Inorganic Chemicals Industry ›› 2021, Vol. 53 ›› Issue (10): 74-80.doi: 10.19964/j.issn.1006-4990.2020-0658

• Research & Development • Previous Articles Next Articles

Study on preparation of GO-TSC/polyimide mixed matrix membrane and its gas separation performance

Guo Xin1( ),Yi Hualei1,Yuan Weiliang2,3,Hao Yun1,Duan Cuijia2,Chen Zan2

),Yi Hualei1,Yuan Weiliang2,3,Hao Yun1,Duan Cuijia2,Chen Zan2

- 1. CNOOC Research Institute Ltd,Beijing 100028,China

2. CenerTech Tianjin Chemical Research and Design Institute Co.,Ltd.

3. Hebei University of Technology

-

Received:2020-12-07Online:2021-10-10Published:2021-10-11

CLC Number:

Cite this article

Guo Xin,Yi Hualei,Yuan Weiliang,Hao Yun,Duan Cuijia,Chen Zan. Study on preparation of GO-TSC/polyimide mixed matrix membrane and its gas separation performance[J]. Inorganic Chemicals Industry, 2021, 53(10): 74-80.

share this article

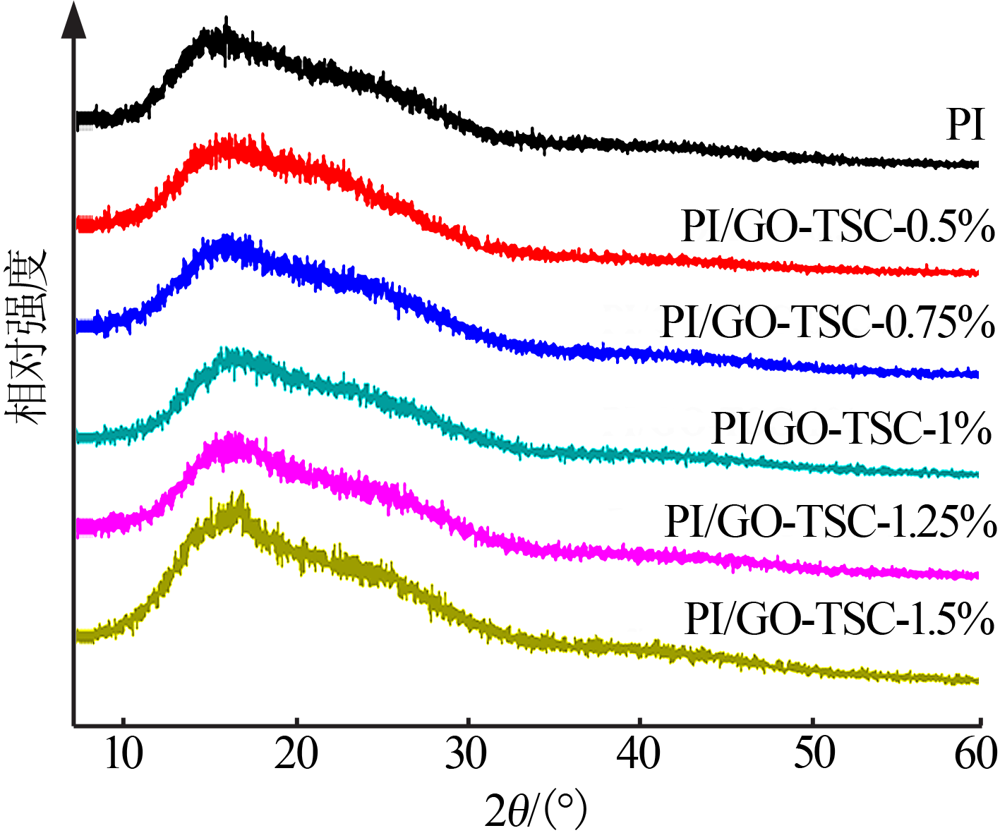

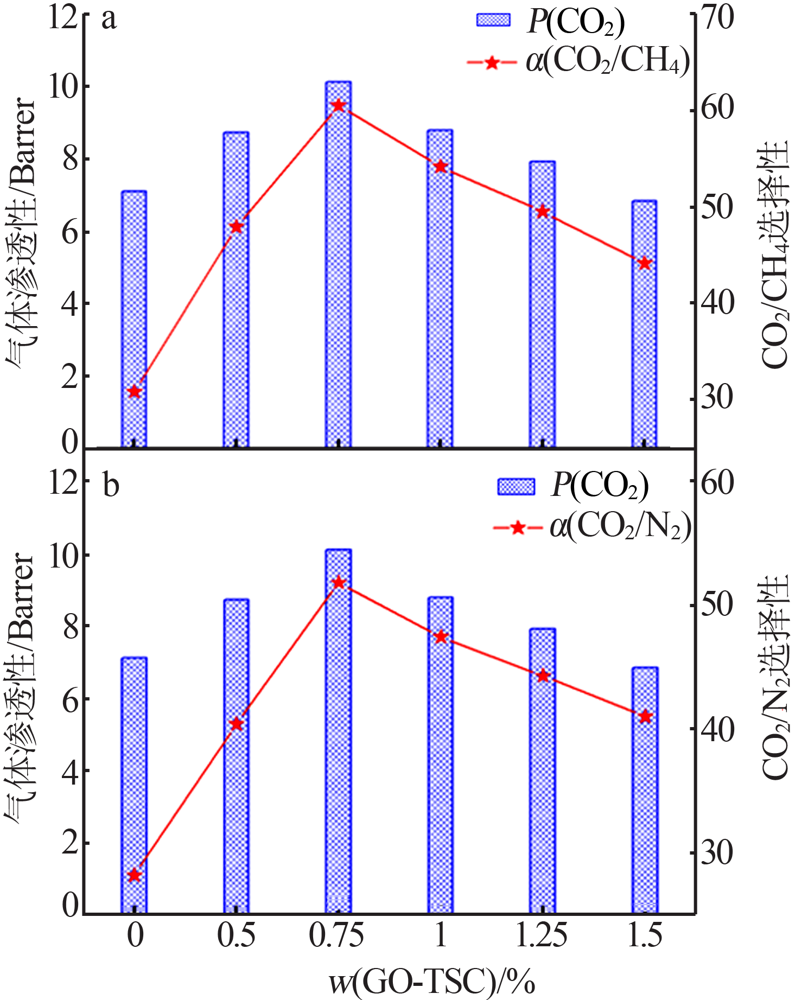

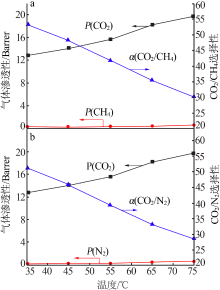

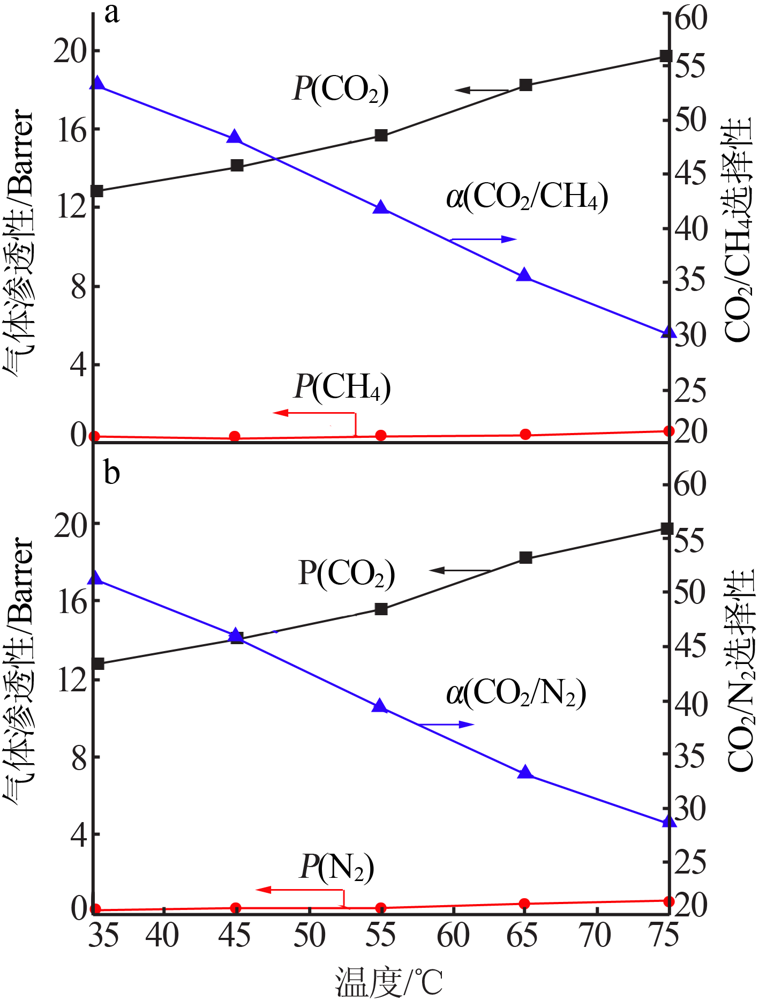

Table 2

Comparison of the separation properties with Matrimid®5218-based membranes"

