| 1 |

BIAN Kai, ZHANG Anfeng, YANG Hong,et al.Synthesis and characterization of Fe-substituted ZSM-5 zeolite and its catalytic performance for alkylation of benzene with dilute ethylene[J].Industrial & Engineering Chemistry Research,2020,59(52):22413-22421.

|

| 2 |

YANG Weimin, WANG Zhendong, SUN Hongmin,et al.Advances in development and industrial applications of ethylbenzene processes[J].Chinese Journal of Catalysis,2016,37(1):16-26.

|

| 3 |

SHAVALEEV D A, PAVLOV M L, BASIMOVA R A,et al.Synthesis of a zeolite-containing catalyst for gas-phase alkylation of benzene with ethylene[J].Petroleum Chemistry,2020,60(10):1164-1169.

|

| 4 |

孙洪敏.乙苯生产技术及市场分析[J].石油化工技术与经济,2019,35(5):18-23.

|

|

SUN Hongmin.Ethylbenzene production technology and market analysis[J].Technology & Economics in Petrochemicals,2019,35(5):18-23.

|

| 5 |

ZHANG Bin, WANG Zhendong, JI Peng,et al.Efficient liquid-phase ethylation of benzene with ethylene over mesoporous MCM-22 catalyst[J].Microporous and Mesoporous Materials,2013,179:63-68.

|

| 6 |

宦明耀,孙洪敏,张斌,等.改性ZSM-5催化剂上苯与FCC干气中乙烯气相烷基化反应[J].化学反应工程与工艺,2008,24(5):395-399.

|

|

HUAN Mingyao, SUN Hongmin, ZHANG Bin,et al.Vapor phase alkylation of benzene with ethylene in FCC dry gas over modified ZSM-5 zeolite catalyst[J].Chemical Reaction Engineering and Technology,2008,24(5):395-399.

|

| 7 |

张丽君,王振东,孙洪敏,等.气相法乙苯清洁生产工艺技术进展[J].工业催化,2016,24(5):1-7.

|

|

ZHANG Lijun, WANG Zhendong, SUN Hongmin,et al.Advance in ethylbenzene processes through vapor-phase alkylation of benzene[J].Industrial Catalysis,2016,24(5):1-7.

|

| 8 |

GU Yunfeng, LIU Wenshuai, WANG Ning.Technological progress of ethylbenzene production by alkylation[J].Tianjin Chemical Industry,2022,36(2):106-109.

|

| 9 |

薛明伟.干气综合利用生产技术进展[J].石油化工技术与经济,2019,35(1):56-62.

|

|

XUE Mingwei.Progress in production technology of dry gas comprehensive utilization[J].Technology & Economics in Petrochemicals,2019,35(1):56-62.

|

| 10 |

SHEN Zhenhao, MA Chongwei, HE Junlin,et al.Preparation of a shaped core-shell structured binder-free ZSM-5 catalyst and its application for benzene alkylation with ethylene[J].Applied Catalysis A:General,2019,577(1):20-27.

|

| 11 |

王文静,武光,吴伟,等.纳米ZSM-5分子筛的酸脱铝改性及其催化萘和甲醇的烷基化反应性能[J].石油学报:石油加工,2014,30(4):620-628.

|

|

WANG Wenjing, WU Guang, WU Wei,et al.Dealumination of ZSM-5 nanocrystals with different acids and their catalytic performances in methylation of naphthalene with methanol[J].Acta Petrolei Sinica:Petroleum Processing Section,2014,30(4):620-628.

|

| 12 |

ZHAO Liang, WANG Hongbo, LIU Min,et al.Shape-selective methylation of 2-methylnaphthalene with methanol over hydrothermal treated HZSM-5 zeolite catalysts[J].Chemical Engineering Science,2008,63(21):5298-5303.

|

| 13 |

RESASCO D E, CROSSLEY S P, WANG Bin,et al.Interaction of water with zeolites:A review[J].Catalysis Reviews,2021,63(2):302-362.

