| [1] |

苗俊艳, 王艳语, 许秀成. 中低品位磷矿及磷尾矿的综合利用现状[J]. 硫磷设计与粉体工程, 2019(6):11-13.

|

| [2] |

蒲勇, 张卫红. 我国工业磷酸生产工艺选择概要[J]. 硫磷设计与粉体工程, 2012(1):27-29.

|

| [3] |

贡长生. 现代磷化工技术和应用[M]. 北京: 化学工业出版社, 2013.

|

| [4] |

陈善继. 我国电炉制磷能耗综述[J]. 硫磷设计, 1995(1):1-7.

|

| [5] |

孙志立, 杜建学. 电热法制磷[M]. 北京: 冶金工业出版社, 2010.

|

| [6] |

田萍, 徐兵, 张琦弦, 等. 电炉生产黄磷的能耗分析与节能潜力[J]. 化工进展, 2009, 28(S1):94-97.

|

| [7] |

陈善继. 窑法磷酸生产工艺特点及展望[J]. 无机盐工业, 2009, 41(6):1-3.

|

| [8] |

吕莉, 梁斌, 刘强, 等. 窑法磷酸中磷酸钙对P2O5反吸过程[J]. 化工学报, 2016, 67(10):4399-4405.

|

| [9] |

HEY D, DIETERMAN A J. Production of wet process phosphoric acid:US,3653827[P]. 1972-04-04.

|

| [10] |

杨建中. 湿法磷酸企业应对磷矿贫化的技术措施[J]. 磷肥与复肥, 2007, 22(4):24-25.

|

| [11] |

吴潘, 吕莉, 李剑锋. 中低品位磷矿窑法磷酸工艺条件的研究[J]. 辽宁化工, 2017, 46(12):1176-1178.

|

| [12] |

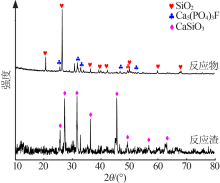

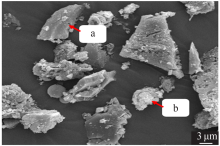

WU P, LV L, TANG S Y, et al. The fouling properties of SiO2-CaO-P2O5 system in high-temperature rotary kiln phosphoric acid pro-cess[J]. Chinese Journal of Chemical Engineering, 2020, 28(7):1824-1831.

doi: 10.1016/j.cjche.2020.01.005

|

| [13] |

周玉新. 实验设计与数据处理[M]. 武汉: 湖北科学技术出版社, 2005.

|

| [14] |

杨宏辉, 李春, 梁斌, 等. 窑法制磷酸反应的热力学[J]. 北京:化学反应工程与工艺, 2011, 27(6):543-550.

|

| [15] |

刘光启. 化学化工物性数据手册[M]. 北京: 化学工业出版社, 2002.

|

| [16] |

邱礼有, 江礼科. 窑法磷酸生产的旋窑制气试验研究[J]. 化学反应工程与工艺, 1993(1):90-97.

|

),ZHENG Hanxiao,LÜ Li(

),ZHENG Hanxiao,LÜ Li( ),TANG Shengwei

),TANG Shengwei