| [1] |

申军.我国芒硝矿产资源及其加工业的现状与发展[J].化工矿物与加工,2003,32(2):1-4.

|

|

SHEN Jun.Status of mirabilite resources and prospect of its processing industry[J].Industrial Minerals and Porocessing,2003,32(2):1-4.

|

| [2] |

陈敏.青海省芒硝资源开发利用现状及前景[J].无机盐工业,2010,42(9):4-5,22.

|

|

CHEN Min.Present status and prospect of development and utilization of mirabilite resources in Qinghai[J].Inorganic Chemicals Industry,2010,42(9):4-5,22.

|

| [3] |

李代荣.中国芒硝矿特征与成因简介[J].矿产勘查,2020,11(3):511-516.

|

|

LI Dairong.Introduction to characteristics and genesis of mirabilite deposits in China[J].Mineral Exploration,2020,11(3):511-516.

|

| [4] |

赵宏旭,刘磊.硝盐联产技术在元明粉生产中的应用[J].化工设计通讯,2020,46(9):52-53.

|

|

ZHAO Hongxu, LIU Lei.Application of nitrate combined production technology in the production process of yuanmingfen[J].Che-mical Engineering Design Communications,2020,46(9):52-53.

|

| [5] |

戎宽伟,徐素国.钙芒硝矿溶浸开采技术进展与展望[J].矿业研究与开发,2014,34(3):1-3,81.

|

|

RONG Kuanwei, XU Suguo.Progress and prospects for solution mining of glauberite[J].Mining Research and Development,2014,34(3):1-3,81.

|

| [6] |

张秀峰,谭秀民,张利珍.钙芒硝矿石的水浸工艺研究[J].矿产保护与利用,2017,37(4):69-72.

|

|

ZHANG Xiufeng, TAN Xiumin, ZHANG Lizhen.Research on water leaching process of glauberite ore[J].Conservation and Utilization of Mineral Resources,2017,37(4):69-72.

|

| [7] |

杨大涌,周堃.钙芒硝尾矿的综合利用[J].化工矿物与加工,2020,49(12):53-56.

|

|

YANG Dayong, ZHOU Kun.Comprehensive utilization of glauberite tailings[J].Industrial Minerals & Processing,2020,49(12):53-56.

|

| [8] |

JIANG Zheyuan, SUN Xinpo, LUO Yaqiong,et al.Recycling,reusing and environmental safety of industrial by-product gypsum in construction and building materials[J].Construction and Building Materials,2024,432:136609.

|

| [9] |

刘林程,左海滨,许志强.工业石膏的资源化利用途径与展望[J].无机盐工业,2021,53(10):1-9.

|

|

LIU Lincheng, ZUO Haibin, XU Zhiqiang.Resource utilization approach of industrial gypsum and its prospect[J].Inorganic Chemicals Industry,2021,53(10):1-9.

|

| [10] |

彭诗谷,李伟,石晴,等.一种高效的芒硝石膏浮选提纯工艺:中国,113289768A[P].2021-08-24.

|

| [11] |

谭明洋,黄平,张营,等.旋流器在磷石膏预处理中的应用研究[J].磷肥与复肥,2018,33(11):42-43.

|

|

TAN Mingyang, HUANG Ping, ZHANG Ying,et al.Application research of hydrocyclone in pretreatment of phosphogypsum[J].Phosphate & Compound Fertilizer,2018,33(11):42-43.

|

| [12] |

赵红涛,包炜军,孙振华,等.磷石膏中杂质深度脱除技术[J].化工进展,2017,36(4):1240-1246.

|

|

ZHAO Hongtao, BAO Weijun, SUN Zhenhua,et al.Deep removal of impurities from phosphogypsum[J].Chemical Industry and Engineering Progress,2017,36(4):1240-1246.