| 填料 | P (CO2)/Barrer | α (CO2/CH4) | α (CO2/N2) | 测试条件 |

|---|---|---|---|---|

| SO3H-MCM-41[ | 11.20 | 40.50 | 37.40 | 0.4 MPa,35 ℃ |

| POSS-Zn2+[ | 4.00 | 57.60 | 30.76 | 1.0 MPa,35 ℃ |

| PEGSS[ | 10.42 | 49.62 | 47.36 | 0.1 MPa,40 ℃ |

| C60[ | 3.79 | 34.80 | 23.70 | 1.0 MPa,35 ℃ |

| CU-BPY-HFS[ | 10.40 | 27.40 | 33.40 | 0.39 MPa,35 ℃ |

| MCM-48[ | 9.35 | 33.39 | 31.16 | 0.25 MPa,35 ℃ |

| GO-TSC | 10.11 | 60.55 | 51.86 | 0.2 MPa,35 ℃ |

| [1] |

Scholes C A, Smith K H, Kentish S E, et al. CO2 capture from pre-combustion processes-Strategies for membrane gas separation[J]. International Journal of Greenhouse Gas Control, 2010, 4(5):739-755.

doi: 10.1016/j.ijggc.2010.04.001 |

| [2] |

Liu Y F, Wang Z, Yang H L, et al. 3-Phenylethynyl phthalimide end-capped imide oligomers and the cured polymers[J]. Journal of Polymer Science Part A:Polymer Chemistry, 2008, 46(12):4227-4235.

doi: 10.1002/(ISSN)1099-0518 |

| [3] |

Zhao S, Wang Z, Qiao Z H, et al. Gas separation membrane with CO2-facilitated transport highway constructed from amino carrier containing nanorods and macromolecules[J]. Journal of Materials Chemistry A, 2013, 1(2):246-249.

doi: 10.1039/C2TA00247G |

| [4] |

Kanehashi S, Chen G Q, Scholes C A, et al. Enhancing gas permea-bility in mixed matrix membranes through tuning the nanoparticle properties[J]. Journal of Membrane Science, 2015, 482(5):49-55.

doi: 10.1016/j.memsci.2015.01.046 |

| [5] |

Yu J, Wang C Q, Xiang L, et al. Enhanced C3H6/C3H8 separation per-formance in poly(vinyl acetate) membrane blended with ZIF-8 nanocrystals[J]. Chemical Engineering Science, 2018, 179(6):1-12.

doi: 10.1016/j.ces.2017.12.051 |

| [6] |

Li X Q, Ma L, Zhang H Y, et al. Synergistic effect of combining car-bon nanotubes and graphene oxide in mixed matrix membranes for efficient CO2 separation[J]. Journal of Membrane Science, 2015, 479(1):1-10.

doi: 10.1016/j.memsci.2015.01.014 |

| [7] |

Li X F, Zhang F, Jiang H Y, et al. Amine-functionalized GO as an active and reusable acid-base bifunctional catalyst for one-pot casc-ade reactions[J]. ACS Catalysis, 2013, 4(2):394-401.

doi: 10.1021/cs400761r |

| [8] | 陈德强, 白云翔, 张春芳, 等. Fe3O4 /PIM-1磁性混合基质膜的制备及其 O2/N2 分离性能研究[J]. 膜科学与技术, 2017, 37(4):27-37. |

| [9] |

Li Y F, Wang S F, He G, et al. Facilitated transport of small molec-ules and ions for energy-efficient membranes[J]. Chemical Society Reviews, 2015, 44(1):103-118.

