| 1 |

牟秀娟,朱干宇,颜坤,等.干法电石渣性质分析及乙炔气逸出行为研究[J].化工学报,2021,72(2):1107-1115.

|

|

MU Xiujuan, ZHU Ganyu, YAN Kun,et al.Properties analysis of dry-process calcium carbide slag and study on acetylene gas escape behavior[J].CIESC Journal,2021,72(2):1107-1115.

|

| 2 |

ZHANG Junjie, TAN Hongbo, HE Xingyang,et al.Utilization of carbide slag-granulated blast furnace slag system by wet grinding as low carbon cementitious materials[J].Construction and Building Materials,2020,249:118763.

|

| 3 |

ZHANG Chunxiao, LI Yingjie, BIAN Zhiguo,et al.Simultaneous CO2 capture and thermochemical heat storage by modified carbide slag in coupled calcium looping and CaO/Ca(OH)2 cycles[J].Chinese Journal of Chemical Engineering,2021,36:76-85.

|

| 4 |

赵立文,朱干宇,李少鹏,等.电石渣特性及综合利用研究进展[J].洁净煤技术,2021,27(3):13-26.

|

|

ZHAO Liwen, ZHU Ganyu, LI Shaopeng,et al.Research progress on characteristics and comprehensive utilization of calcium carbide slag[J].Clean Coal Technology,2021,27(3):13-26.

|

| 5 |

HUANG Zhong, LONG Jimiao, DENG Lei,et al.Feasibility study of using carbide slag as In-bed desulfurizer in circulating fluidized bed boiler[J].Applied Sciences,2019,9(21):4517.

|

| 6 |

ZHU Ganyu, MENG Ziheng, LI Shaopeng,et al.High efficiency desulfurization behavior by the sustainable low carbon utilization of carbide slag[J].Process Safety and Environmental Protection,2022,159:809-818.

|

| 7 |

王新博,周志华,邵明凯.循环利用电石渣制备活性氧化钙技术研究[J].耐火与石灰,2020,45(5):5-8.

|

|

WANG Xinbo, ZHOU Zhihua, SHAO Mingkai.Study on preparation of activated calcium oxide from calcium carbide slag[J].Refractories & Lime,2020,45(5):5-8.

|

| 8 |

侯新凯,武志江,郑伟豪,等.机械筛分法去除电石渣中非钙成分的研究[J].矿产综合利用,2020(2):161-166,155.

|

|

HOU Xinkai, WU Zhijiang, ZHENG Weihao,et al.Study on removal of non-calcium ingredients from carbide slag by mechanical screening[J].Multipurpose Utilization of Mineral Resources,2020(2):161-166,155.

|

| 9 |

WU Lei, QI Guansheng, LU Wei,et al.Study on preparation and performance of calcium carbide slag foam for coal mine disaster reduction and CO2 storage[J].Colloids and Surfaces A:Physicochemical and Engineering Aspects,2020,606:125322.

|

| 10 |

LIU Guofei, MENG Jun, HUANG Yanlan,et al.Effects of carbide slag,lodestone and biochar on the immobilization,plant uptake and translocation of As and Cd in a contaminated paddy soil[J].Environmental Pollution,2020,266:115194.

|

| 11 |

李永宁,暨思叡,严亚军,等.电石渣替代石灰石脱硫的改造实践[J].热电技术,2020(1):22-28.

|

|

LI Yongning, JI Sirui, YAN Yajun,et al.Transformation practice of calcium carbide slag replacing limestone for desulphurizati-on[J].Cogeneration Power Technology,2020(1):22-28.

