Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (11): 165-174.doi: 10.19964/j.issn.1006-4990.2024-0114

• Catalytic Materials • Previous Articles

Study on condensation performance between methyl propionate and formaldehyde catalyzed by Cs/SiO2-ZrO2

DU Haigang1,2( ), WANG Xingyong3, SUN Peiyong1,2, CHEN He3, FU Songbao3, YAO Zhilong1,2(

), WANG Xingyong3, SUN Peiyong1,2, CHEN He3, FU Songbao3, YAO Zhilong1,2( )

)

- 1.College of New Materials and Chemical Engineering,Beijing Institute of Petrochemical Technology,Beijing 102617,China

2.Beijing Key Laboratory of Enze Biomass Fine Chemical,Beijing 102617,China

3.CNOOC Research;Institute of Chemical Engineering and New Materials,Beijing 102209,China

-

Received:2024-03-01Online:2024-11-10Published:2024-11-27 -

Contact:YAO Zhilong E-mail:Mrdu000@163.com;yaozl@bipt.edu.cn

CLC Number:

Cite this article

DU Haigang, WANG Xingyong, SUN Peiyong, CHEN He, FU Songbao, YAO Zhilong. Study on condensation performance between methyl propionate and formaldehyde catalyzed by Cs/SiO2-ZrO2[J]. Inorganic Chemicals Industry, 2024, 56(11): 165-174.

share this article

Table 2

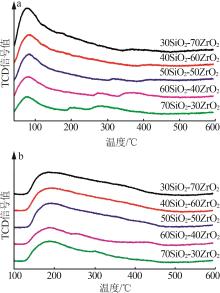

Distribution of basic and acidic sites on surface of SiO2-ZrO2 composite oxides"

SiO2-ZrO2 复合氧化物 | 碱性位点数量/(mmol·g-1) | 酸性位点数量/(mmol·g-1) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 弱碱 | 中强碱 | 强碱 | 总碱 | 弱酸 | 中强酸 | 强酸 | 总酸 | ||

