Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (11): 93-99.doi: 10.19964/j.issn.1006-4990.2023-0052

• Industrial Techniques • Previous Articles Next Articles

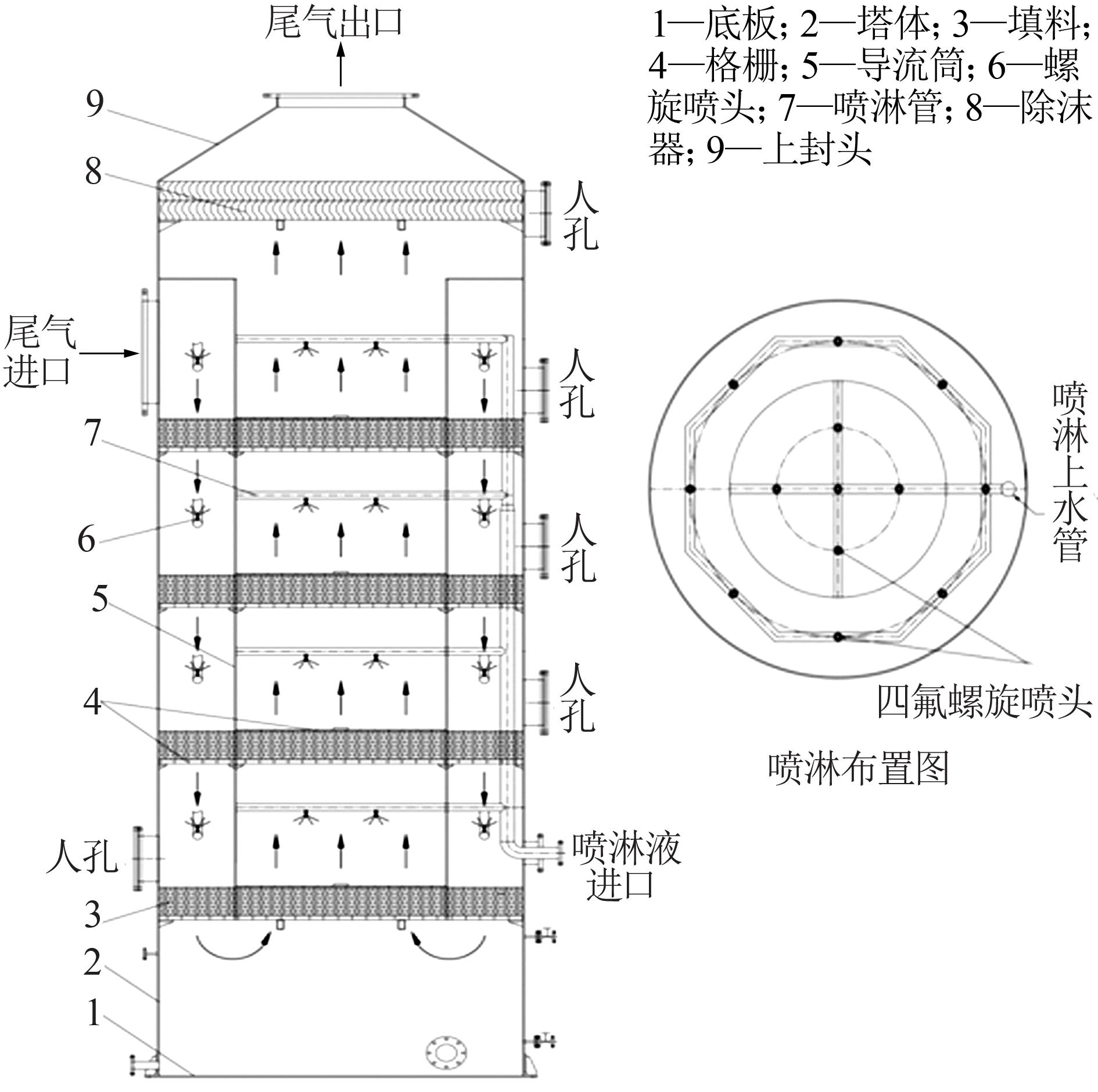

Development and practice of continuous defluoridation technology for by-products fluorinated hydrochloric acid of lithium hexafluorophosphate

ZHOU Xiaoping( ), FENG Haoshou(

), FENG Haoshou( ), ZHANG Guohui, HOU Shilei, ZHANG Shuaipeng, LIU Lixia

), ZHANG Guohui, HOU Shilei, ZHANG Shuaipeng, LIU Lixia

- Do-Fluoride New Materials Co.,Ltd.,Jiaozuo 454191,China