|

| 12 |

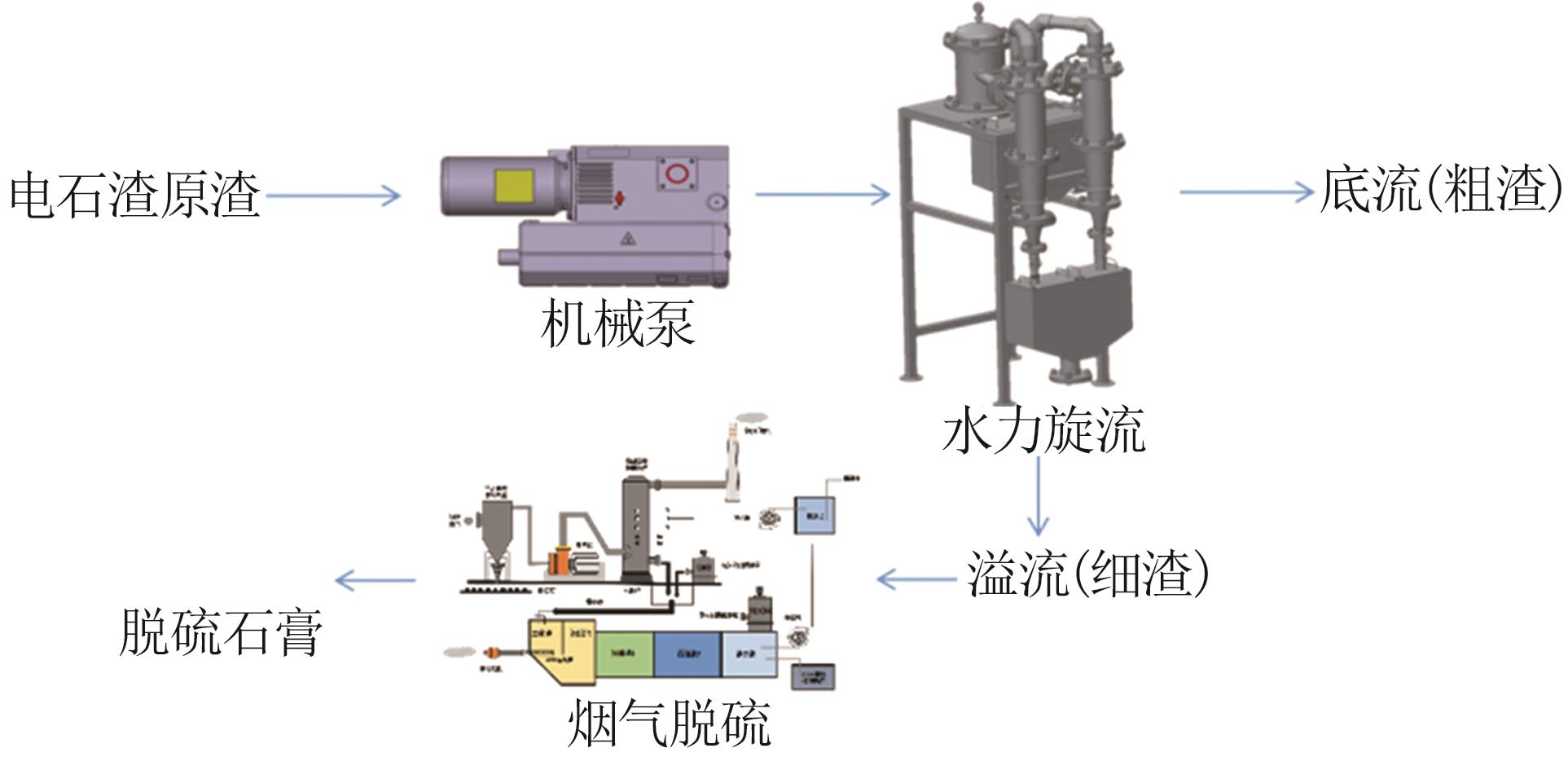

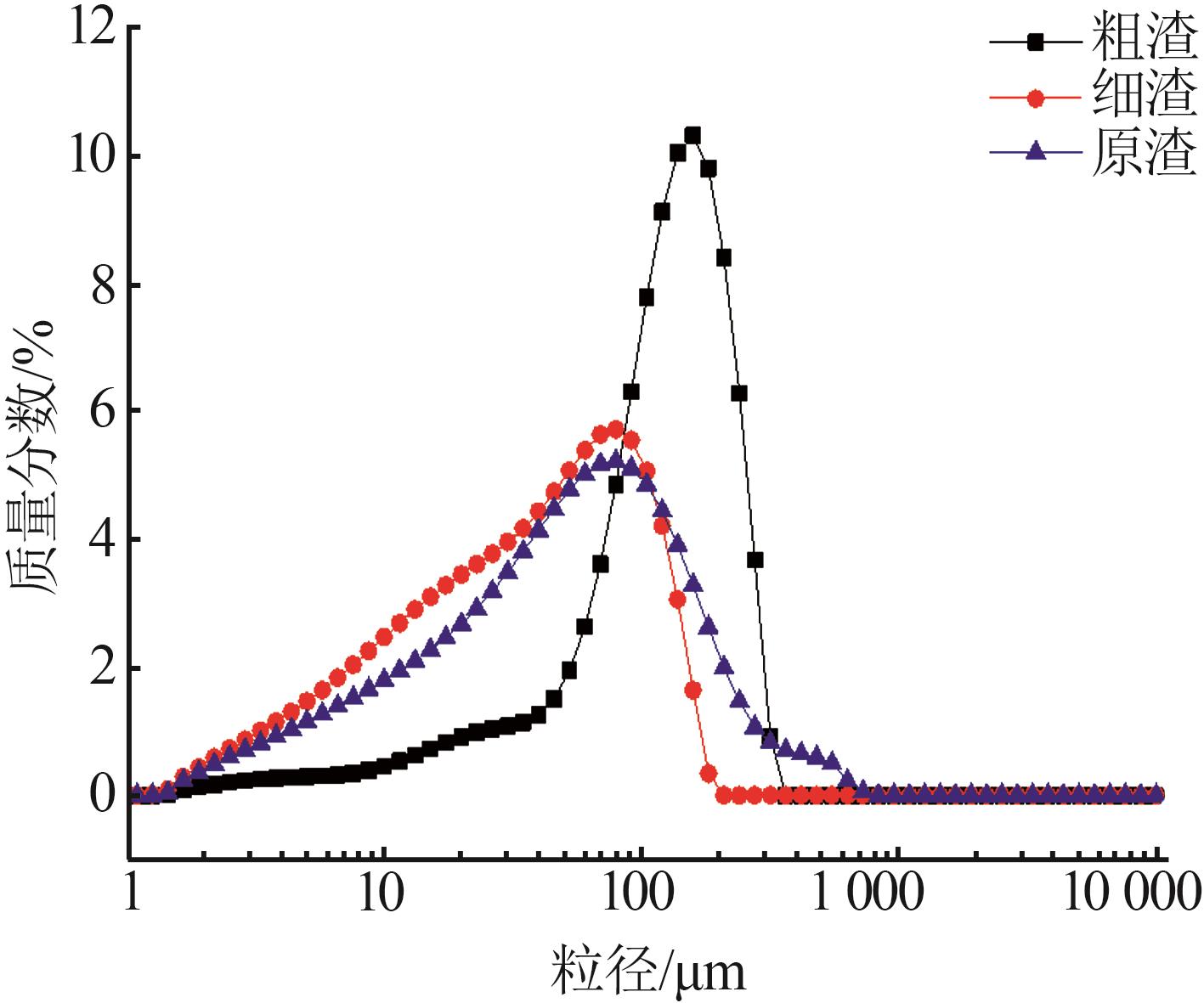

马英,何琦,杨有余,等.水力旋流动态沉降电石渣石膏分级研究[J].中国环保产业,2020(6):64-68.

|

|

MA Ying, HE Qi, YANG Youyu,et al.Study on grading of carbide slag gypsum particles by hydrocyclone and dynamic sedimentation[J].China Environmental Protection Industry,2020(6):64-68.

|

| 13 |

孙吉鹏,王书礼,王磊,等.一种电石渣除杂处理系统:中国,210875709U[P].2020-06-30.

|

| 14 |

张涛,陆飞,焦勇.电厂电石渣-石膏湿法脱硫工艺的应用[J].化工管理,2021(28):169-170.

|

|

ZHANG Tao, LU Fei, JIAO Yong.Application of calcium carbide slag-gypsum wet desulfurization process in power plant[J].Che-mical Enterprise Management,2021(28):169-170.

|

| 15 |

王明嘉.提高水力旋流器分级效率的数值计算研究[J].中国资源综合利用,2022,40(1):50-52.

|

|

WANG Mingjia.Research on numerical calculation for improving the classification efficiency of hydrocyclones[J].China Resources Utilization Comprehensive,2022,40(1):50-52.

|

| 16 |

李玥.结构优化型水力旋流器的数值模拟和实验研究[D].天津:天津大学,2018.

|

|

LI Yue.Experimental and numerical study of A hydrocyclone with the modification of geometrical structure[D].Tianjin:Tianjin University,2018.

|

| 17 |

齐加刚.水力旋流器分级性能分析及其改进[D].哈尔滨:哈尔滨工业大学,2021.

|

|

QI Jiagang.Performance analysis and improvement of hydrocyclone classificatpion[D].Harbin:Harbin Institute of Technology,2021.

|

| 18 |

LIU Bing, LI Luncao, WANG Huajian,et al.Numerical simulation and experimental study on internal and external characteristics of novel Hydrocyclones[J].Heat and Mass Transfer,2020,56(6):1875-1887.

|

| 19 |

夏倩茹,唐楠.旋风分离器的关键制造技术[J].中国化工装备,2022,24(5):14-18.

|

|

XIA Qianru, TANG Nan.Manufacture of cyclone separator[J].China Chemical Industry Equipment,2022,24(5):14-18.

