| 1 |

孙雷.高含碳海洋气田天然气净化的工艺方案[J].化工设计通讯,2019,45(6):40,55.

|

|

SUN Lei.Natural gas purification process scheme in high carbonaceous marine gas field[J].Chemical Engineering Design Communications,2019,45(6):40,55.

|

| 2 |

谢彬,曾恒一.我国海洋深水油气田开发工程技术研究进展[J].中国海上油气,2021,33(1):166-176.

|

|

XIE Bin, ZENG Hengyi.Research advancement in offshore deepwater oil and gas development engineering technologies in China[J].China Offshore Oil and Gas,2021,33(1):166-176.

|

| 3 |

李剑光.高含CO2天然气的综合开发利用综述[J].广州化工,2023,51(11):33-35,70.

|

|

LI Jianguang.Comprehensive development and utilization of high CO2 natural gas[J].Guangzhou Chemical Industry,2023,51(11):33-35,70.

|

| 4 |

李鹏程,陈宏举,路宏,等.单管输送模式开发深水气田水合物的防治措施分析[J].天然气化工—C1化学与化工,2022,47(5):166-170.

|

|

LI Pengcheng, CHEN Hongju, LU Hong,et al.Prevention and remediation of hydrate in deep⁃water gas field development with single pipe transportation mode[J].Low⁃Carbon Chemistry and Chemical Engineering,2022,47(5):166-170.

|

| 5 |

罗秀鹏.气田水下生产系统流动性保障技术研究[J].当代化工研究,2022(6):105-107.

|

|

LUO Xiupeng.Research on liquidity guarantee technology of gas field subsea production system[J].Modern Chemical Research,2022(6):105-107.

|

| 6 |

程兵,付强,李清平,等.我国海洋油气装备发展战略研究[J].中国工程科学,2023,25(3):13-21.

|

|

CHENG Bing, FU Qiang, LI Qingping,et al.Development strategy of China′s offshore oil and gas equipment[J].Strategic Study of CAE,2023,25(3):13-21.

|

| 7 |

徐业峻.南海FLNG关键技术分析[J].船海工程,2017,46(5):148-152.

|

|

XU Yejun.On the key technologies of FLNG in south China sea[J].Ship & Ocean Engineering,2017,46(5):148-152.

|

| 8 |

钟林,王阳,敬佳佳,等.我国LNG产业储运装备发展现状与展望[J].中国重型装备,2022(4):11-17.

|

|

ZHONG Lin, WANG Yang, JING Jiajia,et al.Current status and prospect of development of LNG storage and transportation equipment in China[J].China Heavy Equipment,2022(4):11-17.

|

| 9 |

李恩道,刘淼儿,尹全森.FLNG脱酸工艺技术比选研究[J].海洋工程装备与技术,2015,2(5):305-309.

|

|

LI Endao, LIU Miaoer, YIN Quansen.Comparison and selection of deacidification technologies for FLNG[J].Ocean Engineering Equipment and Technology,2015,2(5):305-309.

|

| 10 |

洪宗平,叶楚梅,吴洪,等.天然气脱碳技术研究进展[J].化工学报,2021,72(12):6030-6048.

|

|

HONG Zongping, YE Chumei, WU Hong,et al.Research progress in CO2 removal technology of natural gas[J].CIESC Journal,2021,72(12):6030-6048.

|

| 11 |

SONG Chunfeng, LIU Qingling, DENG Shuai,et al.Cryogenic⁃based CO2 capture technologies:State⁃of⁃the⁃art developments and current challenges[J].Renewable and Sustainable Energy Reviews,2019,101:265-278.

|

| 12 |

严硕,于海斌,陈赞.膜法脱除天然气中二氧化碳的工艺技术发展现状[J].无机盐工业,2022,54(5):38-46.

|

|

YAN Shuo, YU Haibin, CHEN Zan.Technology development status of carbon dioxide removal from natural gas by membrane process[J].Inorganic Chemicals Industry,2022,54(5):38-46.

|

| 13 |

胡苏阳,花亦怀,李秋英,等.天然气膜分离脱碳技术评述[J].石化技术,2021,28(5):54-55,57.

|

|

HU Suyang, HUA Yihuai, LI Qiuying,et al.Review on membrane separation and decarbonization technology of natural gas[J].Petrochemical Industry Technology,2021,28(5):54-55,57.