| 30SiO2-70ZrO2 | 1.54 | 0.34 | 0.06 | 1.94 | 0.11 | 0.28 | 0.02 | 0.41 | |

| 40SiO2-60ZrO2 | 1.16 | 0.30 | 0.02 | 1.48 | 0.11 | 0.27 | 0.03 | 0.41 | |

| 50SiO2-50ZrO2 | 1.00 | 0.19 | 0.04 | 1.23 | 0.11 | 0.27 | 0.02 | 0.40 | |

| 60SiO2-40ZrO2 | 0.72 | 0.23 | 0.05 | 1.00 | 0.08 | 0.11 | 0.01 | 0.20 | |

| 70SiO2-30ZrO2 | 0.53 | 0.37 | 0.01 | 0.91 | 0.10 | 0.18 | 0.01 | 0.29 | |

Table 3

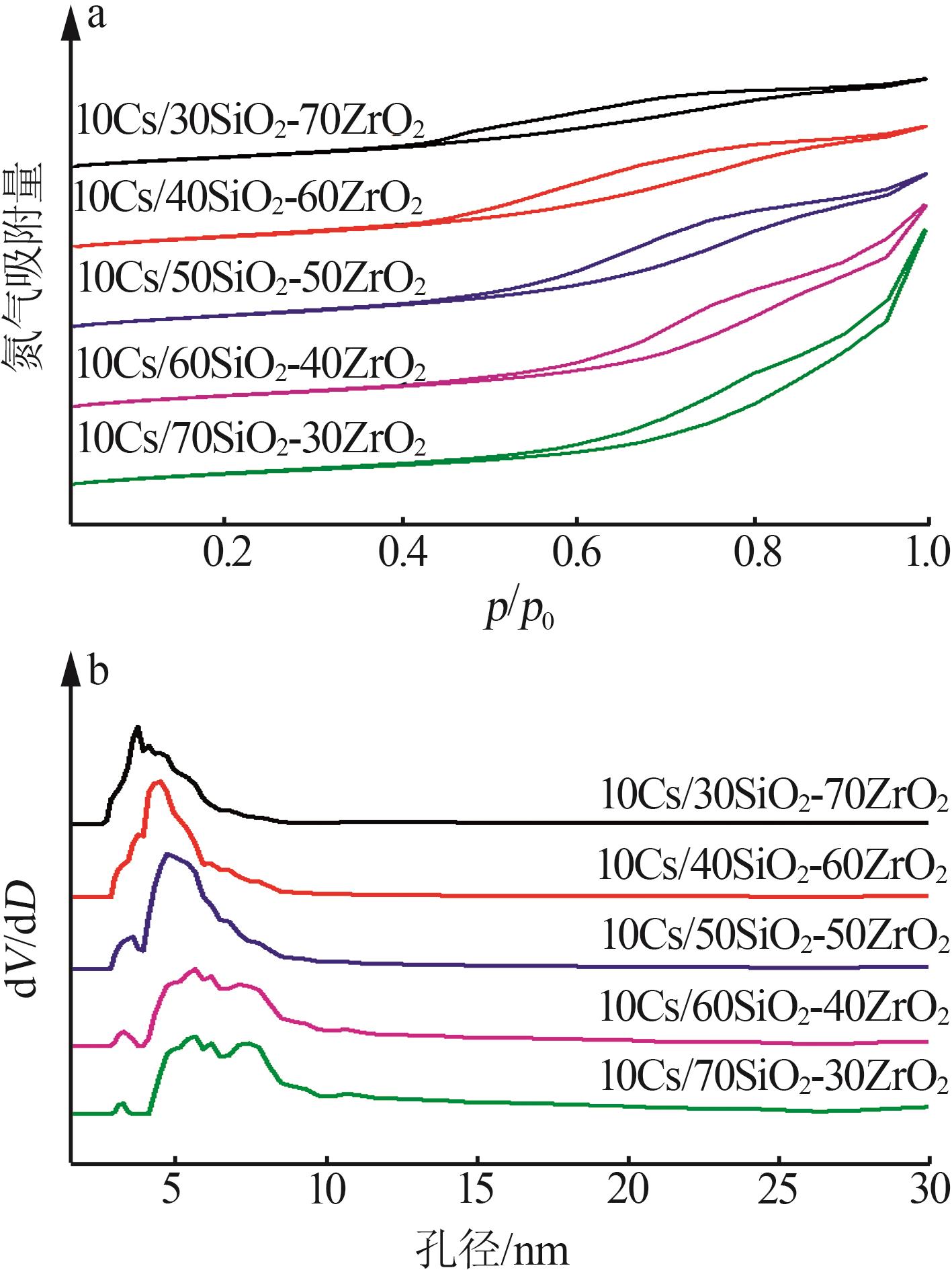

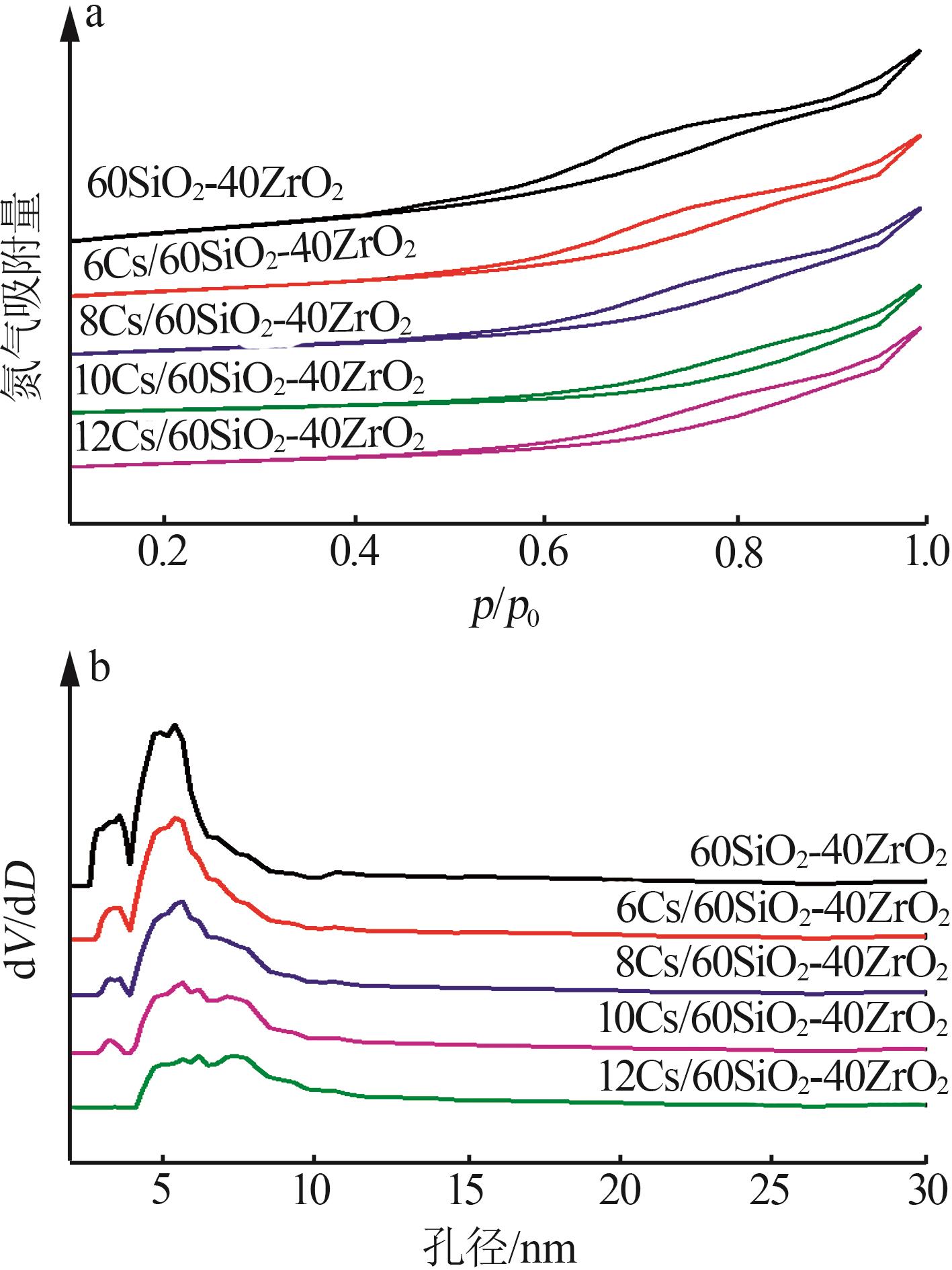

Physicochemical properties of Cs/SiO2-ZrO2 catalysts"

