Inorganic Chemicals Industry ›› 2022, Vol. 54 ›› Issue (5): 54-60.doi: 10.19964/j.issn.1006-4990.2021-0427

• Research & Development • Previous Articles Next Articles

Study on thermophysical properties of solar salt composites doped with nanoparticles

ZHANG Yue1,2,3( ),WANG Min1,2,LI Jinli1,2,ZHAO Youjing1,2,WANG Huaiyou1,2

),WANG Min1,2,LI Jinli1,2,ZHAO Youjing1,2,WANG Huaiyou1,2

- 1.Key Laboratory of Comprehensive and Highly Efficient Utilization of Salt Lake Resources,Qinghai Institute of Salt Lakes,Chinese Academy of Sciences,Xining 810008,China

2.Key Laboratory of Salt Lake Resources Chemistry of Qinghai Province

3.University of Chinese Academy of Sciences

-

Received:2021-07-14Online:2022-05-10Published:2022-05-31

CLC Number:

Cite this article

ZHANG Yue,WANG Min,LI Jinli,ZHAO Youjing,WANG Huaiyou. Study on thermophysical properties of solar salt composites doped with nanoparticles[J]. Inorganic Chemicals Industry, 2022, 54(5): 54-60.

share this article

| 1 | HU Yanwei, HE Yurong, ZHANG Zhenduo,et al.Effect of Al2O3 nanoparticle dispersion on the specific heat capacity of a eutectic binary nitrate salt for solar power applications[J].Energy Conversion and Management,2017,142:366-373. |

| 2 | DENG Ziyang, ZHOU Jianhua, MIAO Lei,et al.The emergence of solar thermal utilization:Solar⁃driven steam generation[J].Journal of Materials Chemistry A,2017,5(17):7691-7709. |

| 3 | LIN Yawen, XU Hao, SHAN Xiaoli,et al.Solar steam generation based on the photothermal effect:From designs to applications,and beyond[J].Journal of Materials Chemistry A,2019,7(33):19203-19227. |

| 4 | GIL A, MEDRANO M, MARTORELL I,et al.State of the art on high temperature thermal energy storage for power generation.Part 1Concepts,materials and modellization[J].Renewable and Sustainable Energy Reviews,2010,14(1):31-55. |

| 5 | CHEN Xia, WU Yuting, ZHANG Ludi,et al.Experimental study on the specific heat and stability of molten salt nanofluids prepared by high-temperature melting[J].Solar Energy Materials and Solar Cells,2018,176:42-48. |

| 6 | TIAN Y, ZHAO C Y.A review of solar collectors and thermal energy storage in solar thermal applications[J].Applied Energy,2013,104:538-553. |

| 7 | 郑天新,梁精龙,李慧,等.熔盐技术在新能源中的应用现状[J].无机盐工业,2018,50(3):11-15. |

| ZHENG Tianxin, LIANG Jinglong, LI Hui,et al.Application status of molten salt technology in new energy[J].Inorganic Chemicals Industry,2018,50(3):11-15. | |

| 8 | MEKHILEF S, SAIDUR R, SAFARI A.A review on solar energy use in industries[J].Renewable and Sustainable Energy Reviews,2011,15(4):1777-1790. |

| 9 | YE Feng, GE Zhiwei, DING Yulong,et al.Multi⁃walled carbon nano⁃ |

| tubes added to Na 2 CO3/MgO composites for thermal energy stor⁃ | |

| age[J].Particuology,2014,15:56-60. | |

| 10 | CHOI S U S, EASTMAN J A.Enhancing thermal conductivity of fluids with nanoparticles[J].ASME International Mechanical Engineering Congress & Exposition,1995,231(1):99-105. |

| 11 | HAN Zhenxing, RAM M K, KAMAL R,et al.Characterization of molten salt doped with different size nanoparticles of Al2O3 [J].International Journal of Energy Research,2019,43(8):3732-3745. |

| 12 | HO M X, PAN C.Optimal concentration of alumina nanoparticles in molten Hitec salt to maximize its specific heat capacity[J].International Journal of Heat and Mass Transfer,2014,70:174-184. |

| 13 | SHIN D, BANERJEE D.Enhancement of specific heat capacity of high⁃temperature silica⁃nanofluids synthesized in alkali chloride salt eutectics for solar thermal⁃energy storage applications[J].International Journal of Heat and Mass Transfer,2011,54(5/6):1064-1070. |

| 14 | CHIERUZZI M, CERRITELLI G F, MILIOZZI A,et al.Heat capacity of nanofluids for solar energy storage produced by dispersing oxide nanoparticles in nitrate salt mixture directly at high temperature[J].Solar Energy Materials and Solar Cells,2017,167:60-69. |

