| [1] |

熊家齐 . 全球稀土市场现状及发展趋势[J]. 稀土, 2006,27(3):98-101.

|

| [2] |

熊春华, 郑展望, 姚彩萍 , 等. 大孔丙烯酸树脂对镧元素的静态与动态吸附研究[J]. 中国稀土学报, 2009,27(5):698-703.

|

| [3] |

常宏涛, 季尚军, 李梅 , 等. 超声波作用下溶剂萃取法分离镧铈元素[J]. 化工进展, 2014,33(1):169-186.

|

| [4] |

陈桂娥, 阎剑, 刘小珍 , 等. PAA络合-超滤耦合法分离镧和铕离子的研究[J]. 稀土, 2007,28(6):6-10.

|

| [5] |

Piazza S D, Cecchi G, Cardinale A M , et al. Penicillium expansum link strain for a biometallurgical method to recover REEs from WEEE[J]. Waste Management, 2016,60:596-600.

|

| [6] |

魏斌, 张自立, 卢杰 . 粘土矿物对低浓度镧、钕的吸附性研究[J]. 中国稀土学报, 2011,29(5):637-642.

|

| [7] |

Frolova L A, Pivovarov A A, Butyrina T E , et al. Purification of wastewaters,containing chromium,by a sorbent based on blast furnace slag[J]. Journal of Water Chemistry & Technology, 2015,37(4):185-190.

|

| [8] |

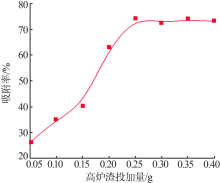

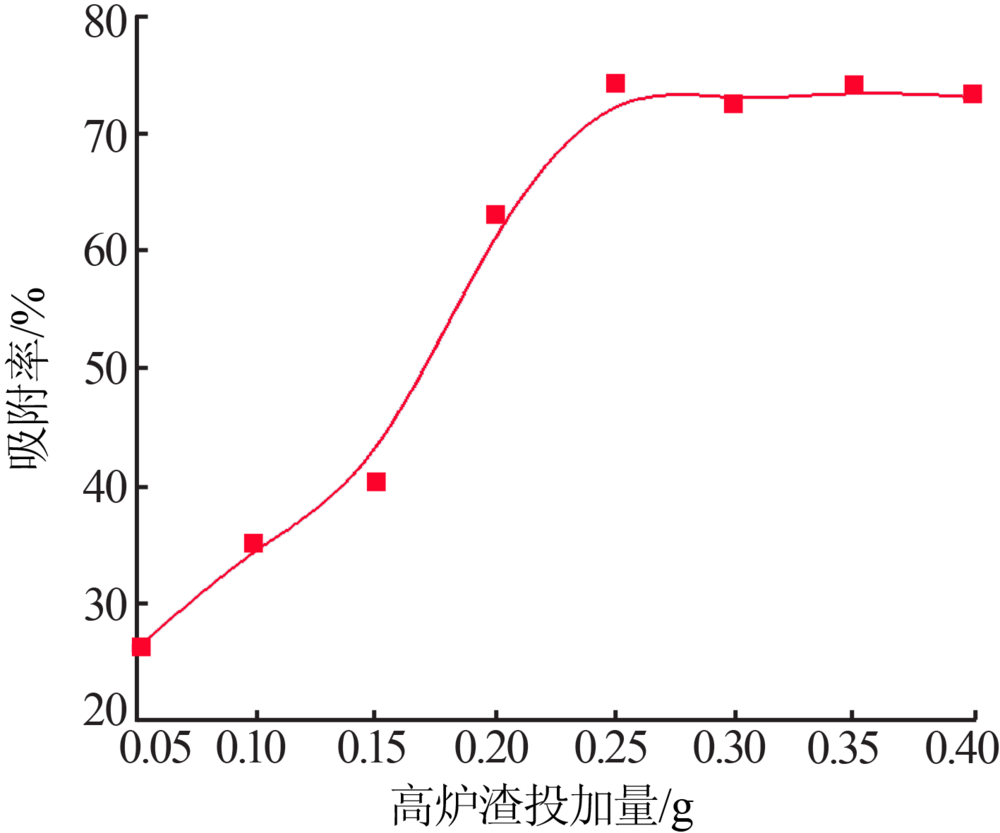

马兴冠, 刘剑梅, 韩冲 , 等. 含钛高炉渣吸附水中磷的实验[J]. 东北大学学报:自然科学版, 2009,30(9):1286-1290.