| 催化剂 | 比表面积/ (m²·g-1) | 平均孔径/ nm | 孔体积/ (10-1 cm³·g-1) |

|---|---|---|---|

| 10Cs/30SiO2-70ZrO2 | 59.0 | 3.8 | 1.0 |

| 10Cs/40SiO2-60ZrO2 | 68.0 | 4.5 | 1.3 |

| 10Cs/50SiO2-50ZrO2 | 74.9 | 4.6 | 1.7 |

| 10Cs/60SiO2-40ZrO2 | 73.6 | 5.7 | 2.2 |

| 10Cs/70SiO2-30ZrO2 | 71.9 | 5.7 | 2.7 |

| 6Cs/60SiO2-40ZrO2 | 107.0 | 5.4 | 2.5 |

| 8Cs/60SiO2-40ZrO2 | 84.2 | 5.7 | 2.3 |

| 10Cs/60SiO2-40ZrO2 | 73.6 | 5.7 | 2.2 |

| 12Cs/60SiO2-40ZrO2 | 61.5 | 7.5 | 1.9 |

Table 4

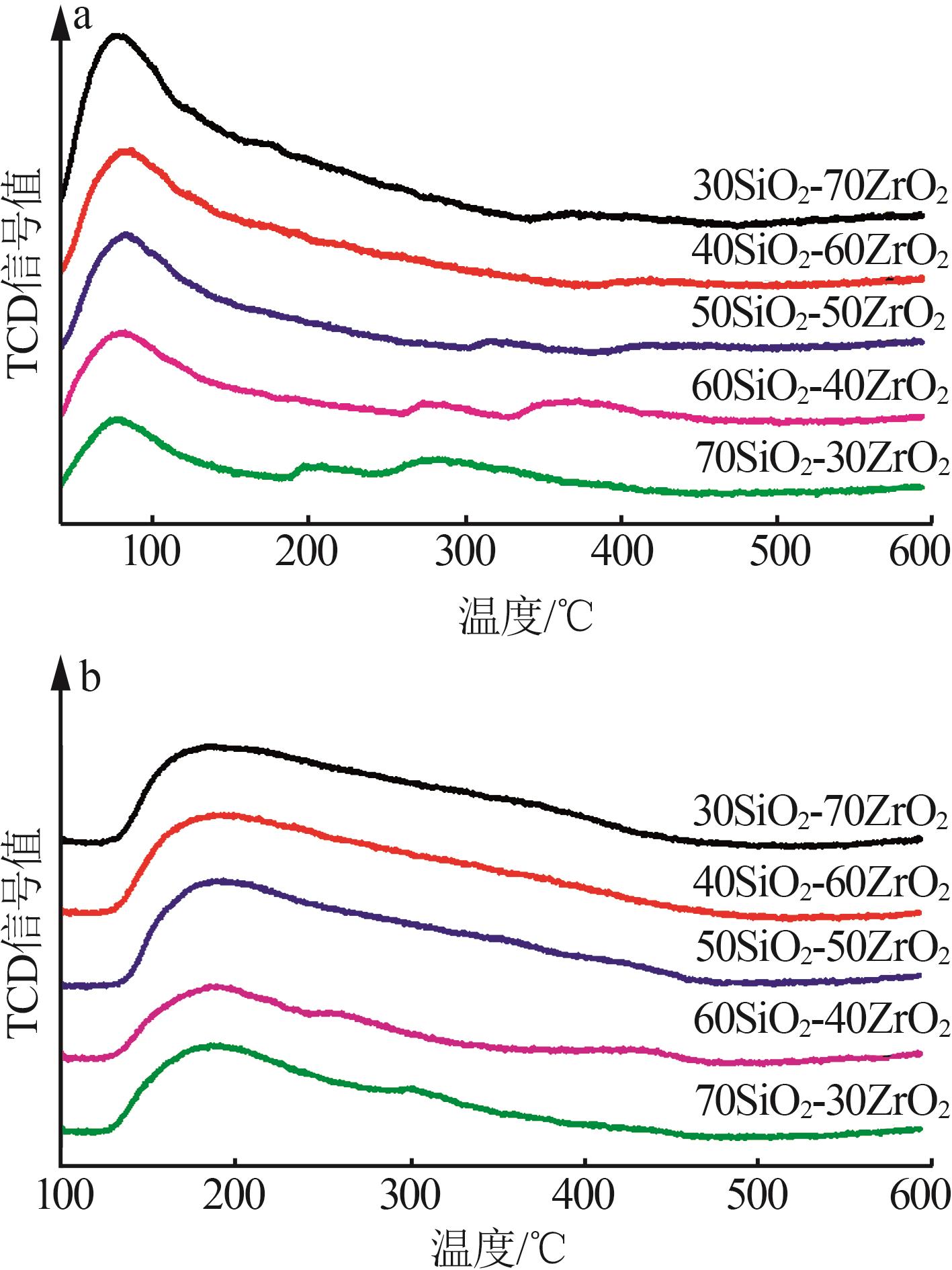

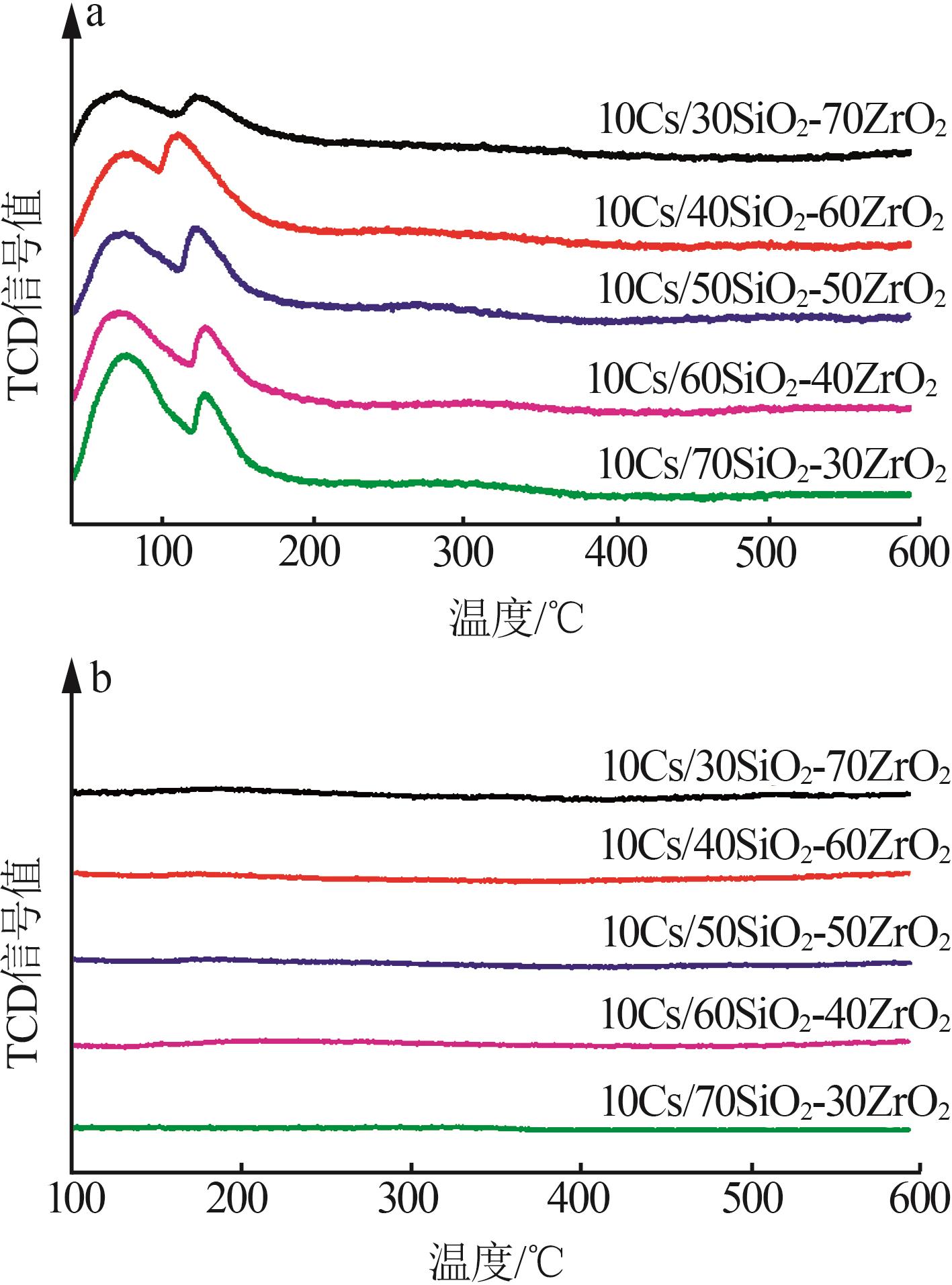

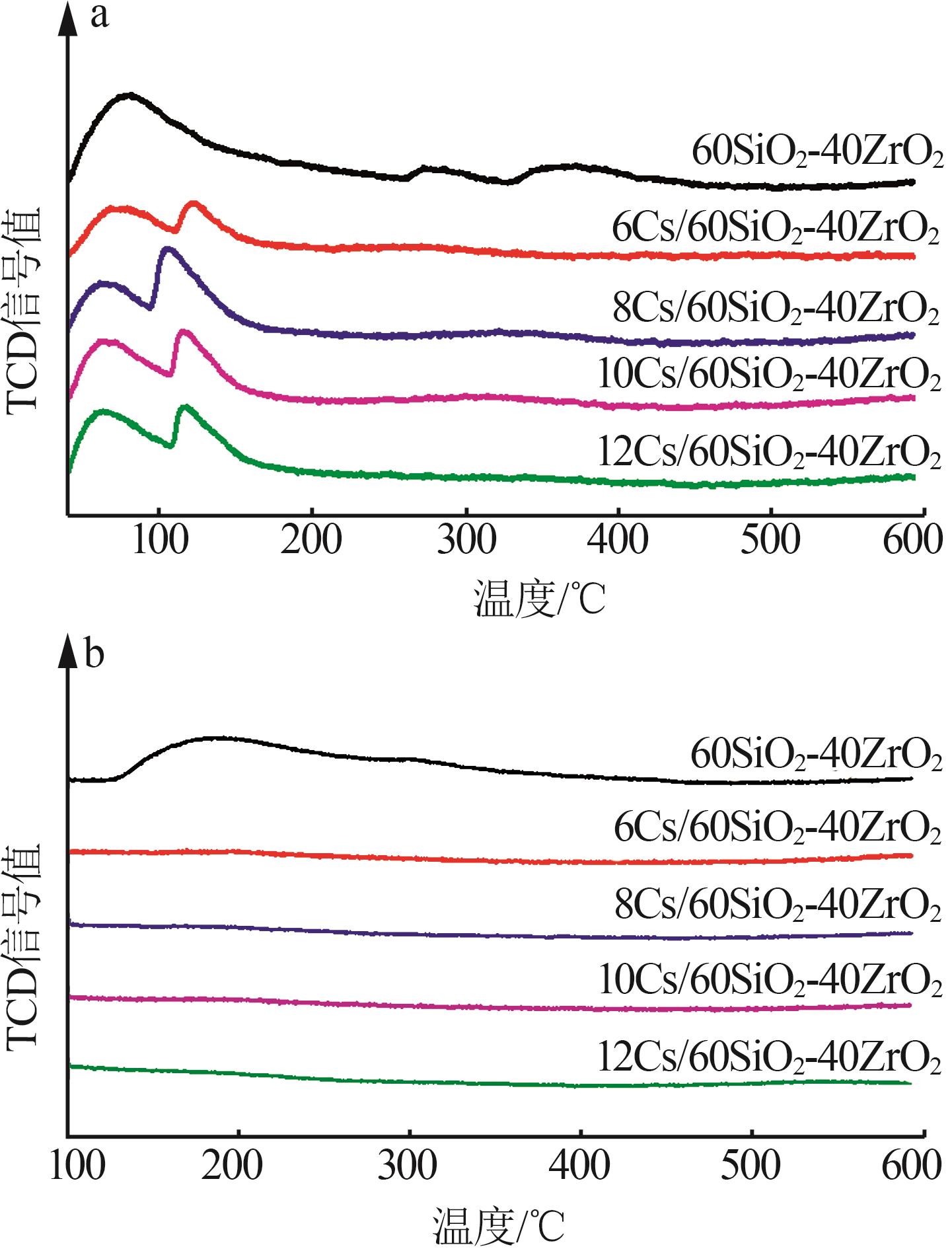

Distribution of basic and acidic sites on surface of Cs/SiO2-ZrO2 catalysts"

| 催化剂 | 碱性位点数量/(mmol·g-1) | 酸性位点数量/(mmol·g-1) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 弱碱 | 中强碱 | 强碱 | 总碱 | 弱酸 | 中强酸 | 强酸 | 总酸 | ||

