Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (5): 87-93.doi: 10.19964/j.issn.1006-4990.2023-0391

• Research & Development • Previous Articles Next Articles

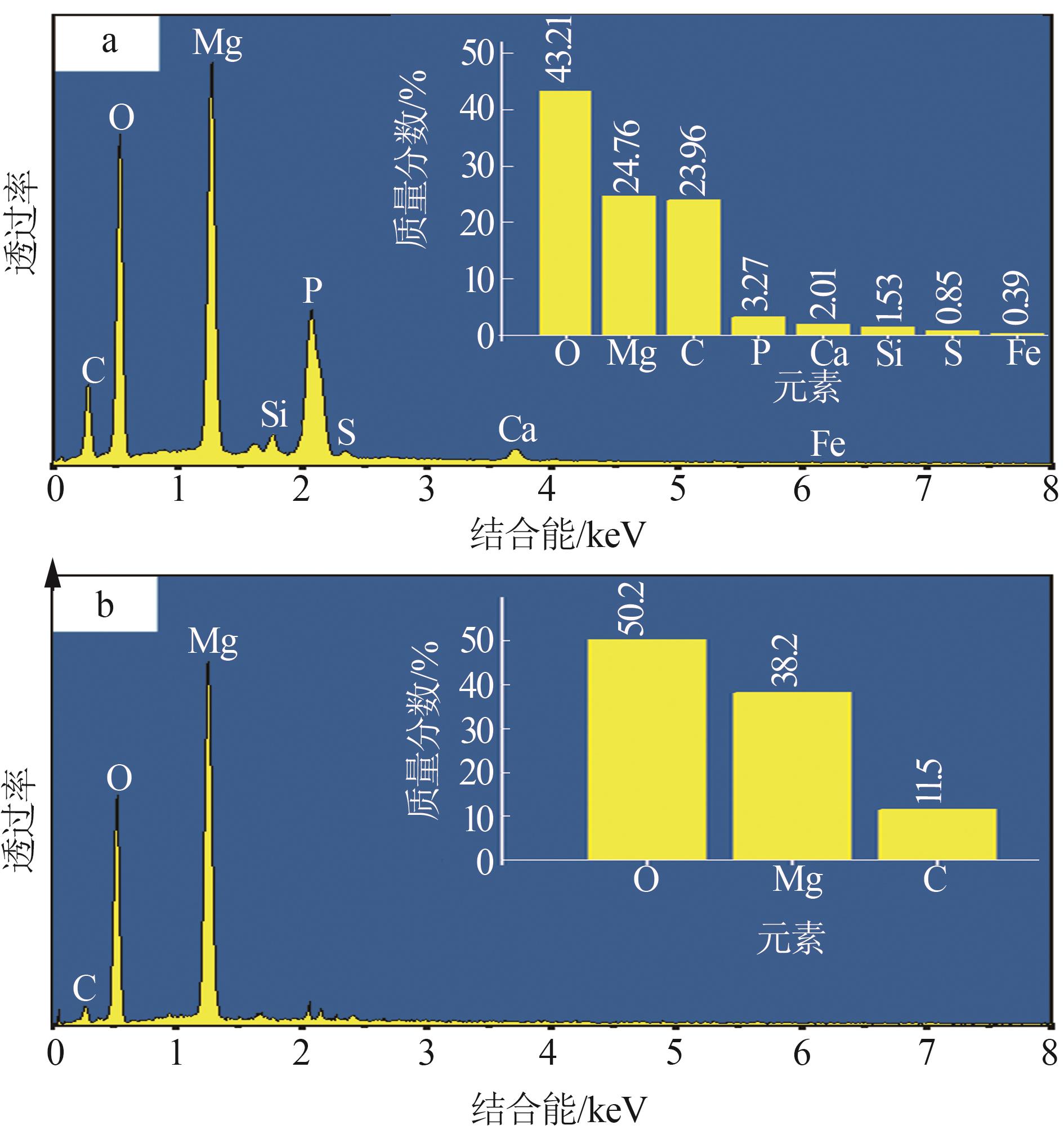

Study on preparation of magnesium hydroxide from calcium magnesium nitrate leaching pretreatment of phosphate rock with high content of magnesium and calcium

