Inorganic Chemicals Industry ›› 2022, Vol. 54 ›› Issue (5): 11-18.doi: 10.19964/j.issn.1006-4990.2021-0756

• Reviews and Special Topics • Previous Articles Next Articles

Research progress on new inorganic solid adsorbents in field of natural gas dehydration

SHI Han1( ),YUAN Biao2(

),YUAN Biao2( ),SHEN Peng2

),SHEN Peng2

- 1.CNOOC China Limited Shenzhen Branch,Shenzhen 518052,China

2.Cener Tech;Tianjin Chemical Research and Design Institute Co. ,Ltd.

-

Received:2021-12-16Online:2022-05-10Published:2022-05-31 -

Contact:YUAN Biao E-mail:han_shi@cnooc.com.cn;yuanbiao3@cnooc.com.cn

CLC Number:

Cite this article

SHI Han,YUAN Biao,SHEN Peng. Research progress on new inorganic solid adsorbents in field of natural gas dehydration[J]. Inorganic Chemicals Industry, 2022, 54(5): 11-18.

share this article

Table 2

Comparison of adsorption dehydration capacity of mesoporous silica and MOFs"

| 样品 | 操作条件 | 吸附能力/ (g·g-1) | ||

|---|---|---|---|---|

| 室温湿度/% | 温度/℃ | p/p0 | ||

| F127-SiO2[ | 84 | 25 | 0.9 | 0.45 |

| Brij56-SiO2[ | 84 | 25 | 0.9 | 0.25 |

| SBA-15[ | — | 20 | 0.9 | 0.084 |

| SBA-15[ | 90 | 35 | 0.9 | 0.54 |

| SiO2/CaCl2[ | 60 | 40 | 0.9 | 0.47 |

| AlFFIVE-1-Ni (KAUST-8)[ | 95 | 35 | 0.9 | 0.27 |

| MOF-303[ | 94 | 15 | 0.3 | 0.48 |

| HKUST-1[ | — | 25 | 0.9 | 0.55 |

| MIL-100(Fe)[ | — | 25 | 0.9 | 0.81 |

| MIL-101[ | — | 25 | 0.9 | 1.28 |

| DUT-4[ | — | 25 | 0.9 | 0.28 |

| ZIF-8[ | — | 25 | 0.9 | 0.02 |

| MIL-101[ | — | 25 | 0.9 | 1.2 |

| MIL-101(Cr)[ | 60 | 30 | 0.57 | 1.5 |

| MIL-101(Cr)-NH2[ | — | 20 | 0.4 | 1.06 |

| MOF-801[ | 100 | 25 | 0.9 | 0.05 |

| MOF-808[ | 100 | 25 | 0.9 | 0.08 |

| MOF-841[ | 100 | 25 | 0.9 | 0.07 |

| MIL-101(Cr)/CaCl2[ | — | 25 | 0.9 | 2.2 |

| 1 | NEAGU M, CURSARU D L.Technical and economic evaluations of the triethylene glycol regeneration processes in natural gas dehydration plants[J].Journal of Natural Gas Science and Engineering,2017,37:327-340. |

| 2 | KONG Zongyang, MAHMOUD A, LIU Shaomin,et al.Revamping existing glycol technologies in natural gas dehydration to improve the purity and absorption efficiency:Available methods and recent developments[J].Journal of Natural Gas Science and Engineering,2018,56:486-503. |

| 3 | 戴国华,桑军,万宇飞.天然气超音速分离脱水技术研究进展[J].石油化工高等学校学报,2021,34(1):63-71. |

| DAI Guohua, SANG Jun, WAN Yufei.Research progress of natural gas dehydration with supersonic separator[J].Journal of Petrochemical Universities,2021,34(1):63-71. | |

| 4 | 周建,陈文峰,于成龙,等.超音速天然气脱水工艺的应用[J].石油和化工设备,2020,23(10):113-115. |

| ZHOU Jian, CHEN Wenfeng, YU Chenglong,et al.Application of super sonic natural gas dehydration process[J].Petro & Chemical Equipment,2020,23(10):113-115. | |