|

| [13] |

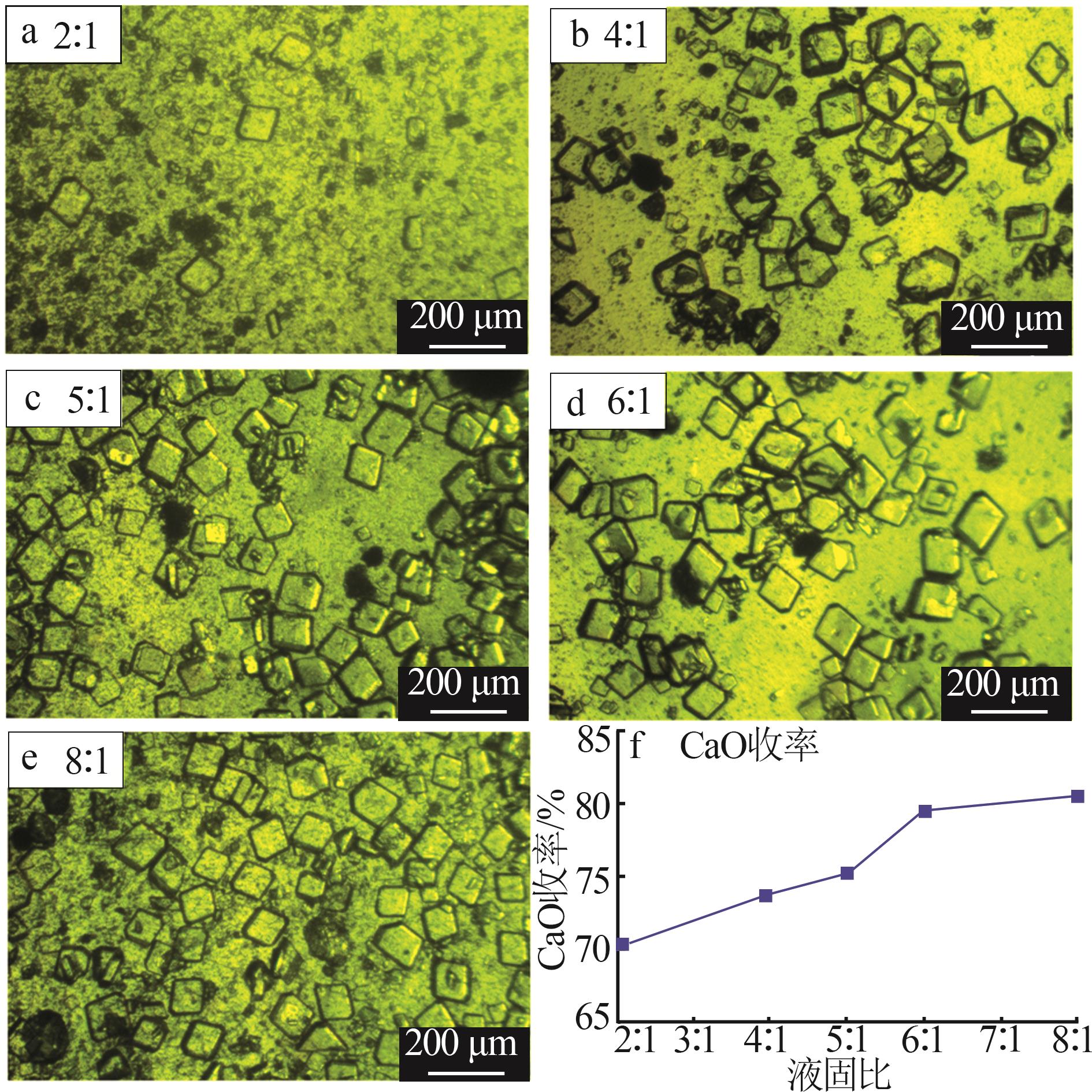

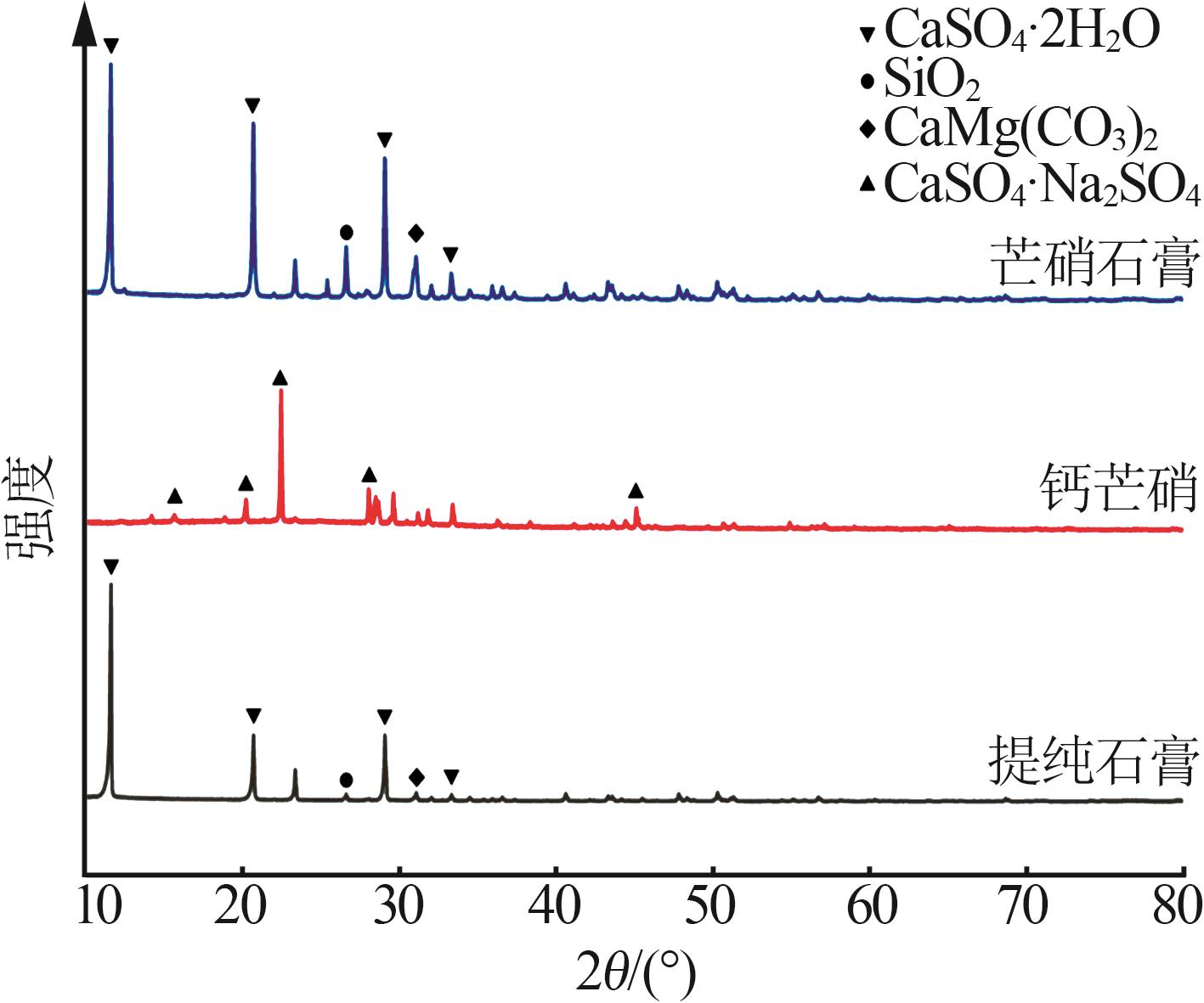

尹会斌,李军,郑卓超.钙芒硝石膏深度提纯工艺的研究[J].无机盐工业,2022,54(11):104-111.

|

|

YIN Huibin, LI Jun, ZHENG Zhuochao.Research on deep purification process of glauberite gypsum[J].Inorganic Chemicals Industry,2022,54(11):104-111.

|

| [14] |

曹涌钢,张子龙,李泽皓,等.工业副产石膏制备α型半水石膏的研究进展[J].化工进展,2025,44(3):1505-1519.

|

|

CAO Yonggang, ZHANG Zilong, LI Zehao,et al.Research progress on preparation of α-hemihydrate gypsum from industrial by-product gypsum[J].Chemical Industry and Engineering Progress,2025,44(3):1505-1519.

|

| [15] |

秦颖,刘新庄,桑海风.工业副产石膏在建材领域的资源化利用现状及展望[J].中国建材科技,2023,32(5):23-25.

|

|

QIN Ying, LIU Xinzhuang, SANG Haifeng.Current situation and prospect of resource utilization of industrial by-product gypsum in the field of building materials[J].China Building Materials Science & Technology,2023,32(5):23-25.

|

| [16] |

POPOVIĆ D, STUPAR G, MILADINOVIĆ J,et al.Solubility in the ternary system CaSO4+Na2SO4+H2O at 298.15 K[J].Russian Journal of Physical Chemistry A,2011,85(13):2349-2353.

|

), ZHENG Zhuochao, LI Jun(

), ZHENG Zhuochao, LI Jun( )

)