Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (7): 118-125.doi: 10.19964/j.issn.1006-4990.2023-0556

• Environment·Health·Safety • Previous Articles Next Articles

Eco⁃friendly extraction of chromium from calcium⁃free roasting slag of chromite ore

JIAN Chengzong( ), JIANG Ziwen, QUAN Xuejun(

), JIANG Ziwen, QUAN Xuejun( ), LI Gang(

), LI Gang( )

)

- School of Chemistry and Chemical Engineering,Chongqing University of Technology,Chongqing 400054,China

-

Received:2023-11-22Online:2024-07-10Published:2024-08-01 -

Contact:QUAN Xuejun, LI Gang E-mail:chengzjian@163.com;hengjunq@cqut.edu.cn;47922138@163.com

CLC Number:

Cite this article

JIAN Chengzong, JIANG Ziwen, QUAN Xuejun, LI Gang. Eco⁃friendly extraction of chromium from calcium⁃free roasting slag of chromite ore[J]. Inorganic Chemicals Industry, 2024, 56(7): 118-125.

share this article

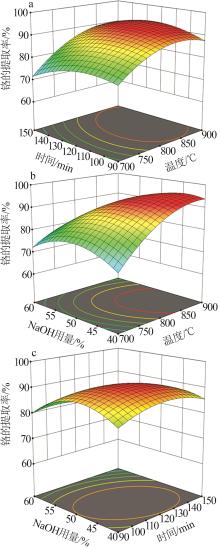

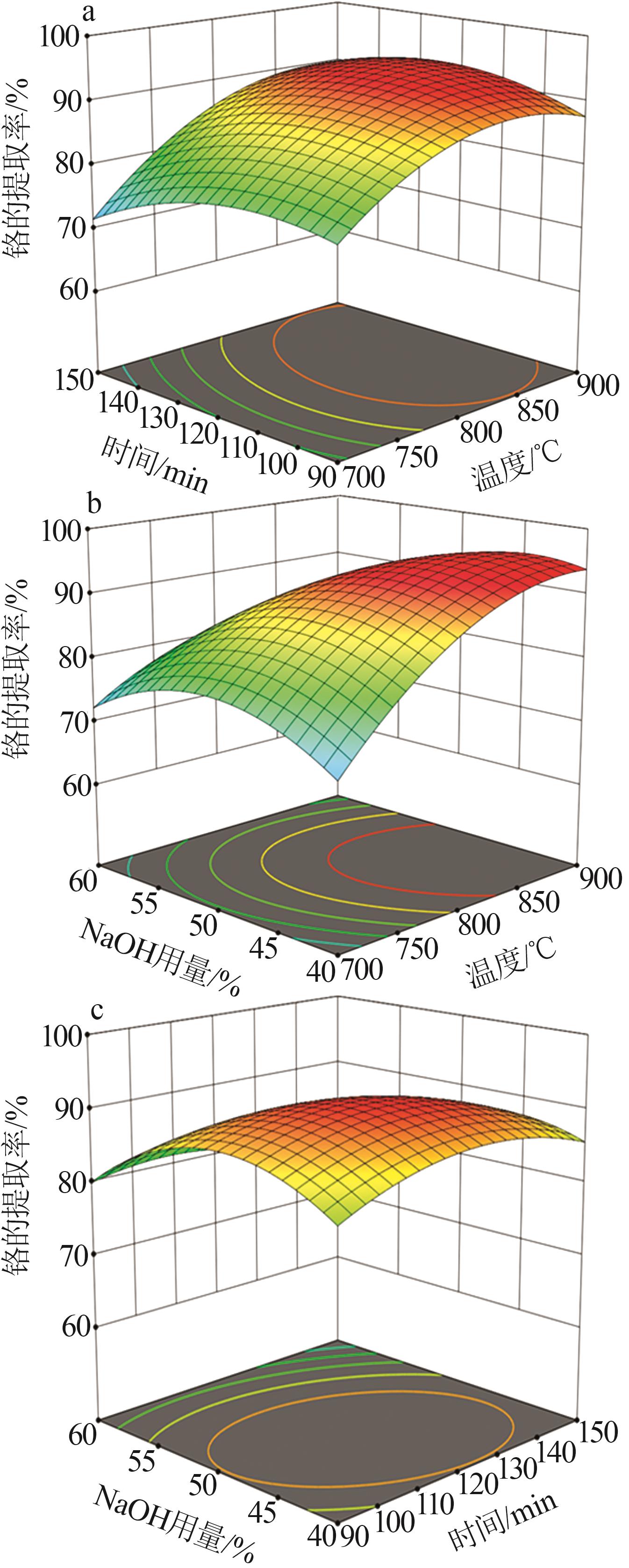

Table 3

Variance analysis of chromium extraction yield model"