| 10Cs/30SiO2-70ZrO2 | 0.43 | 0.08 | — | 0.51 | 0.01 | 0.01 | — | 0.02 | |

| 10Cs/40SiO2-60ZrO2 | 0.69 | 0.12 | — | 0.81 | 0.01 | 0.01 | — | 0.02 | |

| 10Cs/50SiO2-50ZrO2 | 0.64 | 0.12 | — | 0.76 | — | 0.01 | — | 0.01 | |

| 10Cs/60SiO2-40ZrO2 | 0.62 | 0.10 | — | 0.72 | — | — | — | — | |

| 10Cs/70SiO2-30ZrO2 | 0.77 | 0.05 | — | 0.82 | — | — | — | — | |

| 6Cs/60SiO2-40ZrO2 | 0.52 | 0.11 | — | 0.63 | 0.01 | 0.01 | — | 0.02 | |

| 8Cs/60SiO2-40ZrO2 | 0.58 | 0.08 | — | 0.66 | — | 0.01 | — | 0.01 | |

| 10Cs/60SiO2-40ZrO2 | 0.62 | 0.10 | — | 0.72 | — | — | — | — | |

| 12Cs/60SiO2-40ZrO2 | 0.65 | 0.08 | — | 0.73 | — | — | — | — | |

Table 5

Performance evaluation results of Cs/SiO2-ZrO2 series catalysts"