- School of Chemical Engineering,Sichuan University,Chengdu 610065,China

-

Received:2023-07-27Online:2024-05-10Published:2024-05-15 -

Contact:TANG Shengwei E-mail:1990791315@qq.com;tangdynasty@scu.edu.cn

CLC Number:

Cite this article

TANG Biao, TANG Shengwei. Study on preparation of magnesium hydroxide from calcium magnesium nitrate leaching pretreatment of phosphate rock with high content of magnesium and calcium[J]. Inorganic Chemicals Industry, 2024, 56(5): 87-93.

share this article

Table 2

Precipitation pH value of each saturated solid phase"

| 矿物总类 | lg IPA (pH=8.3) | 饱和指数 (pH=8.3) | 饱和指数=0 时的pH |

|---|---|---|---|

| 氢氧化镁 | 14.915 | -2.185 | 8.85 |

| Ca3(PO4)2(am1) | -20.471 | 5.029 | 5.15 |

| Ca3(PO4)2(am2) | -20.471 | 7.779 | 5.15 |

| Ca3(PO4)2(beta) | -20.471 | 8.449 | 5.10 |

| Ca4H(PO4)3∙3H2O(s) | -38.197 | 9.753 | 4.95 |

| CaHPO4(s) | -17.704 | 1.571 | 4.50 |

| CaHPO4∙2H2O(s) | -17.719 | 1.276 | 4.70 |

| 萤石 | -8.058 | 2.442 | 1.25 |

| 羟基磷灰石 | -23.245 | 21.088 | 4.30 |

| Mg(OH)2(active) | 14.915 | -3.879 | 10.10 |

| Mg3(PO4)2(s) | -20.493 | 2.787 | 6.65 |

| MgF2(s) | -8.065 | 0.045 | 6.80 |

| MgHPO4∙3H2O(s) | -17.733 | 0.442 | 5.55 |

| 羟钙石 | 14.922 | -7.782 | 11.95 |

| 鸟粪石 | -10.416 | 2.844 | 5.75 |

Table 2

| 1 | LIU Qiang, LIU Weizao, Li LÜ,et al.Study on reactions of gaseous P2O5 with Ca3(PO4)2 and SiO2 during a rotary kiln process for phosphoric acid production[J].Chinese Journal of Chemical Engineering,2018,26(4):795-805. |

| 2 | CHEN Fang, WANG Xiaomei, LIU Weizao,et al.Selective extraction of nitric and acetic acids from etching waste acid using N235 and MIBK mixtures[J].Separation and Purification Technology,2016,169:50-58. |

| 3 | ABDEL-GHAFAR H M, ABDEL-AAL E A, IBRAHIM M A M,et al.Purification of high iron wet-process phosphoric acid via oxalate precipitation method[J].Hydrometallurgy,2019,184:1-8. |

| 4 | BECKER P.Phosphates and phosphoric acid:Raw materials,technology,and economics of the wet process(Second edition)[M].CRC Press,1989. |

| 5 | ZHANG P.Comprehensive recovery and sustainable development of phosphate resources[J].Procedia Engineering,2014,83:37-51. |

| 6 | LI Hongqiang, GE Wu, ZHANG Jun,et al.Control foaming performance of phosphate rocks used for wet-process of phosphoric acid production by phosphoric acid[J].Hydrometallurgy,2020,195:105364. |

| 7 | SILVA L F O, OLIVEIRA M L S, CRISSIEN T J,et al.A review on the environmental impact of phosphogypsum and potential health impacts through the release of nanoparticles[J].Chemosphere,2022,286:131513. |

| 8 | TAYIBI H, CHOURA M, LÓPEZ F A,et al.Environmental impact and management of phosphogypsum[J].Journal of Environmental Management,2009,90(8):2377-2386. |

| 9 | 何宾宾,魏立军,谢德龙,等.中国湿法磷加工产业现状与可持续发展[J].无机盐工业,2020,52(1):1-4,16. |

| HE Binbin, WEI Lijun, XIE Delong,et al.Current situation and sustainable development of wet process phosphorus processing industry in China[J].Inorganic Chemicals Industry,2020,52(1):1-4,16. | |

| 10 | LV Li, ZHENG Dongyao, TANG Shengwei,et al.Phosphate ore particles dissolution kinetics in hydrochloric acid based on a structure-related segmented model[J].Powder Technology,2021,392:141-149. |