|

| 20 |

邹小艳.水力旋流器分离过程性能的研究[D].长沙:长沙理工大学,2016.

|

|

ZOU Xiaoyan.Study on performance of hydrocyclone separation process[D].Changsha:Changsha University of Science & Technology,2016.

|

| 21 |

张建育,顾剑,蒋明,等.电石渣脱除含硫废气的可行性研究[J].化工设计通讯,2019,45(8):168-169.

|

|

ZHANG Jianyu, GU Jian, JIANG Ming,et al.Feasibility study of removing SO2-containing off gas by carbide slag[J].Chemical Engineering Design Communications,2019,45(8):168-169.

|

| 22 |

石梅,马建荣,段蕊.电石渣代替石灰石在海勃湾发电厂脱硫系统的尝试[J].内蒙古石油化工,2011,37(20):92-93.

|

|

SHI Mei, MA Jianrong, DUAN Rui.Attempt of replacing limestone with carbide slag in desulfurization system of Haibowan Power Plant[J].Inner Mongolia Petrochemical Industry,2011,37(20):92-93.

|

| 23 |

董添.加大工业副产石膏资源综合利用[N].中国证券报,2022-03-05(A07).

|

| 24 |

杨再银.中国工业副产石膏利用现状及“十四五”展望[J].硫酸工业,2021(7):1-4,23.

|

|

YANG Zaiyin.Utilization status of industrial by-product gypsum in China and its prospect in the 14th Five-Year Plan[J].Sulphuric Acid Industry,2021(7):1-4,23.

|

| 25 |

刘芳芳.加快推进工业副产石膏资源化利用[N].中国建材报,2021-03-29(1).

|

| 26 |

陈家伟,张仁亮.工业副产石膏资源化利用生态环境技术发展报告[J].广州化工,2020,48(24):1-3.

|

|

CHEN Jiawei, ZHANG Renliang.Report on ecological environment technology development of industrial by-product gypsum resource utilization[J].Guangzhou Chemical Industry,2020, 48(24):1-3.

|

| 27 |

马晶.工业副产石膏资源化综合利用的探索[J].建材发展导向,2020,18(4):13-16.

|

|

MA Jing.Exploration on comprehensive utilization of industrial by-product gypsum as resource[J].Development Guide to Building Materials,2020,18(4):13-16.

|

| 28 |

赵立文.电石渣湿法脱硫及石膏结晶过程协同调控工艺研究[D].昆明:昆明理工大学,2021.

|

|

ZHAO Liwen.Study on synergistic control technology of wet desulfurization of carbide slag and gypsum crystallization proce-ss[D].Kunming:Kunming University of Science and Technology,2021.

|

| 29 |

ZHANG Yuliang, LIU Xiaoming, XU Yingtang,et al.Preparation of road base material by utilizing electrolytic Manganese residue based on Si-Al structure:Mechanical properties and Mn2+ stabilization/solidification characterization[J].Journal of Hazardous Materials,2020,390:122188.

|

| 30 |

LI Wentao, YI Yaolin.Use of carbide slag from acetylene industry for activation of ground granulated blast-furnace slag[J].Construction and Building Materials,2020,238:117713.

|

| 31 |

MA Xiaotong, LI Yingjie, ZHANG Chunxiao,et al.Development of Mn/Mg-copromoted carbide slag for efficient CO2 capture under realistic calcium looping conditions[J].Process Safety and Environmental Protection,2020,141:380-389.

|

| 32 |

WANG Guodong, GUO Yafei, YU Jun,et al.Ni-CaO dual function materials prepared by different synthetic modes for integrated CO2 capture and conversion[J].Chemical Engineering Jo- urnal,2022,428:132110.

|

| 33 |

QIN Yihe, ZHANG Kai, HE Xuwen.Characteristics and mechanism of adsorption of tartaric acid by carbide slag ascertained and applied to prepare a binder[J].Journal of Cleaner Production,2022,337:130477.

|

| 34 |

国家市场监督管理总局,国家标准化管理委员会. 烟气脱硫石膏: [S].北京:中国标准出版社,2019.

|

), ZHU Ganyu1(

), ZHU Ganyu1( ), ZHANG Jianbo1, MENG Ziheng1, LIU Xinhui2, YANG Jing3, YAN Kun1, PENG Zonggui2, WANG Qiujian3, LI Huiquan1,4

), ZHANG Jianbo1, MENG Ziheng1, LIU Xinhui2, YANG Jing3, YAN Kun1, PENG Zonggui2, WANG Qiujian3, LI Huiquan1,4