|

| 14 |

王开岳.天然气净化工艺:脱硫脱碳、脱水、硫黄回收及尾气处理[M].2版.北京:石油工业出版社,2015:16-54.

|

| 15 |

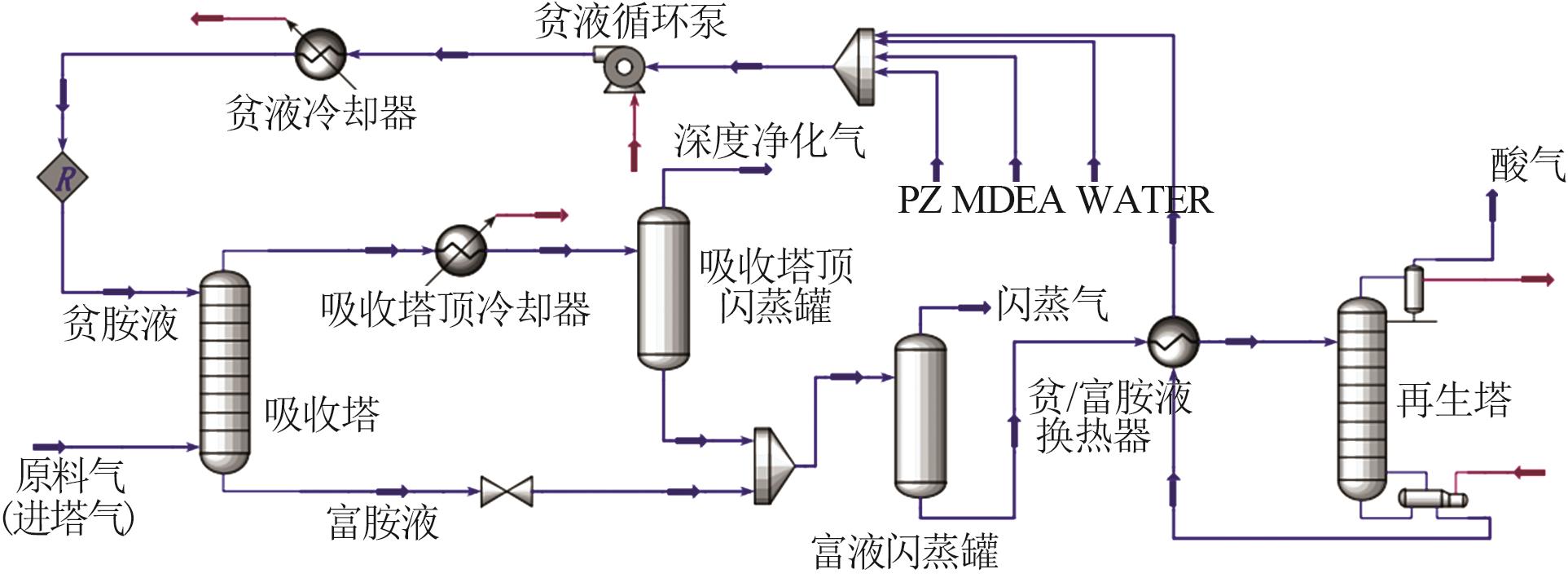

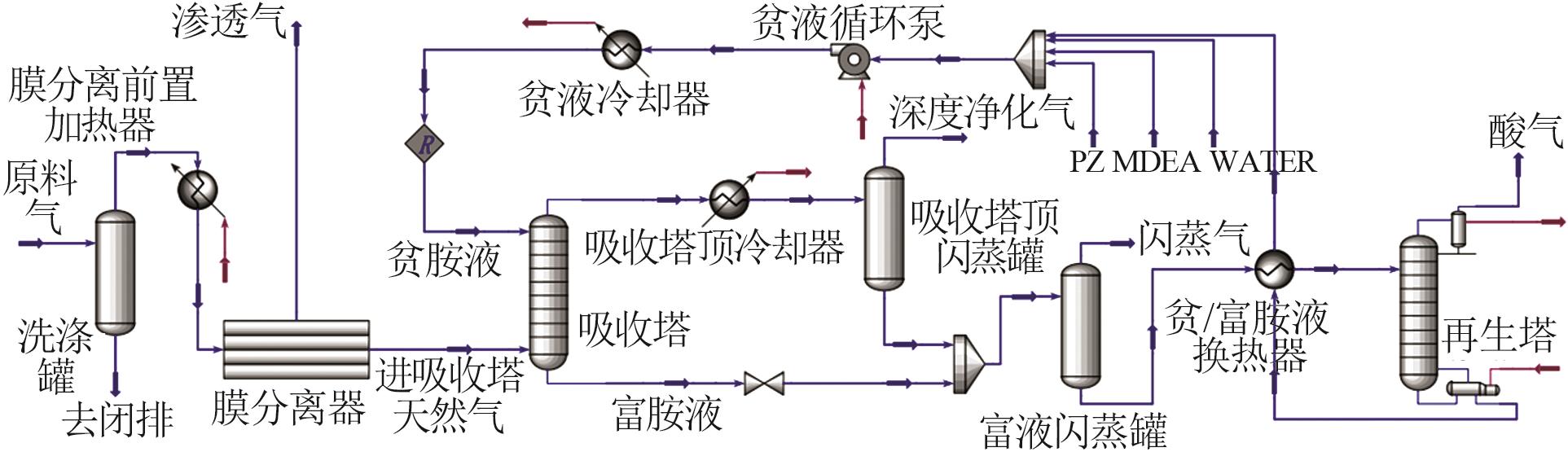

蒋洪,程祥,陈泳村,等.PZ活化MDEA乙烷深度脱碳工艺研究[J].石油与天然气化工,2023,52(3):24-29,40.

|

|

JIANG Hong, CHENG Xiang, CHEN Yongcun,et al.Ethane deep decarbonization process with PZ activated MDEA[J].Chemical Engineering of Oil & Gas,2023,52(3):24-29,40.

|

| 16 |

GEORGE G, BHORIA N, ALHALLAQ S,et al.Polymer membrananes for acid gas removal from natural gas[J].Separation and Purification Technology,2016,158:333-356.

|

| 17 |

JOSÉ L D M, LARA D O A, ALEXANDER M T,et al.Offshore processing of CO2-rich natural gas with supersonic separator[M].Switzerland:Springer Nature Switzerland AG,2019:163-211.

|

| 18 |

张春.南海荔湾气田浮式LNG预处理技术研究[D].东营:中国石油大学(华东),2011.

|

|

ZHANG Chun.Study on pretreatment technology of floating LNG in liwan gas field of south China sea[D].Dongying:China University of Petroleum (Huadong),2011.

|

| 19 |

曾树兵.混合胺脱碳工艺在珠海天然气液化项目中的应用研究[D].青岛:中国石油大学(华东),2014.

|

|