doi: 10.1039/C4CS00215F |

| [10] | Zhao Y, Wang F S, Winston H, et al. Steric hindrance effect on amine demonstrated in solid polymer membranes for CO2 transpo-rt[J]. Journal of Membrane Science, 2012, 4(12):132-138. |

| [11] |

Xin Q, Zhao L, Li C, et al. Enhancing the CO2 separation perfor-mance of composite membranes by the incorporation of amino acid-functionalized graphene oxide[J]. Journal of Materials Chemistry A, 2015, 3(12):6629-6641.

doi: 10.1039/C5TA00506J |

| [12] |

Peng D D, Wang S F, Tian Z, et al. Facilitated transport membran-es by incorporating graphene nanosheets with high zinc ion loading for enhanced CO2 separation[J]. Journal of Membrane Science, 2017, 522:351-362.

doi: 10.1016/j.memsci.2016.09.040 |

| [13] |

Xin Q P, Ma F X, Zhang L, et al. Interface engineering of mixed matrix membrane via CO2-philic polymer brush functionalized graphene oxide nanosheets for efficient gas separation[J]. Journal of Membrane Science, 2019, 586(9):23-33.

doi: 10.1016/j.memsci.2019.05.050 |

| [14] | Jia X L, Zhang Q, Zhao M Q, et al. Dramatic enhancements in toug-hness of polyimide nanocomposite via long-CNT-induced long-range creep[J]. Journal of Materials Chemistry, 2012, 22(14):45-58. |

| [15] | Zambare R, Song X, Bhuvana S, et al. Ultrafast dye removal using ionic liquid-graphene oxide sponge[J]. ACS Sustainable Chemistry& Engineering, 2017, 5(7):6026-6035. |

| [16] |

Jia M M, Feng Y, Qiu J, et al. Amine-functionalized MOFs@GO as filler in mixed matrix membrane for selective CO2 separation[J]. Separation and Purification Technology, 2019, 213(2):63-69.

doi: 10.1016/j.seppur.2018.12.029 |

| [17] | Wang C Y, Lan Y F, Yu W T, et al. Preparation of amino-function-alized graphene oxide/polyimide composite films with improved mechanical,thermal and hydrophobic properties[J]. Applied Sur-face Science, 2016, 362(2):11-19. |

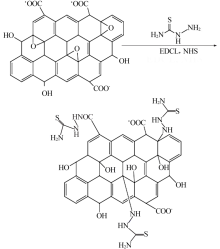

| [18] | Bu J Q, Yuan L, Zhang N, et al, High-efficiency adsorption of me-thylene blue dye from wastewater by a thiosemicarbazide function-alized graphene oxide composite[J]. Diamond and Related Materi-als, 2020, 101(2):67-79. |

| [19] |

Shang N Z, Feng C, Zhang H Y, et al, Suzuki-miyaura reaction ca-talyzed by graphene oxide supported palladium nanoparticles[J]. Catalysis Communications, 2013, 40(8):111-115.

doi: 10.1016/j.catcom.2013.06.006 |

| [20] | Huang D D, Xin Q P, Li Y Z, et al. Synergistic effects of zeolite imidazole framework@graphene oxide composites in humidified mixed matrix membranes on CO2 separation[J]. RSC Advances, 2018, 7(8):6099-6109. |

| [21] | Liu Y, Peng D D, He G, et al, Enhanced CO2 permeability of mem-branes by incorporating polyzwitterion@CNT composite particles into polyimide matrix[J]. ACS Applied Materials & Interfaces, 2014, 6(15):13051-13060. |

| [22] | Li X Q, Cheng Y D, Zhang H Y, et al. Efficient CO2 capture by func-tionalized graphene oxide nanosheets as fillers to fabricate multi-permselective mixed matrix membranes[J]. ACS Applied Materi-als & Interfaces, 2015, 7(9):177-189. |

| [23] |

Cui Y, Kundalwal S I, Kumar S. Gas barrier performance of grap-hene/polymer nanocomposites[J]. Carbon, 2016, 98(3):313-333.

doi: 10.1016/j.carbon.2015.11.018 |

| [24] |

Ge B S, Wang T, Sun H X, et al. Preparation of mixed matrix mem-branes based on polyimide and aminated graphene oxide for CO2 separation[J]. Polymers for Advanced Technologies, 2018, 29(4):1334-1343.