|

| 14 |

边凯,候章贵,段欣瑞,等.二维HZSM-5纳米片的合成及催化苯与稀乙烯烷基化制乙苯[J].高等学校化学学报,2019,40(4):784-792.

|

|

BIAN Kai, HOU Zhanggui, DUAN Xinrui,et al.Synthesis and catalytic performance of 2D HZSM-5 nano-sheet for ethylbenzene production from benzene with dilute ethylene[J].Chemical Journal of Chinese Universities,2019,40(4):784-792.

|

| 15 |

段欣瑞,李孝国,张永坤,等.纳米HZSM-5的酸性调控及其催化苯和稀乙烯制乙苯[J].石油学报:石油加工,2021,37(1):181-189.

|

|

DUAN Xinrui, LI Xiaoguo, ZHANG Yongkun,et al.Acid modification of nanosized HZSM-5 for alkylation of benzene with dilute ethylene[J].Acta Petrolei Sinica:Petroleum Processing Section,2021,37(1):181-189.

|

| 16 |

谢卓涵,韩贺,李孝国,等.纳米Ga-ZSM-5分子筛的合成及其在苯和稀乙烯烷基化反应中的应用[J].无机盐工业,2022,54(2):123-128.

|

|

XIE Zhuohan, HAN He, LI Xiaoguo,et al.Synthesis of nano Ga-ZSM-5 zeolite and its application in alkylation of benzene with dilute ethylene[J].Inorganic Chemicals Industry,2022,54(2):123-128.

|

| 17 |

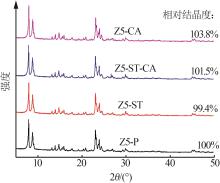

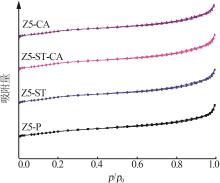

FAN Yu, BAO Xiaojun, LIN Xiuying,et al.Acidity adjustment of HZSM-5 zeolites by dealumination and realumination with stea-ming and citric acid treatments[J].The Journal of Physical Che-mistry B,2006,110(31):15411-15416.

|

| 18 |

毛东森,郭强胜,孟涛,等.水热处理对纳米HZSM-5分子筛酸性及催化甲醇制丙烯反应性能的影响[J].物理化学学报,2010,26(2):338-344.

|

|

MAO Dongsen, GUO Qiangsheng, MENG Tao,et al.Effect of hydrothermal treatment on the acidity and catalytic performance of nanosized HZSM-5 zeolites for the conversion of methanol to propene[J].Acta Physico-Chimica Sinica,2010,26(2):338-344.

|

| 19 |

BAERLOCHER C, MCCUSKER L B, OLSON D H.C2/C[M]//Atlas of Zeolite Framework Types.Amsterdam:Elsevier,2007:258- 259.

|

| 20 |

ONG L H, DÖMÖK M, OLINDO R,et al.Dealumination of HZSM-5 via steam-treatment[J].Microporous and Mesoporous Materials,2012,164:9-20.

|

| 21 |

LI Wenlin, LI Feng, WANG Hongyan,et al.Hierarchical mesoporous ZSM-5 supported nickel catalyst for the catalytic hydrodeoxygenation of anisole to cyclohexane[J].Molecular Catalysis,2020,480:110642.

|

| 22 |

王辉,张汉军,孔德金,等.ZSM-5催化剂水蒸汽处理对甲苯选择性歧化性能的影响[J].石油化工,2000,29(6):401-404.

|

|

WANG Hui, ZHANG Hanjun, KONG Dejin,et al.Effects of hydrothermal treatment on selective toluene disproportionation[J].Petrochemical Technology,2000,29(6):401-404.

|

), CHANG Yang1, LI Xiaoguo1, LIU Yan2, XING Changxin2, GAO Jinping1, XIAO Jiawang1, HOU Zhanggui1(

), CHANG Yang1, LI Xiaoguo1, LIU Yan2, XING Changxin2, GAO Jinping1, XIAO Jiawang1, HOU Zhanggui1( )

)