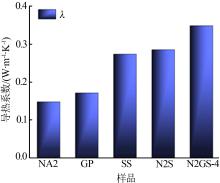

| 15 | WU Yanze, LI Jinli, WANG Min,et al.Solar salt doped by MWCNTs as a promising high thermal conductivity material for CSP[J].RSC Advances,2018,8(34):19251-19260. |

| 16 | MURSHEDS M S, LEONGK C, YANG C.Enhanced thermal conductivity of TiO2—Water based nanofluids[J].International Journal of Thermal Sciences,2005,444:367-373. |

| 17 | 冯晓平,郝学军.强化三元混合熔盐的传热性能的实验研究[J].无机盐工业,2021,53(8):66-70. |

| FENG Xiaoping, HAO Xuejun.Experimental study on enhanced heat transfer performance of ternary mixed molten salts[J].Inorganic Chemicals Industry,2021,53(8):66-70. | |

| 18 |

ZHANG Yue, LI Jinli, GAO Lin,et al.Nitrate based nanocomposite thermal storage materials:Understanding the enhancement of thermophysical properties in thermal energy storage[J].Solar Energy Materials and Solar Cells,2020,216.Doi:org/10.1016/j.solmat.2020.110727 .

doi: org/10.1016/j.solmat.2020.110727 |

| 19 | NOMURA T, OKINAKA N, AKIYAMA T.Technology of latent heat storage for high temperature application:A review[J].ISIJ International,2010,50(9):1229-1239. |

| 20 | PINCEMIN S, OLIVES R,PY X,et al.Highly conductive composites made of phase change materials and graphite for thermal storage[J].Solar Energy Materials and Solar Cells,2008,92(6): |

| 603-613. | |

| 21 | XIA L, ZHANG P.Thermal property measurement and heat transfer analysis of acetamide and acetamide/expanded graphite composite phase change material for solar heat storage[J].Solar Energy Materials and Solar Cells,2011,95(8):2246-2254. |

| 22 | XIAO X, ZHANG P, LI M.Thermal characterization of nitrates and nitrates/expanded graphite mixture phase change materials for solar energy storage[J].Energy Conversion and Management,2013,73:86-94. |

| 23 | LAING D, BAUER T, STEINMANN W D,et al.Advanced high temperature latent heat storage system⁃design and test resul⁃ |

| ts[C]∥In Proceedings of the 11th International Conference on Thermal Energy Storage-Effstock,2009:1-8. | |

| 24 |

STEINMANN W D, LAING D, TAMME R.Development of PCM storage for process heat and power generation[J].Journal of Solar Energy Engineering,2009,131(4).Doi:org/10.1115/1.3197834 .

doi: org/10.1115/1.3197834 |

| 25 | SHABGARD H, BERGMAN T L, SHARIFI N,et al.High temperature latent heat thermal energy storage using heat pipes[J].International Journal of Heat and Mass Transfer,2010,53(15/16):2979-2988. |

| 26 | NITHYANANDAM K, PITCHUMANI R.Analysis and optimization of a latent thermal energy storage system with embedded heat pipes[J].International Journal of Heat and Mass Transfer,2011,54(21/22):4596-4610. |

| 27 | NITHYANANDAM K, PITCHUMANI R.Design of a latent thermal energy storage system with embedded heat pipes[J].Applied Energy,2014,126:266-280. |

| 28 | JEGADHEESWARAN S, POHEKAR S D.Performance enhancement in latent heat thermal storage system:A review[J].Renewable and Sustainable Energy Reviews,2009,13(9):2225- |

| 2244. | |

| 29 | MICHELS H, PITZ-PAAL R.Cascaded latent heat storage for parabolic trough solar power plants[J].Solar Energy,2007,81(6):829-837. |

| 30 | WANG Jianfeng, CHEN Guangming, JIANG Haobo.Theoretical study on a novel phase change process[J].International Journal of Energy Research,1999,23(4):287-294. |

| 31 | WANG Jianfeng, OUYANG Yingxiu, CHEN Guangming.Experimental study on charging processes of a cylindrical heat storage capsule employing multiple⁃phase⁃change materials[J].International Journal of Energy Research,2001,25(5):439-447. |

| 32 |

O'HANLEY H, BUONGIORNO J, MCKRELL T,et al.Measurement and model validation of nanofluid specific heat capacity with differential scanning calorimetry[J].Advances in Mechanical Engineering,2012,4.Doi:10.1155/2012/181079 .