| 5 | RAHIMPOUR M R, SAIDI M, SEIFI M.Improvement of natural gas dehydration performance by optimization of operating conditions:A case study in Sarkhun gas processing plant[J].Journal of Natural Gas Science and Engineering,2013,15:118-126. |

| 6 | 杨秘.节流制冷技术在海上平台天然气脱水系统中的应用[J].化学工程与装备,2020(11):78-79. |

| YANG Mi.Application of throttling refrigeration technology in natural gas dehydration system of offshore platform [J].Chemical Engineering & Equipment,2020(11):78-79. | |

| 7 | MOKHATAB S, POE W A.Handbook of natural gas transmission & processing[M].Second edition.USA:Elsevier,2012,1-802. |

| 8 | LAVRENKO V A, PODCHERNYAEVA I A, SHCHUR D V,et al.Features of physical and chemical adsorption during interaction of polycrystalline and nanocrystalline materials with gases[J].Powder Metallurgy and Metal Ceramics,2018,56(9/10):504-511. |

| 9 | GHIASI M M, BAHADORI A, ZENDEHBOUDI S.Estimation of the water content of natural gas dried by solid calcium chloride dehydrator units[J].Fuel,2014,117:33-42. |

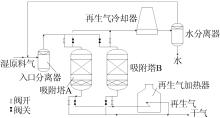

| 10 | 邹龙华,赵凌霜,李怀洲,等.天然气分子筛脱水装置吸附塔设计探讨[J].石油化工建设,2021,43(S2):116-118. |

| ZOU Longhua, ZHAO Lingshuang, LI Huaizhou,et al.Discussion on design of adsorption tower of natural gas molecular sieve dehydration unit[J].Petroleum and Chemical Construction,2021,43(S2):116-118. | |

| 11 | FARAG H A A, EZZAT M M, AMER H,et al.Natural gas dehydration by desiccant materials[J].Alexandria Engineering Journal,2011,50(4):431-439. |

| 12 | SANTOS M G R S, CORREIA L M S, DE MEDEIROS J L,et al.Natural gas dehydration by molecular sieve in offshore plants:Impact of increasing carbon dioxide content[J].Energy Conversion and Management,2017,149:760-773. |

| 13 | SHIRAZIAN S, ASHRAFIZADEH S N.Synthesis of substrate⁃modified LTA zeolite membranes for dehydration of natural gas[J].Fuel,2015,148:112-119. |

| 14 | 袁亚伟,李勇.ZSM-5分子筛吸附剂应用于污染治理的研究进展[J].无机盐工业,2019,51(10):18-21. |

| YUAN Yawei, LI Yong.Research progress of ZSM-5 molecular sieve adsorbents used in pollution control[J].Inorganic Chemicals Industry,2019,51(10):18-21. | |

| 15 | KIM Y T, JUNG K D, PARK E D.Gas-phase dehydration of glycerol over silica⁃alumina catalysts[J].Applied Catalysis B:Environmental,2011,107(1/2):177-187. |

| 16 | SERBEZOV A, MOORE J D, WU Yaqin.Adsorption equilibrium of water vapor on selexsorb-CDX commercial activated alumina adsorbent[J].Journal of Chemical & Engineering Data,2011,56(5):1762-1769. |

| 17 | HANIF A, DASGUPTA S, NANOTI A.High temperature CO2 adsorption by mesoporous silica supported magnesium aluminum mixed oxide[J].Chemical Engineering Journal,2015,280:703- |

| 710 | |

| 18 | LAKHI K S, CHA W S, CHOY J H,et al.Synthesis of mesoporous carbons with controlled morphology and pore diameters from SBA-15 prepared through the microwave⁃assisted process and their CO2 adsorption capacity[J].Microporous and Mesoporous Materials,2016,233:44-52. |

| 19 | RUSSELL B A, MIGONE A D.Low temperature adsorption study of CO2 in ZIF-8[J].Microporous and Mesoporous Materials,2017,246:178-185. |