| 催化剂 | XMP/% | SMMA/% | SMIB/% | SMAL/% | SC8/% | SDME/% |

|---|---|---|---|---|---|---|

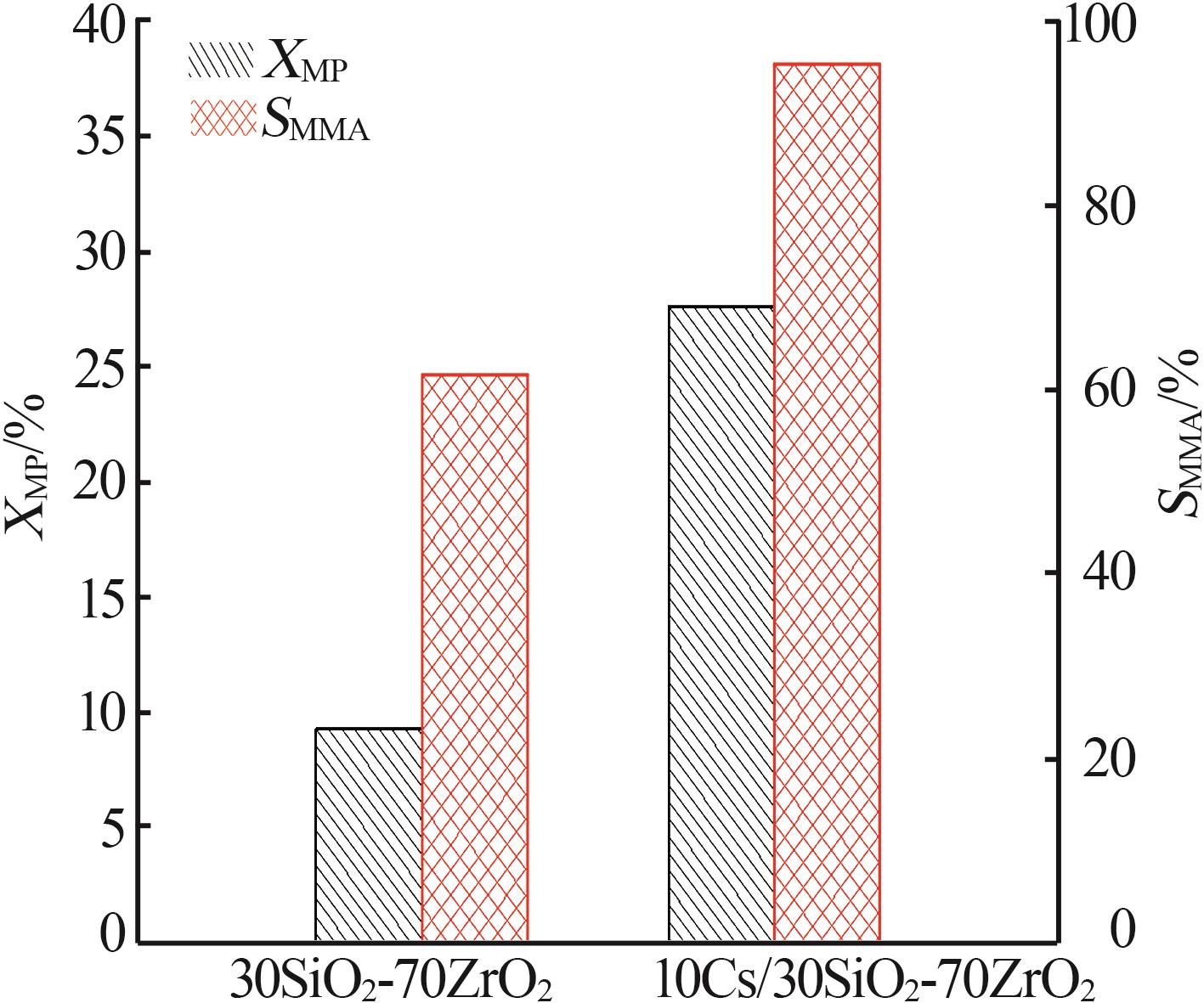

| 30SiO2-70ZrO2 | 9.27 | 61.62 | 16.88 | 1.14 | — | 20.36 |

| 10Cs/30SiO2-70ZrO2 | 27.59 | 95.42 | 2.17 | 1.34 | 1.07 | — |

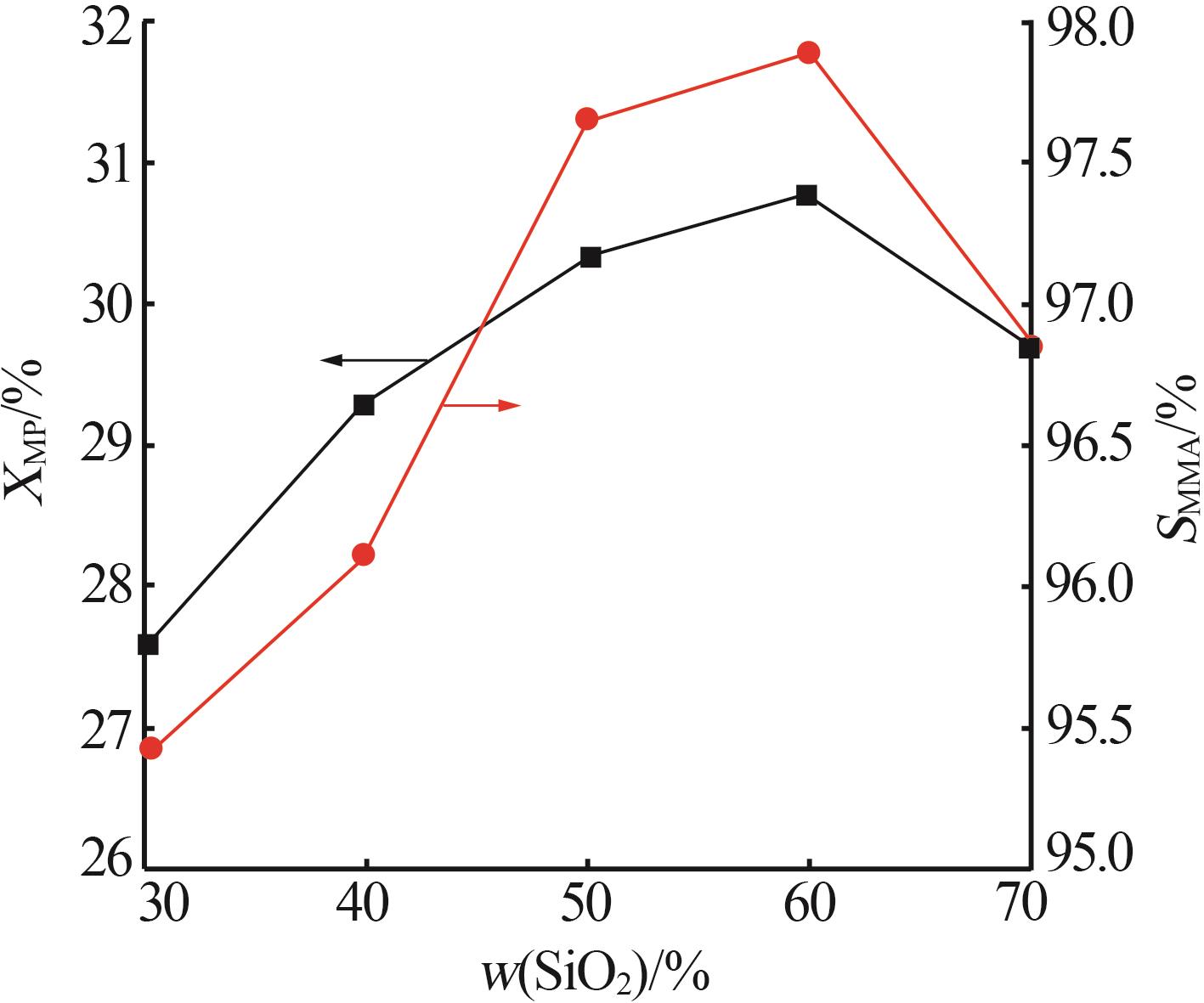

| 10Cs/40SiO2-60ZrO2 | 29.29 | 96.12 | 1.98 | 1.17 | 0.73 | — |

| 10Cs/50SiO2-50ZrO2 | 30.34 | 97.66 | 1.88 | 0.19 | 0.27 | — |

| 10Cs/60SiO2-40ZrO2 | 30.77 | 97.89 | 2.11 | — | — | — |

| 10Cs/70SiO2-30ZrO2 | 29.68 | 96.86 | 1.43 | 1.71% | — | — |

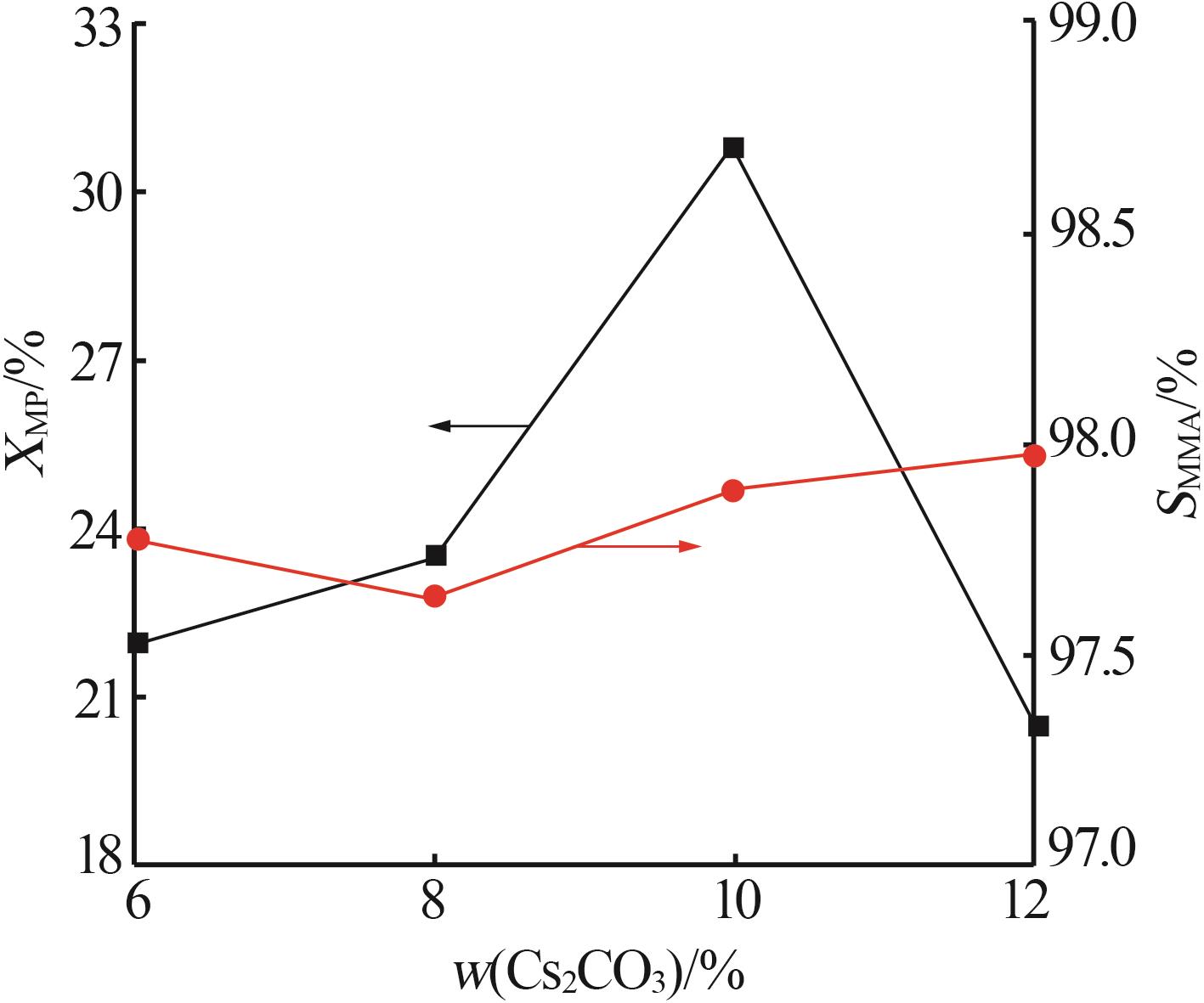

| 6Cs/60SiO2-40ZrO2 | 21.90 | 97.77 | 0.97 | 0.76 | 0.50 | — |

| 8Cs/60SiO2-40ZrO2 | 23.50 | 97.64 | 1.87 | 0.19 | 0.30 | — |

| 10Cs/60SiO2-40ZrO2 | 30.77 | 97.89 | 2.11 | — | — | — |

| 12Cs/60SiO2-40ZrO2 | 20.43 | 97.97 | 2.03 | — | — | — |

| 1 | 李华胤,李洁,谭媛,等.甲基丙烯酸甲酯生产工艺及所用贵金属催化剂研究进展[J].化工进展,2021,40(1):183-194. |

| LI Huayin, LI Jie, TAN Yuan,et al.Research progress on production technology and noble metal catalyst for synthesis of methyl methacrylate[J].Chemical Industry and Engineering Progress,2021,40(1):183-194. | |

| 2 | 陆赟涛,江力,蒋其民,等.甲基丙烯酸甲酯自由基聚合歧化终止机理[J].高分子通报,2023(2):241-247. |

| LU Yuntao, JIANG Li, JIANG Qimin,et al.Disproportionation termination mechanism in the free-radical polymerization of methyl methacrylate[J].Polymer Bulletin,2023(2):241-247. | |

| 3 | CHIN M T, YANG Tiangang, QUIRION K P,et al.Implementing a doping approach for poly(methyl methacrylate) recycling in a circular economy[J].Journal of the American Chemical Society,2024,146(9):5786-5792. |

| 4 | 王刚,李增喜,李春山.温和条件下丙酸甲酯和甲醇一步合成甲基丙烯酸甲酯[J].中国科学:化学,2021,51(2):235-241. |