| 来源 | 平方和 | 自由度 | 均方差 | F值 | P值 |

|---|---|---|---|---|---|

| 模型 | 1 088.93 | 9 | 120.99 | 9.52 | 0.003 6 |

| A | 378.13 | 1 | 378.13 | 29.76 | 0.001 0 |

| B | 10.12 | 1 | 10.12 | 0.80 | 0.401 7 |

| C | 128.00 | 1 | 128.00 | 10.07 | 0.015 6 |

| AB | 16.00 | 1 | 16.00 | 1.26 | 0.298 8 |

| AC | 72.25 | 1 | 72.25 | 5.69 | 0.048 6 |

| BC | 20.25 | 1 | 20.25 | 1.59 | 0.247 2 |

| A2 | 154.12 | 1 | 154.12 | 12.13 | 0.010 2 |

| B2 | 69.06 | 1 | 69.06 | 5.43 | 0.052 5 |

| C2 | 194.69 | 1 | 194.69 | 15.32 | 0.005 8 |

| 残差 | 88.95 | 7 | 12.71 | ||

| 失拟值 | 83.75 | 3 | 27.92 | 21.47 | 0.006 3 |

| 纯误差 | 5.20 | 4 | 1.30 | ||

| 总离差 | 1 177.88 | 16 |

| 1 | GU Foquan, ZHANG Yuanbo, SU Zijian,et al.Recovery of chromium from chromium⁃bearing slags produced in the stainless⁃steel smelting:A review[J].Journal of Cleaner Production,2021,296(2):126467. |

| 2 | LI Ming, XIAO Liang, LIU Jingjing,et al.Effective extraction of vanadium and chromium from high chromium content vanadium slag by sodium roasting and water leaching[J].Materials Science Forum,2016,863:144-148. |

| 3 | 庆朋辉,张红玲,石义朗,等.添加剂对铬铁矿氧化焙烧过程的影响[J].无机盐工业,2019,51(12):26-29. |

| QING Penghui, ZHANG Hongling, SHI Yilang,et al.Effect of additive on oxidative roasting process of chromite[J].Inorganic Che⁃Industry micals,2019,51(12):26-29. | |

| 4 | 兰嗣国,殷惠民,狄一安,等.浅谈铬渣解毒技术[J].环境科学研究,1998,11(3):53-56. |

| LAN Siguo, YIN Huimin, DI Yian,et al.Detoxication techniques for chromium slag[J].Research of Environmental Sciences,1998,11(3):53-56. | |

| 5 | 蔡焕兴,梁金利,段雪梅,等.铬渣污染场地修复技术研究进展[J].环境监控与预警,2012,4(5):48-50. |

| CAI Huanxing, LIANG Jinli, DUAN Xuemei,et al.Research progress on remediation technology of chrome contaminated site[J].Environmental Monitoring and Forewarning,2012,4(5):48-50. | |

| 6 | 杜良,王金生.铬渣毒性对环境的影响与产出量分析[J].安全与环境学报,2004,4(2):34-37. |

| DU Liang, WANG Jinsheng.Environmental impact of chromic slag and analysis of chromic slag′s output[J].Journal of Safety and Environment,2004,4(2):34-37. | |

| 7 | MATERN K, WEIGAND H, SINGH A,et al.Environmental status of groundwater affected by chromite ore processing residue (COPR) dumpsites during pre⁃monsoon and monsoon seasons[J].Environmental Science and Pollution Research International,2017,24(4):3582-3592. |

| 8 | 胡晓娇,白艳萍,张生萍,等.危险废物铬渣和碱渣联合处置技术应用[J].广东化工,2019,46(9):187-188. |

| HU Xiaojiao, BAI Yanping, ZHANG Shengping,et al.Application of combined disposal technology of chromium residue and alkali residue of hazardous waste[J].Guangdong Chemical Industry,2019,46(9):187-188. | |

| 9 | 毛汉云,金学坤.铬渣工业化治理及综合利用技术进展[J].辽宁化工,2014,43(7):878-879,882. |

| MAO Hanyun, JIN Xuekun.Industrial treatment and comprehensive utilization of chromium slag[J].Liaoning Chemical Industry,2014,43(7):878-879,882. | |