| 20 | LIU Defei, WU Yongbiao, XIA Qibin,et al.Experimental and molecular simulation studies of CO2 adsorption on zeolitic imidazolate frameworks:ZIF-8 and amine⁃modified ZIF-8[J].Adsorption,2013,19(1):25-37. |

| 21 |

SANTOS K M C, MENEZES T R, OLIVEIRA M R,et al.Natural

doi: 10 |

|

gas dehydration by adsorption using MOFs and silicas:A revi⁃

doi: 10 |

|

|

ew[J].Separation and Purification Technology,2021,276.Doi:10 .

doi: 10 |

|

|

1016/j.seppur.2021.119409.

doi: 10 |

|

| 22 | GANDHIDASAN P, AL-FARAYEDHI A A, AL-MUBARAK A A.Dehydration of natural gas using solid desiccants[J].Energy,2001,26(9):855-868. |

| 23 | NEISHABORI SALEHI R, SHARIFNIA S, RAHIMPOUR F.Natural gas upgrading by selective separation on zeotype adsorbents[J].Journal of Natural Gas Science and Engineering,2018,54:37-46. |

| 24 | TAGLIABUE M, FARRUSSENG D, VALENCIA S,et al.Natural gas treating by selective adsorption:Material science and chemical engineering interplay[J].Chemical Engineering Journal,2009, |

| 155(3):553-566. | |

| 25 | MESGARIAN R, HEYDARINASAB A, RASHIDI A,et al.Adsorption and growth of water clusters on UiO-66 based nanoadsorbents:A systematic and comparative study on dehydration of natural gas[J].Separation and Purification Technology,2020, |

| 239 |

Doi:10.1016/j.seppur.2020.116512 .

doi: 10.1016/j.seppur.2020.116512 |

| 26 | CADIAU A, BELMABKHOUT Y, ADIL K,et al.Hydrolytically stable fluorinated metal⁃organic frameworks for energy⁃efficient dehydration[J].Science,2017,356(6339):731-735. |

| 27 | FURUKAWA H, GÁNDARA F, ZHANG Yuebiao,et al.Water adsorption in porous metal⁃organic frameworks and related materials[J].Journal of the American Chemical Society,2014,136(11):4369-4381. |

| 28 | SALIBA S, RUCH P, VOLKSEN W,et al.Combined influence of pore size distribution and surface hydrophilicity on the water adsorption characteristics of micro- and mesoporous silica[J].Microporous and Mesoporous Materials,2016,226:221-228. |

