Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (1): 90-95.doi: 10.19964/j.issn.1006-4990.2023-0145

• Environment·Health·Safety • Previous Articles Next Articles

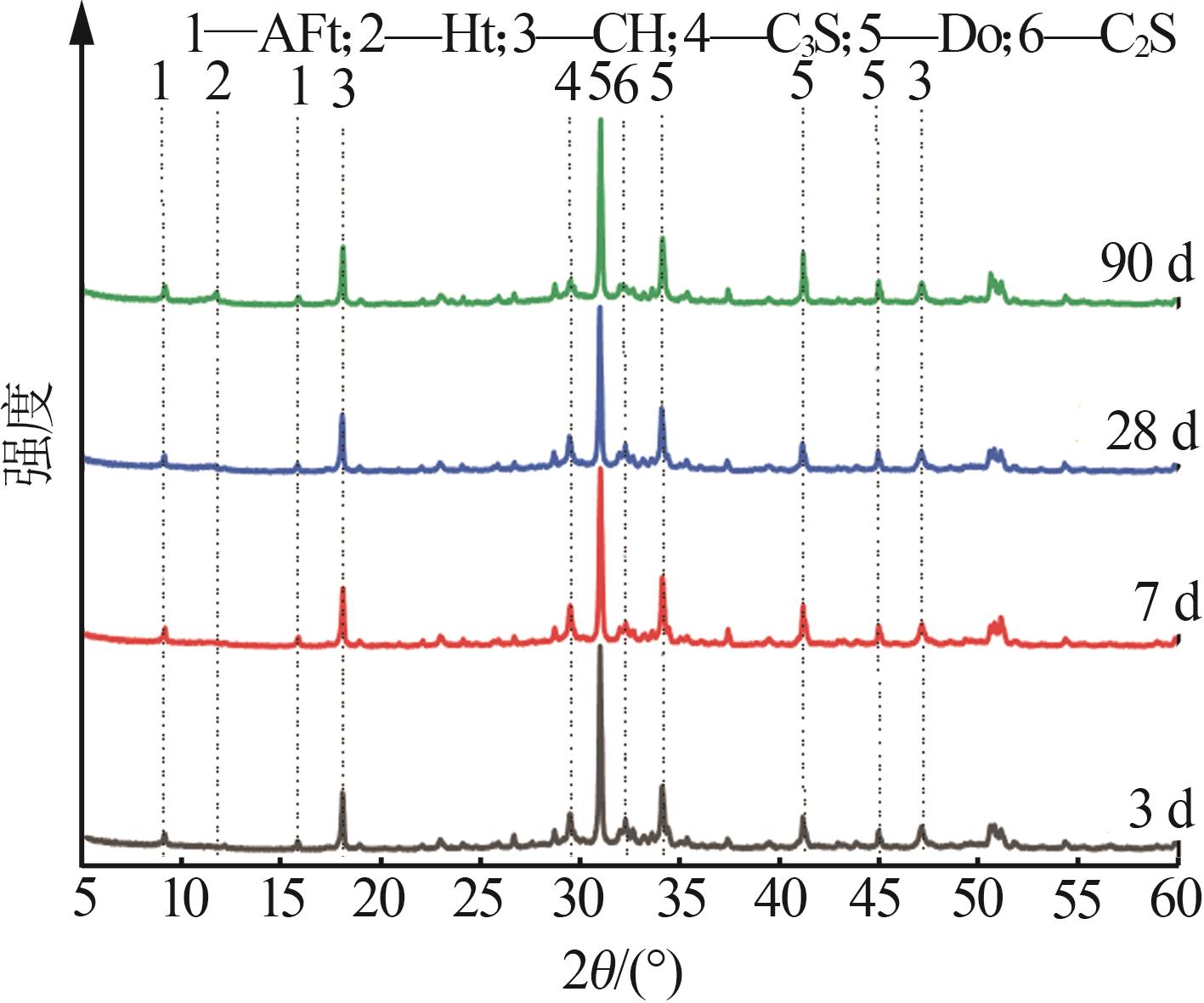

Study on performance of concrete with high-Mg phosphate tailing as mineral admixture

JIANG Lilong1( ), LI Jianqiu2, YANG Lin1(

), LI Jianqiu2, YANG Lin1( ), ZHANG Qinggang2

), ZHANG Qinggang2

- 1. School of Chemistry and Chemical Engineering,Guizhou University,Guiyang 550025,China

2. Guizhou Chuanheng Chemical Co.,Ltd.,Fuquan 550500,China