| WANG Gang, LI Zengxi, LI Chunshan.One-step synthesis of methyl methacrylate from methyl propionate and methanol under mild condition[J].Scientia Sinica Chimica,2021,51(2):235-241. | |

| 5 | SUN Bo, ZHANG Jie, WANG Maolin,et al.Valorization of waste biodegradable polyester for methyl methacrylate production[J].Nature Sustainability,2023,6:712-719. |

| 6 | 李斌,解铭,齐翔,等.乙烯路线制备甲基丙烯酸甲酯研究进 展[J].化工进展,2019,38(4):1739-1745. |

| LI Bin, XIE Ming, QI Xiang,et al.Progress in preparation of methyl methacrylate by ethylene route[J].Chemical Industry and Engineering Progress,2019,38(4):1739-1745. | |

| 7 | 王光永,李荣,鄢义,等.羟醛缩合法制甲基丙烯酸甲酯催化剂研究及技术经济性分析[J].化工进展,2021,40(5):2574-2580. |

| WANG Guangyong, LI Rong, YAN Yi,et al.Catalyst and technical-economic analysis for the synthesis of methyl methacrylate by aldol condensation[J].Chemical Industry and Engineering Progress,2021,40(5):2574-2580. | |

| 8 | 刘金成,陈谦,刘玉佩,等.甲基丙烯酸甲酯的合成技术研究进展[J].中国塑料,2022,36(1):178-183. |

| LIU Jincheng, CHEN Qian, LIU Yupei,et al.Research progress in synthesis technologies of methyl methacrylate[J].China Plastics,2022,36(1):178-183. | |

| 9 | 孙玉玉,黄益平,黄晶晶,等.异丁烯/叔丁醇法生产甲基丙烯酸甲酯研究进展[J].石油化工,2022,51(11):1342-1347. |

| SUN Yuyu, HUANG Yiping, HUANG Jingjing,et al.Progress in production technologiec of methyl methacrylate from isobutene/tert-butyl alcohol[J].Petrochemical Technology,2022,51(11):1342-1347. | |

| 10 | 石永杰,孙向前,石好亮,等.甲基丙烯酸甲酯工业化合成技术研究进展[J].精细与专用化学品,2020,28(5):38-43. |

| SHI Yongjie, SUN Xiangqian, SHI Haoliang,et al.Research progress in industrial synthesis of methyl methacrylate[J].Fine and Specialty Chemicals,2020,28(5):38-43. | |