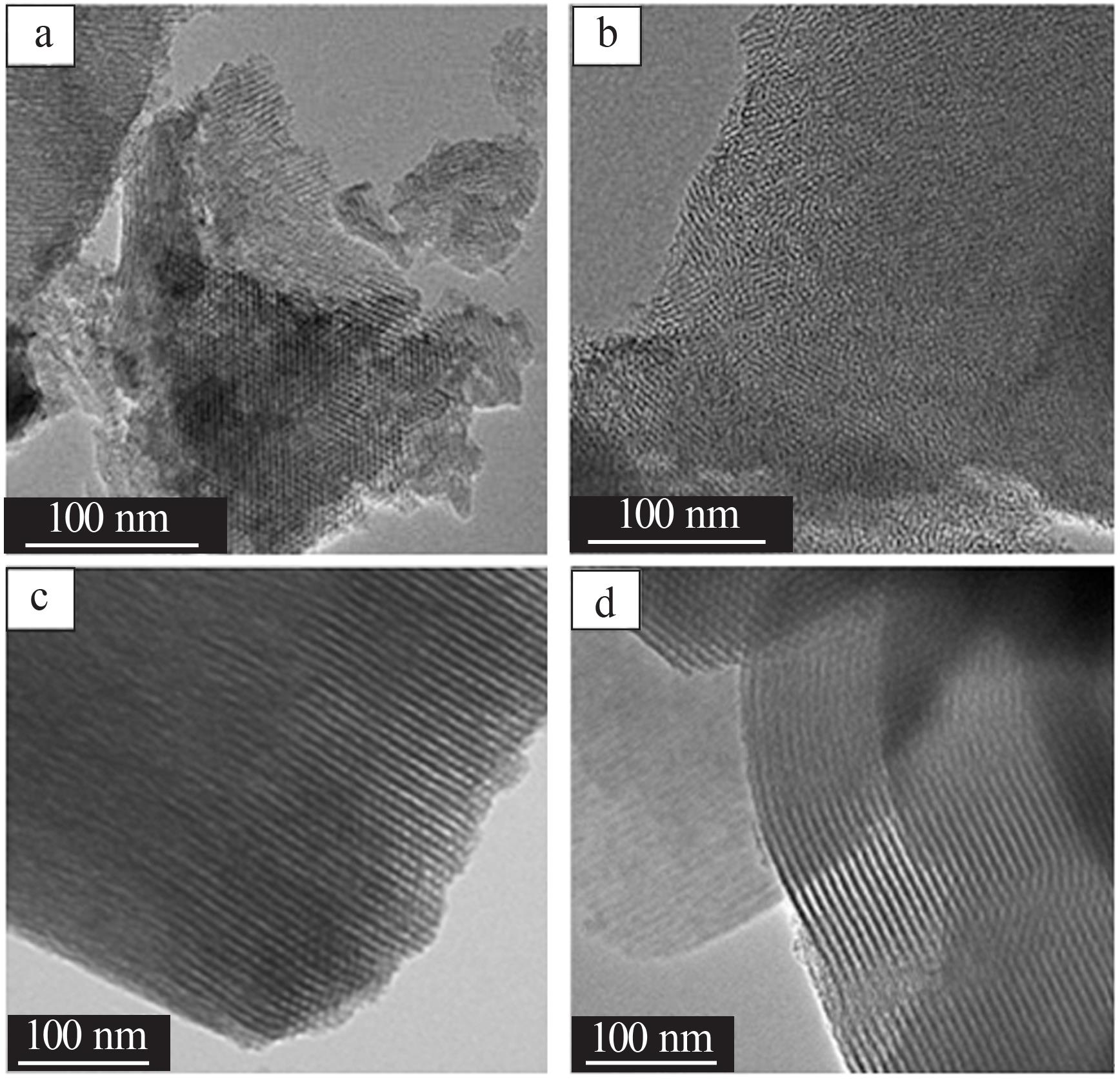

| 29 | 孙振海,李滨,郭春垒,等.介孔二氧化硅合成及其吸附分离性能研究[J].无机盐工业,2021,53(7):68-72. |

| SUN Zhenhai, LI Bin, GUO Chunlei,et al.Study on synthesis of mesoporous silica and its adsorption and separation properties[J].Inorganic Chemicals Industry,2021,53(7):68-72. | |

| 30 | LI Haibin, AI Minghuan, LIU Baizhan,et al.Water vapor sorption on surfactant⁃templated porous silica xerogels[J].Microporous and Mesoporous Materials,2011,143(1):1-5. |

| 31 | MAAZ S, ROSE M, PALKOVITS R.Systematic investigation of the pore structure and surface properties of SBA-15 by water vapor physisorption[J].Microporous and Mesoporous Materials,2016,220:183-187. |

| 32 | CENTINEO A, NGUYEN H G T, ESPINAL L,et al.An experimental and modelling study of water vapour adsorption on SBA-15[J].Microporous and Mesoporous Materials,2019,282:53- |

| 72 | |

| 33 | BU Xianbiao, WANG Lingbao, HUANG Yuanfeng.Effect of pore size on the performance of composite adsorbent[J].Adsorption,2013,19(5):929-935. |

| 34 |

FATHIEH F, KALMUTZKI M J, KAPUSTIN E A,et al.Practical water production from desert air[J].Science Advances,2018,4(6).Doi:10.1126/sciadv.aat3198 .