|

| [9] |

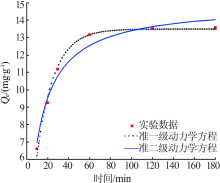

王哲, 黄国和, 安春江 , 等. 高炉水淬渣吸附Zn2+的平衡与动力学研究 [J]. 环境科学学报, 2015,35(12):3838-3846.

|

| [10] |

刘静, 温馨, 长山 , 等. 改性高炉渣对甲基橙的吸附[J]. 环境工程学报, 2018,12(5):1355-1359.

|

| [11] |

季凌晨, 刘荣, 王国祥 , 等. 含钛高炉渣对水中氨氮的吸附特性[J]. 化学通报, 2017,80(6):579-584.

|

| [12] |

Ho Y S, Mckay G . The sorption of lead(Ⅱ) ions on peat[J]. Water Research, 1999,33(2):578-584.

|

| [13] |

Ho Y S, Mckay G . Pseudo-second order model for sorption processes[J]. Process Biochemistry, 1999,34(5):451-465.

doi: 10.1016/S0032-9592(98)00112-5

|

| [14] |

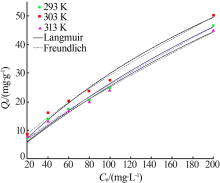

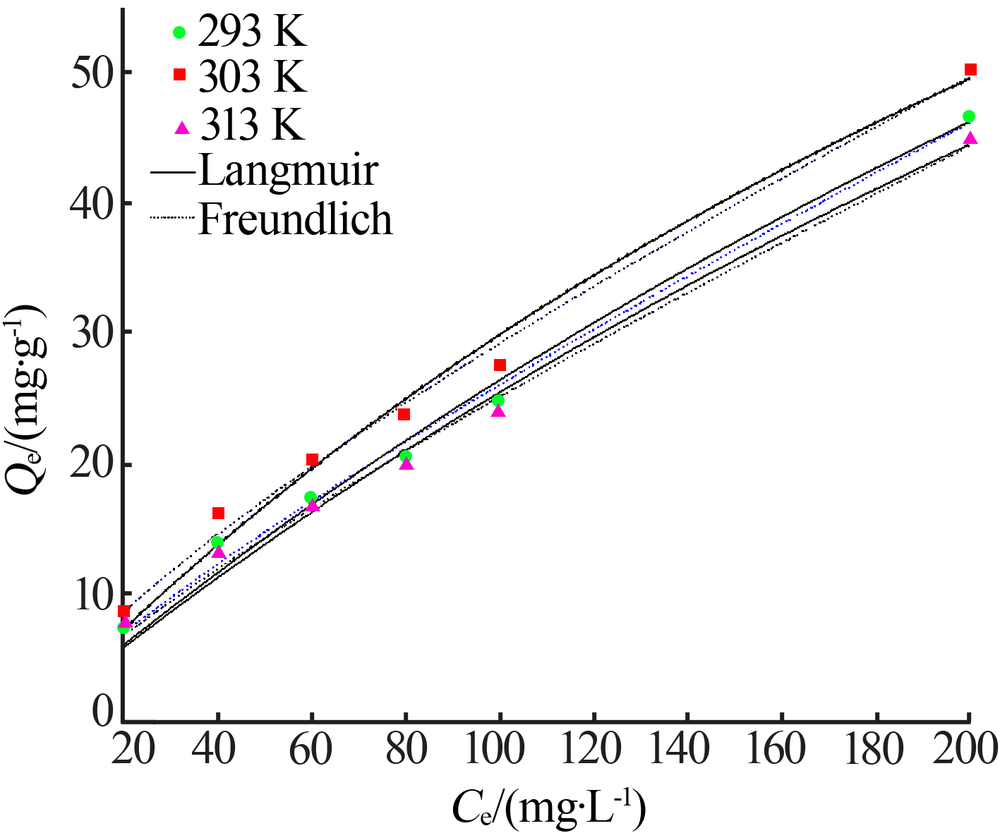

Langmuir I . The adsorption of gases on plane surfaces of glass,mica and platinum[J]. Journal of Chemical Physics, 2015,40(12):1361-1403.

|

| [15] |

Levan M D, Vermeulen T . Binary Langmuir and Freundlich isotherms for ideal adsorbed solutions[J]. Journal of Physical Chemistry, 1981,85(22):3247-3250.

doi: 10.1021/j150622a009

|