| 11 | 方进,李菊,孟品品,等.冷冻法硝酸磷肥副产粗硝钙液用于磷矿脱镁的研究[J].无机盐工业,2021,53(6):180-184. |

| FANG Jin, LI Ju, MENG Pinpin,et al.Study on by-product crude calcium nitrate solution of frozen nitrophosphate fertilizer for phosphate rock demagnesium[J].Inorganic Chemicals Industry,2021,53(6):180-184. | |

| 12 | 殷灵,李军,唐湘.硝酸磷肥生产新工艺研究[J].无机盐工业,2014,46(12):50-53. |

| YIN Ling, LI Jun, TANG Xiang.Study on new production technology of nitrophosphate fertilizer[J].Inorganic Chemicals Industry,2014,46(12):50-53. | |

| 13 | WU Junhu, XU Dehua, YANG Xiushan,et al.Determination and correlation of vapor-liquid equilibria for the nitric acid+water,nitric acid+water+phosphoric acid,and nitric acid+water+phosphoric acid+sulfuric acid system[J].Journal of Chemical & Engineering Data,2023,68(3):633-641. |

| 14 | 向伟,王勃,应建康.硫酸铵法硝酸磷肥生产高品质硫酸钙工艺研究[J].无机盐工业,2013,45(1):17-20. |

| XIANG Wei, WANG Bo, YING Jiankang.Study on producing process of high-quality calcium sulfate from nitric phosphate by ammonium sulfate method[J].Inorganic Chemicals Industry,2013,45(1):17-20. | |

| 15 | 李晓妍,刘佳,钟永恒,等.青海镁产业专利导航发展分析[J].无机盐工业,2021,53(5):26-32. |

| LI Xiaoyan, LIU Jia, ZHONG Yongheng,et al.Analysis on patent navigation development of Qinghai magnesium industry[J].Inorganic Chemicals Industry,2021,53(5):26-32. | |

| 16 | CHEN Zhan, ZHANG Weijun, WANG Dongsheng,et al.Enhancement of activated sludge dewatering performance by combined composite enzymatic lysis and chemical re-flocculation with inorganic coagulants:Kinetics of enzymatic reaction and re-flocculation morphology[J].Water Research,2015,83:367-376. |

| 17 | MANTILAKA M M M G P G, PITAWALA H M T G A, KARUNARATNE D G G P,et al.Nanocrystalline magnesium oxide from dolomite via poly(acrylate) stabilized magnesium hydroxide colloids[J].Colloids and Surfaces A:Physicochemical and Engineering Aspects,2014,443:201-208. |