doi: 10.1126/sciadv.aat3198 |

| 35 | KÜSGENS P, ROSE M, SENKOVSKA I,et al.Characterization of metal⁃organic frameworks by water adsorption[J].Microporous and Mesoporous Materials,2009,120(3):325-330. |

| 36 | AKIYAMA G, MATSUDA R, SATO H,et al.Effect of functional groups in MIL-101 on water sorption behavior[J].Microporous and Mesoporous Materials,2012,157:89-93. |

| 37 | SEO Y K, YOON J W, LEE J S,et al.Energy⁃efficient dehumidification over hierachically porous metal⁃organic frameworks as advanced water adsorbents[J].Advanced Materials,2012,24(6):806-810. |

| 38 | KHUTIA A, RAMMELBERG H U, SCHMIDT T,et al.Water sorption cycle measurements on functionalized MIL-101Cr for heat transformation application[J].Chemistry of Materials,2013,25(5):790-798. |

| 39 | ELSAYED E, ANDERSON P, AL-DADAH R,et al.MIL-101(Cr)/calcium chloride composites for enhanced adsorption cooling and water desalination[J].Journal of Solid State Chemistry,2019,277:123-132. |

| 40 | THOMMES M, KANEKO K, NEIMARK A V,et al.Physisorption of gases,with special reference to the evaluation of surface area and pore size distribution(IUPAC Technical Report)[J].Pure and Applied Chemistry,2015,87(9/10):1051-1069. |

| 41 | MALEKI H, DURÃES L, PORTUGAL A.An overview on silica aerogels synthesis and different mechanical reinforcing strategi⁃ |

| es[J].Journal of Non-Crystalline Solids,2014,385:55-74. | |

| 42 | IVANOVA M, KARETH S, SPIELBERG E T,et al.Silica ionogels synthesized with imidazolium based ionic liquids in presence of supercritical CO2 [J].The Journal of Supercritical Fluids,2015,105:60-65. |

| 43 | WANG Ding, MCLAUGHLIN E, PFEFFER R,et al.Adsorption of oils from pure liquid and oil⁃water emulsion on hydrophobic silica aerogels[J].Separation and Purification Technology,2012,99:28-35. |

| 44 | KON’KOVA T V, GORDIENKO M G, MEN’SHUTINA N V,et al.Adsorption properties of aerosilicagels prepared by drying in a supercritical carbon dioxide medium[J].Russian Journal of Physical Chemistry B,2018,12(7):1120-1124. |

| 45 | OLIVEIRA R J, DE CONTO J F, OLIVEIRA M R,et al.CO2/CH4 adsorption at high⁃pressure using silica-APTES aerogel as adsorbent and near infrared as a monitoring technique[J].Journal of CO2 Utilization,2019,32:232-240. |

| 46 | RUEDA M, SANZ-MORAL L M, NIETO-MÁRQUEZ A,et al.Production of silica aerogel microparticles loaded with ammonia borane by batch and semicontinuous supercritical drying techniques[J].The Journal of Supercritical Fluids,2014,92:299-310. |

| 47 | OKUTAN C, ARBAG H, YASYERLI N,et al.Catalytic activity of SBA-15 supported Ni catalyst in CH4 dry reforming:Effect of Al,Zr,and Ti co⁃impregnation and Al incorporation to SBA-15[J].International Journal of Hydrogen Energy,2020,45(27):13911-13928. |

| 48 | BECK J S, VARTULI J C, ROTH W J,et al.A new family of mesoporous molecular sieves prepared with liquid crystal templates[J].Journal of the American Chemical Society,1992,114(27):10834-10843. |

| 49 | CHEN C, LI Hongxin, DAVIS M E.Studies on mesoporous materialsI.synthesis and characterization of MCM-41[J].Microporous Materials,1993,2(1): 17-26. |

| 50 | BAGSHAW S A, PROUZET E, PINNAVAIA T J.Templating of mesoporous molecular sieves by nonionic polyethylene oxide surfactants[J].Science,1995,269(5228):1242-1244. |

| 51 | TANEV P T, PINNAVAIA T J.A neutral templating route to mesoporous molecular sieves[J].Science,1995,267(5199):865- |

