| [1] |

LIU Kailong, ZHU Kongyi, GUO Chunlei, MA Xiaobiao, WANG Yujian, SHENG Qiang, LI Xiang, WANG Yinbin, JIN Fengying.

Effects of process condition on performance of diesel aromatic to light aromatic

[J]. Inorganic Chemicals Industry, 2024, 56(6): 139-146.

|

| [2] |

ZHAO Chuang, CHEN Zihao, ZHANG Boyu, LI Ben, JIN Fengying, LI Bin, SUN Zhenhai, GUO Chunlei.

Study on adsorption and separation performance of molecular sieve adsorbents for different types of diesel

[J]. Inorganic Chemicals Industry, 2024, 56(3): 80-85.

|

| [3] |

MA Zhiyuan, LÜ Dawei, WANG Hui, JIN Nannan, ZHU Jinjian, ZHANG Jingcheng.

Industrial application of THDS-2/3 catalyst in capacity expansion of hydrofining plant

[J]. Inorganic Chemicals Industry, 2023, 55(8): 140-144.

|

| [4] |

Wang Chaoqiang,Yu Fei,Chang Shiying,Lai Huilong,Ma Jiangli,Yang Dongxia,Zhang Zhongchun.

Research status and prospects of diesel SCRF catalysts

[J]. Inorganic Chemicals Industry, 2021, 53(2): 5-10.

|

| [5] |

ZHAO Chuang,GUO Chunlei,LI Ben,LI Bin.

Comparative study on decolorization and nitrogen removal of diesel oil by porous materials

[J]. Inorganic Chemicals Industry, 2021, 53(11): 129-132.

|

| [6] |

Han Longnian,Yang Jie,Xin Jing,Chen Yufei,Wei Linlin.

Analysis of scale sample of high pressure heat exchanger in diesel hydrocracking unit and suggestion for unit

[J]. Inorganic Chemicals Industry, 2021, 53(1): 91-96.

|

| [7] |

Xiao Han,Nan Jun,Yang Tao,Song Guoliang,Zeng Huan,Zhang Jingcheng,Zhu Jinjian,Zhang Guohui.

Experimental study on coker light gas oil hydrocracking by blending hydrogenated diesel

[J]. Inorganic Chemicals Industry, 2020, 52(7): 94-98.

|

| [8] |

Huang Zhenxu,Chen Lingxia,Ren Li,Li Yingxin,Jia Panpan,Zhang Wenhui.

Study on Na2SiO3/ZrO2 solid base-catalyzed transesterification of soybean oil to biodiesel

[J]. Inorganic Chemicals Industry, 2020, 52(6): 83-86.

|

| [9] |

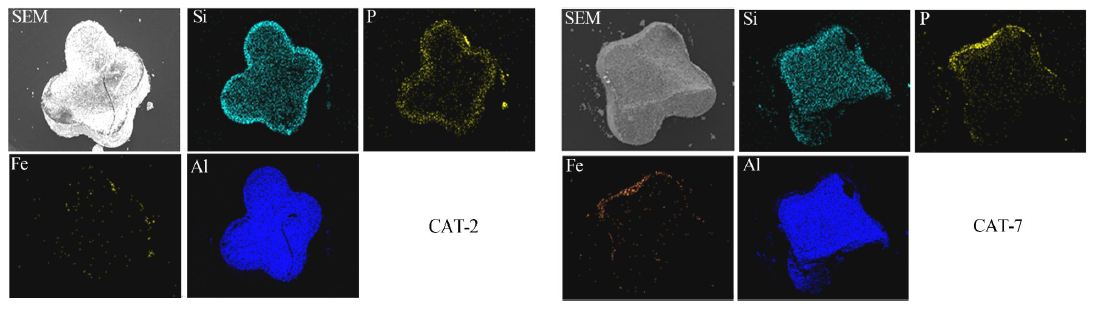

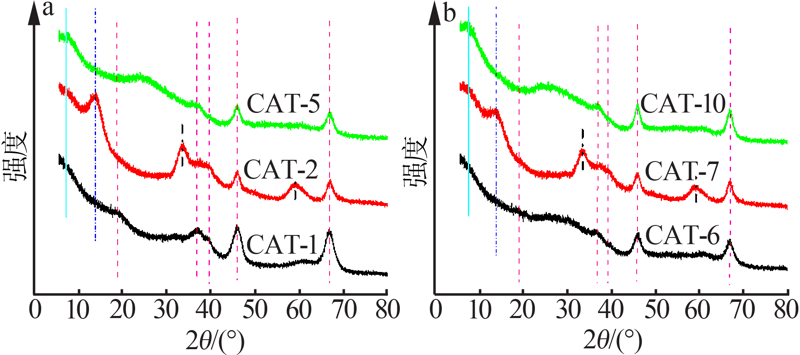

Han Longnian,Xin Jing,Zhang Ping,Chen Yufei,Fan Wenxuan,Wei Linlin.

Analysis of impurity deposition on guard catalyst for diesel hydrocracking device

[J]. Inorganic Chemicals Industry, 2020, 52(12): 113-117.

|

| [10] |

Wei Yuewen,Zhang Dandan,Qi Bangfeng.

Determination of Ni, Mo, W and P in hydrofining catalysts by X-ray fluorescence spectrometry

[J]. Inorganic Chemicals Industry, 2020, 52(11): 91-94.

|

| [11] |

Nan Jun,Yu Qun,Yu Haibin,Zhang Jingcheng,Xiao Han,Zhu Jinjian,Li Xiaoyun.

Study on a new production process of pseudo-boehmite and its application in hydrofining catalysts

[J]. Inorganic Chemicals Industry, 2019, 51(6): 80-82.

|

| [12] |

Hu Zhen;Zhang Li;Yu Hailian.

Study on removing of basic nitrogen compounds from diesel oil with complexant ferric trichloride

[J]. INORGANICCHEMICALSINDUSTRY, 2010, 0(1): 0-0.

|

),Xin Jing,Wei Linlin,Fan Wenxuan,Zhang Ping,Chen Yufei

),Xin Jing,Wei Linlin,Fan Wenxuan,Zhang Ping,Chen Yufei