU Peng,KONG Dewen,LI Yuan,YU Ke,HUANG Yansen,WU Ningbo,CHANG Juanjuan. Effect of external admixtures on mechanical and thermal conductivity of phosphogypsum composite cementitious materials [J]. Inorganic Chemicals Industry, 2022, 54(9): 113-118. |

| [14] | HAO Jianying,HU Tao,CHENG Guanji,GUO Bing. Preparation of high?performance building gypsum by desulfurization gypsum doped with ZnO crystal transformation [J]. Inorganic Chemicals Industry, 2022, 54(6): 96-101. |

| [15] | XU Lihua,HUANG Zheng,ZHANG Xing,DU Huaiming,CHEN Xiaochao,HUANG Bin. Preparation and properties of composite materials from natural gas?based acetylene process produced carbon black and silica [J]. Inorganic Chemicals Industry, 2022, 54(5): 121-125. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||