| 867 | |

| 52 | HUO Q, LEON R, PETROFF P M,et al.Mesostructure design with gemini surfactants:Supercage formation in a three⁃dimensional hexagonal array[J].Science,1995,268(5215):1324-1327. |

| 53 | ZHAO D, FENG J, HUO Q,et al.Triblock copolymer syntheses of mesoporous silica with periodic 50 to 300 angstrom pores[J].Science,1998,279(5350):548-552. |

| 54 | YANG R T.Adsorbents:Fundamentals and Applications[M].Ho⁃ |

| boken,NJ,USA:John Wiley & Sons Inc,2003. | |

| 55 | MAYANOVIC R A, YAN Hao, BRANDT A D,et al.Mechanical and hydrothermal stability of mesoporous materials at extreme conditions[J].Microporous and Mesoporous Materials,2014,195: |

| 161-166. | |

| 56 | GOUZE B, CAMBEDOUZOU J, PARRÈS-MAYNADIÉ S,et al.How hexagonal mesoporous silica evolves in water on short and long term:Role of pore size and silica wall porosity[J].Microporous and Mesoporous Materials,2014,183:168-176. |

| 57 | ZHENG X, GE T S, WANG R Z.Recent progress on desiccant materials for solid desiccant cooling systems[J].Energy,2014,74:280-294. |

| 58 | JIA C X, DAI Y J, WU J Y,et al.Use of compound desiccant to develop high performance desiccant cooling system[J].International Journal of Refrigeration,2007,30(2):345-353. |

| 59 | SIMONOVA I A, FRENI A, RESTUCCIA G,et al.Water sorption on composite “silica modified by calcium nitrate”[J].Microporous and Mesoporous Materials,2009,122(1/2/3):223-228. |

| 60 | ARISTOV Y I, SAPIENZA A, OVOSHCHNIKOV D S,et al.Reallocation of adsorption and desorption times for optimisation of cooling cycles[J].International Journal of Refrigeration,2012,35(3):525-531. |

| 61 | SUKHYY K M, BELYANOVSKAYA E A, KOZLOV Y N,et al.Structure and adsorption properties of the composites‘silica gel-sodium sulphate’,obtained by Sol-gel method[J].Applied Thermal Engineering,2014,64(1/2):408-412. |

| 62 | LENZA R F S, NUNES E H M, VASCONCELOS D C L,et al.Preparation of Sol-gel silica samples modified with drying control chemical additives[J].Journal of Non-Crystalline Solids,2015, |

| 423/ 424:35-40. | |

| 63 | YAGHI O M, LI Hailian.Hydrothermal synthesis of a metal⁃organic framework containing large rectangular channels[J].Journal of the American Chemical Society,1995,117(41):10401-10402. |

| 64 | LI Jianrong, SCULLEY J, ZHOU Hongcai.Metal⁃organic frameworks for separations[J].Chemical Reviews,2012,112(2):869- |

| 932 | |

| 65 | LI Jianrong, KUPPLER R J, ZHOU Hongcai.Selective gas adsorption and separation in metal⁃organic frameworks[J].Chemical Society Reviews,2009,38(5):1477-1504. |

| 66 |

GHAFFAR I, IMRAN M, PERVEEN S,et al.Synthesis of chitosan coated metal organic frameworks(MOFs) for increasing vancomycin bactericidal potentials against resistant S.aureus strain[J].Materials Science and Engineering:C,2019,105.Doi:10.1016/j.msec.2019.110111 .

doi: 10.1016/j.msec.2019.110111 |

| 67 |

KNOZOWSKA K, THÜR R, KUJAWA J,et al.Fluorinated MOF-808 with various modulators to fabricate high⁃performance hybrid

doi: 10.1016/j.seppur.2021.118315 |

|

membranes with enhanced hydrophobicity for organic⁃organic pe⁃

doi: 10.1016/j.seppur.2021.118315 |

|

|

rvaporation[J].Separation and Purification Technology,2021,264. Doi:10.1016/j.seppur.2021.118315 .