doi: 10.1002/pat.v29.4 |

| [25] | Khan A, Klaysom C, Gahlaut A, et al. Mixed matrix membranes co-mprising of Matrimid and-SO3H functionalized mesoporous MCM-41 for gas separation[J]. Journal of Membrane Science, 2013, 47(4):73-79. |

| [26] |

Li F, Li Y, Chung T S, et al. Facilitated transport by hybrid POSS®-Matrimid®-Zn2+ nanocomposite membranes for the separation of natural gas[J]. Journal of Membrane Science, 2010, 356(3):14-21.

doi: 10.1016/j.memsci.2010.03.021 |

| [27] | Wang S, Tian Z Z, Feng J, et al. Enhanced CO2 separation proper-ties by incorporating poly(ethylene glycol)-containing polymeric submicrospheres into polyimide membrane[J]. Journal of Mem-brane Science, 2015, 473(1):310-317. |

| [28] |

Zornoza B, Téllez C, Coronas J. Mixed matrix membranes compris-ing glassy polymers and dispersed mesoporous silica spheres for gas separation[J]. Journal of Membrane Science, 2011, 368(2):100-109.

doi: 10.1016/j.memsci.2010.11.027 |

| [29] |

Zhang Y, Musselman I H, Ferraris J P, et al. Gas permeability pro-perties of Matrimid® membranes containing the metal-organic fra-mework Cu-BPY-HFS[J]. Journal of Membrane Science, 2018, 313(5):170-181.

doi: 10.1016/j.memsci.2008.01.005 |

| [30] |

Zhang Y, Balkus K J, Musselman I H, et al. Mixed-matrix membra-nes composed of Matrimid® and mesoporous ZSM-5 nanoparticl-es[J]. Journal of Membrane Science, 2008, 325(1):28-39.

doi: 10.1016/j.memsci.2008.04.063 |

| [1] | GUO Yingjun, WU Songsong, DING Chunyan, ZHAO Shikai, SONG Tao, WEN Guangwu. Preparation of SSZ-13 zeolite membrane from glass-ceramics-strontium feldspar by crystal transformation method [J]. Inorganic Chemicals Industry, 2025, 57(2): 76-82. |

| [2] | ZHANG Ruijun, CHEN Guoliang, SONG Chuncao, ZHU Yafei. Effects of graphene oxide on mechanical properties and chloride penetration resistance of ultra⁃high performance concrete incorporating recycled sand [J]. Inorganic Chemicals Industry, 2024, 56(8): 54-59. |

| [3] | LI Bo, LIAO Bihai. Preparation of functionalized graphene oxide and its application in portland cement [J]. Inorganic Chemicals Industry, 2023, 55(6): 57-62. |

| [4] | ZHAO Liping, WANG Fei. Effect of amine-functionalized graphene oxide on mechanical properties of cement composites [J]. Inorganic Chemicals Industry, 2023, 55(3): 66-70. |

| [5] | CUI Xiangmei, PAN Tongtong, LUO Qinglong, BIAN Fuxuan, YE Xiushen. Preparation of amino alcohol modified GO/CNTs composite aerogel and boron adsorption from salt lake brines [J]. Inorganic Chemicals Industry, 2023, 55(12): 59-65. |

| [6] | DU Changqing, WANG Zhangxuan, TONG Teng, LIU Xiaofan, LIU Liang. Study on dispersion of silica fume/graphene oxide in hardened cement paste [J]. Inorganic Chemicals Industry, 2023, 55(11): 115-120. |

| [7] | YUAN Biao,SHI Yake,CHEN Zan. Study on chemically crosslinked polyimide separators for lithium-ion batteries with enhanced performance [J]. Inorganic Chemicals Industry, 2021, 53(11): 42-48. |

| [8] | Bai Lu,Wang Min,Yang Hongjun,Peng Zhengjun,Zhao Youjing,Li Zhilu. Research progress of graphene oxide modified polyamide membrane [J]. Inorganic Chemicals Industry, 2021, 53(10): 15-21. |

| [9] | Quan Kaidong,Pan Fusheng,Chen Zan,Duan Cuijia,Yuan Biao,Yan Shuo. Research progress of improving gas separation performance of inorganic fillers for mixed matrix membranes [J]. Inorganic Chemicals Industry, 2021, 53(1): 1-6. |

| [10] | Xing Shujian;Zang Jiazhong;Liu Wei;Liu Guanfeng;Sun Chunhui;Yu Haibin. Progress on industrial application of molecular sieve adsorbents [J]. INORGANICCHEMICALSINDUSTRY, 2009, 0(3): 0-0. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||