| 10 | 王兴润,李丽,刘雪,等.铬渣治理技术的应用进展及特点分析[J].中国给水排水,2009,25(4):10-14. |

| WANG Xingrun, LI Li, LIU Xue,et al.Application developments and characteristics analysis of treatment technologies of chromium residues[J].China Water & Wastewater,2009,25(4):10-14. | |

| 11 | 蒋子文,全学军,李纲,等.铬渣资源化利用研究进展[J].无机盐工业,2023,55(2):26-35. |

| JIANG Ziwen, QUAN Xuejun, LI Gang,et al.Research progress of resource utilization of chromium slag[J].Inorganic Chemicals Industry,2023,55(2):26-35. | |

| 12 | PANKAJ K, KUMAR P S, KUMAR T S,et al.Efficient utilization of nickel rich chromite ore processing tailings by carbothermic smelting[J].Journal of Cleaner Production,2021,315:128046. |

| 13 | ZHAO Qingjie, LIU Chengjun, LI Baokuan,et al.Recovery of chromium from residue of sulfuric acid leaching of chromite[J].Process Safety and Environmental Protection,2018,113:78-87. |

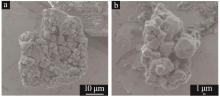

| 14 | 吴俊,程雯,全学军,等.铬铁矿无钙焙烧渣的酸浸解毒及浸出行为[J].无机盐工业,2019,51(7):64-67. |

| WU Jun, CHENG Wen, QUAN Xuejun,et al.Acid leaching detoxification and leaching behavior of chromite ore processing residue[J].Inorganic Chemicals Industry,2019,51(7):64-67. | |

| 15 | PENG Hao, GUO Jing, LV Liping,et al.Recovery of chromium by calcium⁃roasting,sodium⁃roasting,acidic leaching,alkaline leaching and sub⁃molten technology:A review[J].Environmental Chemistry Letters,2021,19(2):1383-1393. |

| 16 | 孙红艳,曹婧,温婧,等.钒渣钙化焙烧过程的富氧强化研究[J].材料与冶金学报,2020,19(3):170-175,184. |

| SUN Hongyan, CAO Jing, WEN Jing,et al.Study of oxygen enriched strengthening from vanadium slag with calcified roast⁃ing[J].Journal of Materials and Metallurgy,2020,19(3):170-175,184. | |

| 17 | CHENG Jie, LI Hongyi, CHEN Xinmian,et al.Eco⁃friendly chromium recovery from hazardous chromium⁃containing vanadium extraction tailings via low⁃dosage roasting[J].Process Safety and Environmental Protection,2022,164:818-826. |

| 18 | YU Kaiping, ZHANG Hongling, CHEN Bo,et al.Investigation of reaction mechanism on the lime⁃free roasting of chromium⁃containing slag[J].Metallurgical and Materials Transactions B,2015,46(6):2553-2563. |

| 19 | 付自碧,蒋霖,李明,等.钒铬渣钠化焙烧同步提取钒和铬[J].钢铁钒钛,2020,41(4):1-6. |

| FU Zibi, JIANG Lin, LI Ming,et al.Simultaneous extraction of vanadium and chromium from vanadium⁃chromium slag by sodium roasting[J].Iron Steel Vanadium Titanium,2020,41(4):1-6. | |

| 20 | CHECA-GARCIA R, SHINE K P, HEGGLIN M I.The contribution of greenhouse gases to the recent slowdown in global⁃mean temperature trends[J].Environmental Research Letters,2016,11(9):94018. |

| 21 | PRASAD S, KUMAR M, RANDHAWA N S.Processing of chromite overburden by soda roasting to recover chromium as sodium chromate[J].Transactions of the Indian Institute of Metals,2021,74(9):2221-2230. |

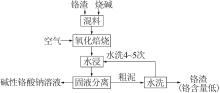

| 22 | 庆朋辉,董玉明,王兴润,等.铬铁矿无钙焙烧铬渣的深度提铬与无害化处理[J].无机盐工业,2020,52(6):63-67,104. |

| QING Penghui, DONG Yuming, WANG Xingrun,et al.Chromium extraction and detoxification of processing residue from lime⁃free roasting process of chromite ore[J].Inorganic Chemicals Industry,2020,52(6):63-67,104. | |

| 23 | 张洋,郑诗礼,王晓辉,等.ICP-AES法对铬铁矿中的多种元素进行定性与定量分析[J].光谱学与光谱分析,2010,30(1):251-254. |

| ZHANG Yang, ZHENG Shili, WANG Xiaohui,et al.Qualitative and quantitative analysis of various elements in chromite ore by ICP-AES[J].Spectroscopy and Spectral Analysis,2010,30(1):251-254. | |