ZENG Shubing.Applied research of mixed amine decarburization process in liquefied natural gas project in Zhuhai[D] Qingdao:China University of Petroleum(East China),2014.

|

| 20 |

兰州石油机械研究所.现代塔器技术[M].2版.北京:中国石化出版社,2005:607-624.

|

| 21 |

邰晓亮,陈杰,尹全森,等.半贫液脱酸工艺应用于浮式天然气液化装置中的可行性研究[J].中国海上油气,2014,26(4):96-99,105.

|

|

TAI Xiaoliang, CHEN Jie, YIN Quansen,et al.The feasibility study of semi⁃lean solution acid gas removal process used on FLNG[J].China Offshore Oil and Gas,2014,26(4):96-99,105.

|

| 22 |

张卫风,舒建辉.膜吸收技术捕获CO2研究进展[J].安全与环境学报,2015,15(3):205-211.

|

|

ZHANG Weifeng, SHU Jianhui.On the latest advancements in the membrane⁃based technologies for CO2 capture[J].Journal of Safety and Environment,2015,15(3):205-211.

|

| 23 |

刘艳武,邓海发,邢传胜,等.高压膜吸收天然气脱碳研究进展[J].现代化工,2022,42(4):62-66.

|

|

LIU Yanwu, DENG Haifa, XING Chuansheng,et al.Research progress on CO2 removal from natural gas by high⁃pressure membrane absorption[J].Modern Chemical Industry,2022,42(4):62-66.

|

), YU Tongchuan, CAO Yanyu, HU Rong, FAN Xuejun, JU Pengpeng

), YU Tongchuan, CAO Yanyu, HU Rong, FAN Xuejun, JU Pengpeng