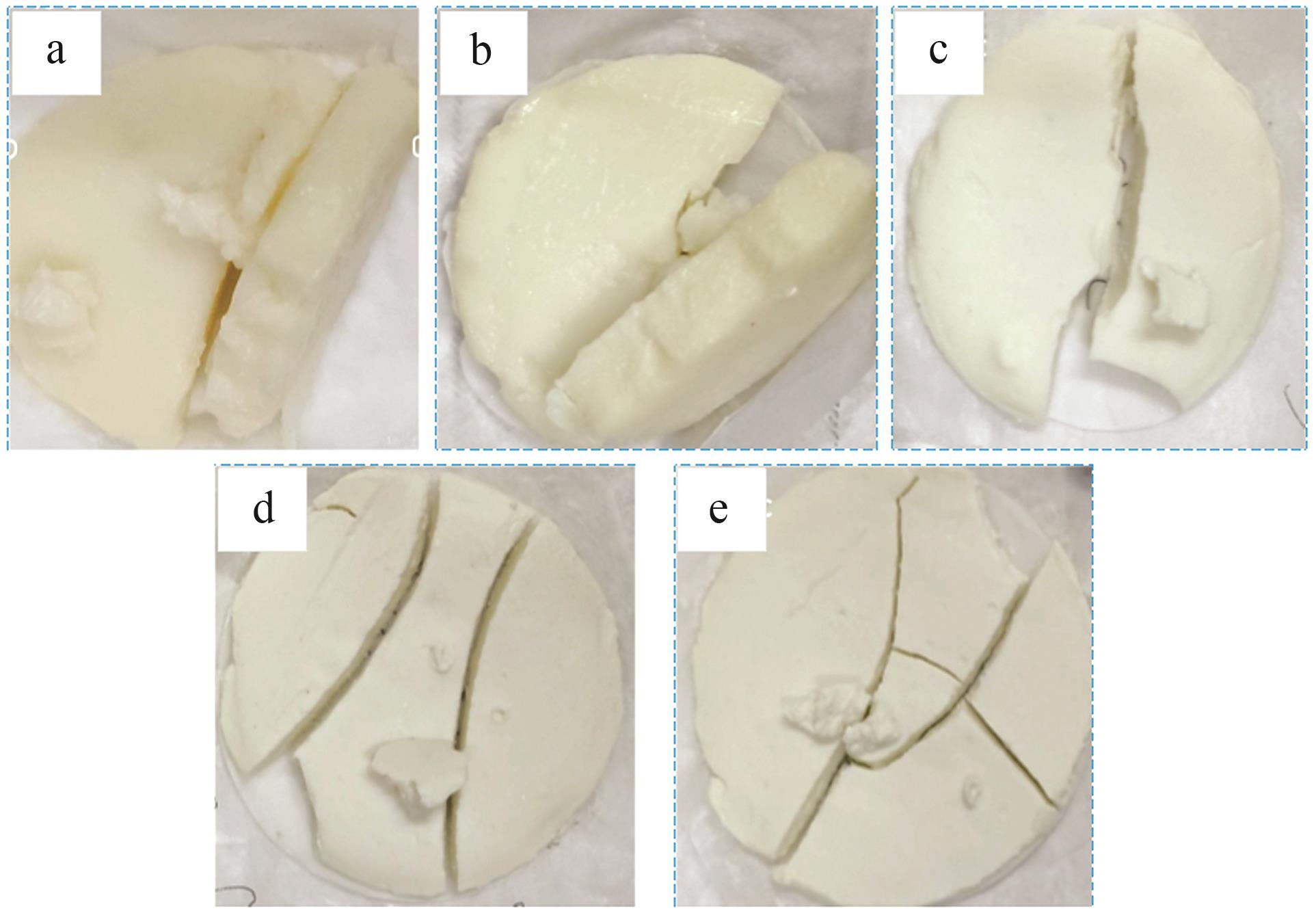

| 18 | 申红艳,刘有智,白俊红.改善氢氧化镁过滤性能的实验研究[J].无机盐工业,2014,46(8):33-36. |

| SHEN Hongyan, LIU Youzhi, BAI Junhong.Study on improvement of magnesium hydroxide filtration performance[J].Inorganic Chemicals Industry,2014,46(8):33-36. | |

| 19 | BATES R G, PINCHING G D.Dissociation constant of aqueous ammonia at 0 to 50° from E.m.f. studies of the ammonium salt of a weak acid[J].Journal of the American Chemical Society,1950,72(3):1393-1396. |

| 20 | LOCKWOOD A P G, PEAKALL J, WARREN N J,et al.Structure and sedimentation characterisation of sheared Mg(OH)2 suspensions flocculated with anionic polymers[J].Chemical Engineering Science,2021,231:116274. |

| 21 | AGERAEK M L, KEIDING K.On the origin of specific resistance to filtration[J].Water Science and Technology,1993,28(1):159-168. |

| 22 | BAI Shaojun, YU Pan, DING Zhang,et al.New insights into lead ions activation for microfine particle ilmenite flotation in sulfuric acid system:Visual MINTEQ models,XPS,and TOF-SIMS studies[J].Minerals Engineering,2020,155. |

| 23 | LV Li, LIAO Hang, TAO Zhang,et al.Separation of calcium chloride from waste acidic raffinate in HCl wet process for phosphoric acid manufacture:Simulated and experimental study[J].Journal of Environmental Chemical Engineering,2022,10(5): 108076. |

| 24 | FAN Tianbo, HAN Dongxue, JIA Xiaohui,et al.Study on preparation and growth mechanism of MgSO4·5Mg(OH)2·3H2O whiskers in NH4 +-NH3 buffer system[J].Journal of Chemical Engineering of Japan,2020,53(10):646-652. |

| 25 | KADUK J A, BILLINGE S J L, DINNEBIER R E,et al.Powder diffraction[J].Nature Reviews Methods Primers,2021,1:77. |

| 26 | GOLUBEV S V, POKROVSKY O S, SAVENKO V S.Homogeneous precipitation of magnesium phosphates from seawater solutions[J].Journal of Crystal Growth,2001,223(4):550-556. |