doi: 10.1016/j.seppur.2021.118315 |

|

| 68 | BOURRELLY S, LLEWELLYN P L, SERRE C,et al.Different adsorption behaviors of methane and carbon dioxide in the isotypic nanoporous metal terephthalates MIL-53 and MIL-47[J].Journal of the American Chemical Society,2005,127(39):13519-13521. |

| 69 | KITAGAWA S, MATSUDA R.Chemistry of coordination space of porous coordination polymers[J].Coordination Chemistry Revie⁃ ws,2007,251(21/22/23/24):2490-2509. |

| 70 | CHANG Ze, YANG Donghui, XU Jian,et al.Flexible metal⁃organic frameworks:Recent advances and potential applications[J].Advanced Materials,2015,27(36):5432-5441. |

| 71 | 明宗营.天然气饱和含水量计算[J].当代化工,2014,43(2):305-307. |

| MING Zongying.The saturation moisture content calculation of natural gas[J].Contemporary Chemical Industry,2014,43(2):305-307. | |

| 77 |

TSALAPORTA E, MACELROY J M D.A comparative study of the physical and chemical properties of pelletized HKUST-1,ZIF-8,ZIF-67 and UiO-66 powders[J].Heliyon,2020,6(9).Doi:10.1016/j.heliyon.2020.e04883 .

doi: 10.1016/j.heliyon.2020.e04883 |

| 73 | YANG Jiangfeng, BAI Honghao, ZHANG Feifei,et al.Effects of activation temperature and densification on adsorption performance of MOF MIL-100(Cr)[J].Journal of Chemical & Engineering Data,2019,64(12):5814-5823. |

| 74 | CHANUT N, WIERSUM A D, LEE U H,et al.Observing the effects of shaping on gas adsorption in metal⁃organic frameworks[J].European Journal of Inorganic Chemistry,2016(27):4416-4423. |

| 75 | DELGADO J A, ÁGUEDA V I, UGUINA M A,et al.Comparison and evaluation of agglomerated MOFs in biohydrogen purification by means of pressure swing adsorption(PSA)[J].Chemical Engineering Journal,2017,326:117-129. |

| 76 | PETERSON G W, DECOSTE J B, GLOVER T G,et al.Effects of pelletization pressure on the physical and chemical properties of the metal⁃organic frameworks Cu3(BTC)2 and UiO-66[J].Microporous and Mesoporous Materials,2013,179:48-53. |

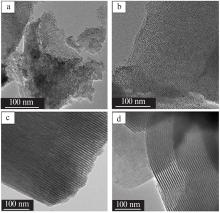

| [1] | HONG Meihua,LIU Guanfeng,GONG Yupeng,LI Liqing,CHEN Tiehong. Synthesis of mesoporous silica KIT-6 microspheres with single-crystalline mesostructure [J]. Inorganic Chemicals Industry, 2022, 54(7): 149-156. |

| [2] | Wang Lixia,Ren Dongmei,Wang Qiong,Chang Chun. Stduy on preparation of magnetic metal-organic frame materials and their adsorption properties [J]. Inorganic Chemicals Industry, 2021, 53(9): 46-50. |

| [3] | Sun Zhenhai,Li Bin,Guo Chunlei,Zang Jiazhong,Li Ben,Fan Jingxin,Wang Yang. Study on synthesis of mesoporous silica and its adsorption and separation properties [J]. Inorganic Chemicals Industry, 2021, 53(7): 68-72. |

| [4] | GUO Wei,SHI Han,YUAN Biao. Research progress of inorganic solid adsorbents in carbon dioxide capture [J]. Inorganic Chemicals Industry, 2021, 53(12): 29-34. |

| [5] | DONG Jia-Li, WANG Lu-Xun, LI Jian, YANG Li-Na, XU Long, SUN Yu-Meng. Research progress of preparation of bimodal mesoporous silica [J]. INORGANICCHEMICALSINDUSTRY, 2014, 46(6): 17-. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||