doi: 10.1155/2012/181079 |

| 33 | DUDDAB, SHIN D.Effect of nanoparticle dispersion on specific heat capacity of a binary nitrate salt eutectic for concentrated solar power applications[J].International Journal of Thermal Sciences,2013,69:37-42. |

| 34 |

VALIZADEH Z, ABBASPOUR M.Surface energy,relative stability,and structural properties of Au-Pt,Au-Rh,Au-Cu,and Au-Pd nanoclusters created in inert⁃gas condensation process using MD simulation[J].Journal of Physics and Chemistry of Solids,2020,144.Doi:10.1016/j.jpcs.2020.109480 .

doi: 10.1016/j.jpcs.2020.109480 |

| 35 |

SHIN D, BANERJEE D.Enhanced specific heat of silica nanofluid[J].Journal of Heat Transfer,2011,133(2).Doi:10.1115/1.4002600 .

doi: 10.1115/1.4002600 |

| 36 | XU Zhaomei, GE Daohan, ZHANG Liqiang.Simulation and prediction on phonon thermal conductivity of Al/Cu interface[J].Journal of Physics and Chemistry of Solids,2018,122:184-188. |

| 37 | JANG S P, CHOI S U S.Role of Brownian motion in the enhanced thermal conductivity of nanofluids[J].Applied Physics Letters,2004,84(21):4316-4318. |

| 38 | ALY K A, KHALIL N M, ALGAMAL Y,et al.Lattice strain estimation for CoAl2O4 nano particles using Williamson-Hall analysis[J].Journal of Alloys and Compounds,2016,676:606-612. |

| [1] | GUO Jianye, WANG Dong, SU Lijun, LI Wenjing. Effect of aerogel doping on thermal insulation performance of glass fiber felt [J]. Inorganic Chemicals Industry, 2023, 55(11): 53-57. |

| [2] | CHEN Mingsheng,LIU Peng,KONG Dewen,LI Yuan,YU Ke,HUANG Yansen,WU Ningbo,CHANG Juanjuan. Effect of external admixtures on mechanical and thermal conductivity of phosphogypsum composite cementitious materials [J]. Inorganic Chemicals Industry, 2022, 54(9): 113-118. |

| [3] | YAN Chen,LIU Hantao. Research progress on two-dimensional nanosheet-based composite phase change materials for thermal energy storage [J]. Inorganic Chemicals Industry, 2022, 54(2): 30-37. |

| [4] | Feng Xiaoping,Hao Xuejun. Experimental study on enhanced heat transfer performance of ternary mixed molten salts [J]. Inorganic Chemicals Industry, 2021, 53(8): 66-70. |

| [5] | Liu Yonghe,Zhang Yanyan. Effect of modification process of thermal conductive alumina on thermal conductivity of interfacial materials [J]. Inorganic Chemicals Industry, 2020, 52(9): 70-72. |

| [6] | LIU Xin-Wei, FENG Ya-Li, LI Hao-Ran. Establishment of differential equations of magnesite thermal decomposition [J]. INORGANICCHEMICALSINDUSTRY, 2011, 43(11): 15-. |

| [7] | Zhang Tao;Zeng Liang;Zhang Dong. Improvement of thermal properties of hybrid inorganic salt phase change materials by expanded graphite and graphene [J]. INORGANICCHEMICALSINDUSTRY, 2010, 0(5): 0-0. |

| [8] | Chen Yao;Feng Zhaolong;Huang Xianghua;Yu Xinwei;Zheng Wenzhi;Ren Zhijun. Progress in nano-sized silica gel-thermal insulation material [J]. INORGANICCHEMICALSINDUSTRY, 2010, 0(11): 0-0. |

| [9] | Peng Qiang;Wei Xiaolan;Ding Jing;Yang Jianping;Yang Xiaoxi. Calculation of thermal conductivity coefficient of ternary nitrate salt [J]. INORGANICCHEMICALSINDUSTRY, 2009, 0(2): 0-0. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||