| 11 | 王光永,李荣,鄢义,等.羟醛缩合法制甲基丙烯酸甲酯催化剂研究[J].天然气化工(C1化学与化工),2020,45(5):1-5,30. |

| WANG Guangyong, LI Rong, YAN Yi,et al.Study on aldol condensation catalyst for methyl methacrylate synthesis[J].Natural Gas Chemical Industry,2020,45(5):1-5,30. | |

| 12 | AI M.Formation of methyl methacrylate by condensation of methyl propionate with formaldehyde over silica-supported cesium hydroxide catalysts[J].Applied Catalysis A:General,2005,288(1/2):211-215. |

| 13 | HE Teng, QU Yixin, WANG Jidong.Experimental and theoretical study for vapor phase aldol condensation of methyl acetate and formaldehyde over alkali metal oxides supported on SBA-15[J].Industrial & Engineering Chemistry Research,2018,57(8):2773-2786. |

| 14 | LI Bin, YAN Ruiyi, WANG Lei,et al.Synthesis of methyl methacrylate by aldol condensation of methyl propionate with formaldehyde over acid-base bifunctional catalysts[J].Catalysis Letters,2013,143(8):829-838. |

| 15 | DE MARON J, EBERLE M, CAVANI F,et al.Continuous-flow methyl methacrylate synthesis over gallium-based bifunctional catalysts[J].ACS Sustainable Chemistry & Engineering,2021, 9(4):1790-1803. |

| 16 | 张伟,贾鑫,王兴永,等.催化剂酸碱性与催化酯醛缩合性能的关系[J].精细化工,2024,41(3):687-696. |

| ZHANG Wei, JIA Xin, WANG Xingyong,et al.Relationship between catalyst acid-base property and condensation performance for ester aldehydes[J].Fine Chemicals,2024,41(3):687-696. | |

| 17 | 尚城城,郭湾,姚志龙,等.异丁烯与醋酸酯化合成醋酸叔丁酯[J].精细化工,2019,36(8):1604-1609. |

| SHANG Chengcheng, GUO Wan, YAO Zhilong,et al.Esterification of acetic acid with isobutene to tert-butyl acetate[J].Fine Chemicals,2019,36(8):1604-1609. | |

| 18 | 冯裕发.丙酸甲酯气相法合成甲基丙烯酸甲酯工艺研究[D].常州:常州大学,2015. |

| FENG Yufa.Study on synthesis of methyl methacrylate from methyl propionate by gas phase method[D].Changzhou:Changzhou University,2015. | |

| 19 | 贾鑫,张伟,王兴永,等.Cs/SiO2催化合成MMA工艺及宏观动力学研究[J].现代化工,2024,44(1):210-215,220. |

| JIA Xin, ZHANG Wei, WANG Xingyong,et al.Synthesis process for methyl methacrylate over Cs/SiO2 and its macro-kinetics[J].Modern Chemical Industry,2024,44(1):210-215,220. | |

| 20 | WU Zhigang, ZHAO Yongxiang, LIU Diansheng.The synthesis and characterization of mesoporous silica-zirconia aerogels[J].Microporous and Mesoporous Materials,2004,68(1/2/3):127-132. |

| 21 | 杨小林,冯裕发,周鹏鹏.Cs/SiO2催化丙酸甲酯合成甲基丙烯酸甲酯工艺[J].精细石油化工,2020,37(2):5-10. |

| YANG Xiaolin, FENG Yufa, ZHOU Pengpeng.Synthesis process of methyl methacrylate from methyl propionate over Cs/SiO2 [J].Speciality Petrochemicals,2020,37(2):5-10. | |

| 22 | WANG Dengfeng, ZHANG Xuelan, MA Jie,et al.La-modified mesoporous Mg-Al mixed oxides:Effective and stable base catalysts for the synthesis of dimethyl carbonate from methyl carbamate and methanol[J].Catalysis Science & Technology,2016, 6(5):1530-1545. |

| 23 | KATADA N, NIWA M.Analysis of acidic properties of zeolitic and non-zeolitic solid acid catalysts using temperature-programmed desorption of ammonia[J].Catalysis Surveys from Asia,2004,8(3):161-170. |

| 24 | AL-DUGHAITHER A S, DE LASA H.HZSM-5 zeolites with different SiO2/Al2O3 ratios.Characterization and NH3 desorption kinetics[J].Industrial & Engineering Chemistry Research,2014,53(40):15303-15316. |

| 25 | 马中义,徐润,杨成,等.不同形态ZrO2的制备及其表面性质研究[J].物理化学学报,2004,20(10):1221-1225. |

| MA Zhongyi, XU Run, YANG Cheng,et al.Preparation and surface properties of different zirconia polymorphs[J].Acta Physico-chimica Sinica,2004,20(10):1221-1225. | |

| 26 | 陈崇城,陈航榕,俞建长,等.多级孔WO3/ZrO2固体酸催化剂的制备与表征[J].催化学报,2011,32(4):647-651. |

| CHEN Chongcheng, CHEN Hangrong, YU Jianchang,et al.Preparation and characterization of WO3/ZrO2 solid acid catalyst with hierarchically porous structure[J].Chinese Journal of Catalysis,2011,32(4):647-651. | |

| 27 | GUO Zhijun, ZHANG Guoliang, WANG Lei,et al.Fe-modified Cs-P/γ-Al2O3 catalyst for synthesis of methyl methacrylate from methyl propionate and formaldehyde[J].Industrial & Engineering Chemistry Research,2020,59(8):3334-3341. |

| [1] | WANG Jing, SU Jin, ZHANG Lijie, ZHOU Peng, SUN Yanmin, LI Jia. Study on effect of different calcination atmospheres on properties of acrylic acid catalysts [J]. Inorganic Chemicals Industry, 2024, 56(9): 164-170. |

| [2] | TAN Wenxi,GUO Xiaohui. Enhanced effect of ultrasound on adsorption of inorganic arsenic species from wastewater by FeMn oxides [J]. Inorganic Chemicals Industry, 2022, 54(3): 102-108. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||