| [1] | YANG En, SHEN Hongyan, LIU Youzhi. In situ modification of superfine magnesium hydroxide with silicon polyether [J]. Inorganic Chemicals Industry, 2024, 56(4): 42-49. |

| [2] | JIANG Demin, LI Shunmei, Li Qingqing, Chen Yuxin, LIU Daijun. Hydrothermal synthesis of basic magnesium sulfate whiskers from magnesium hydroxide and magnesium sulfate heptahydrate [J]. Inorganic Chemicals Industry, 2023, 55(12): 74-81. |

| [3] | PANG Hongchang,WANG Zhiyu,TIAN Peng,NING Guiling. Study on synthesis and properties of two component magnesium based flame retardant by“one?pot method” [J]. Inorganic Chemicals Industry, 2022, 54(8): 54-58. |

| [4] | FAN Tianbo,HU Tingting,HAN Dongxue,JIA Xiaohui,ZHAO Yibo,WANG Xin′an,GUO Hongfan,LI Li,LIU Yunyi. Preparation of micro-nano round flake magnesium hydroxide from calcined dolomite powder [J]. Inorganic Chemicals Industry, 2022, 54(1): 29-33. |

| [5] | KONG Huimin,ZOU Laixi,LIU Yuan,CAO Yuwei,LIN Yanjun,LUO Xianping. Study on preparation of hexagonal plates of magnesium hydroxide by light-burned magnesium oxide [J]. Inorganic Chemicals Industry, 2022, 54(1): 39-44. |

| [6] | Zhang Jing,Ke Changmei,Duan Guoquan,Wang Jingwen. Study on modification of nano-magnesium hydroxide by new polyacrylate emulsion [J]. Inorganic Chemicals Industry, 2021, 53(9): 35-39. |

| [7] | Huang Jiancui,Ling Guanshuang,Zong Jun. Study on new conditions for preparation of highly-dispersed hexagonal magnesium hydroxide nanoparticles from hydromagnesite [J]. Inorganic Chemicals Industry, 2021, 53(2): 55-60. |

| [8] | Zhu Huayang,Zhong Jianchu,Yu Benru,Liu Jianxing,Luo Xinhu. Study on controllable synthesis of spherical magnesium oxide [J]. Inorganic Chemicals Industry, 2020, 52(11): 33-36. |

| [9] | Fan Tianbo,Jiang Yu,Chen Si,You Gang,Ding Ke,Sun Xiaojun,Liu Luping,Li Li,Liu Yunyi,Hu Kaizhou,Ma Junru,Guo Xiyao. Application of TRIZ theory in preparation of magnesium hydroxide by light burning ammonia [J]. Inorganic Chemicals Industry, 2019, 51(5): 23-27. |

| [10] | Ding Ke1,Sun Xiaojun1,Li Huijie1,Huang Nana1,Qiu Long1,Liu Yunyi1,2,Li Xue1,2. Study on kinetics and mechanism of ammonia evaporation reaction of magnesium oxide [J]. Inorganic Chemicals Industry, 2019, 51(11): 31-35. |

| [11] | Liu Xing,Liu Runjing,Zhao Hua,Han Xiaosuo,Sun Ye. Effect of microstructure of basic magnesium carbonate on apparent specific volume [J]. Inorganic Chemicals Industry, 2019, 51(11): 42-45. |

| [12] | Chen Yunhai,Wang Haiyan,Zhou Xiu. Study on process of eliminating impurities from brine by crystallization [J]. Inorganic Chemicals Industry, 2019, 51(11): 57-58. |

| [13] | ZHENG Yan, HE Wei-Yan. Study on preparation of magnesium hydroxide with magnesium chloride-dolomite as raw materials [J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(8): 52-. |

| [14] | WU Jian-Song, HUANG Xue-Qing, WU Si-Yun, PAN Lin-Qing, DENG Guo-Li. Preparation of flame-retardant magnesium hydroxide with brine from Xuwen salt field [J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(3): 56-. |

| [15] | JIN Wei, XU Yue-Xin, ZHOU Jun-Hong, WANG Jue. Study on preparation of magnesium hydroxide and calcium carbonate by washing-carbonization method from phosphorus tailings [J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(3): 49-. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||