| 24 | 齐天贵.铬铁矿强氧化焙烧理论与技术研究[D].长沙:中南大学,2012. |

| QI Tiangui.Theory and technonlogy for intensified oxidative roasting of chromite ore[D].Changsha:Central South University,2012. | |

| 25 | QI Tiangui, LI Yaomin, WANG Peng,et al.Effect of sodium aluminate on chromium spinels oxidation in chromite lime⁃free roast⁃ing process[J].Transactions of Nonferrous Metals Society of China,2023,33(8):2497-2510. |

| 26 | 陈永安.铬铁矿焙烧后期复杂物相中铬氧化机理研究[D].北京:北京有色金属研究总院,2015. |

| CHEN Yongan.Chromium oxidation mechanism of complex phase during the late stages of the chromite roasting process[D].Beijing:General Research Institute for Nonferrous Metals,2015. | |

| 27 | 陈永安,王武育,李平,等.铬铁矿焙烧后期铬再氧化机理[J].中国有色金属学报,2015,25(1):203-210. |

| CHEN Yongan, WANG Wuyu, LI Ping,et al.Re⁃oxidation mechanism of chromite roasting in late stages[J].The Chinese Journal of Nonferrous Metals,2015,25(1):203-210. | |

| 28 | LI Y, NI H, ZHOU Y,et al.Kinetic study of titanium⁃bearing electric arc furnace molten slag treated by molten sodium hydroxide[J].Minerals & Metallurgical Processing,2017,34(1):44- 52. |

| 29 | 赵昌明,翟玉春,刘岩,等.红土镍矿在NaOH亚熔盐体系中的预脱硅[J].中国有色金属学报,2009,19(5):949-954. |

| ZHAO Changming, ZHAI Yuchun, LIU Yan,et al.Pre⁃desilication of laterite in NaOH sub⁃molten salt system[J].The Chinese Journal of Nonferrous Metals,2009,19(5):949-954. | |

| 30 | 唐景春,丁立强,殷红,等.铬渣制砖的毒性浸出及评价[J].工业安全与环保,2001,27(8):33-34. |

| TANG Jingchun, DING Liqiang, YIN Hong,et al.Assessment and toxicity extraction on brickmaking from chrome slags[J].Industrial Safety and Environmental Protection,2001,27(8):33- 34. |

| [1] | Qing Penghui,Dong Yuming,Wang Xingrun,Zhu Kaisheng,Niu Renjie,Meng Jingjuan,Chen Xiaohong,Chen Huixia,Zhang Hongling,Xu Hongbin. Chromium extraction and detoxification of processing residue from lime-free roasting process of chromite ore [J]. Inorganic Chemicals Industry, 2020, 52(6): 63-67. |

| [2] | Qin Xianfeng,Quan Xuejun,Ye Peng,Feng Chengfei,Li Gang. Research progress of process intensification of acid leaching technology from chromite ore and separation of chromium-iron [J]. Inorganic Chemicals Industry, 2020, 52(6): 13-19. |

| [3] | Wu Jun,Cheng Wen,Quan Xuejun,Wu Haifeng,Li Gang,Luo Huazheng. Acid leaching detoxification and leaching behavior of chromite ore processing residue [J]. Inorganic Chemicals Industry, 2019, 51(7): 64-67. |

| [4] | JIANG Chun-Li, SONG Hong-Jun, HAN Biao, ZHAO Wei, DONG Li-Chun, HUANG Shi-You, WEN Feng-Yu. Production process of extraction chromium from chromite with sub-molten sodium hydroxide [J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(7): 39-. |

| [5] | ZHOU Guang-Zhu, ZHOU Jing, LIU Yi-Zhang, LIU Kai-Kai. Mineralogical properties and significance of hydro-based detoxication of chromite ore processing residue [J]. INORGANICCHEMICALSINDUSTRY, 2013, 45(4): 5-. |

| [6] | WANG Tian-Gui, LI Qiang, QIN Li-Ling, 吕Shu-Ling . Evaluation of methods for determination of hexavalent chromium contained in chromite ore processing residue [J]. INORGANICCHEMICALSINDUSTRY, 2012, 44(4): 1-. |

| [7] | QIN Li-Ling, LI Qiang, WANG Tian-Gui. Comparison of hexavalent chromium leaching efficacy of different methods from chromite ore processing residue [J]. INORGANICCHEMICALSINDUSTRY, 2012, 44(2): 51-. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||